The material installed at the intersection of a chimney and roof serves as a critical weatherproofing component. It prevents water penetration where the chimney structure meets the roofing surface. This application typically involves thin pieces of metal, strategically layered and shaped to direct water away from vulnerable areas. For example, individual pieces are often embedded within the mortar joints of the chimney brickwork and overlapped by subsequent layers adhered to the roof shingles.

Effective mitigation of water intrusion is paramount for preventing structural damage to both the chimney and the roof. Persistent leaks can lead to deterioration of masonry, rotting of wood framing, and the growth of mold and mildew. Historically, various materials such as lead and copper have been employed, with modern solutions often incorporating aluminum or galvanized steel due to their durability and resistance to corrosion. Proper installation and maintenance are crucial for long-term performance and the preservation of a building’s integrity.

The following sections will delve into specific techniques for ensuring a robust and watertight seal, addressing common issues, and providing guidance on material selection and preventative maintenance strategies. The aim is to provide a comprehensive understanding of best practices for a durable and weather-resistant chimney and roof interface.

Essential Guidance for Chimney Flashing Integrity

The following recommendations are crucial for ensuring the long-term performance and weather resistance of the intersection between a chimney and a roof. Strict adherence to these guidelines will minimize the risk of water damage and structural deterioration.

Tip 1: Select Appropriate Materials: The choice of metal is paramount. Corrosion-resistant materials such as copper, aluminum, or stainless steel are recommended. Avoid mixing dissimilar metals, as galvanic corrosion can accelerate degradation.

Tip 2: Employ Step Flashing Techniques: Utilize step flashing along the sides of the chimney. Each piece should be integrated into the mortar joints and overlapped by the roof shingles, providing a layered defense against water penetration.

Tip 3: Install Counterflashing: Counterflashing should be embedded in the chimney’s mortar joints and extend down over the step flashing. This directs water away from the step flashing and prevents moisture from seeping behind it.

Tip 4: Ensure Proper Overlap: Maintain adequate overlap between individual pieces. A minimum of 2 inches of overlap is generally recommended to ensure a continuous barrier against water intrusion.

Tip 5: Seal Gaps and Cracks: Apply a high-quality sealant to any gaps or cracks around the interface. This should be a sealant specifically designed for exterior use and compatible with the chosen flashing material.

Tip 6: Inspect Regularly: Conduct routine inspections to identify and address potential issues early. Pay close attention to areas where the material meets the chimney and roof surfaces.

Tip 7: Professional Installation: Whenever possible, engage qualified professionals for installation. Expert knowledge ensures proper techniques and material usage, enhancing the long-term effectiveness of the solution.

Proper installation and maintenance are critical for preventing costly repairs and preserving structural integrity. Diligent application of these tips will contribute to a secure and weather-resistant chimney system.

The subsequent sections will examine advanced troubleshooting techniques and explore strategies for addressing complex flashing configurations.

1. Material Durability

Material durability is a foundational element in the longevity and efficacy of weatherproofing at the chimney-roof interface. The selection of robust materials directly impacts the system’s ability to withstand environmental stressors and prevent water intrusion over extended periods.

- Corrosion Resistance

The material must resist degradation from exposure to moisture, temperature fluctuations, and chemical pollutants. Metals prone to corrosion, such as uncoated steel, are unsuitable. Examples of durable options include copper, stainless steel, and aluminum. The implications of corrosion in the chimney environment manifest as leaks, structural weakening, and eventual system failure.

- Thermal Expansion Compatibility

Fluctuations in temperature cause materials to expand and contract. The chosen material should exhibit a coefficient of thermal expansion similar to that of the surrounding roofing and chimney materials. Significant differences can induce stress, leading to cracking and compromised seals. This is particularly relevant in regions with extreme temperature variations.

- Physical Strength and Malleability

The material must possess adequate physical strength to withstand impact from debris, wind, and ice. It should also be malleable enough to be shaped and formed to fit the contours of the chimney and roof. Brittle materials are prone to cracking, while excessively soft materials may deform under pressure. Copper, for instance, combines both strength and workability.

- Lifespan and Maintenance Requirements

Different materials exhibit varying lifespans. Copper may last for over a century, while aluminum may require replacement sooner. Consider the maintenance requirements of each material. Some may require periodic cleaning or sealing to maintain their protective properties. Lower maintenance options often translate to reduced long-term costs and enhanced system reliability.

