A protective covering designed to be affixed to the uppermost part of a flue, typically constructed from metal, prevents the ingress of rain, snow, debris, and animals into the chimney. For example, a homeowner might install one on a newly built house or replace a damaged one on an existing structure.

These devices are critical for maintaining the efficiency and safety of a fireplace or furnace system. By preventing water damage and blockages, they contribute to proper draft and reduce the risk of carbon monoxide buildup inside a dwelling. Historically, simpler designs existed, but modern versions incorporate features to improve performance and longevity, reflecting advancements in materials and engineering.

The following sections will delve into the different types available, the materials used in their construction, installation procedures, common issues and maintenance, and considerations for selecting the appropriate model.

Guidance on Chimney Flue Termination Protection

This section provides essential guidance regarding the selection, installation, and maintenance of protective coverings for chimney flues. Proper implementation of these recommendations will enhance the safety and efficiency of venting systems.

Tip 1: Material Selection: Prioritize stainless steel or copper construction for superior resistance to corrosion and prolonged lifespan, especially in coastal or high-precipitation environments. Aluminum is a less expensive alternative, but its durability is reduced.

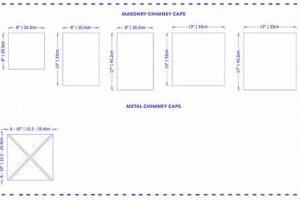

Tip 2: Sizing and Compatibility: Ensure the selected model is appropriately sized to match the flue diameter, and that its design is compatible with the specific type of fuel-burning appliance being vented. Improper sizing can negatively impact draft.

Tip 3: Spark Arrestor Screens: When utilizing wood-burning appliances, verify that the device incorporates a spark arrestor screen compliant with local fire codes. Regularly inspect and clean this screen to prevent blockage and ensure adequate ventilation.

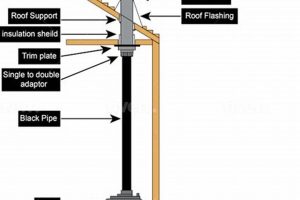

Tip 4: Secure Installation: Adhere strictly to the manufacturer’s installation instructions and use appropriate fasteners to securely attach the device to the flue. A loose or improperly installed unit poses a significant hazard.

Tip 5: Annual Inspection: Conduct a thorough inspection of the device annually, preferably during the fall season, to identify any signs of damage, corrosion, or deterioration. Address any issues promptly to prevent further degradation.

Tip 6: Debris Removal: Regularly remove accumulated leaves, twigs, and other debris from the top of the protective covering to maintain proper airflow and prevent potential chimney fires.

Tip 7: Professional Consultation: If unfamiliar with chimney systems or unsure about the selection or installation process, consult with a qualified chimney sweep or HVAC technician for professional guidance.

Adhering to these guidelines will contribute significantly to the safe and efficient operation of residential venting systems, protecting property and occupants from potential hazards.

The concluding section will offer a summary of the key considerations discussed and provide recommendations for ongoing maintenance to ensure optimal performance.

1. Material Durability

The functional lifespan of a chimney vent cap is directly correlated to the durability of its constituent materials. Premature failure of these protective devices, often resulting from material degradation, compromises the integrity of the entire chimney system. Material selection dictates the component’s ability to withstand environmental stressors, including extreme temperature fluctuations, prolonged exposure to moisture, and corrosive byproducts of combustion. For instance, a vent cap constructed from low-grade steel will exhibit accelerated corrosion compared to one fabricated from stainless steel, leading to potential structural failure and reduced effectiveness in preventing water or debris ingress.

The consequences of using materials with inadequate durability extend beyond the immediate need for replacement. A corroded or structurally unsound vent cap can lead to water damage within the chimney, potentially affecting the building’s structural elements and promoting mold growth. Ingress of debris, such as leaves and animal nests, can obstruct the flue, increasing the risk of carbon monoxide buildup and chimney fires. Therefore, investing in a vent cap constructed from durable, corrosion-resistant materials represents a proactive measure in ensuring long-term safety and minimizing maintenance costs. Copper and certain grades of stainless steel are demonstrably superior choices in demanding environments due to their inherent resistance to corrosion.

In summary, material durability is not merely a desirable attribute in a chimney vent cap, but rather a fundamental requirement for ensuring its long-term functionality and contribution to overall chimney system safety. Selection of appropriate materials, based on environmental conditions and anticipated usage, is crucial. Neglecting this aspect can lead to significant structural issues, potential health hazards, and increased costs over the long term.

2. Correct Sizing

The proper dimensions of a chimney vent cap, relative to the flue opening, are paramount to its effective operation. An inappropriately sized cap will compromise both its protective function and the chimney’s draft characteristics.

- Impeded Draft

A vent cap that is too small restricts the flow of exhaust gases. This reduced draft can lead to incomplete combustion, increasing the risk of carbon monoxide buildup and potential backdrafting of smoke into the building. For example, a cap designed for a 6-inch flue installed on an 8-inch flue will create a bottleneck, severely hindering ventilation.

