This structure, typically installed above a cooking range, serves to capture and expel airborne grease, smoke, odors, heat, and steam produced during cooking. An example of its function would be in a commercial kitchen, where this device maintains air quality by removing cooking byproducts.

The advantages of this type of ventilation system are considerable. It improves indoor air quality, reducing the potential for health problems related to accumulated pollutants. Historically, simpler forms were developed to vent smoke from hearths, evolving into more sophisticated models with filtration and powerful extraction capabilities.

This discussion will now proceed to detail the various types available, factors influencing their selection, proper installation techniques, and maintenance procedures to ensure optimal performance and longevity.

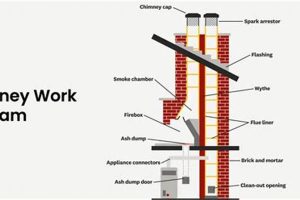

Chimney Hood

Following these guidelines will ensure optimal performance, extend the service life, and maintain the effectiveness of a crucial kitchen ventilation component.

Tip 1: Select the Appropriate Size: The width of the device should equal or exceed the width of the cooking surface below. Undersized units will not effectively capture all cooking byproducts.

Tip 2: Ensure Adequate Airflow (CFM): Calculate the cubic feet per minute (CFM) requirements based on the cooktop’s BTU rating. Insufficient CFM results in poor ventilation.

Tip 3: Regularly Clean Filters: Grease accumulation reduces airflow and poses a fire hazard. Clean filters monthly or as needed based on usage.

Tip 4: Ductwork Design is Critical: Use smooth, rigid ductwork of the correct diameter. Avoid sharp bends which restrict airflow and reduce efficiency.

Tip 5: Consider Make-Up Air: High-CFM units can depressurize a home. Install a make-up air system to balance indoor air pressure and improve ventilation effectiveness.

Tip 6: Check for Proper Sealing: Seal all ductwork connections to prevent air leaks and ensure efficient exhaust. Leaks diminish the overall performance.

Tip 7: Verify Backdraft Damper Function: Ensure the backdraft damper operates correctly to prevent outside air from entering the kitchen when the unit is off.

Adherence to these recommendations will maximize the benefits of this system, including improved air quality, reduced fire risk, and a more comfortable cooking environment.

The subsequent section will address common troubleshooting issues and diagnostic procedures.

1. Material Composition

The material composition of a device significantly impacts its durability, performance, and suitability for various kitchen environments. Selection of appropriate materials is crucial for withstanding heat, grease, and frequent cleaning, directly influencing the appliance’s lifespan and effectiveness.

- Stainless Steel Alloys

Stainless steel alloys are frequently employed due to their resistance to corrosion, high-temperature tolerance, and ease of cleaning. The specific grade of stainless steel affects its resistance to pitting and staining from acidic cooking byproducts. For instance, 304 stainless steel offers a good balance of cost and corrosion resistance, while 316 stainless steel provides enhanced protection in environments with high salt content.

- Powder-Coated Finishes

Powder-coated finishes provide an aesthetic appeal and a protective layer against scratches and minor impacts. This coating is typically applied over a metal substrate, such as steel or aluminum. The durability of the powder coat depends on the quality of the application and the type of powder used. Lower-quality coatings may chip or fade over time, reducing the unit’s visual appeal and potentially exposing the underlying metal to corrosion.

- Tempered Glass

Tempered glass is often used in the construction of canopies or decorative elements, offering a modern aesthetic while providing heat resistance and ease of cleaning. Its strength makes it less susceptible to shattering under normal kitchen conditions. However, impact with hard objects can still cause breakage, necessitating careful handling and maintenance.

- Aluminum Components

Aluminum is used for some components due to its lightweight nature and resistance to corrosion. It is often found in ductwork or internal structural elements. While aluminum is generally durable, it is less resistant to high temperatures and physical impacts than stainless steel. Aluminum is less suitable for surfaces directly exposed to cooking heat or potential impacts.

The selection of materials must align with the intended application of the ventilation system. High-volume commercial kitchens necessitate robust materials like stainless steel, while residential applications may prioritize aesthetic appeal and cost-effectiveness with powder-coated finishes and tempered glass. Careful consideration of material properties ensures the device’s longevity and performance in its intended environment.