These facets of material durability are integral to designing and implementing effective weatherproofing solutions at the chimney-roof junction. Choosing the right material is a critical investment that directly affects the long-term performance and protection of the structure. Failure to consider these factors can result in premature system failure and significant repair expenses.

2. Proper Installation

The efficacy of any weatherproofing system at the chimney-roof interface hinges critically on meticulous installation. Regardless of material quality, substandard installation practices will invariably lead to premature failure and water intrusion.

- Precision Cutting and Shaping

Accurate cutting and shaping are fundamental. Each piece must conform precisely to the contours of the chimney and roof, ensuring a tight, continuous seal. Gaps or improperly fitted components provide direct pathways for water penetration. Field measurements must be precise, and templates should be employed when necessary to guarantee dimensional accuracy. For instance, step flashing requires careful cuts to match the roof pitch, ensuring proper overlap and water shedding.

- Correct Overlapping and Layering

Flashing systems rely on overlapping and layering to create a redundant barrier against water. Each layer must effectively shed water onto the layer below, directing it away from vulnerable areas. Improper overlapping, such as insufficient overlap distances or reversed layering, defeats the system’s intended function. Counterflashing, for example, must extend adequately over the step flashing to prevent water from seeping behind it.

- Secure Fastening and Sealing

Flashing components must be securely fastened to both the chimney and the roof to prevent displacement by wind or ice. Fasteners must be corrosion-resistant and appropriate for the materials being joined. In addition to mechanical fastening, high-quality sealants are essential for filling gaps and creating a watertight bond. The selection of a compatible sealant is critical to prevent degradation and maintain long-term adhesion. Improper fastening or sealant application will lead to leaks and system failure.

- Integration with Roofing Materials

Seamless integration with surrounding roofing materials is crucial for overall weatherproofing. The flashing system must be properly interwoven with the shingles or other roofing elements to create a continuous, uninterrupted barrier. This requires careful planning and execution to avoid creating dams or obstructions that can trap water. For instance, integrating step flashing with asphalt shingles involves embedding each piece beneath the subsequent shingle course, ensuring a watertight seal.

These facets of proper installation, when executed with precision and attention to detail, are essential for achieving durable and effective weatherproofing at the chimney-roof interface. Neglecting any of these aspects can compromise the entire system, resulting in water damage, structural deterioration, and costly repairs. Professional expertise is often necessary to ensure that these critical installation procedures are performed correctly.

3. Weather Resistance

Weather resistance is a primary performance criterion for any system installed at the intersection of a chimney and roof. Its effectiveness dictates the system’s ability to protect the building envelope from the detrimental effects of environmental elements.

- Water Repellency and Drainage

The system must effectively repel water from rain, snow, and ice, while also providing adequate drainage to prevent accumulation. The angle of the material, overlapping design, and surface treatments all contribute to water repellency. For instance, a smooth, non-porous surface allows water to run off easily, while properly angled pieces direct water away from vulnerable seams and joints. Inadequate repellency leads to water infiltration, promoting decay and structural damage.

- Resistance to Temperature Extremes

The system must withstand extreme temperature fluctuations without cracking, warping, or otherwise compromising its integrity. Repeated expansion and contraction can weaken materials and seals over time. Materials with low thermal expansion coefficients, such as stainless steel, are often preferred in regions with significant temperature variations. Failure to account for temperature extremes results in material fatigue and eventual system failure.

- Wind Uplift and Impact Resistance

The system must resist displacement from high winds and impact from falling debris, such as branches or hail. Secure fastening and durable materials are essential for maintaining structural integrity during severe weather events. A properly installed and secured system will remain intact even under strong wind conditions, preventing water intrusion and minimizing damage. Insufficient resistance to wind and impact leads to system detachment and exposure of the underlying structure.

- Ultraviolet (UV) Radiation Resistance

Prolonged exposure to UV radiation can degrade certain materials, leading to embrittlement, discoloration, and loss of protective properties. UV-resistant coatings and materials, such as certain polymers and metals, are necessary to maintain long-term performance. Without adequate UV protection, the system will deteriorate prematurely, requiring frequent repairs or replacement.

