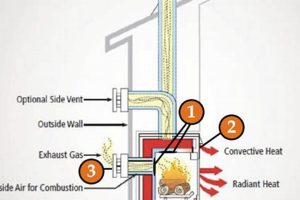

A residential heating appliance that uses natural gas or propane as its fuel source, venting combustion byproducts through a vertical structure designed for that purpose, provides supplemental warmth and aesthetic appeal within a dwelling. It simulates the look of a traditional wood-burning unit while offering enhanced convenience and operational control. Proper installation is paramount to ensure safe and efficient operation, preventing hazards such as carbon monoxide leaks.

This type of heating system offers numerous advantages including ease of use, consistent heat output, and reduced maintenance compared to its wood-burning counterpart. The venting system design has evolved significantly over time, progressing from rudimentary flues to sophisticated configurations that optimize draft and minimize backdrafting. The use of gaseous fuels for residential heating has increased dramatically in the last century, reflecting a shift towards cleaner and more efficient energy solutions.

The subsequent sections delve into the essential components, maintenance procedures, inspection protocols, and safety considerations associated with this common home amenity. Understanding these aspects is crucial for homeowners seeking to maximize the lifespan and performance of their heating appliance while prioritizing the health and well-being of their families.

Essential Considerations

Adherence to best practices is essential for the safe and efficient operation of a residential heating system utilizing gaseous fuel. Proper maintenance and periodic inspection are critical for preventing potential hazards and ensuring optimal performance.

Tip 1: Regular Inspection: Annual professional inspection is recommended to identify potential issues such as gas leaks, blockages in the venting system, or deterioration of components. Early detection can prevent costly repairs and hazardous conditions.

Tip 2: Venting System Maintenance: The vertical structure responsible for exhaust should be inspected for obstructions such as nests or debris. A blocked vent can lead to carbon monoxide buildup indoors.

Tip 3: Pilot Light Awareness: Understand the operational characteristics of the pilot light. If the pilot light frequently extinguishes, a malfunctioning thermocouple or gas supply issue may be present. Consult a qualified technician.

Tip 4: Carbon Monoxide Detectors: Install and maintain functional carbon monoxide detectors on every level of the home, particularly near sleeping areas. Test detectors regularly and replace batteries as needed.

Tip 5: Professional Cleaning: Schedule professional cleaning of the unit periodically, especially if excessive soot or residue is observed. This will improve efficiency and reduce the risk of fire hazards.

Tip 6: Gas Leak Detection: If a gas odor is detected, immediately evacuate the premises and contact the gas company or fire department. Do not attempt to locate the leak or operate electrical switches.

Tip 7: Component Replacement: Replace worn or damaged components promptly with manufacturer-approved parts. Using non-approved parts can compromise the safety and performance of the appliance.

By prioritizing preventative maintenance and adhering to safety guidelines, homeowners can ensure the reliable and secure operation of this type of heating system. Diligence in these areas contributes significantly to the overall well-being and safety of the household.

The following sections will address troubleshooting common issues and provide resources for professional assistance when necessary.

1. Venting system integrity

Venting system integrity is a paramount consideration in the operation of any gas fireplace connected to a chimney. The safe and efficient removal of combustion byproducts is directly contingent upon the structural soundness and functional effectiveness of this venting pathway. Compromised integrity introduces significant risks to occupants and the dwelling itself.

- Structural Integrity and Material Degradation

The physical condition of the chimney liner and associated venting components dictates their ability to contain and expel hot, corrosive exhaust gases. Cracks, breaches, or deterioration due to age, moisture, or chemical attack can compromise this function. For instance, a cracked clay flue liner allows combustion gases to escape into the surrounding structure, potentially leading to carbon monoxide infiltration or structural damage. Regular inspections are crucial for identifying and addressing material degradation.

- Obstructions and Flow Restriction

The presence of obstructions within the venting system, such as bird nests, debris accumulation, or collapsed liner sections, impedes the flow of exhaust gases. Reduced airflow can lead to incomplete combustion, increased carbon monoxide production, and potential backdrafting into the living space. An example is a chimney cap that becomes clogged with leaves, effectively blocking the venting path and creating a hazardous situation. Regular clearing of obstructions is vital for maintaining proper airflow.

- Draft Effectiveness and Backdraft Prevention

A properly functioning venting system establishes a reliable draft, drawing combustion gases upwards and out of the dwelling. Factors such as chimney height, diameter, and surrounding obstructions influence draft effectiveness. Insufficient draft can result in backdrafting, where combustion gases are drawn back into the living space, posing a serious health hazard. For example, a short chimney located near a taller structure may experience downdrafts, negating its ability to properly vent the gas fireplace. Proper design and maintenance are essential for ensuring adequate draft.