2. Extraction Power (CFM)

Extraction power, measured in Cubic Feet per Minute (CFM), represents a critical performance metric for this ventilation system. It quantifies the volume of air that the system can remove from the kitchen environment per minute. Insufficient extraction power results in the inadequate removal of cooking pollutants such as smoke, grease, and odors. For instance, a residential unit with a CFM rating of 300 might be suitable for light cooking on an electric stovetop. However, the same unit would be insufficient for high-heat cooking on a professional-grade gas range. The selection of an appropriate CFM rating necessitates careful consideration of the cooking styles and equipment employed.

In practical applications, the effectiveness of this device is directly correlated with its CFM rating relative to the cooking load. For example, a commercial kitchen preparing large quantities of fried food requires a system with a high CFM rating, potentially exceeding 1200, to maintain acceptable air quality. Conversely, a small apartment kitchen used for occasional cooking might only require a unit with a CFM rating between 150 and 300. Ductwork length and configuration also influence the effective CFM, with longer or more convoluted duct runs reducing the actual airflow at the hood’s intake. Therefore, selecting a unit with a CFM rating that compensates for ductwork losses is essential.

In summary, extraction power (CFM) constitutes a primary determinant of the effectiveness of any ventilation system. Choosing the appropriate CFM rating, accounting for cooking styles, equipment, and ductwork considerations, ensures optimal removal of cooking pollutants. Failure to adequately match the CFM rating to the cooking load can lead to poor air quality, increased grease buildup, and potential fire hazards. Therefore, meticulous evaluation of CFM requirements is paramount when selecting a new system.

3. Ductwork Compatibility

Ductwork compatibility constitutes an essential consideration in the effective implementation of a ventilation system. The diameter, material, and configuration of the ductwork directly influence the system’s airflow, noise levels, and overall performance. Incompatible ductwork can significantly reduce the intended extraction power, leading to poor air quality and potential safety hazards. For example, reducing the duct diameter from the system’s recommended size creates backpressure, diminishing airflow and increasing the risk of motor overheating. Similarly, using flexible ductwork, with its inherent friction losses, can significantly reduce the system’s CFM compared to rigid ductwork.

The material of the ductwork also plays a crucial role. Galvanized steel is a common choice due to its durability and resistance to corrosion. However, PVC piping is inappropriate due to its inability to withstand the high temperatures generated during cooking. Consider a commercial kitchen scenario: A ventilation system is installed with undersized PVC ductwork. The resulting backpressure causes the motor to work harder, leading to premature failure and rendering the system ineffective at removing smoke and grease. This highlights the importance of adhering to the manufacturer’s specifications and local building codes regarding ductwork material and sizing.

In summary, proper ductwork compatibility is not merely an accessory but an integral component of any ventilation system’s performance. Choosing the correct duct diameter, material, and configuration ensures optimal airflow, minimizes noise, and maximizes the system’s effectiveness. Incompatible ductwork can compromise the system’s functionality, leading to diminished air quality, increased energy consumption, and potential safety risks. Therefore, careful attention to ductwork compatibility is paramount for ensuring a safe and efficient kitchen environment.

4. Filter Maintenance

Filter maintenance is intrinsically linked to the operational efficiency and safety of ventilation systems. The primary function of the filters within these systems is to capture airborne grease, particulate matter, and other cooking byproducts. Neglecting filter maintenance results in a progressive accumulation of these substances, which, in turn, reduces airflow. This reduced airflow compromises the system’s capacity to effectively remove smoke, odors, and heat from the cooking environment. A real-world example illustrates this: a restaurant neglecting regular filter cleaning experienced a gradual increase in kitchen temperature and a persistent smoky odor, ultimately leading to a health code violation due to inadequate ventilation.

Regular filter maintenance not only ensures optimal airflow but also mitigates the risk of fire. Accumulated grease within the filters poses a significant fire hazard. If ignited, this grease can rapidly spread through the ductwork, potentially causing extensive damage to the building. Different filter types necessitate varying maintenance schedules. Metal mesh filters, common in residential units, can be cleaned in a dishwasher or by hand. Charcoal filters, used for odor removal in ductless systems, require periodic replacement. Proper filter maintenance schedules are generally specified by the manufacturer and should be strictly adhered to.

