A vertical structure designed for venting combustion byproducts from a building can sometimes exist without a traditional hearth. This configuration arises when heating or exhaust systems are connected to the flue, but there is no open fire feature within the structure. For example, a central furnace, a water heater, or even a kitchen range hood might utilize the draft provided by such a structure.

Such a setup offers several advantages. It allows for efficient removal of noxious gases, ensuring indoor air quality and occupant safety. Furthermore, in older buildings, the presence of this structure may indicate a past heating method that has since been replaced with a more modern system. Historically, these structures were essential for removing smoke and fumes from dwellings and continue to serve a vital function even in the absence of an open fire.

The following sections will delve into the various reasons for this architectural element’s existence, exploring its use in modern ventilation systems, historical adaptations, and potential inspection and maintenance considerations.

Important Considerations

The presence of a venting structure without a connected hearth necessitates careful assessment and maintenance to ensure continued functionality and safety. The following points offer guidance for understanding and managing such configurations.

Tip 1: Conduct a Thorough Inspection: Engage a qualified professional to examine the structure’s integrity. This includes assessing the brickwork, mortar, and flue lining for cracks, deterioration, or obstructions. Damaged components can compromise the structure’s ability to safely vent gases.

Tip 2: Identify the Venting Appliance: Determine precisely which appliance or system is using the structure for venting. This knowledge is crucial for understanding the type of gases being expelled and ensuring compatibility with the flue material.

Tip 3: Ensure Proper Ventilation: Verify that the appliance is correctly connected and venting properly. Inadequate venting can lead to the buildup of dangerous gases, such as carbon monoxide, within the building.

Tip 4: Address Unused Flues: If the structure contains unused flues, consider sealing them to prevent drafts and potential moisture issues. Unsealed flues can contribute to energy loss and allow pests to enter the building.

Tip 5: Maintain Clear Access: Ensure that the structure’s base and top are easily accessible for inspection and maintenance purposes. Overgrown vegetation or accumulated debris can hinder these vital tasks.

Tip 6: Monitor for Moisture Intrusion: Regularly check for signs of water damage, such as staining or efflorescence, which can indicate leaks or condensation within the structure. Moisture can accelerate deterioration and compromise the structure’s integrity.

Tip 7: Consider a Chimney Cap: Install a properly fitted cap to prevent rain, snow, and debris from entering the structure. A cap can also help to prevent downdrafts and improve venting efficiency.

Proper attention to these factors is paramount to ensuring the safe and efficient operation of venting systems. Regular maintenance and professional inspections are essential for identifying and addressing potential issues before they escalate into costly or hazardous problems.

The subsequent discussion will explore specific scenarios and troubleshooting techniques related to these less common, yet essential, architectural features.

1. Flue Integrity

Flue integrity is a critical aspect when a venting structure lacks a traditional hearth. The flue is the channel within the structure responsible for safely carrying combustion byproducts away from the building. Its condition directly impacts the efficiency and safety of any connected heating or exhaust systems.

- Material Degradation

Flue liners, often constructed from materials like clay, metal, or concrete, are susceptible to deterioration over time. Exposure to acidic combustion byproducts and temperature fluctuations can cause cracking, spalling, or corrosion. A compromised liner allows gases to leak into the building’s interior or the structure itself, potentially leading to carbon monoxide poisoning or structural damage.

- Obstructions and Blockages

The flue can become obstructed by debris such as animal nests, leaves, or creosote buildup. These blockages impede airflow, reducing the efficiency of the connected appliance and increasing the risk of backdrafting, where gases are forced back into the building. Regular inspections and cleaning are necessary to prevent and remove obstructions.

- Mortar Joint Deterioration

In older structures, the mortar joints between flue tiles can weaken and crumble. This deterioration allows for gas leakage and compromises the structural stability of the flue. Repointing or relining the flue may be necessary to restore its integrity.

- Water Damage

Water penetration, often due to a missing or damaged chimney cap, can accelerate the degradation of flue materials and mortar joints. Freeze-thaw cycles can exacerbate this damage, leading to cracks and structural instability. Addressing water damage promptly is crucial to prevent further deterioration.

