Structures designed for the safe and efficient venting of combustion byproducts from heating appliances and open fires, coupled with an architectural element that contains a fire chamber for heating and aesthetic purposes, are essential components of many residential and commercial buildings. These integrated systems require careful design, installation, and maintenance to ensure optimal performance and safety.

Such systems offer numerous benefits, including improved indoor air quality by removing harmful gases and particulates, enhanced energy efficiency by directing heat where it’s needed, and a focal point for social gathering within a dwelling. Historically, these systems have evolved from simple smoke holes to sophisticated designs incorporating features like dampers, liners, and catalytic converters to further improve performance and reduce environmental impact. They represent a crucial element in both the functionality and the overall ambiance of a property.

The following sections will delve into specific aspects of these systems, including inspection procedures, repair techniques, and preventative maintenance strategies, all aimed at ensuring their safe and effective operation for years to come. Proper understanding and care are paramount for safeguarding property and occupants from potential hazards.

Essential Upkeep Guidance

Maintaining the integrity and functionality of these systems requires adherence to specific guidelines and proactive measures. Regular attention to detail can prevent costly repairs and ensure the safety of the building and its occupants.

Tip 1: Schedule Annual Inspections: A certified professional should conduct a thorough assessment annually. This inspection identifies potential hazards, such as creosote buildup, structural damage, or flue obstructions, allowing for timely remediation.

Tip 2: Use Seasoned Wood: Burning dry, seasoned wood minimizes creosote accumulation. Creosote is a flammable byproduct of incomplete combustion that poses a significant fire risk. Wood should be dried for at least six months before use.

Tip 3: Install and Maintain Carbon Monoxide Detectors: Carbon monoxide is a colorless, odorless gas produced during combustion. Functioning detectors are crucial for alerting occupants to dangerous levels, allowing for prompt evacuation and ventilation.

Tip 4: Clean Regularly: Depending on usage, professional cleaning should occur at least once a year, or more frequently for systems used heavily. This removes creosote and other debris, reducing fire hazards and improving efficiency.

Tip 5: Address Water Leaks Promptly: Water intrusion can damage the structure and lead to corrosion of metal components. Addressing leaks immediately prevents further deterioration and costly repairs.

Tip 6: Maintain Proper Ventilation: Ensure adequate airflow to the appliance to promote complete combustion. Restricted airflow can lead to increased creosote buildup and carbon monoxide production.

Tip 7: Repair Damaged Components Immediately: Cracks in the firebox, damaged flue liners, or loose bricks should be repaired promptly. These issues can compromise the system’s integrity and create fire hazards.

Adhering to these maintenance practices ensures optimal performance, reduces the risk of fire, and extends the lifespan of the system. Consistent attention to detail safeguards the property and its inhabitants.

The subsequent sections will explore specific repair techniques and preventative measures in greater detail, providing a comprehensive guide to maintaining a safe and efficient system.

1. Inspection Frequency

Consistent evaluation is paramount to ensuring the safety and operational effectiveness of venting and heating systems. Regular assessment allows for early detection of potential hazards and facilitates preventative maintenance, thereby minimizing risks associated with compromised structural integrity or inefficient combustion.

- Creosote Buildup Monitoring

Frequent inspections enable monitoring of creosote accumulation within the flue. Creosote, a highly flammable byproduct of incomplete combustion, poses a significant fire hazard. Regular assessments determine the rate of buildup and dictate the necessary cleaning schedule to mitigate this risk.

- Structural Integrity Assessment

Scheduled inspections provide opportunities to assess the structural integrity of the structure itself. Cracks, spalling, or mortar deterioration can compromise its ability to safely contain combustion byproducts and support the weight of the flue. Early detection allows for timely repairs, preventing further degradation and potential collapse.

- Flue Obstruction Identification

Routine examinations can identify obstructions within the flue, such as bird nests or debris. Obstructions impede proper ventilation, leading to inefficient combustion and increased carbon monoxide production. Prompt removal of obstructions ensures optimal performance and reduces the risk of carbon monoxide poisoning.

- Component Wear and Tear Evaluation

Regular inspections allow for evaluation of the wear and tear on system components, including dampers, liners, and spark arrestors. Identifying worn or damaged components enables timely replacement, preventing potential malfunctions and maintaining system efficiency. Neglecting component wear can lead to costly repairs and compromised safety.

The facets described demonstrate the crucial role inspection frequency plays in maintaining a safe and efficient system. By consistently monitoring creosote buildup, assessing structural integrity, identifying flue obstructions, and evaluating component wear, property owners can proactively mitigate risks and ensure the long-term functionality of venting and heating systems. A proactive approach to inspection frequency is essential for safeguarding property and occupants from potential hazards.