In conclusion, the correlation between filter maintenance and the performance of these ventilation devices is undeniable. Consistent and appropriate filter maintenance is essential for maintaining optimal airflow, reducing fire risk, and ensuring a safe and healthy cooking environment. The consequences of neglecting this crucial aspect can range from diminished ventilation effectiveness to potentially catastrophic fire hazards. Therefore, integrating filter maintenance into a routine kitchen maintenance schedule is not merely a recommendation but a necessity.

5. Installation Precision

Installation precision is a non-negotiable factor in the effective operation of ventilation systems. Deviations from specified installation parameters can significantly compromise performance, safety, and longevity. A ventilation system installed without precise attention to duct alignment, securing mechanisms, and electrical connections will invariably exhibit reduced airflow, increased noise levels, and a heightened risk of malfunction. The correlation is direct: inaccurate installation undermines the engineering design intended to optimize extraction and ventilation.

Consider, for instance, a scenario in which a unit is mounted without proper leveling. The resulting imbalance can strain the internal fan motor, leading to premature failure and inconsistent airflow. Similarly, inadequate sealing of ductwork connections permits the leakage of grease and smoke, negating the intended capture efficiency and potentially contaminating the surrounding environment. Another example involves incorrect wiring: a ventilation system wired with insufficient gauge wiring can overheat, posing a fire hazard and reducing the unit’s operational lifespan.

In conclusion, achieving the intended functionality of the device hinges upon meticulous installation. Challenges associated with installation such as restricted access, complex ductwork configurations, and adherence to building codes necessitate qualified installers. The practical significance lies in the reduced risk of fire, improved air quality, and extended operational life of the equipment, ensuring a safe and efficient kitchen environment. Therefore, installation precision is not merely a procedural step but a foundational requirement for realizing the full benefits of this ventilation equipment.

6. Noise Level

Noise level constitutes a significant performance parameter for range hoods, directly impacting user experience and perceived product quality. A high noise level can be disruptive and reduce the enjoyment of the cooking environment. The noise generated by a range hood is primarily attributable to the motor, fan blade design, and ductwork configuration. For instance, a poorly designed fan blade may create excessive turbulence, resulting in increased noise. Similarly, a motor operating at high speed to compensate for restricted airflow will generate more noise than a properly matched system. The sound intensity, typically measured in sones or decibels (dB), varies considerably across different range hood models and operational settings.

Real-world examples illustrate the practical significance of noise level. In open-concept kitchen designs, a noisy range hood can interfere with conversations and entertainment in adjacent living areas. This is particularly relevant in residential settings where the kitchen serves as a central gathering space. Conversely, in commercial kitchens, while background noise levels may be higher, excessive range hood noise can contribute to overall auditory fatigue among kitchen staff. Manufacturers often employ noise reduction technologies such as insulated housings, variable speed motors, and optimized fan blade designs to mitigate noise. The effectiveness of these technologies varies, and consumers should carefully review noise level specifications before making a purchase.

Ultimately, understanding the interplay between design features and noise level is essential for selecting a suitable range hood. Challenges remain in balancing extraction power with noise reduction, as higher CFM ratings often correlate with increased noise. The practical significance lies in selecting a model that provides adequate ventilation without creating an uncomfortably loud cooking environment. Ongoing research and development efforts aim to further refine noise reduction technologies, enhancing the user experience and broadening the appeal of range hoods in diverse kitchen environments.

7. Lighting Integration

Lighting integration within a ventilation system serves as a critical element in enhancing both the functionality and the aesthetic appeal of the cooking environment. The strategic placement and appropriate intensity of integrated lighting fixtures contribute significantly to task illumination and overall kitchen ambiance. The absence of adequate lighting can hinder cooking precision and compromise safety, whereas well-integrated lighting enhances visibility and reduces shadows, improving the culinary experience.

- Task Illumination Enhancement

Integrated lighting systems are specifically designed to provide focused illumination directly onto the cooking surface. This eliminates shadows and ensures that cooks have clear visibility of their work, promoting safety and accuracy during food preparation. For example, halogen or LED lights positioned beneath the ventilation system canopy provide direct task lighting, allowing chefs to monitor cooking progress effectively and preventing accidents related to obscured vision.