- Ineffective Precipitation Barrier

An oversized vent cap may fail to adequately shield the flue from rain and snow. Water ingress can damage the chimney lining, reduce the efficiency of the heating system, and contribute to structural deterioration. Consider a cap that extends significantly beyond the flue’s perimeter; wind-driven rain may still bypass the protective covering.

- Compromised Spark Arrestor Functionality

If the dimensions are incorrect, a spark arrestor incorporated within the vent cap may not function as intended. Gaps around the cap’s base could allow embers to escape, posing a fire hazard. For instance, a poorly fitted cap might leave spaces large enough for sparks to be carried aloft by updrafts.

- Increased Wind Resistance

A disproportionately large cap can increase the surface area exposed to wind, making the structure more vulnerable to damage during storms. The increased stress on the chimney and vent cap can lead to detachment or structural failure. A top-heavy installation is especially prone to wind damage.

These facets underscore the importance of precise measurement and adherence to manufacturer specifications when selecting a chimney vent cap. Deviations from recommended sizing guidelines can negate the protective benefits and create significant safety hazards. The integration of a correctly sized cap is not merely a matter of aesthetics but a critical factor in maintaining the integrity and performance of the chimney system.

3. Draft Optimization

Draft optimization within a chimney system is intrinsically linked to the design and functionality of the chimney vent cap. This optimization pertains to the controlled movement of combustion gases, ensuring efficient removal of byproducts while preventing backdraft and maintaining proper appliance operation.

- Cap Design and Flow Restriction

The vent cap’s design directly influences airflow dynamics. A poorly designed cap can impede the natural draft, causing turbulence and increased resistance. Intricate, decorative caps, while aesthetically pleasing, may substantially reduce the cross-sectional area available for exhaust, hindering draft. For example, a cap with excessive screening or narrow outlet vents will restrict airflow more than a streamlined design.

- Height Above Flue Termination

The height of the cap above the flue termination impacts wind effects on draft. A cap positioned too close to the flue may experience downdrafts or wind-induced pressure variations that disrupt the flow of exhaust gases. Ideally, the cap should extend a sufficient distance above the flue to minimize these disturbances. This distance varies depending on local wind conditions and building geometry.

- Material and Thermal Characteristics

The material composition of the vent cap affects its thermal properties and, consequently, draft. Metal caps, particularly those with high thermal conductivity, can rapidly cool exhaust gases, reducing buoyancy and draft. Insulated or ceramic caps mitigate this effect, helping maintain the temperature of the exhaust stream. This is especially pertinent in colder climates where temperature differentials exacerbate draft issues.

- Screen Mesh Size and Buildup

The mesh size of any integrated spark arrestor screen affects airflow and the potential for blockage. Finer meshes offer greater protection against sparks but increase flow resistance. Over time, soot and creosote accumulation on the screen further restricts airflow, negatively impacting draft. Regular cleaning is essential to maintain optimal performance; neglect can lead to significant draft reduction.

These facets underscore the essential role of vent cap selection and maintenance in ensuring optimal draft within a chimney system. Careful consideration of design, height, material, and maintenance requirements is necessary to maximize efficiency and minimize the risk of performance-related issues. A properly optimized draft contributes directly to the safe and efficient operation of the connected appliance, mitigating potential hazards and prolonging the lifespan of the entire system.

4. Debris Prevention

The capacity to prevent the ingress of foreign materials constitutes a primary function of a chimney vent cap. The accumulation of debris within a chimney flue can initiate a cascade of adverse effects, culminating in compromised system performance and heightened safety risks. Leaves, twigs, animal nests, and other extraneous matter impede the free flow of combustion gases, resulting in reduced draft and potential backdraft. A chimney vent cap serves as a physical barrier, mitigating these risks by preventing the introduction of such materials into the venting system. For example, without an appropriately designed and installed cap, a chimney is vulnerable to nesting birds, which can rapidly create substantial blockages.

The practical significance of effective debris prevention extends beyond merely maintaining optimal draft. Blocked flues elevate the risk of carbon monoxide poisoning due to incomplete combustion and subsequent backflow into the living space. Furthermore, accumulated debris, especially organic matter, acts as fuel, increasing the likelihood of chimney fires. The design of the vent cap is therefore critical, requiring a balance between effective barrier function and minimal restriction of airflow. Implementation of a suitable screening system, typically constructed of wire mesh, prevents the entry of debris while allowing for adequate ventilation. This screening system must also be robust enough to withstand environmental stressors, such as high winds and ice accumulation, which could compromise its integrity.

In summary, debris prevention is an indispensable element of chimney system safety and efficiency, directly addressed by the proper selection and maintenance of a chimney vent cap. The vent cap’s ability to effectively block the introduction of foreign materials into the flue is a critical determinant of its overall performance. Mitigation of blockages directly reduces the risk of carbon monoxide poisoning and chimney fires, ensuring safer operation. Regular inspection and cleaning of the vent cap are essential to maintain its debris prevention capabilities and ensure continuous optimal functionality.