These interconnected facets of weather resistance are crucial for ensuring the durability and effectiveness of a system at the chimney-roof interface. Each factor contributes to the overall ability of the system to protect the building from the elements, preventing costly damage and maintaining structural integrity over the long term. Selection of appropriate materials and adherence to proper installation techniques are vital for maximizing weather resistance and ensuring lasting protection.

4. Water Diversion

Effective water diversion is a core function of weatherproofing at the juncture where a chimney penetrates a roof. The primary objective is to channel water away from vulnerable areas, preventing infiltration and subsequent damage to the building’s structure. Failure to achieve adequate water diversion will invariably result in leaks, wood rot, and compromised structural integrity.

- Stepped Configuration

Stepped configurations are integral to the process, employing a series of overlapping pieces that ascend along the side of the chimney. Each piece is integrated with the roofing material, directing water downwards and outwards. The efficacy of this system relies on precise installation and adequate overlap to prevent water from seeping behind the material. This approach is crucial for managing water flow on sloped roofs where water tends to concentrate along the chimney’s sides.

- Counterflashing Application

Counterflashing complements the stepped configuration by overlaying it and channeling water away from the seams. This component is embedded in the chimney’s masonry joints and extends downwards, covering the top edge of the stepped pieces. Proper counterflashing prevents water from penetrating the junction between the step component and the chimney, a common point of vulnerability. The installation angle and secure anchoring of the counterflashing are critical for achieving effective water diversion.

- Cricket Construction

A cricket, a small, peaked structure installed on the roof behind the chimney, plays a vital role in water diversion, particularly on wider chimneys. The cricket’s angled surfaces redirect water around the chimney, preventing it from pooling and creating hydrostatic pressure against the structure. Proper cricket construction requires precise measurements and careful integration with the roofing materials to ensure seamless water flow. The absence of a cricket on a wide chimney can lead to significant water accumulation and subsequent leaks.

- Drip Edge Implementation

The implementation of a drip edge is designed to direct water away from the fascia and underlying roofing components. The drip edge should extend beyond the edge of the roof and feature a downward-sloping flange that directs water away from the building. Proper installation of the drip edge, in conjunction with the system, is essential for managing water runoff and preventing water damage to the eaves and soffit. The drip edge acts as a final line of defense against water intrusion, complementing the water diversion provided by other elements.

In summation, robust water diversion relies on a combination of these elements. The precise configuration and integration of each component are paramount for preventing water infiltration and ensuring the long-term integrity of the chimney-roof interface. Regular inspections and timely repairs are essential for maintaining the effectiveness of these water diversion mechanisms and safeguarding the building from water damage. The selection of durable, weather-resistant materials is equally important, complementing the design and installation techniques to achieve comprehensive water management.

5. Long-Term Performance

Long-term performance is a critical consideration in the design and installation of systems at the chimney-roof interface. It signifies the ability of the system to maintain its protective function over an extended period, resisting degradation and preventing water intrusion despite exposure to environmental stressors. The system’s longevity directly impacts the building’s structural integrity and reduces the need for costly repairs or replacements.

- Material Selection and Degradation Resistance

Material selection is paramount for ensuring long-term performance. Durable materials, such as copper, stainless steel, or high-grade aluminum, exhibit superior resistance to corrosion, UV radiation, and temperature fluctuations. Degradation of materials compromises the system’s integrity, leading to leaks and structural damage. For example, using galvanized steel in coastal environments can lead to rapid corrosion and failure, while copper, though initially more expensive, offers decades of reliable service.

- Joint Integrity and Sealant Longevity

Joint integrity and sealant longevity are essential for maintaining a watertight seal over time. Sealants must be compatible with the materials being joined and resistant to cracking, shrinking, or hardening due to environmental exposure. Inadequate sealant selection or improper application will result in leaks and water intrusion. For example, using a low-quality sealant that cracks and hardens within a few years necessitates costly repairs to restore the system’s weatherproofing capabilities.

- Design Considerations for Thermal Expansion and Contraction

Proper design must account for thermal expansion and contraction to prevent stress and fatigue. Materials expand and contract with temperature changes, and differential expansion between dissimilar materials can lead to cracking or loosening of fasteners. Incorporating expansion joints or selecting materials with similar thermal expansion coefficients minimizes stress and maintains system integrity. Failure to address thermal movement can result in premature failure and water intrusion, particularly in regions with extreme temperature variations.

