The structure is a local landmark. Its primary function is venting byproducts from a heating or industrial process. Located within the Houston metropolitan area, it serves as a crucial component of infrastructure for a specific facility.

Such structures are essential for maintaining air quality and safety standards. Their design and construction often incorporate considerations for environmental regulations and community well-being. Furthermore, the presence of these tall structures can have historical significance, reflecting the industrial development of the surrounding area.

The following sections will provide further detailed information about specific aspects related to this type of engineering structure, including its construction, maintenance, and its impact on the surrounding environment.

Guidance Regarding Industrial Exhaust Structures

The following are considerations regarding the maintenance and operation of tall industrial exhaust structures, crucial for safety and regulatory compliance. Adhering to these guidelines is vital for the longevity and responsible operation of any such system.

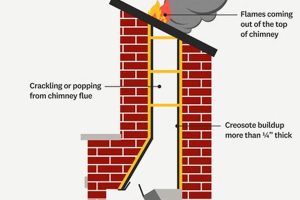

Tip 1: Routine Inspection is Paramount: Regular visual inspections by qualified engineers are essential for identifying early signs of structural degradation. This includes checking for cracks, corrosion, or any other anomalies that could compromise the structure’s integrity.

Tip 2: Material Degradation Mitigation: Implement corrosion control measures. This may involve applying protective coatings, cathodic protection systems, or using corrosion-resistant materials during repairs and upgrades.

Tip 3: Regulatory Compliance Adherence: Maintain meticulous records of all inspections, maintenance activities, and emission tests. Strict compliance with local, state, and federal environmental regulations is non-negotiable.

Tip 4: Wind Load and Seismic Stability Assessment: Periodically evaluate the structure’s ability to withstand wind loads and seismic activity. Updates to structural reinforcement may be necessary based on evolving environmental factors and building codes.

Tip 5: Controlled Demolition Planning: In the event that the structure reaches the end of its useful life, a carefully planned and executed demolition is crucial. This requires expertise in implosion techniques and adherence to strict safety protocols.

Tip 6: Proper Maintenance: Ensuring all necessary maintenance procedures are followed and up to date. This not only improves the safety of the industrial structure, but increases the longevity of it as well.

Prioritizing these practices will ensure the long-term safe and efficient operation of industrial exhaust structures, minimizing environmental impact and safeguarding public safety. Failure to follow these guidelines can result in serious risks and penalties.

The next section will address some common misconceptions regarding these types of structures.

1. Structural Integrity Monitoring

Structural Integrity Monitoring is paramount for long-term safe operation. Consistent assessment is a crucial factor in ensuring a facility’s sustainability and regulatory compliance.

- Corrosion Detection and Prevention

Corrosion, due to environmental exposure and internal gas composition, is a primary concern. Regular inspections using non-destructive testing methods (NDT) are essential for detecting corrosion early. Prevention strategies include protective coatings and cathodic protection systems.

- Wind Load and Vibration Analysis

These types of structures are subject to significant wind loads, potentially leading to structural fatigue and failure. Continuous monitoring of vibration patterns and stress levels is important. This data informs maintenance schedules and potential reinforcement requirements.

- Foundation Stability Assessment

Ground settlement or seismic activity can compromise the foundation’s integrity. Regular surveys and geotechnical investigations are necessary to identify and address any movement or instability.

- Material Fatigue Analysis

Constant stress from temperature variations and vibrations leads to material fatigue. Regular laboratory testing of material samples taken during inspections helps determine material strength and potential for failure.

Monitoring structural integrity is a crucial for the long term safety and operational capacity. Neglecting routine inspections or necessary repairs increases the risk of structural failure, environmental hazards, and financial liabilities. Continuous monitoring and proactive measures are therefore essential for maintaining the functional integrity.

2. Emissions Regulation Compliance

Adherence to emissions regulations is a critical aspect of operating an industrial exhaust structure. These structures, common in industrial areas, are subject to stringent rules designed to protect air quality and public health.

- Permitting Requirements

Before construction and operation, a facility must obtain necessary permits from regulatory agencies. These permits specify allowable emission rates for various pollutants, based on factors such as stack height, gas flow rates, and the nature of the industrial process. Compliance with permit conditions is continuously monitored.