The absence of a hearth does not diminish the importance of maintaining flue integrity. Regardless of the connected appliance, a compromised flue poses significant safety risks. Regular inspections, prompt repairs, and preventive measures are essential for ensuring the safe and efficient operation of any system venting through such a structure.

2. Ventilation System

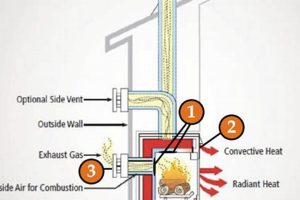

A ventilation system, when connected to a structure originally intended for hearth venting, represents a modified application of existing infrastructure. This adaptation necessitates careful consideration of system compatibility, draft requirements, and potential safety implications. The absence of a traditional hearth changes the dynamics of airflow and combustion byproduct removal, requiring tailored solutions.

- Appliance Compatibility

Connecting a modern furnace, water heater, or kitchen exhaust system to a structure designed for hearth venting requires ensuring the appliance’s exhaust characteristics align with the structure’s flue dimensions and draft capacity. Mismatched systems can lead to inefficient venting, increased energy consumption, and the potential for backdrafting of harmful gases. Proper sizing and liner selection are critical for safe and effective operation.

- Draft Control and Regulation

The draft, or airflow, within the venting structure is essential for drawing combustion byproducts away from the appliance. Factors such as the structure’s height, diameter, and exposure to wind influence the draft. Systems without a traditional hearth may require modifications such as draft regulators or induced draft fans to ensure adequate and consistent airflow, preventing the buildup of dangerous gases.

- Material Compatibility and Corrosion Resistance

Different appliances produce different types of combustion byproducts, some of which can be corrosive to certain materials. Connecting a high-efficiency furnace, for example, may produce acidic condensate that can damage traditional clay flue liners. Selecting materials that are resistant to corrosion is crucial for ensuring the long-term integrity of the venting system and preventing leaks or structural damage.

- Inspection and Maintenance Protocols

Ventilation systems connected to repurposed venting structures require regular inspection and maintenance to ensure continued safe and efficient operation. Inspections should include assessing the condition of the flue liner, checking for obstructions, and verifying the proper functioning of any draft control devices. Regular cleaning is necessary to remove creosote or other deposits that can impede airflow and increase the risk of fire. Proper maintenance protocols are essential for preventing hazards and extending the lifespan of the system.

The adaptation of a hearth venting structure for a modern ventilation system presents both opportunities and challenges. By carefully considering appliance compatibility, draft requirements, material selection, and maintenance protocols, building owners can ensure the safe and efficient operation of these modified systems, maximizing energy efficiency and minimizing the risk of hazards. Failing to take into account these factors when connecting a system to venting structure that was initially designed for a hearth can, in turn, lead to the hazards and problems discussed earlier in this text.

3. Moisture intrusion

Moisture intrusion poses a significant threat to venting structures, particularly when a traditional hearth is absent. This absence often means the structure is connected to a different type of appliance or system, altering the heat dynamics and potentially increasing the risk of condensation and water damage. The effects of moisture can compromise structural integrity and system efficiency.

- Rainwater Infiltration

Without a properly fitted cap, rainwater directly enters the structure, saturating the brickwork and mortar. This saturation leads to deterioration, especially in climates with freeze-thaw cycles where water expands and contracts within the porous materials. Ingress can also damage the flue liner, potentially blocking or restricting the venting path of exhaust gases from connected appliances. An example is rainwater pooling at the base of a disconnected flue and corroding the metal connector.

- Condensation Formation

When warm, moist exhaust gases from appliances like high-efficiency furnaces or water heaters encounter cooler surfaces within the structure, condensation forms. Over time, this condensation saturates the flue liner and surrounding masonry. Acidic condensate from certain appliances can accelerate corrosion of the liner and mortar, leading to structural weakening. An example is condensate forming on a cold clay tile liner and dripping back down onto the furnace, damaging the appliance and the structure.