- Maintenance and Inspection Protocols

Regular maintenance and inspection protocols are crucial for identifying and addressing potential issues before they escalate. Inspections should focus on checking for corrosion, cracks, sealant degradation, and loose fasteners. Timely repairs, such as replacing damaged or deteriorated components, extend the system’s lifespan and prevent costly water damage. Neglecting routine maintenance can lead to undetected problems that compromise the system’s long-term performance, requiring extensive repairs or complete replacement.

In conclusion, achieving long-term performance at the chimney-roof interface necessitates a holistic approach that encompasses careful material selection, meticulous design, proper installation, and diligent maintenance. Employing durable materials, ensuring joint integrity, accommodating thermal movement, and implementing regular inspections are essential strategies for maximizing the system’s lifespan and protecting the building from water damage. The initial investment in quality materials and proper installation is offset by reduced maintenance costs and the avoidance of costly repairs over the long term, underscoring the economic and structural benefits of prioritizing long-term performance.

6. Seal Integrity

Seal integrity, the sustained ability to prevent water intrusion, is a paramount attribute of effective systems at the intersection of a chimney and roof. Its absence invariably leads to water damage, structural deterioration, and compromised indoor air quality. The following details the critical facets of seal integrity and their implications in maintaining a robust and weather-resistant system.

- Material Compatibility and Adhesion

The selection of compatible materials and the assurance of adequate adhesion are foundational to seal integrity. Dissimilar materials can react negatively, causing sealant degradation or bond failure. For example, applying a sealant incompatible with the system’s metal can lead to corrosion and a breach in the seal. Proper surface preparation, including cleaning and priming, is also essential for promoting optimal adhesion. The absence of material compatibility and adhesion undermines the system’s ability to maintain a watertight barrier.

- Joint Design and Configuration

The design and configuration of joints significantly influence seal integrity. Joints must be designed to accommodate thermal expansion and contraction, preventing stress and cracking. Overlapping joints, for instance, provide a redundant barrier against water penetration, mitigating the impact of minor sealant failures. In contrast, butt joints are more vulnerable to leakage, particularly when subjected to movement or stress. Proper joint design minimizes stress on sealant materials and enhances the system’s long-term water resistance.

- Sealant Application Techniques

Proper sealant application techniques are crucial for achieving and maintaining seal integrity. Sealants must be applied evenly and consistently, filling all gaps and voids to create a continuous, watertight barrier. Overapplication can lead to sealant sagging or running, while underapplication leaves vulnerable areas exposed. Correct tooling and finishing of the sealant surface promote adhesion and prevent water from pooling. Adherence to manufacturer’s recommendations for sealant application is essential for optimizing performance and preventing premature failure.

- Environmental Resistance and Degradation

Seal integrity is challenged by environmental factors, including UV radiation, temperature fluctuations, and chemical pollutants. Sealants must be resistant to degradation from these elements to maintain their protective properties over time. UV radiation can cause sealants to become brittle and crack, while temperature extremes can lead to expansion and contraction, compromising the bond. Selecting sealants specifically formulated for exterior use and resistant to environmental degradation is essential for ensuring long-term seal integrity. Periodic inspections and maintenance are also necessary to identify and address any signs of sealant deterioration, such as cracking, shrinking, or discoloration.

In summary, the effective system relies on a combination of compatible materials, sound joint design, proper sealant application, and environmental resistance. By addressing these facets, the risk of water intrusion is minimized, thereby safeguarding the building structure and preserving indoor environmental quality. The sustained integrity of seals contributes significantly to the overall durability and weather-resistance of the roof-chimney assembly.

7. Preventative Maintenance

Preventative maintenance constitutes a critical element in preserving the integrity and functionality of weatherproofing around chimneys. Consistent attention and proactive measures mitigate potential degradation and ensure long-term protection against water intrusion.

- Routine Inspections

Scheduled inspections are essential for identifying early signs of deterioration or damage. These inspections should include a thorough examination of the material, sealant, and surrounding roofing components. For example, an annual inspection can reveal hairline cracks in the sealant or minor corrosion on the metal before these issues escalate into significant leaks. Early detection facilitates timely repairs, preventing costly water damage and structural deterioration.