- Sealing and Leak Prevention

The joints and connections within the venting system must be properly sealed to prevent leakage of combustion gases. Gaps or cracks in the sealant allow exhaust gases to escape into the surrounding structure, potentially exposing occupants to carbon monoxide. A loose connection at the gas appliance collar, for instance, can leak combustion byproducts directly into the room. Regular inspection and repair of seals are critical for maintaining a gas-tight venting system.

The aspects of structural soundness, air flow regulation, draft reliability, and sealing integrity directly impact the efficiency and safety of a gas fireplace system. Their roles cannot be overstated in the proper functioning for the reliable use of any gas fireplace and chimney.

2. Gas line safety

Gas line safety is an indispensable component of any gas fireplace installation connected to a chimney. The secure and leak-free conveyance of natural gas or propane fuel from the supply source to the appliance is crucial for preventing hazardous conditions. Compromises in gas line integrity can result in gas leaks, fire hazards, and potentially fatal explosions. For example, a corroded or improperly installed gas line can develop leaks, leading to the accumulation of flammable gas within the dwelling. This accumulated gas can be ignited by a spark or open flame, causing a devastating explosion. Rigorous adherence to safety protocols during installation and periodic inspection are essential to mitigate these risks.

The practical significance of understanding gas line safety extends beyond mere compliance with regulations. Regular inspection of gas lines for signs of corrosion, damage, or loose connections allows for the early detection and remediation of potential problems. Utilizing proper leak detection methods, such as applying a soap solution to gas line connections, can identify even small leaks before they escalate into larger, more dangerous situations. Moreover, ensuring that gas lines are properly sized and rated for the BTU input of the gas fireplace is vital for preventing over-pressurization or fuel starvation. Professional installation and maintenance by qualified technicians are paramount to ensure the safe and reliable operation of the gas supply system.

In summary, gas line safety represents a foundational element in the safe operation of a gas fireplace and chimney system. Vigilance in maintaining the integrity of gas lines through regular inspection, proper installation techniques, and prompt repair of any identified issues is essential for protecting life and property. Addressing challenges such as aging infrastructure, improper modifications, and inadequate maintenance practices requires a proactive approach, prioritizing safety above all else. The broader theme of home safety is inextricably linked to responsible gas line management.

3. Combustion efficiency

Combustion efficiency represents a critical performance metric for gas fireplaces connected to a chimney. Maximizing this efficiency minimizes fuel consumption, reduces emissions of harmful byproducts, and ensures optimal heating performance. Inefficiencies in combustion can lead to incomplete fuel burning, resulting in higher concentrations of carbon monoxide and other pollutants vented into the atmosphere or, potentially, the living space.

- Air-to-Fuel Ratio Optimization

The ratio of air to fuel is paramount for complete and clean combustion. An inadequate air supply leads to incomplete combustion, producing carbon monoxide and soot. Conversely, excessive air can cool the flame, reducing efficiency and potentially leading to instability. Gas fireplace systems are designed with specific air intake mechanisms, and obstructions or improper adjustments can disrupt the ideal ratio. Maintenance should ensure these pathways remain clear and calibrated to the manufacturer’s specifications. An example of maladjustment would be an obstruction near the air intake, which could lead to an elevated Carbon Monoxide risk.

- Venting System Impact on Combustion

The venting system, specifically the chimney, plays a crucial role in combustion efficiency. A properly functioning chimney creates a draft that draws combustion gases out of the fireplace and introduces fresh air to support the combustion process. A blocked or improperly sized chimney can impede this airflow, leading to incomplete combustion and reduced efficiency. For instance, a chimney clogged with debris restricts airflow, causing the fireplace to burn less efficiently and produce more pollutants. Also, if the venting is not properly maintained, a phenomenon called backdrafting may occur, where combustion gasses are drawn back into the living space. Regular chimney inspections and cleaning are essential for maintaining optimal combustion.

- Burner Design and Maintenance

The burner design significantly influences the completeness of combustion. Burners are engineered to mix air and fuel in a specific manner to promote efficient burning. Over time, burners can become clogged with debris or corroded, disrupting the fuel-air mixture and reducing combustion efficiency. A common issue is the accumulation of dust or soot on the burner ports, which can restrict fuel flow and lead to uneven burning. Regular cleaning and maintenance of the burner are necessary to ensure consistent and efficient combustion.