- Ambient Lighting Contribution

Beyond task lighting, integrated lighting can also contribute to the ambient lighting scheme of the kitchen. Dimmable LED fixtures allow users to adjust the light intensity, creating a more inviting and comfortable atmosphere. A kitchen with a well-integrated lighting system can transition seamlessly from a bright, functional workspace to a softly lit dining area, enhancing the overall appeal and versatility of the space.

- Energy Efficiency Considerations

Modern systems increasingly employ energy-efficient lighting technologies such as LEDs. LEDs consume significantly less energy than traditional halogen or incandescent bulbs, reducing electricity costs and minimizing environmental impact. The long lifespan of LEDs also reduces maintenance requirements and replacement frequency. For example, replacing a 50-watt halogen bulb with a 10-watt LED equivalent provides comparable light output with a substantial reduction in energy consumption.

- Design Aesthetic Integration

Integrated lighting contributes to the overall aesthetic design of the kitchen. Lighting fixtures can be seamlessly incorporated into the system’s canopy, creating a streamlined and visually appealing look. Options include recessed lighting, strip lighting, and directional spotlights, allowing designers to tailor the lighting to match the kitchen’s style and architectural features. A ventilation system with thoughtfully integrated lighting can serve as a focal point, enhancing the kitchen’s visual appeal and functionality.

In summation, lighting integration within the ventilation apparatus is not merely an accessory but an essential feature that enhances both the practicality and the ambiance of the culinary space. From enhancing task performance to contributing to the overall design aesthetic, integrated lighting plays a pivotal role in creating a functional, safe, and visually appealing kitchen environment. Effective lighting design should be a primary consideration when selecting a new ventilation system.

Frequently Asked Questions

The following section addresses common inquiries regarding the selection, operation, and maintenance of this kitchen ventilation equipment.

Question 1: What factors dictate the appropriate CFM rating for a chimney hood?

The required Cubic Feet per Minute (CFM) is determined by the cooktop’s British Thermal Unit (BTU) rating and the kitchen’s size. Higher BTU outputs and larger kitchens necessitate higher CFM ratings to effectively remove cooking pollutants.

Question 2: How frequently should the filters in a chimney hood be cleaned or replaced?

Metal mesh filters should be cleaned monthly or as needed, depending on cooking frequency. Charcoal filters, used in ductless systems, require replacement every three to six months, or as specified by the manufacturer.

Question 3: What are the primary benefits of selecting a stainless steel chimney hood?

Stainless steel offers corrosion resistance, ease of cleaning, and durability. It is a robust material suitable for withstanding the high temperatures and grease exposure inherent in kitchen environments.

Question 4: What potential issues can arise from incorrect ductwork installation for a chimney hood?

Undersized ductwork, sharp bends, and flexible ducting can restrict airflow, reducing the hood’s effectiveness and potentially causing motor overheating or increased noise.

Question 5: Is professional installation recommended for a chimney hood, or can it be installed by a homeowner?

Professional installation is strongly recommended. It ensures proper electrical connections, secure mounting, and correct ductwork configuration, all crucial for safe and effective operation. Building codes also may mandate professional installation.

Question 6: What is the significance of make-up air when using a high-CFM chimney hood?

High-CFM hoods can depressurize a home, potentially drawing in air from other sources, such as combustion appliances. A make-up air system balances indoor air pressure, preventing backdrafting and ensuring efficient ventilation.

Proper selection, installation, and maintenance are critical for maximizing the performance and longevity of this essential kitchen appliance.

The subsequent section will provide a comparative analysis of different types and brands.

Conclusion

This exploration has detailed the multifaceted aspects of a chimney hood. From its operational principles and material composition to considerations for installation, maintenance, and integration of lighting, each element directly impacts performance and safety. Proper selection and upkeep are essential for maintaining a healthy and efficient kitchen environment.

Given the criticality of kitchen ventilation for indoor air quality and fire safety, further research and adherence to established guidelines remain paramount. Continued advancements in design, materials, and energy efficiency will enhance the effectiveness and sustainability of this vital appliance in the years to come. Investing in a properly specified and maintained chimney hood is a worthwhile measure for any cooking space.