- Sealant Reapplication

Sealants are subject to degradation from UV radiation, temperature fluctuations, and weathering. Regular reapplication of sealant is necessary to maintain a watertight seal. For instance, a visual inspection may reveal that the sealant has become brittle, cracked, or detached from the substrate. Removing the old sealant and applying a fresh layer restores the system’s ability to prevent water intrusion. Adhering to the manufacturer’s recommendations for sealant reapplication ensures optimal performance and longevity.

- Debris Removal

Accumulation of debris, such as leaves, branches, and moss, can trap moisture and accelerate corrosion. Regular removal of debris from the chimney-roof interface prevents water from pooling and damaging the materials. For example, removing accumulated leaves from behind a chimney cricket prevents water from being held against the masonry, reducing the risk of water absorption and freeze-thaw damage. Maintaining a clean and unobstructed area promotes proper water drainage and extends the lifespan of the system.

- Flashing Repair or Replacement

Damaged or corroded components require prompt repair or replacement to prevent water intrusion. Physical damage from falling debris or severe weather events can compromise the system’s integrity. For example, a section of metal may be dented or torn, creating a pathway for water to enter. Replacing the damaged section with new material ensures a watertight seal and restores the system’s protective function. Addressing damage promptly prevents further deterioration and minimizes the risk of costly repairs.

The consistent application of these preventative maintenance practices is paramount for preserving the effectiveness and longevity of the chimney weatherproofing. Neglecting these proactive measures increases the likelihood of water damage, structural problems, and costly repairs. Regular inspections, sealant maintenance, debris removal, and prompt repair of damaged components are essential for ensuring long-term protection and maintaining the integrity of the building envelope.

Frequently Asked Questions

This section addresses common inquiries concerning the critical weatherproofing at the chimney-roof interface. The information provided aims to clarify misconceptions and provide accurate guidance on best practices.

Question 1: What materials are suitable for use in chimney flashing applications?

Suitable materials exhibit resistance to corrosion, thermal expansion, and UV degradation. Common choices include copper, stainless steel, and aluminum. The selection should consider environmental factors and compatibility with existing roofing materials.

Question 2: How often should chimney flashing be inspected?

Routine inspections are recommended at least annually, and following any severe weather events. Inspections should focus on identifying signs of corrosion, sealant degradation, and physical damage.

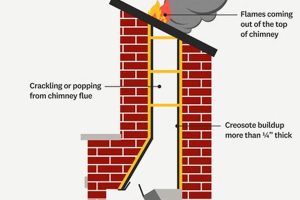

Question 3: What are the key indicators of failing chimney flashing?

Key indicators include water stains on ceilings or walls near the chimney, visible rust or corrosion, cracked or missing sealant, and loose or displaced material.

Question 4: Is it necessary to hire a professional for chimney flashing installation or repair?

Professional installation or repair is highly recommended, particularly for complex configurations or when dealing with heights. Qualified professionals possess the expertise and tools to ensure proper installation and mitigate the risk of future problems.

Question 5: What is the purpose of step flashing in chimney weatherproofing?

Step flashing creates a layered defense against water intrusion along the sides of the chimney. Each piece is integrated with the roofing material, directing water downwards and outwards, preventing it from seeping behind the material.

Question 6: How can homeowners prevent premature failure of chimney flashing systems?

Homeowners can prevent premature failure by conducting routine inspections, removing debris from the chimney-roof interface, maintaining sealant, and addressing any signs of damage promptly. Proactive maintenance extends the system’s lifespan and prevents costly repairs.

The information presented in this FAQ section provides a foundation for understanding the importance and maintenance requirements of weatherproofing. Adherence to these guidelines will contribute to the long-term preservation of the building.

The following section will delve into advanced troubleshooting techniques for addressing complex chimney problems.

Conclusion

This exposition has underscored the critical role of effective weatherproofing at the intersection of a chimney and roof. Proper execution, from material selection to installation techniques, is paramount for preventing water intrusion and preserving structural integrity. The long-term performance hinges on material durability, seal integrity, and consistent preventative maintenance protocols.

Diligent adherence to established best practices, combined with regular inspections and timely repairs, represents a sound investment in the enduring protection of any building. Neglecting the principles outlined herein invites potential water damage and costly structural remediation, underscoring the enduring significance of ensuring a robust, watertight seal at this vulnerable juncture. Consider consulting with qualified professionals to guarantee lasting protection.