The crafting of enclosed vertical structures for ventilation incorporates a strategic design element, often concealed within the manufacturing process, influencing the overall performance and longevity. This element involves precise shaping and material selection to optimize airflow and structural integrity. For example, a subtly tapered internal dimension improves the expulsion of combustion byproducts, while the specific alloy composition enhances resistance to thermal stress and corrosion.

The significance of this concealed aspect lies in its direct impact on safety, efficiency, and the extended operational lifespan of the unit. Historically, understanding and application of this technique have reduced incidents of backdraft, minimized energy waste, and contributed to the preservation of structures against the damaging effects of flue gases. The mastery of this procedure signifies an advanced understanding of thermodynamics and material science applied to practical engineering.

The following discussion will explore the intricacies of material properties, the mechanics of gas flow, and the engineering principles underpinning the creation of durable and effective vertical ventilation systems. Subsequent sections will delve into specific design considerations, manufacturing techniques, and methods for ensuring optimal performance throughout the lifespan of such constructs.

Guidance on Optimizing Vertical Ventilation Systems

The following guidelines emphasize critical considerations for enhancing the functionality and durability of enclosed vertical ventilation structures, focusing on principles often imperceptible to the untrained observer.

Tip 1: Material Selection: Employ alloys specifically engineered for high-temperature exposure and resistance to corrosive flue gases. For example, stainless steel grades with molybdenum content exhibit superior performance compared to standard carbon steel.

Tip 2: Internal Geometry Optimization: Implement a tapered internal profile to facilitate laminar airflow and minimize back pressure. Computational fluid dynamics can assist in determining the ideal taper angle for specific applications.

Tip 3: Joint Integrity Assurance: Prioritize robust welding techniques and non-destructive testing to eliminate potential leak points. Radiographic inspection and ultrasonic testing are effective methods for detecting subsurface flaws.

Tip 4: Insulation Implementation: Apply high-temperature insulation to reduce heat loss and prevent condensation. Mineral wool or ceramic fiber insulation offers superior thermal resistance and fireproofing capabilities.

Tip 5: Draft Control Mechanisms: Integrate adjustable dampers or barometric regulators to maintain consistent draft and prevent excessive heat loss during periods of inactivity. Regular calibration of these devices is crucial.

Tip 6: Height and Diameter Calibration: Precisely calculate the structure’s height and diameter to ensure sufficient draft and minimize flow resistance. These calculations should account for appliance input, fuel type, and geographical factors.

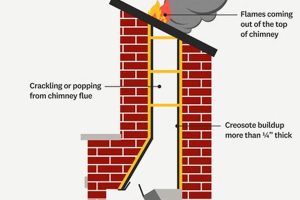

Tip 7: Regular Inspections and Maintenance: Implement scheduled inspections to detect signs of deterioration, such as corrosion, cracks, or blockages. Promptly address any issues to prevent system failures.

Adhering to these recommendations contributes to enhanced safety, improved energy efficiency, and prolonged structural integrity, ultimately mitigating risks associated with vertical ventilation systems.

The subsequent sections will delve into specific case studies and practical applications, illustrating the real-world impact of these critical design and maintenance considerations.

1. Alloy Composition

Alloy composition constitutes a fundamental determinant of a vertical ventilation structure’s efficacy and durability. This aspect, often concealed within the manufacturing specifications, significantly impacts the system’s ability to withstand corrosive byproducts of combustion and extreme temperature fluctuations. The strategic selection and precise blending of constituent metals directly correlate to the unit’s lifespan and operational safety. For example, the substitution of standard carbon steel with a high-chromium alloy markedly increases resistance to oxidation and sulfidation, common failure mechanisms in environments exposed to flue gases.

The influence of alloy composition extends beyond simple resistance to material degradation. It also affects thermal expansion characteristics, which must be carefully considered in relation to joint design and sealing methods. Utilizing dissimilar metals with significantly different expansion coefficients can lead to premature failure due to stress concentrations at the interfaces. Furthermore, the presence of specific alloying elements, such as molybdenum, enhances high-temperature tensile strength and creep resistance, crucial for maintaining structural integrity under sustained thermal loading. Specific examples, such as Inconel alloys used in demanding industrial applications, illustrate the correlation between specialized compositions and enhanced performance.

In summary, the selection of appropriate alloys represents a critical, albeit often overlooked, element in the creation of effective and long-lasting vertical ventilation structures. A thorough understanding of the interaction between material properties, operational conditions, and manufacturing processes is essential for maximizing system performance and minimizing the risk of failure. The optimization of alloy composition, therefore, constitutes an indispensable factor for ensuring the safety and efficiency of these essential structural components.

