These heating systems represent a specific category of appliances designed to warm interior spaces by combusting oil. A defining characteristic is their reliance on a vertical structure to exhaust combustion byproducts. This structure, typically constructed of brick or metal, facilitates the safe removal of gases and particulate matter from the living area. The system draws air for combustion, mixes it with oil, ignites the mixture, and then vents the resulting gases through this dedicated flue.

The advantage of such a system lies in its ability to provide a consistent and reliable source of heat, especially in regions where alternative fuels are less readily available or more expensive. Historically, these appliances offered a significant improvement over less controlled heating methods, contributing to improved indoor air quality (by properly venting combustion byproducts) and enhanced comfort during colder months. Their continued use in certain locales is a testament to their longevity and proven effectiveness.

The following discussion will elaborate on the operational principles, safety considerations, maintenance requirements, and relevant efficiency metrics associated with these established heating solutions. Understanding these aspects is crucial for ensuring optimal performance and maximizing the lifespan of the unit.

Tips for Optimal Operation

The following recommendations are intended to promote safe, efficient, and reliable operation of the system. Adherence to these guidelines can extend the lifespan of the appliance and minimize potential hazards.

Tip 1: Annual Inspection is Paramount. A qualified technician must perform a comprehensive inspection at least once per year. This inspection should include assessment of the venting system, burner components, and safety controls. Failure to inspect can lead to undetected malfunctions.

Tip 2: Use Specified Fuel Grade. Operation should only occur with the fuel grade explicitly recommended by the manufacturer. Utilizing alternative fuel types can result in incomplete combustion, increased soot production, and potential damage to the appliance.

Tip 3: Ensure Adequate Ventilation. The room housing the unit must have sufficient ventilation to ensure adequate air supply for combustion. Insufficient ventilation can lead to carbon monoxide buildup and impaired burner performance.

Tip 4: Regularly Clean the Venting System. Soot accumulation within the venting system restricts airflow and can lead to dangerous backdraft conditions. Scheduled cleaning, as recommended by a qualified technician, is essential.

Tip 5: Monitor for Unusual Odors. Any unusual odors, particularly the smell of fuel oil within the living space, warrant immediate investigation. This could indicate a fuel leak or incomplete combustion, requiring prompt attention.

Tip 6: Verify Carbon Monoxide Detector Functionality. A functioning carbon monoxide detector is a critical safety device. Regularly test the detector to ensure it is operational and replace batteries as needed.

Tip 7: Maintain Proper Chimney Draft. Ensure the structure is adequately sized and free from obstructions to maintain proper draft. Insufficient draft can cause combustion byproducts to vent improperly into the dwelling.

These practices are crucial for the continued safe and efficient operation of the heating appliance. Neglecting these recommendations can compromise safety, reduce efficiency, and shorten the lifespan of the system.

The subsequent sections will delve into troubleshooting common issues and understanding the environmental impact of this heating technology.

1. Venting System Integrity

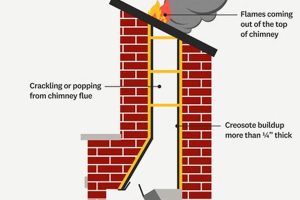

The operational safety and efficiency of any appliance that combusts fuel within an enclosed space hinges critically on the integrity of its venting system. In the context of a “chimney vented oil heater,” the venting system, which typically comprises a chimney or flue, serves as the primary conduit for the evacuation of harmful combustion byproducts, including carbon monoxide, nitrogen oxides, and particulate matter. A compromised venting system poses a direct threat to the health and safety of building occupants. For example, a cracked or obstructed chimney can lead to the backflow of these dangerous gases into the living space, resulting in carbon monoxide poisoning or respiratory irritation.

The design and construction of the venting system must adhere to strict building codes and industry standards to ensure proper draft and effective removal of combustion byproducts. Regular inspections are essential to identify and address potential issues, such as cracks, blockages caused by debris or animal nests, and deterioration due to corrosion or weathering. Neglecting these inspections can lead to significant performance degradation, reduced heating efficiency, and increased risk of hazardous conditions. A poorly maintained venting system places undue stress on the oil heater itself, potentially leading to premature component failure and costly repairs.

In conclusion, the relationship between the structural soundness of the venting system and the safe and efficient operation of the “chimney vented oil heater” is inextricable. Maintaining a structurally sound and properly functioning venting system is not merely a matter of routine maintenance; it is a fundamental prerequisite for ensuring the health, safety, and well-being of individuals residing within the heated space. The implications of neglecting this critical aspect extend beyond mere inconvenience, potentially resulting in severe health consequences and property damage.