2. Creosote Removal

The accumulation of creosote within a structure designed for venting combustion byproducts and housing a fire chamber poses a significant fire hazard. Effective creosote removal is therefore paramount to ensuring the safe and efficient operation of the system. Neglecting this critical maintenance task can lead to dangerous consequences, underscoring the importance of proactive and thorough creosote management.

- Creosote Formation Process

Creosote forms as a byproduct of incomplete combustion when wood burns at low temperatures or when there is insufficient air supply. The unburned gases and particles condense on the cooler inner surfaces of the flue, forming a tar-like substance that hardens over time. Factors influencing creosote formation include wood moisture content, appliance design, and burning habits.

- Risk Mitigation Strategies

Mitigation strategies involve promoting complete combustion through the use of seasoned wood, ensuring adequate air supply to the fire, and employing proper burning techniques. Additionally, regular professional cleaning is essential to remove accumulated creosote before it reaches dangerous levels. Chemical creosote removers can supplement mechanical cleaning but should not be considered a substitute.

- Inspection Techniques

Visual inspection is the primary method for assessing creosote buildup. A certified professional uses specialized tools, such as mirrors and cameras, to examine the interior of the flue for creosote deposits. The thickness, texture, and location of the creosote are documented to determine the appropriate cleaning method and frequency.

- Cleaning Methods

Mechanical cleaning involves the use of brushes, scrapers, and vacuums to physically remove creosote from the flue walls. The specific tools and techniques employed depend on the type and amount of creosote present. In severe cases, specialized equipment may be required to break down hardened deposits. Proper disposal of removed creosote is also essential due to its flammable nature.

Effective creosote removal is not merely a maintenance task; it is a critical safety measure that directly impacts the overall functionality and longevity of a structure designed for venting combustion products. By understanding the formation process, implementing appropriate mitigation strategies, employing thorough inspection techniques, and utilizing effective cleaning methods, property owners can significantly reduce the risk of fire and ensure the safe operation of their integrated heating system. The proactive management of creosote is thus an indispensable aspect of responsible property ownership and fire safety.

3. Flue Integrity

Flue integrity is a critical component of a fully operational combustion venting system, directly impacting safety and efficiency. The flue liner, a key element of any system, serves to contain harmful combustion byproducts, such as carbon monoxide and creosote, preventing them from seeping into the building’s structure. Breaches in the flue liner, whether caused by age, weathering, or improper installation, compromise this protective function. The direct consequence can be carbon monoxide exposure to occupants, posing a severe health risk, and accelerated deterioration of the surrounding brickwork or masonry due to acidic creosote penetration.

Consider, for example, a case where a home’s flue liner, unseen for years, developed cracks due to thermal stress. Over time, the cracks widened, allowing carbon monoxide to seep into the living spaces. Residents experienced flu-like symptoms, eventually prompting an investigation that revealed the compromised flue integrity. In another instance, creosote seeped through a damaged flue liner, saturating the adjacent wood framing and creating a significant fire hazard. These real-world scenarios underscore the practical significance of maintaining flue integrity as a fundamental aspect of combustion system operation.

In summary, flue integrity is not merely a matter of compliance but a fundamental safeguard for property and life. Regular inspections by qualified professionals are essential for detecting and addressing potential issues before they escalate into dangerous and costly problems. Maintaining a structurally sound flue liner is integral to the safe and efficient function of any system designed for venting combustion products, directly impacting the well-being of a building’s occupants and the preservation of its structural components.

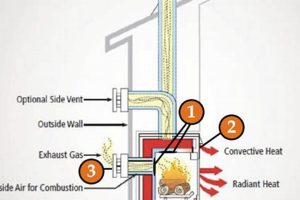

4. Proper Ventilation

Adequate airflow is integral to the safe and efficient operation of a combustion-based heating system. The system’s capability to properly vent combustion gases relies on a continuous and sufficient supply of oxygen to the fire. This balance enables complete combustion, reducing the production of harmful byproducts such as carbon monoxide and creosote. Insufficient ventilation, conversely, leads to incomplete combustion, increasing the risk of both carbon monoxide poisoning and accelerated creosote buildup within the flue. Real-world examples include homes with tightly sealed windows and doors, where inadequate oxygen supply results in inefficient burning and increased carbon monoxide levels. In such cases, residents may experience persistent headaches, nausea, or dizziness, indicating the presence of elevated carbon monoxide.

Moreover, the relationship between ventilation and combustion extends to the system’s overall lifespan and efficiency. Proper airflow prevents overheating and reduces stress on components, prolonging the system’s operational life. For instance, restricted airflow forces the system to work harder to maintain the desired temperature, leading to increased fuel consumption and potential damage to the firebox or flue. Conversely, a well-ventilated system operates more efficiently, consuming less fuel and minimizing wear and tear on its internal components. The selection of appropriate fuels, in conjunction with ensuring proper ventilation, significantly contributes to both the system’s efficiency and the reduction of harmful emissions.