- Fuel Quality and its Influence

The quality and type of fuel used impact combustion efficiency. Natural gas and propane have different energy contents and require specific burner and air intake adjustments. Contaminants in the fuel can also affect combustion, leading to incomplete burning and increased emissions. While natural gas purity is generally high, propane can sometimes contain impurities that affect combustion. Using the correct fuel type and ensuring its purity contribute to maximizing combustion efficiency. The purity of the fuel is related to the elevation of Carbon Monoxide as the fuel contains contaminants.

Therefore, optimizing the air-to-fuel ratio, ensuring proper venting, maintaining the burner, and utilizing high-quality fuel are essential for maximizing combustion efficiency in gas fireplaces. Addressing these factors not only improves heating performance but also minimizes environmental impact and enhances safety through lower emissions.

4. Carbon Monoxide Risk

The potential for carbon monoxide (CO) exposure represents a significant safety concern associated with gas fireplaces and their corresponding chimneys. This odorless, colorless, and tasteless gas poses a severe health hazard, as it inhibits the blood’s ability to carry oxygen. Deficiencies in appliance maintenance, venting malfunctions, or improper installation significantly elevate the risk of CO poisoning.

- Incomplete Combustion

Incomplete combustion of natural gas or propane within the fireplace generates carbon monoxide as a byproduct. This occurs when there is insufficient oxygen to fully oxidize the fuel. Factors contributing to incomplete combustion include a blocked chimney, a malfunctioning burner, or an improperly adjusted air-to-fuel mixture. As an example, a chimney obstructed by debris prevents the proper venting of combustion gases, leading to CO buildup within the dwelling. Regular maintenance ensures proper combustion and reduces CO production.

- Venting System Failure

The chimney serves as the primary conduit for expelling combustion gases, including carbon monoxide, from the living space. A compromised venting system, characterized by cracks, leaks, or blockages, impedes the safe removal of these gases. A common scenario involves a deteriorated chimney liner, allowing CO to seep through the chimney structure and into adjacent rooms. Regular inspection and repair of the venting system are essential for preventing CO infiltration.

- Backdrafting

Backdrafting occurs when the natural draft within the chimney reverses, drawing combustion gases, including carbon monoxide, back into the home. This can be caused by negative pressure within the dwelling, resulting from factors such as tightly sealed windows and doors or the operation of exhaust fans. As an illustration, a kitchen range hood operating simultaneously with a gas fireplace can create negative pressure, inducing backdrafting and increasing CO levels indoors. Proper ventilation and appliance operation can mitigate this risk.

- Lack of Carbon Monoxide Detectors

The absence of functional carbon monoxide detectors deprives occupants of an early warning system for CO exposure. These detectors provide audible alerts when CO levels reach dangerous thresholds, enabling timely evacuation and intervention. A homeowner who neglects to install or maintain CO detectors remains unaware of elevated CO concentrations until symptoms of poisoning manifest. The strategic placement of CO detectors on every level of the home, particularly near sleeping areas, is crucial for safeguarding against CO-related incidents.

Collectively, these factors underscore the critical importance of regular maintenance, inspection, and proper operation of gas fireplaces and chimneys. Moreover, the consistent use of working carbon monoxide detectors serves as an essential safety measure to protect against the silent threat of CO poisoning. Prioritizing these precautions minimizes the potential for adverse health outcomes and ensures a safe and comfortable living environment.

5. Inspection frequency

Inspection frequency represents a critical variable in maintaining the operational safety and efficiency of gas fireplaces and connected chimney systems. The accumulation of soot, debris, or structural degradation within the chimney, alongside potential gas leaks or burner malfunctions within the fireplace unit, necessitates periodic evaluation. An insufficient inspection schedule directly correlates with an increased likelihood of undetected hazards, potentially resulting in carbon monoxide exposure, fire risks, or diminished heating performance. For instance, a flue obstructed by bird nests, undetected due to infrequent inspections, compromises the venting of combustion gases, elevating the risk of carbon monoxide backdraft into the living space. Therefore, establishing and adhering to an appropriate inspection frequency forms a cornerstone of responsible gas fireplace ownership.

The establishment of a suitable inspection schedule should consider several factors, including the frequency of fireplace use, the age of the appliance and chimney system, and prevailing environmental conditions. Gas fireplaces used frequently during colder months warrant more frequent inspections compared to those used sparingly. Older systems, particularly those with masonry chimneys, are more susceptible to structural deterioration and require closer monitoring. In coastal regions, the corrosive effects of salt air can accelerate the degradation of metal chimney components, necessitating increased inspection frequency. An example of a region-specific recommendation involves coastal homeowners scheduling inspections annually, regardless of usage patterns, to address potential corrosion. Routine inspection protocols should encompass a comprehensive assessment of the chimney liner, flue, damper, burner assembly, gas connections, and carbon monoxide detectors.