2. Fuel Efficiency Optimization

Fuel efficiency optimization, in the context of a chimney vented oil heater, directly translates to minimizing the consumption of fuel oil required to achieve a desired heating output. The efficiency of the combustion process, the heat transfer rate within the appliance, and the effective venting of combustion byproducts all play critical roles. Inefficient combustion leads to unburnt fuel being exhausted, representing a direct loss of energy and increased fuel costs. Similarly, scale buildup on heat exchanger surfaces impedes heat transfer, requiring the burner to operate for longer periods to maintain the set temperature. An inadequately maintained or poorly designed venting system can also contribute to inefficiency by creating back pressure, hindering proper combustion, and potentially allowing heat to escape up the chimney instead of radiating into the space.

Real-world examples highlight the significance of this connection. A properly tuned burner, calibrated for optimal air-to-fuel ratio, can yield a substantial improvement in fuel efficiency compared to one that is misadjusted. Regularly cleaning the heat exchanger surfaces to remove soot and scale deposits can restore heat transfer efficiency to near-original levels. Upgrading to a modern, high-efficiency burner can further enhance performance by optimizing the combustion process and minimizing fuel waste. In practical terms, a homeowner who invests in these optimization measures can expect to see a noticeable reduction in their annual fuel oil consumption, resulting in significant cost savings and a reduced environmental impact.

Understanding the link between fuel efficiency optimization and the operational effectiveness of the heating appliance is essential for responsible energy consumption and cost management. While older systems may inherently exhibit lower efficiency compared to modern alternatives, proactive maintenance and strategic upgrades can significantly improve their performance. Overlooking these aspects not only leads to increased fuel costs but also contributes to unnecessary environmental strain through the increased emission of greenhouse gases. Therefore, prioritizing fuel efficiency is paramount for both economic and ecological reasons.

3. Safe Combustion Practices

The operation of a chimney vented oil heater fundamentally relies on the controlled combustion of fuel oil. Deviations from established safe combustion practices directly and negatively impact the functionality and safety of the heating system, potentially resulting in hazardous conditions and reduced efficiency. Incomplete combustion, for instance, generates carbon monoxide, an odorless and colorless gas that poses a severe health risk. Similarly, excessive soot accumulation, a byproduct of inefficient burning, can obstruct the chimney, leading to backdrafting of combustion gases into the living space and increasing the risk of fire. Safe combustion, therefore, is not merely a desirable attribute but a critical prerequisite for the safe and effective operation of these heating appliances.

Real-world examples underscore this point. Homes with malfunctioning or poorly maintained oil burners are demonstrably more susceptible to carbon monoxide incidents. Regular professional inspection and maintenance, including burner cleaning and adjustment, are essential to ensure complete combustion and minimize the production of hazardous byproducts. Furthermore, the use of appropriate fuel oil grades, as specified by the manufacturer, is crucial for maintaining optimal combustion conditions. Utilizing improper fuel can lead to incomplete burning and increased soot formation. Strict adherence to these safe combustion practices is a key component of responsible ownership and operation.

In summary, safe combustion practices are inextricably linked to the safe and efficient operation of chimney vented oil heaters. Neglecting these practices introduces significant risks, ranging from carbon monoxide poisoning and fire hazards to reduced heating efficiency and increased fuel consumption. Prioritizing safe combustion through regular maintenance, proper fuel usage, and professional inspections is essential for ensuring the well-being of occupants and the longevity of the heating system. The challenges lie in consistently adhering to these best practices and recognizing the subtle warning signs of combustion-related problems before they escalate into more serious issues.

4. Regular Maintenance Schedule

The sustained operational effectiveness and safety profile of a chimney vented oil heater are inextricably linked to adherence to a regular maintenance schedule. The operational characteristics of these appliances necessitate consistent attention to critical components, given the inherent nature of fuel combustion and the potential for wear and tear over time. Neglecting routine maintenance directly precipitates a decline in heating efficiency, an elevated risk of system malfunctions, and a heightened probability of safety hazards stemming from incomplete combustion or compromised venting.

Consider, for example, the accumulation of soot within the flue. Over time, this buildup restricts airflow, impeding the proper exhaust of combustion byproducts and potentially leading to carbon monoxide backdraft into the living space. Similarly, burner components, such as the nozzle and electrodes, degrade with use, resulting in inefficient fuel atomization and incomplete combustion. A regularly scheduled maintenance program addresses these issues proactively, incorporating chimney cleaning, burner tuning, and component replacement as necessary. These interventions maintain optimal combustion efficiency, reduce the risk of hazardous emissions, and extend the overall lifespan of the heating appliance. Data from appliance manufacturers and heating service providers consistently demonstrate that systems adhering to recommended maintenance schedules exhibit significantly lower failure rates and achieve greater energy efficiency compared to those that are neglected.

In summation, the implementation of a regular maintenance schedule is not merely a recommended practice but a critical imperative for ensuring the safe, efficient, and reliable operation of a chimney vented oil heater. The ramifications of neglecting this aspect extend beyond mere inconvenience, potentially encompassing significant financial costs associated with repairs or replacements, and more importantly, posing tangible threats to the health and safety of building occupants. Therefore, prioritizing and diligently executing a comprehensive maintenance program represents a responsible and prudent approach to heating system ownership.