2. Internal Dimensions

The internal dimensions of a vertical ventilation structure are intrinsically linked to its overall efficacy, representing a critical, yet often unseen, component of its design. The precise geometry of the internal passage directly influences airflow dynamics, impacting draft efficiency and the expulsion of combustion byproducts. A suboptimal design can lead to diminished draft, increased back pressure, and the potential accumulation of hazardous gases within the structure. The selection of appropriate internal dimensions is therefore not arbitrary, but rather a calculated engineering decision predicated on factors such as appliance input, fuel type, and prevailing environmental conditions.

The practical significance of optimized internal dimensions is readily apparent in scenarios involving inadequate design. For instance, an undersized internal diameter may restrict airflow, leading to incomplete combustion and increased creosote buildup. Conversely, an excessively large internal diameter can result in reduced flue gas velocity, promoting condensation and corrosion. Examples can be found in historical structures exhibiting compromised performance due to adherence to outdated dimensional standards or deviations from the original design specifications. Advanced modeling tools, such as computational fluid dynamics (CFD), enable engineers to precisely simulate airflow patterns and optimize internal dimensions for specific applications, mitigating the risks associated with suboptimal designs.

In conclusion, the meticulous consideration of internal dimensions is essential for maximizing the performance and safety of vertical ventilation structures. Understanding the complex interplay between geometry, airflow dynamics, and material properties is crucial for achieving optimal draft, minimizing the accumulation of hazardous byproducts, and ensuring long-term structural integrity. Addressing the challenges associated with dimensional optimization requires a comprehensive approach, incorporating advanced modeling techniques and a thorough understanding of fundamental engineering principles. This focus on internal dimensions directly enhances the overall effectiveness and safety.

3. Mold Design

Mold design constitutes a foundational element governing the final properties of a vertical ventilation structure, directly influencing structural integrity and performance characteristics. The geometry of the mold dictates the precise dimensions and surface finish of the cast component, thereby impacting airflow dynamics, thermal resistance, and overall durability. Any deviation from the intended design during the mold creation process can propagate into defects within the finished product, compromising its ability to effectively channel combustion byproducts and withstand extreme temperature fluctuations. For instance, imperfections in the mold surface can translate into surface irregularities on the cast component, increasing frictional resistance to airflow and promoting the accumulation of creosote or other contaminants.

The importance of mold design extends beyond mere dimensional accuracy. It also encompasses the strategic placement of features such as reinforcing ribs and integrated insulation channels. These design elements, carefully incorporated into the mold, contribute to enhanced structural stability and improved thermal efficiency. Consider the example of a mold designed with integrated channels for the insertion of high-temperature insulation. This approach streamlines the manufacturing process, ensures uniform insulation coverage, and minimizes heat loss from the flue gas stream, ultimately improving the overall energy efficiency of the ventilation system. Proper draft characteristics are also a product of accurate mold design and its effect on the inner surface, as an irregular surface may disrupt ideal ventilation characteristics.

In summation, meticulous mold design is integral to realizing the full potential of a vertical ventilation structure. Accurate dimensional control, strategic integration of functional features, and careful consideration of material properties all contribute to a final product that is both durable and efficient. The investment in high-quality mold design translates directly into improved system performance, enhanced safety, and extended operational lifespan, underscoring its critical role in the overall manufacturing process.

4. Thermal Resistance

Thermal resistance, a critical property related to heat transfer, significantly influences the performance and safety of vertical ventilation systems. It represents a structure’s ability to impede the flow of heat, directly affecting flue gas temperature, draft efficiency, and the potential for condensation. The effective management of thermal resistance is therefore integral to optimizing the overall performance and longevity of such systems.

- Material Conductivity

The inherent thermal conductivity of the materials used in construction directly impacts overall thermal resistance. Materials with low thermal conductivity, such as ceramic fiber or mineral wool, effectively impede heat transfer, minimizing heat loss from the flue gas. Conversely, materials with high thermal conductivity, like metals, readily transmit heat, potentially leading to reduced draft and increased condensation. The selection of appropriate materials based on their thermal conductivity is crucial for maintaining optimal flue gas temperatures and preventing the formation of corrosive condensates.