5. Secure Attachment

The reliable affixation of a chimney vent cap to the flue termination is paramount for its continued functionality and the overall safety of the venting system. A compromised attachment mechanism renders the vent cap ineffective, negating its protective benefits and introducing potential hazards. The connection between the vent cap and the chimney must withstand environmental stressors, including wind loads, thermal expansion and contraction, and precipitation, all of which contribute to the gradual degradation of attachment points. A poorly secured cap is susceptible to dislodgement, particularly during periods of high winds, rendering the chimney vulnerable to water damage, debris accumulation, and animal intrusion. For instance, a vent cap inadequately fastened with corroded screws may detach during a storm, leaving the flue exposed and susceptible to blockage.

The consequences of a failed attachment extend beyond the immediate need for replacement. A dislodged vent cap poses a safety hazard if it falls from the chimney, potentially causing property damage or injury. Furthermore, the unprotected flue becomes a pathway for rainwater, which can saturate the chimney lining and lead to structural deterioration. The ingress of debris, such as leaves and animal nests, can obstruct the flue, increasing the risk of carbon monoxide buildup and chimney fires. Secure attachment, therefore, is not merely a matter of convenience but a critical factor in maintaining the integrity and performance of the entire venting system. Proper installation techniques, utilizing appropriate fasteners and adhering to manufacturer specifications, are essential for ensuring long-term stability. Regular inspections should include a thorough assessment of the attachment mechanism, identifying any signs of corrosion, loosening, or damage.

In summary, secure attachment is an indispensable requirement for a functional and effective chimney vent cap, directly influencing its ability to protect the chimney and ensure the safe operation of connected appliances. Prevention of detachment necessitates the use of robust attachment methods and the implementation of a regular maintenance schedule. Neglecting this aspect can lead to significant structural issues, potential health hazards, and increased costs over the long term. Prioritizing secure attachment contributes significantly to the longevity and reliable performance of the chimney system.

Frequently Asked Questions

This section addresses common inquiries regarding the function, selection, and maintenance of chimney vent caps, providing clarity on their role in maintaining a safe and efficient venting system.

Question 1: What is the primary function of a chimney vent cap?

A chimney vent cap primarily prevents the ingress of precipitation, debris, and animals into the chimney flue, protecting the chimney structure and ensuring proper draft.

Question 2: Are all chimney vent caps universally compatible with all chimney types?

No, chimney vent caps are not universally compatible. Proper selection requires consideration of flue diameter, chimney material, and the type of fuel-burning appliance being vented.

Question 3: What materials are commonly used in the construction of chimney vent caps, and what are their relative merits?

Common materials include stainless steel, copper, and aluminum. Stainless steel and copper offer superior corrosion resistance and durability, while aluminum provides a more economical option with reduced lifespan.

Question 4: How frequently should a chimney vent cap be inspected and maintained?

A chimney vent cap should be inspected at least annually, preferably in the fall, to identify any signs of damage, corrosion, or debris accumulation. Cleaning should be performed as needed to maintain proper airflow.

Question 5: Can a damaged chimney vent cap negatively impact the performance of a heating appliance?

Yes, a damaged or improperly functioning chimney vent cap can impede draft, leading to incomplete combustion, carbon monoxide buildup, and reduced heating efficiency.

Question 6: Is professional installation of a chimney vent cap recommended?

While some homeowners may opt for self-installation, professional installation by a qualified chimney sweep or HVAC technician is generally recommended to ensure proper sizing, secure attachment, and code compliance.

In summary, a chimney vent cap is a crucial component of a venting system, and its proper selection, installation, and maintenance are essential for ensuring safety and efficiency.

The next section will explore troubleshooting common problems associated with chimney vent caps, providing practical guidance for diagnosing and resolving issues.

Conclusion

This exploration of the chimney vent cap underscores its critical role in safeguarding chimney systems. Key aspects reviewed include material durability, correct sizing, draft optimization, debris prevention, and secure attachment. Each facet contributes significantly to the overall performance and longevity of the system. Neglecting any of these considerations can compromise safety and efficiency, leading to potential hazards and increased maintenance costs.

Therefore, diligent attention to the selection, installation, and maintenance of a chimney vent cap is paramount. Proactive measures, including regular inspection and prompt remediation of any identified issues, are essential to ensure continued protection and optimal functionality. Prioritizing these practices ultimately contributes to the safe and efficient operation of residential and commercial venting systems.

![Local Chimney Liner Installers Near Me: [Cost & Quality] Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Local Chimney Liner Installers Near Me: [Cost & Quality] | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/02/th-512-300x200.jpg)

![Protect Your Chimney: 9 Inch Round Chimney Cap [Debris Free] Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Protect Your Chimney: 9 Inch Round Chimney Cap [Debris Free] | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/02/th-483-300x200.jpg)