Conclusively, the adoption of a well-defined inspection frequency, tailored to specific usage patterns and environmental considerations, is paramount for ensuring the safe and efficient operation of gas fireplaces and chimney systems. While annual professional inspections represent a prudent baseline, more frequent evaluations may be warranted for older systems, frequently used fireplaces, or installations in harsh environments. Prioritizing consistent inspection schedules effectively mitigates the risks associated with undetected malfunctions, contributing to a safer and more reliable home heating experience. This practice is not merely a recommendation but a necessary component of responsible homeownership when utilizing gas fireplace systems.

6. Professional maintenance crucial

The imperative of professional maintenance for gas fireplaces and associated chimney systems stems from the inherent complexity and potential hazards associated with their operation. These systems involve the combustion of flammable gases and the venting of toxic byproducts, requiring specialized knowledge and equipment to ensure safety and efficiency. Reliance on professional expertise minimizes risks and maximizes the lifespan of the appliance.

- Gas Leak Detection and Repair

Professionally trained technicians possess the tools and expertise to detect and repair gas leaks, a critical safety concern. Specialized equipment, such as gas leak detectors, can identify minute leaks that may go unnoticed by homeowners. Repairing gas lines requires adherence to strict safety protocols and often involves specialized tools and materials. The consequences of undetected or improperly repaired gas leaks can be catastrophic, including explosions and carbon monoxide poisoning.

- Chimney Inspection and Cleaning

Chimney systems require periodic inspection to identify structural damage, blockages, or creosote buildup. Professional chimney sweeps employ specialized brushes and vacuums to remove accumulated soot and debris, ensuring proper venting of combustion gases. Structural damage, such as cracks or spalling, can compromise the integrity of the chimney and allow for the leakage of carbon monoxide into the home. Untrained individuals attempting chimney cleaning may damage the flue liner or fail to remove all obstructions, negating the benefits of the process.

- Burner Assembly Maintenance and Calibration

The burner assembly of a gas fireplace requires periodic cleaning and calibration to ensure efficient combustion. Professional technicians can disassemble the burner, clean the ports, and adjust the air-to-fuel mixture for optimal performance. Improper calibration can lead to incomplete combustion, resulting in increased carbon monoxide production and reduced heating efficiency. Furthermore, damaged or worn burner components may require replacement with manufacturer-approved parts, ensuring compatibility and safety.

- Carbon Monoxide Detection System Verification

Professional maintenance includes verifying the functionality of carbon monoxide detectors installed within the home. Technicians can test the detectors to ensure they are responding appropriately to elevated CO levels and replace batteries as needed. Many homeowners neglect to regularly test or replace the batteries in their CO detectors, rendering them ineffective in the event of a gas leak or venting malfunction. Professional verification provides an added layer of safety, ensuring the detectors are functioning properly and providing timely alerts in the event of a CO emergency.

In conclusion, the integration of professional maintenance protocols for gas fireplaces and chimney systems is essential for mitigating risks and ensuring long-term operational reliability. The specialized knowledge, tools, and expertise of trained technicians provide a level of safety and performance that cannot be replicated through DIY efforts. Prioritizing professional maintenance represents a prudent investment in the safety and well-being of occupants, as well as the preservation of the appliance and chimney system.

7. Regulations Compliance

Adherence to established codes and standards is crucial for the safe and efficient operation of gas fireplaces and their associated chimney systems. Regulatory compliance ensures that these appliances are installed, maintained, and operated in a manner that minimizes risks to occupants and the environment. Failure to comply with relevant regulations can result in penalties, voided warranties, and, more importantly, increased safety hazards.

- Installation Codes and Permitting

Local building codes dictate the permissible methods for installing gas fireplaces and chimneys, often requiring permits and inspections to verify compliance. These codes address aspects such as proper venting distances from combustible materials, gas line sizing, and carbon monoxide detector placement. Non-compliance can lead to unsafe installations that increase the risk of fire or carbon monoxide poisoning. For example, improperly sized gas lines can result in inadequate fuel supply, leading to incomplete combustion and increased CO emissions. Permitting processes ensure that installations meet minimum safety standards.