- Freeze-Thaw Damage

Water absorbed into the brickwork or mortar joints expands when frozen, creating internal pressure that leads to cracks and spalling. Repeated freeze-thaw cycles progressively weaken the structure. This damage is particularly pronounced in older structures with deteriorated mortar or compromised flashing. For instance, water trapped within cracked brickwork expands during freezing temperatures, widening the cracks and potentially causing bricks to dislodge.

- Flashing Failure

Flashing, the metal sheeting that seals the junction between the structure and the roof, prevents water from penetrating the building envelope. Damaged, corroded, or improperly installed flashing allows water to seep into the structure, leading to interior leaks and structural damage. This problem is compounded in instances where the structure is no longer actively used for hearth venting, leading to neglect and delayed repairs. An example would be corroded flashing around a disconnected flue allowing water to run down the exterior structure wall and cause interior water damage.

These moisture-related issues are further exacerbated when the structure is not actively used for its original purpose, often leading to a lack of maintenance and inspection. This lack of attention accelerates deterioration, underscoring the importance of regular monitoring and preventative measures, irrespective of whether a traditional hearth is present.

4. Structural Stability

The absence of a functional hearth significantly alters the thermal dynamics within a venting structure, impacting its long-term structural stability. A hearth provides consistent heat that helps to mitigate moisture accumulation and prevent freeze-thaw damage. When the hearth is removed, and the structure is used for other purposes (or left unused), the lack of consistent heat creates conditions that can accelerate deterioration. For example, a structure originally designed to vent a hearth but now connected only to a seldom-used water heater experiences less frequent heat exposure, increasing the likelihood of moisture buildup and subsequent freeze-thaw damage to the brickwork and mortar.

Furthermore, the structural integrity is tied to its foundation and connection to the building. Settlement, shifting soil, or deterioration of supporting elements can compromise the entire structure, irrespective of its venting function. Consider a structure leaning due to foundation settlement; the instability affects its ability to function safely, even if it is used only for venting a small appliance. Regular inspections are vital to identifying potential issues such as cracks, spalling, or shifting, enabling timely repairs to maintain stability. Overlooking these signs can lead to costly repairs or even complete structural failure.

In summary, maintaining structural stability is paramount for any venting structure, irrespective of whether a functional hearth is present. The absence of consistent heat from a hearth can accelerate deterioration processes, making regular inspections and proactive maintenance critical. Ignoring these factors can result in significant structural damage, posing safety risks and financial burdens. Understanding this connection underscores the importance of a comprehensive approach to structure maintenance, addressing both its operational purpose and inherent structural vulnerabilities.

5. Code Compliance

Code compliance for venting structures lacking a traditional hearth necessitates a nuanced understanding of building regulations, appliance specifications, and material standards. Local codes and manufacturer’s guidelines dictate the acceptable use, maintenance, and alteration of these structures. Adherence to these standards is essential for ensuring safety, preventing hazards, and maintaining legal compliance.

- Flue Sizing and Material Requirements

Building codes stipulate the appropriate flue size and material type based on the connected appliance’s heat output and exhaust gas characteristics. Mismatched flue dimensions or incompatible materials can lead to inefficient venting, condensation issues, and corrosion. An undersized flue restricts airflow, increasing the risk of backdrafting, while an improper material can degrade quickly due to acidic exhaust. Compliance requires meticulous calculations and material selection to match the specific appliance.

- Inspection and Maintenance Schedules

Many jurisdictions mandate periodic inspections of venting systems to identify potential hazards and ensure continued safe operation. These inspections are often required when selling a property or after significant modifications to the heating system. Codes may also specify required maintenance tasks, such as cleaning and repairs, to prevent obstructions and maintain structural integrity. Failing to comply with inspection and maintenance schedules can result in fines or legal liabilities.

- Termination Height and Clearance Requirements

Building codes regulate the minimum height of venting structures above the roofline and the required clearances from nearby obstructions, such as trees or adjacent buildings. These requirements prevent exhaust gases from re-entering the building or affecting neighboring properties. Insufficient height or inadequate clearances can lead to poor draft, nuisance odors, and potential health hazards. Compliance necessitates careful consideration of the building’s architecture and surroundings.