- Continuous Emission Monitoring Systems (CEMS)

Many facilities are required to install and maintain CEMS. These systems continuously measure pollutant concentrations in the exhaust gas. Data from CEMS is reported to regulatory agencies, allowing for real-time tracking of emissions and prompt identification of potential exceedances.

- Pollution Control Technologies

To meet emission limits, facilities often employ pollution control technologies. These may include scrubbers, filters, electrostatic precipitators, or catalytic converters. The selection of appropriate technology depends on the specific pollutants being emitted and the required level of control. Regular maintenance and optimization of these systems are crucial for sustained compliance.

- Record Keeping and Reporting

Detailed records of emissions data, equipment maintenance, and any incidents of non-compliance must be maintained. Regular reports are submitted to regulatory agencies, providing a comprehensive overview of the facility’s environmental performance. Accurate and transparent reporting is essential for maintaining credibility and avoiding penalties.

Compliance with emissions regulations is not merely a legal obligation; it reflects a commitment to environmental stewardship and community responsibility. Failure to adhere to these regulations can result in significant financial penalties, legal action, and reputational damage. Therefore, robust emissions monitoring and control programs are essential for the sustainable operation of any facility utilizing these types of structures.

3. Environmental Impact Mitigation

Environmental Impact Mitigation, when considering industrial exhaust structures, represents a critical facet of responsible operation. These structures, designed for the dispersal of emissions, necessitate comprehensive strategies to minimize potential adverse effects on the surrounding environment.

- Air Quality Monitoring and Control

Air quality monitoring forms the foundation of effective mitigation. Continuous monitoring of emissions, including particulate matter and gaseous pollutants, enables real-time assessment of air quality. Data obtained is crucial for implementing adaptive control measures, such as adjusting operational parameters or deploying enhanced filtration technologies, to maintain air quality standards.

- Wastewater Treatment and Discharge Management

In certain industrial processes, exhaust structures may be associated with wastewater streams. Proper treatment of wastewater to remove contaminants before discharge is essential. This involves employing various treatment technologies, such as chemical precipitation, biological treatment, and membrane filtration, to ensure that discharged water meets regulatory standards and minimizes harm to aquatic ecosystems.

- Noise Reduction Strategies

The operation of industrial equipment associated with exhaust structures can generate significant noise levels. Implementing noise reduction strategies, such as installing sound barriers, employing vibration damping materials, and optimizing equipment design, is crucial for minimizing noise pollution and protecting the acoustic environment of nearby communities.

- Ecological Impact Assessment and Remediation

Before construction or significant modifications to exhaust structures, ecological impact assessments are necessary to identify potential impacts on local ecosystems. These assessments inform the development of mitigation measures, such as habitat restoration, wildlife protection plans, and compensatory mitigation projects, to offset any unavoidable environmental damage.

The efficacy of Environmental Impact Mitigation rests on integrating these measures throughout the lifecycle of the industrial structure. Regular audits, adaptive management strategies, and community engagement are essential for ensuring continuous improvement and fostering a responsible operational culture. Proper management reduces damage on environment and increases the structure’s sustainability.

4. Community Health Protection

The structural exhaust apparatus, common in industrial areas, necessitates careful consideration of community health protection. The purpose of such structures is to disperse emissions away from ground level, theoretically reducing the concentration of pollutants in immediate proximity to residential areas. However, the effectiveness of this dispersion hinges on factors such as stack height, prevailing wind patterns, and the nature of the emitted substances. Improperly designed or maintained structures can contribute to localized air pollution, potentially impacting respiratory health, particularly among vulnerable populations such as children and the elderly. The long-term effects of exposure to even low levels of certain pollutants necessitate rigorous monitoring and adherence to emissions standards.

Effective community health protection requires a multi-faceted approach. This includes continuous emissions monitoring to ensure compliance with regulatory limits, the implementation of advanced pollution control technologies to minimize the release of harmful substances, and transparent communication with the local community regarding potential risks and mitigation efforts. For example, public health agencies often conduct epidemiological studies to assess the health outcomes of populations living near industrial facilities. These studies can provide valuable data for informing policy decisions and guiding further mitigation strategies. Furthermore, community advisory panels can serve as a forum for dialogue between industry representatives, government regulators, and local residents, fostering trust and ensuring that community concerns are addressed proactively.