- Product Safety Standards

Gas fireplaces and chimneys must meet stringent product safety standards established by organizations such as ANSI (American National Standards Institute) and CSA (Canadian Standards Association). These standards dictate the design, materials, and performance requirements for these appliances. Compliance is typically indicated by a certification label displayed on the product. Appliances lacking proper certification may pose safety risks due to substandard construction or inadequate safety features. Using only certified appliances is a fundamental aspect of regulatory compliance.

- Venting Requirements and Chimney Height

Regulations specify minimum chimney heights and venting configurations to ensure adequate draft and proper dispersal of combustion gases. Insufficient chimney height or improper venting can lead to backdrafting, where combustion gases are drawn back into the living space, posing a serious health hazard. Local codes often reference national standards, such as those published by the National Fire Protection Association (NFPA), regarding venting requirements. Compliance with these regulations is essential for preventing carbon monoxide exposure.

- Maintenance and Inspection Guidelines

Some jurisdictions mandate periodic inspections and maintenance of gas fireplaces and chimneys to ensure continued compliance with safety standards. These guidelines may specify the frequency of inspections and the qualifications of the inspectors. Neglecting to adhere to these maintenance requirements can lead to undetected problems, such as gas leaks or chimney blockages, increasing the risk of accidents. Following recommended maintenance schedules is a critical component of regulatory compliance and overall safety.

Comprehensively adhering to installation codes, utilizing certified products, complying with venting requirements, and implementing maintenance guidelines collectively reinforce the safety and efficacy of gas fireplaces and connected chimneys. Prioritizing regulatory compliance minimizes potential hazards and ensures that these heating appliances operate in a safe and environmentally responsible manner. Strict adherence to these safety protocols further protects inhabitants from dangers in the home.

Frequently Asked Questions

This section addresses common inquiries regarding the safe and efficient operation of residential gas fireplaces connected to chimney venting systems. The following questions and answers provide essential information for homeowners.

Question 1: How often should a gas fireplace and chimney be professionally inspected?

A professional inspection is recommended annually. This evaluation assesses the integrity of the venting system, gas connections, and burner assembly to ensure safe operation and prevent potential hazards.

Question 2: What are the primary indicators of a potential carbon monoxide leak from a gas fireplace?

Symptoms of carbon monoxide exposure, such as headaches, dizziness, nausea, and flu-like symptoms, may indicate a leak. A malfunctioning or improperly vented fireplace can also produce a smoky or sooty odor. The presence of functional carbon monoxide detectors is crucial for early detection.

Question 3: What are the common causes of a gas fireplace pilot light extinguishing frequently?

Frequent pilot light outages can be attributed to a faulty thermocouple, a dirty pilot orifice, or a draft affecting the flame. A qualified technician should diagnose and resolve the underlying issue to ensure consistent operation.

Question 4: Can a gas fireplace be safely operated without a functional chimney?

No, a functional chimney or appropriate venting system is essential for the safe operation of a gas fireplace. Without proper venting, combustion byproducts, including carbon monoxide, can accumulate within the living space, posing a significant health hazard.

Question 5: What measures can be taken to prevent chimney blockages in a gas fireplace system?

Installing a chimney cap prevents the entry of debris, animals, and precipitation. Regular chimney inspections and cleaning remove accumulated soot and creosote, ensuring unobstructed venting.

Question 6: Is it permissible to convert a wood-burning fireplace to a gas fireplace without professional assistance?

Conversion of a wood-burning fireplace to gas requires professional expertise to ensure proper gas line installation, venting compatibility, and adherence to local building codes. Improper conversion can result in gas leaks, carbon monoxide exposure, and fire hazards.

These frequently asked questions highlight the importance of proactive maintenance, professional expertise, and adherence to safety protocols in ensuring the reliable and secure operation of gas fireplace systems. Vigilance in these areas protects occupants from potential hazards and promotes a comfortable living environment.

The subsequent section provides resources for locating qualified technicians and accessing relevant safety information.

Gas Fireplace and Chimney

This exploration of gas fireplaces and chimney systems has underscored the critical aspects of safe and efficient operation. Proper venting, gas line integrity, combustion efficiency, and regular inspections are not merely recommended practices, but essential components of responsible homeownership. The potential for carbon monoxide exposure necessitates unwavering vigilance and adherence to established safety protocols.

The reliable functioning of a gas fireplace system demands diligence in maintenance, a commitment to professional expertise, and a comprehensive understanding of potential hazards. Neglecting these responsibilities introduces unacceptable risks to the well-being of occupants and the structural integrity of the dwelling. Therefore, prioritize safety, seek professional guidance, and ensure continuous adherence to established guidelines to safeguard the home.