- Abandonment and Sealing Procedures

When a venting structure is no longer in use, codes may require it to be properly sealed to prevent drafts, moisture intrusion, and pest infestations. Abandonment procedures often involve capping the structure, filling the flue, or removing it entirely. Improper abandonment can lead to energy loss, structural damage, and potential safety hazards. Compliance involves following prescribed methods to ensure the structure is safely and effectively sealed.

The implications of code non-compliance extend beyond potential fines; they directly impact the safety and well-being of building occupants. Adherence to building regulations, appliance specifications, and material standards is crucial for ensuring the safe and efficient operation of venting systems. Ignoring these requirements can lead to serious hazards, structural damage, and legal liabilities, underscoring the importance of professional expertise and meticulous attention to detail when dealing with venting structures lacking a traditional hearth.

Frequently Asked Questions

The following questions address common inquiries regarding the presence of a venting structure in the absence of a traditional hearth. The responses aim to provide clarity and guidance based on established building practices and safety considerations.

Question 1: Why might a structure designed for venting exist without an open fire feature?

A structure intended for venting may remain even after a traditional hearth has been removed or replaced. It can be utilized by alternative heating systems such as furnaces, water heaters, or even kitchen exhaust systems. In some instances, it may represent a remnant of a previous heating method.

Question 2: Is a venting structure without a hearth still subject to building codes and regulations?

Yes, the structure remains subject to applicable building codes and regulations, even in the absence of a hearth. These codes address structural integrity, flue integrity, termination height, and required clearances to ensure continued safety and prevent hazards.

Question 3: What potential safety hazards are associated with a structure used for venting without a hearth?

Potential hazards include flue deterioration, obstructions, inadequate draft, and moisture intrusion. A compromised flue can leak dangerous gases, such as carbon monoxide, into the building. Inadequate draft can cause backdrafting, while moisture intrusion can accelerate structural damage.

Question 4: How frequently should a structure without a hearth be inspected?

It is recommended to have the structure inspected at least annually by a qualified professional. More frequent inspections may be necessary if there are signs of deterioration, such as cracks, spalling, or water damage. Following the manufacturer’s guidelines and local codes regarding inspection is important.

Question 5: What steps can be taken to prevent moisture intrusion into a structure without a hearth?

Preventive measures include installing a properly fitted cap, ensuring proper flashing around the base, and sealing any unused flues. Regular inspections should be conducted to identify and address any signs of water damage promptly.

Question 6: If a venting structure is no longer in use, what is the proper procedure for abandonment?

The proper procedure for abandonment involves sealing the structure to prevent drafts, moisture intrusion, and pest infestations. This may include capping the structure, filling the flue, or removing it entirely, depending on local codes and regulations. A qualified professional can advise on the appropriate method.

The preceding questions and answers offer essential information regarding the assessment and management of venting structures in the absence of a traditional hearth. Regular maintenance and professional inspections remain crucial for ensuring safety and preventing costly repairs.

The subsequent section will provide a practical guide for troubleshooting common issues encountered with these specific architectural features.

Chimney but No Fireplace

The preceding discussion has explored the presence of a chimney but no fireplace, delving into its implications for structural integrity, ventilation system compatibility, code compliance, and overall safety. Emphasis has been placed on the unique challenges posed by the absence of a hearth, including moisture intrusion, the potential for accelerated deterioration, and the need for diligent inspection and maintenance.

While a venting structure lacking a traditional hearth may serve a vital function in modern heating and ventilation systems, its long-term viability hinges on responsible stewardship. Regular inspections, adherence to building codes, and proactive maintenance are essential for mitigating risks and ensuring the continued safe and efficient operation of these architectural elements. Neglecting these considerations can lead to significant structural damage, potential hazards, and costly repairs. Therefore, a comprehensive understanding of the principles outlined herein is crucial for informed decision-making and the preservation of building integrity.