In conclusion, the operation of these structures presents both benefits and risks to community health. While they serve a crucial function in dispersing emissions, their potential impact on air quality and human health cannot be ignored. Proactive measures, including continuous monitoring, advanced pollution control, transparent communication, and community engagement, are essential for minimizing risks and maximizing the protection of public health. Understanding the complex interplay between industrial emissions and community health is crucial for promoting sustainable development and ensuring a healthy environment for all.

5. Operational Longevity Planning

Operational Longevity Planning for an industrial exhaust structure necessitates a forward-thinking approach, encompassing design, construction, maintenance, and decommissioning. Given the significant investment and critical function of such structures, a long-term perspective is paramount to ensure continued operational efficiency, regulatory compliance, and community safety.

- Material Selection and Corrosion Prevention

The choice of construction materials significantly impacts the lifespan. Corrosion-resistant alloys or protective coatings are essential in mitigating degradation from harsh chemical environments and weather exposure. Implementing robust corrosion prevention strategies from the outset reduces the need for costly repairs and extends the structure’s useful life.

- Structural Health Monitoring Systems

Integrating advanced Structural Health Monitoring (SHM) systems allows for continuous assessment of structural integrity. These systems employ sensors to detect minute changes in strain, vibration, and temperature, providing early warning of potential problems. Data from SHM systems enables proactive maintenance and prevents catastrophic failures.

- Adaptive Maintenance Scheduling

Rather than adhering to fixed maintenance schedules, an adaptive approach based on real-time condition monitoring optimizes maintenance efforts. This involves prioritizing repairs based on actual need, reducing unnecessary interventions, and extending the intervals between major overhauls. Predictive maintenance techniques, such as oil analysis and thermal imaging, further enhance the effectiveness of adaptive scheduling.

- Decommissioning and Repurposing Strategies

Operational Longevity Planning must also consider the eventual decommissioning of the structure. Developing a detailed decommissioning plan early in the lifecycle ensures a safe and environmentally responsible dismantling process. Exploring options for repurposing the structure, such as converting it into a telecommunications tower or observation platform, can extend its economic value beyond its original function.

The integration of these facets is crucial for maximizing the operational lifespan. A proactive approach to material selection, structural monitoring, maintenance scheduling, and decommissioning not only extends the useful life but also enhances safety, minimizes environmental impact, and optimizes return on investment. Prioritizing Operational Longevity Planning is essential for responsible asset management.

Frequently Asked Questions About Industrial Exhaust Structures

The following questions and answers address common inquiries regarding industrial exhaust structures, their function, and their impact on the environment and surrounding communities.

Question 1: What is the primary purpose of an industrial exhaust structure?

The primary purpose is to vent exhaust gases from industrial processes at a height that minimizes ground-level concentrations of pollutants.

Question 2: What factors determine the appropriate height of an industrial exhaust structure?

Factors include the volume and composition of exhaust gases, surrounding topography, meteorological conditions, and applicable regulatory requirements.

Question 3: How are emissions from industrial exhaust structures regulated?

Emissions are regulated by local, state, and federal environmental agencies, which set limits on allowable pollutant concentrations and require monitoring and reporting.

Question 4: What measures are in place to prevent structural failure of these structures?

Preventative measures include regular inspections, corrosion protection systems, wind load and seismic analysis, and adherence to engineering standards.

Question 5: What are the potential environmental impacts associated with industrial exhaust structures?

Potential environmental impacts include air pollution, deposition of pollutants on soil and water, and noise pollution.

Question 6: How are community concerns regarding industrial exhaust structures addressed?

Community concerns are addressed through public hearings, environmental impact assessments, community advisory panels, and transparent communication regarding emissions data and mitigation measures.

The answers provided offer a general overview of key aspects related to these types of structures. For more specific information, consult with qualified engineers, environmental professionals, and regulatory agencies.

The following segment addresses the societal impact of the industrial structure.

Conclusion

This exploration of structures such as those, including one near Houston, reveals a network of regulations and engineering standards aimed at minimizing environmental impact and ensuring structural integrity. Maintenance, regulation compliance and impact mitigation are important.

Continued vigilance and proactive strategies are essential for safeguarding both environmental health and the well-being of surrounding communities, particularly in areas marked by significant industrial activity. Further research and advancements in monitoring technologies may enhance these safety measure.