- Insulation Thickness

The thickness of the insulation layer directly correlates with the overall thermal resistance. Increasing the insulation thickness reduces heat loss, maintaining higher flue gas temperatures and promoting a stronger draft. However, excessive insulation thickness can also increase the overall size and cost of the system. The optimal insulation thickness must be determined based on a balance between thermal performance, cost, and installation constraints. For example, a thicker insulation layer may be necessary in colder climates to prevent excessive heat loss and maintain adequate draft.

- Surface Emissivity

The emissivity of the external surface affects heat transfer via radiation. A surface with low emissivity reflects more heat, reducing radiative heat loss and contributing to higher overall thermal resistance. Applying specialized coatings with low emissivity characteristics can enhance the thermal performance of ventilation systems, particularly in exposed locations. The choice of surface finish, therefore, represents a strategic consideration in minimizing heat loss and maintaining optimal flue gas temperatures.

- Air Gap Insulation

The inclusion of air gaps within the structure can significantly enhance thermal resistance. Air gaps impede conductive heat transfer by creating a barrier of low-density air. This approach, commonly employed in double-walled designs, can improve thermal performance without substantially increasing material costs. However, the effectiveness of air gap insulation depends on minimizing convective air currents within the gap, which can negate the insulating effect. Proper sealing and ventilation control are therefore essential for maximizing the benefits of air gap insulation.

The facets discussed are directly tied to the secret of chimneys cast, as the selection of materials with appropriate thermal resistance, the application of insulation, the control of surface emissivity, and the utilization of air gaps all contribute to minimizing heat loss, maintaining optimal draft, and preventing condensation, ultimately ensuring the safe and efficient operation of the entire system. By managing thermal properties, it ensures that the flue operates efficiently and without undue hazards.

5. Structural Integrity

Structural integrity, a cardinal attribute of any vertical ventilation system, dictates its capacity to withstand various stresses throughout its operational lifespan. The maintenance of structural integrity is inextricably linked to the methodologies employed in the fabrication process, making it a core component of the information underlying the creation of these structures.

- Material Selection and Load Bearing Capacity

The selection of appropriate construction materials, possessing the necessary load-bearing capacity and resistance to degradation, forms the foundation of structural integrity. For instance, a system fabricated from inferior-grade steel may exhibit premature failure due to corrosion or fatigue, posing significant safety risks. The choice of material must consider factors such as wind loading, seismic activity, and the weight of the system itself, ensuring that the selected material is inherently capable of withstanding these forces. In regions prone to seismic events, reinforced designs and flexible couplings are incorporated to mitigate the risk of collapse. This facet is directly influenced by processes related to the making of ventilation structures, where material choice reflects a deep understanding of stresses, corrosion rates, and thermal effects.

- Joint Design and Welding Techniques

The design and execution of joints, particularly welds, are critical to maintaining structural continuity. Poorly executed welds can introduce stress concentrations and weaken the overall structure, making it susceptible to failure under load. Proper welding techniques, including pre-heating and post-weld heat treatment, are essential for minimizing residual stresses and ensuring adequate weld penetration. Non-destructive testing methods, such as ultrasonic or radiographic inspection, are employed to verify the integrity of welds and detect any hidden flaws. The expertise applied to joint design and welding is fundamental to long-term structural performance, closely linked to fabrication knowledge.

- Corrosion Resistance and Protective Coatings

Corrosion, a ubiquitous threat to metallic structures, can significantly compromise structural integrity over time. Implementing effective corrosion control measures, such as the application of protective coatings or the utilization of corrosion-resistant alloys, is essential for prolonging the lifespan of the system. Coatings, such as epoxy or zinc-based paints, provide a barrier between the metal surface and the corrosive environment, preventing the onset of rust or other forms of degradation. Regularly inspecting and maintaining these protective coatings is crucial for ensuring their continued effectiveness. The secret of ventilation structures contains the understanding that any weakness or lack of protection against corrosion can undermine its function, causing potential failure.

- Design for Thermal Expansion and Contraction

Temperature fluctuations can induce significant thermal stresses within structures. Designs must accommodate these stresses through the incorporation of expansion joints or flexible connectors. Expansion joints allow for controlled movement of structural components, preventing the buildup of compressive or tensile forces that can lead to cracking or buckling. Flexible connectors, such as bellows or flexible hoses, provide a similar function, allowing for relative movement between different sections of the system. Proper design for thermal expansion and contraction is crucial for preventing stress-induced failures and maintaining long-term structural integrity. It underscores the integrated system needed, where casting or forming processes are designed to reduce the stresses induced by thermal changes during operation.