In conclusion, proper ventilation is not merely an ancillary consideration but a fundamental requirement for the safe and effective operation of combustion-based heating systems. Addressing ventilation challenges through proper design, regular inspections, and adherence to recommended practices is essential for safeguarding property and occupants from potential hazards. Understanding the critical link between ventilation and combustion is paramount for ensuring the system operates efficiently, safely, and reliably over its intended lifespan.

5. Carbon Monoxide Detection

The presence of a structure for venting combustion byproducts and housing a fire chamber inherently introduces the risk of carbon monoxide (CO) exposure. Vigilant CO detection is thus a critical safety measure, ensuring early warning in the event of a malfunction or incomplete combustion, thereby protecting occupants from potentially lethal consequences.

- Sensor Placement and Functionality

CO detectors should be strategically placed in proximity to sleeping areas and on every level of the dwelling. These devices employ electrochemical sensors that trigger an alarm upon detecting elevated CO levels in the ambient air. Regular testing of detector functionality is essential to ensure their operational readiness. Failure to maintain working detectors negates the primary line of defense against CO poisoning.

- Sources of Carbon Monoxide in Residential Settings

Incomplete combustion resulting from malfunctioning heating systems, obstructed flues, or inadequate ventilation can lead to CO production. The use of unvented space heaters or generators indoors presents a heightened risk. Addressing the source of CO production is paramount, requiring professional inspection and repair of the implicated system.

- Symptoms of Carbon Monoxide Poisoning

CO poisoning symptoms often mimic those of the flu, including headache, nausea, dizziness, and fatigue. Prolonged exposure can lead to loss of consciousness and death. Prompt recognition of these symptoms and immediate evacuation to fresh air are crucial steps in mitigating the effects of CO poisoning.

- Preventative Measures and Maintenance

Annual inspections, coupled with regular flue cleaning, are essential preventative measures. Ensuring proper ventilation and avoiding the use of unvented combustion appliances indoors further reduces the risk of CO exposure. Maintenance of the system involves replacing CO detectors every five to seven years or as recommended by the manufacturer.

The integration of functional CO detection systems represents an indispensable element of a comprehensive safety strategy for any dwelling equipped with combustion-based heating. Regular testing, maintenance, and prompt response to alarms are critical to safeguarding occupants from the insidious threat of CO poisoning, reinforcing the importance of proactive safety measures in residential settings.

6. Waterproofing Quality

Waterproofing quality is an indispensable factor in preserving the structural integrity and operational efficiency of a structure designed for venting combustion byproducts and housing a fire chamber. The penetration of water into brickwork, mortar, or flue liners initiates a cascade of detrimental effects. Freeze-thaw cycles cause expansion and contraction within porous materials, leading to cracking, spalling, and eventual structural failure. Moisture also accelerates the corrosion of metal components, weakening supports and compromising the flue’s ability to safely vent combustion gases.

Consider, for example, the prolonged exposure of a chimney to rainwater without adequate waterproofing. Over time, water saturates the brick, initiating a deterioration process that weakens the mortar joints. These weakened joints allow further water infiltration, exacerbating the damage. The resulting structural instability can necessitate costly repairs or even complete reconstruction. Furthermore, moisture within the flue liner combines with acidic combustion byproducts, forming a corrosive solution that rapidly degrades the liner’s integrity, posing a significant safety hazard. A compromised liner allows dangerous gases, such as carbon monoxide, to seep into the living space.

Consequently, investing in high-quality waterproofing measures is essential for safeguarding the longevity and safety of any system designed for venting combustion products. Effective waterproofing techniques, such as applying sealant to the crown, flashing, and brickwork, create a protective barrier against water intrusion. Regular inspections to identify and address any breaches in the waterproofing layer are also critical. By prioritizing waterproofing quality, property owners can prevent costly structural damage, mitigate safety risks, and ensure the continued efficient operation of their integrated heating systems. The practical significance of this understanding lies in preventing future costs and damages with regular waterproofing maintenance for a long-lasting fireplace and chimney.

7. Firebox Condition

The integrity of the firebox is paramount to the safe and efficient operation of any structure designed for venting combustion byproducts and housing a fire chamber. A compromised firebox can lead to a multitude of problems, ranging from reduced heating efficiency to increased risk of fire and carbon monoxide leakage. Careful attention to its condition is, therefore, a critical aspect of maintaining such a system.