5. Carbon Monoxide Mitigation

The operation of a chimney vented oil heater presents an inherent risk of carbon monoxide (CO) production. This colorless, odorless gas is a byproduct of incomplete combustion, a condition arising from various factors affecting the appliance’s functionality. Compromised venting systems, malfunctioning burners, and inadequate air supply for combustion can all contribute to elevated CO levels within a building. Effective CO mitigation is not merely a supplemental safety measure; it is an integral component of the safe and responsible operation of any such heating system. For example, a blocked chimney prevents proper exhaust of combustion byproducts, directly increasing the concentration of CO in the indoor environment. A faulty burner, unable to achieve complete fuel combustion, exacerbates the issue.

Practical applications of CO mitigation strategies involve multiple layers of defense. The first line of defense is regular professional maintenance of the heating appliance, including inspection and cleaning of the burner and venting system. This proactive approach minimizes the likelihood of incomplete combustion. The second layer involves the installation and maintenance of CO detectors. These devices provide continuous monitoring of CO levels and alert occupants to potentially dangerous conditions. Critically, the detectors must be functional, properly located according to manufacturer instructions, and regularly tested. A real-life example illustrates the point: a family unknowingly experienced elevated CO levels due to a cracked chimney liner. The presence of functioning CO detectors provided an early warning, enabling them to evacuate the home and seek professional repairs before experiencing severe health consequences.

In conclusion, carbon monoxide mitigation is a critical safety consideration for any dwelling utilizing a chimney vented oil heater. A multifaceted approach, encompassing proactive maintenance, functional CO detection, and occupant awareness, is essential for minimizing the risk of CO poisoning. The challenges lie in maintaining consistent vigilance and ensuring that all safety measures are in place and functioning correctly. The practical significance of this understanding is underscored by the potentially life-threatening consequences of neglecting CO mitigation strategies.

Frequently Asked Questions about Chimney Vented Oil Heaters

The following section addresses common inquiries regarding the operation, safety, and maintenance of these heating systems. The answers provided are intended to offer clarity and promote a better understanding of their functionality.

Question 1: What are the primary safety concerns associated with a chimney vented oil heater?

The foremost safety concerns revolve around the potential for carbon monoxide (CO) poisoning due to incomplete combustion or inadequate venting. Additionally, the risk of fire exists due to fuel leaks, improper maintenance, or chimney obstructions. Regular inspections and adherence to safety protocols are essential to mitigate these risks.

Question 2: How frequently should a chimney vented oil heater undergo professional maintenance?

A qualified technician should inspect and service the unit annually. This inspection should include assessment of the burner, venting system, and safety controls. More frequent maintenance may be required depending on the unit’s age, usage, and environmental conditions.

Question 3: What are the typical symptoms of carbon monoxide exposure related to this type of heating system?

Symptoms can include headache, nausea, dizziness, fatigue, confusion, and loss of consciousness. High levels of CO exposure can be fatal. Functional carbon monoxide detectors are crucial for early detection.

Question 4: What fuel grade is recommended for use in a chimney vented oil heater?

The manufacturer’s specifications should always be consulted. Typically, these units utilize fuel oil grade number 2. Using an incorrect fuel grade can lead to incomplete combustion, reduced efficiency, and potential damage to the appliance.

Question 5: What are the key indicators of a malfunctioning venting system?

Indicators include visible soot buildup around the appliance or chimney, unusual odors, a smoky smell within the living space, and the activation of carbon monoxide detectors. Any of these signs warrants immediate professional inspection.

Question 6: Can the efficiency of an older chimney vented oil heater be improved?

Yes, several measures can enhance efficiency, including burner tuning, cleaning of heat exchanger surfaces, and upgrading to a more efficient burner model. Replacing an older, less efficient unit with a modern, high-efficiency model offers the most significant improvement.

These responses highlight the critical aspects of safety and maintenance for chimney vented oil heaters. Prioritizing these considerations ensures the reliable and safe operation of the appliance.

The subsequent discussion will delve into troubleshooting common issues and understanding the environmental impact of this heating technology.

Chimney Vented Oil Heater

This exploration has detailed the critical facets of the chimney vented oil heater, encompassing its operational principles, safety requirements, and maintenance necessities. The importance of venting system integrity, optimized fuel efficiency, safe combustion practices, scheduled maintenance, and carbon monoxide mitigation has been thoroughly emphasized. These elements collectively determine the appliance’s reliability, longevity, and safety profile.

Given the inherent risks associated with fuel combustion, diligent adherence to established safety protocols and routine maintenance schedules is paramount. Individuals responsible for the operation of a chimney vented oil heater must recognize the significance of professional inspections, prompt repairs, and functional carbon monoxide detection. Neglecting these critical aspects not only compromises the appliance’s performance but also introduces potentially life-threatening hazards. The long-term viability of this heating technology depends on a sustained commitment to responsible operation and proactive risk mitigation.