In essence, structural integrity is not merely an inherent property but rather a carefully engineered attribute. The selection of suitable materials, the execution of robust joints, the implementation of effective corrosion control measures, and the accommodation of thermal stresses all contribute to ensuring the long-term stability and safety of vertical ventilation systems. By addressing these factors, engineers can create structures that are not only capable of withstanding the forces imposed upon them but also resistant to the degrading effects of time and environment. Such knowledge encompasses the core understanding involved in creating durable and safe ventilation systems.

6. Curing Process

The curing process, often an overlooked stage in the creation of vertical ventilation structures, constitutes a pivotal element impacting their long-term performance and durability. This process, when meticulously executed, enhances material properties and minimizes inherent weaknesses, contributing significantly to the overall integrity and safety of the finished product.

- Solidification Control

The controlled cooling and solidification rates during curing directly influence the microstructure of the cast material. Rapid cooling can lead to the formation of internal stresses and micro-cracks, compromising structural integrity. Conversely, a slow, controlled cooling process allows for the gradual release of stresses, resulting in a more homogeneous and robust microstructure. For instance, a controlled curing process for a ceramic liner will prevent shrinkage cracking and promote uniform density. The secret here is that a poor choice of curing temperature will result in early failure and compromise structural integrity.

- Stress Relief

The curing process provides an opportunity to relieve residual stresses induced during casting or forming. Elevated temperature curing, often employed for metal components, allows for the relaxation of stressed regions within the material, reducing the likelihood of stress corrosion cracking or premature failure. Examples include annealing processes applied to steel ventilation components to relieve stresses from welding. The precise knowledge of proper stress relief during the process is at the core of a well made and safe product.

- Moisture Removal and Binder Hardening

For structures incorporating cementitious materials or organic binders, the curing process facilitates the removal of excess moisture and the complete hardening of the binder phase. Incomplete curing can lead to reduced strength, increased permeability, and susceptibility to freeze-thaw damage. Proper humidity and temperature controls during curing of these materials are paramount. As is, too rapid of curing will result in cracking and a compromised structural part. An example of this includes refractory linings within chimney flues and their ability to resist chemical attack at elevated temperature.

- Chemical Reaction Completion

The curing process can drive chemical reactions necessary for achieving the desired material properties. For example, in some high-temperature coatings, the curing cycle promotes cross-linking between polymer chains, resulting in a more durable and heat-resistant coating. Incomplete cross-linking can compromise the coating’s ability to protect the underlying metal from corrosion or oxidation. These high temperature surfaces are what makes up part of the secret, and without, premature failure and danger can occur.

The influence of the curing process extends beyond mere material properties. It also impacts the dimensional stability and long-term performance of the vertical ventilation structure. A well-executed curing cycle minimizes the risk of distortion, shrinkage, or cracking, ensuring that the final product meets the required specifications and performs reliably throughout its operational lifespan. Careful adherence to established curing protocols is essential for unlocking the full potential of these systems and avoiding potentially catastrophic failures.

7. Surface Treatment

Surface treatment constitutes a critical, yet often overlooked, aspect directly influencing the durability and long-term performance of vertical ventilation systems. It encompasses a range of processes applied to the exterior and interior surfaces to enhance resistance to corrosion, improve thermal properties, and facilitate airflow. The appropriate selection and application of surface treatments are fundamental for achieving optimal performance and extending the lifespan of these essential components, revealing another element integral to effective design and construction.

- Corrosion Protection

Application of protective coatings forms the primary line of defense against corrosive flue gases and environmental elements. Techniques such as galvanizing, powder coating, and specialized ceramic coatings create a barrier that prevents direct contact between the base metal and corrosive agents. For instance, galvanizing provides sacrificial protection, corroding preferentially to the underlying steel, while ceramic coatings offer exceptional resistance to high-temperature oxidation and chemical attack. The selection of the coating depends on the specific operating conditions and the materials used in the chimney’s construction.

- Thermal Emissivity Control

Surface treatments can modify the thermal emissivity of the material, influencing heat transfer characteristics. Applying a low-emissivity coating to the exterior reduces radiative heat loss, improving energy efficiency. Conversely, a high-emissivity coating on the interior can enhance heat transfer to the flue gases, promoting better draft. For example, blackening the internal surface of a metal flue increases its emissivity, enhancing heat absorption and improving its draft. This is particularly relevant in colder climates where maintaining flue gas temperature is essential for preventing condensation and creosote formation.