- Structural Integrity and Safety

Cracks, spalling, or gaps in the firebox compromise its ability to contain the fire safely. These breaches can allow embers and hot gases to escape, potentially igniting nearby combustible materials within the structure. Regular inspections for any signs of damage are crucial for preventing fire hazards and ensuring the safety of the building and its occupants. Undetected structural issues within the firebox drastically increase the likelihood of a house fire.

- Combustion Efficiency

A properly sealed firebox ensures optimal airflow for efficient combustion. Air leaks, caused by cracks or deteriorated mortar, disrupt the intended airflow patterns, leading to incomplete combustion and increased creosote production. Inefficient combustion not only reduces the heating output but also contributes to the buildup of hazardous materials within the flue, increasing the risk of chimney fires and carbon monoxide poisoning. Airtight fireboxes contribute to fuel-efficient and effective heating.

- Liner Integrity and Protection

The firebox liner, typically made of firebrick or cast iron, protects the surrounding masonry from the intense heat of the fire. Damage to the liner exposes the underlying structure to extreme temperatures, accelerating deterioration and potentially compromising the chimney’s stability. Regular inspections of the liner are essential for identifying and addressing any signs of wear or damage before they lead to more significant structural problems. The fireplace liner protects the brick and mortar, which can deteriorate with use over time.

- Carbon Monoxide Risk

A poorly maintained firebox can contribute to the production of carbon monoxide, a colorless, odorless, and potentially lethal gas. Cracks and gaps in the firebox allow combustion gases to escape into the living space, posing a significant health risk to occupants. Regular inspections, coupled with the installation and maintenance of carbon monoxide detectors, are vital for safeguarding against this silent threat. Ensuring regular carbon monoxide detection and firebox inspection will minimize risk and prioritize safety.

The condition of the firebox is intrinsically linked to the overall safety and performance of a structure designed for venting combustion byproducts and housing a fire chamber. Neglecting its maintenance can have severe consequences, underscoring the importance of regular inspections, prompt repairs, and adherence to best practices for safe operation. A well-maintained firebox is essential for ensuring both efficient heating and the protection of property and lives.

Frequently Asked Questions Regarding Residential Chimney and Fireplace Systems

The following addresses common inquiries concerning the installation, maintenance, and safe operation of residential venting and heating systems.

Question 1: What is the recommended frequency for professional venting system inspections?

Annual inspections by a certified professional are strongly advised. More frequent inspections may be necessary depending on usage patterns and fuel type.

Question 2: How can creosote buildup be minimized within the venting system?

Burning seasoned wood, ensuring adequate airflow during combustion, and scheduling regular professional cleanings are effective methods for minimizing creosote accumulation.

Question 3: What are the primary indicators of a compromised flue liner?

Visible cracks, spalling, or mortar deterioration are primary indicators of a compromised flue liner. A professional inspection can provide a more definitive assessment.

Question 4: Why is proper ventilation crucial for safe operation of a heating system?

Proper ventilation ensures complete combustion, reducing the production of carbon monoxide and minimizing creosote buildup. It also prevents overheating and extends the lifespan of the system components.

Question 5: What are the recommended placement guidelines for carbon monoxide detectors within a dwelling?

Carbon monoxide detectors should be installed on every level of the home, particularly in proximity to sleeping areas. Regular testing of detector functionality is essential.

Question 6: What maintenance practices can prevent water damage to a structure designed for venting combustion byproducts and housing a fire chamber?

Applying waterproofing sealant to the crown, flashing, and brickwork is an effective preventative measure. Regular inspections should be conducted to identify and address any breaches in the waterproofing layer.

These responses offer guidance on maintaining the safety and efficiency of residential systems designed for venting combustion products. Adherence to these recommendations is crucial for safeguarding property and occupants.

The subsequent sections will provide detailed information on specific repair techniques and advanced diagnostic procedures for maintaining optimal system performance.

Conclusion

This exploration has underscored the multifaceted considerations involved in ensuring the safe and efficient operation of Warrington Chimney & Fireplace systems. From the critical importance of regular inspections and creosote removal to the necessity of maintaining flue integrity and promoting proper ventilation, each element plays a vital role in safeguarding property and occupants. The consistent thread throughout has been the emphasis on proactive measures and diligent attention to detail as cornerstones of responsible system ownership.

As technology and building codes evolve, staying informed about best practices for maintaining these systems is paramount. Continued vigilance and adherence to professional guidance are essential for preserving the long-term functionality and safety of Warrington Chimney & Fireplace structures, ensuring their continued contribution to comfortable and secure living environments. The integrity of these systems directly influences both property value and, more importantly, the well-being of those within the dwelling. Neglecting appropriate care carries considerable risk.

![Lisle's Top Fireplace & Chimney Authority | [Your Brand] Pros Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Lisle's Top Fireplace & Chimney Authority | [Your Brand] Pros | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/02/th-503-300x200.jpg)