- Surface Smoothness Enhancement

Reducing surface roughness minimizes frictional resistance to airflow, improving draft efficiency. Techniques such as polishing, grinding, or applying specialized coatings can smooth the internal surface, reducing turbulence and pressure drop. This is especially important in systems with long or complex flue runs, where even minor reductions in friction can significantly improve overall performance. Examples are found in modern ventilation systems where specialized ceramic liners with smooth internal surfaces reduce flow resistance and enhance draft.

- Chemical Resistance Improvement

Specific surface treatments enhance resistance to chemical attack from acidic condensates or other corrosive agents present in flue gases. These treatments create a chemically inert barrier that protects the base material from degradation. For instance, specialized epoxy coatings or fluoropolymer linings are employed to resist the corrosive effects of sulfuric acid, a common byproduct of combustion. This is particularly crucial in systems burning fuels with high sulfur content, where acidic condensate formation is more prevalent.

In summary, surface treatment is a multifaceted aspect that significantly influences the long-term performance and safety of vertical ventilation systems. Appropriate selection and application of these treatments can enhance corrosion resistance, improve thermal properties, facilitate airflow, and extend the lifespan of these essential components. Understanding and implementing effective surface treatment strategies constitute an integral part of the broader understanding of how to build or maintain safe and efficient ventilation systems. These measures protect against corrosive agents, enhance heat transfer, and maintain structural integrity over the long term.

Frequently Asked Questions Regarding the Construction of Vertical Ventilation Systems

The following section addresses common inquiries and misconceptions pertaining to the manufacturing and design aspects often veiled within the creation of vertical ventilation structures. These questions seek to clarify misunderstandings and provide a deeper understanding of the engineering principles involved.

Question 1: How significantly does the choice of alloy impact a vertical ventilation system’s lifespan?

Alloy selection is a critical determinant of longevity. Inadequate alloy selection will precipitate premature failure due to corrosion, oxidation, or fatigue. High-chromium alloys, for example, exhibit superior resistance to high-temperature corrosion compared to standard carbon steel, leading to a substantially prolonged service life.

Question 2: What role does the internal shape play in the performance of these structures?

Internal geometry significantly impacts airflow dynamics and draft efficiency. A carefully designed tapered internal profile minimizes back pressure and promotes laminar airflow, optimizing the expulsion of combustion byproducts and reducing the risk of backdraft.

Question 3: Why is quality mold design so essential in the construction process?

Mold design dictates the precision and surface finish of the cast component, which in turn affects airflow, thermal resistance, and structural integrity. Imperfections in the mold translate into defects in the final product, compromising its overall performance and durability.

Question 4: In what manner does thermal resistance affect ventilation performance?

Thermal resistance influences flue gas temperature, draft efficiency, and the potential for condensation. Insufficient thermal resistance can lead to reduced draft, increased condensation, and accelerated corrosion. Proper insulation and material selection are crucial for maintaining optimal flue gas temperatures and preventing these issues.

Question 5: What are the principal threats to structural integrity, and how are they mitigated?

Corrosion, thermal stress, and mechanical loading pose the most significant threats to structural integrity. These threats are mitigated through the selection of corrosion-resistant materials, the implementation of robust joint designs, and the incorporation of expansion joints to accommodate thermal expansion and contraction.

Question 6: How important is the curing process in determining the long-term stability of these structures?

The curing process is crucial for relieving residual stresses, removing excess moisture, and completing chemical reactions necessary for achieving the desired material properties. Inadequate curing can lead to reduced strength, increased permeability, and susceptibility to cracking or distortion, compromising long-term stability.

Key takeaways emphasize the interconnected nature of material selection, design considerations, and manufacturing processes in ensuring the safety, efficiency, and longevity of vertical ventilation systems. Attention to these details minimizes the risk of failure and maximizes operational performance.

The subsequent section will present practical considerations for ensuring ongoing maintenance and inspection procedures that uphold the structural integrity and operational effectiveness of these essential building components.

The Secret of Chimneys Cast

The preceding examination has elucidated critical aspects influencing the efficacy and longevity of vertical ventilation structures. From the selection of specialized alloys and the optimization of internal dimensions to the importance of mold design, thermal resistance management, structural integrity assurance, proper curing procedures, and effective surface treatments, a comprehensive understanding of these elements is paramount. Ignoring these considerations compromises the functionality and safety of these vital building components.

Continued research and adherence to rigorous engineering principles are essential for advancing the performance and durability of vertical ventilation systems. The integration of these insights into design and maintenance protocols will mitigate risks, enhance operational efficiency, and ensure the enduring safety and reliability of these indispensable infrastructural elements. The pursuit of further knowledge and the implementation of best practices remain crucial for safeguarding both property and human life.