The process of replacing or repairing the metal flashing around a chimney is a critical aspect of building maintenance. This intervention is typically required when the existing material has degraded, become damaged, or was improperly installed initially, leading to potential water intrusion. For instance, a homeowner might observe water stains on the ceiling near a chimney, indicating a likely failure of the protective barrier at the roof-chimney interface, thus necessitating corrective action.

Effective protection against water damage provided by sound flashing is paramount to the longevity and structural integrity of a building. This safeguard prevents costly repairs associated with rot, mold growth, and compromised structural supports. Historically, lead and copper have been utilized for their durability and malleability, but modern materials, such as aluminum and stainless steel, offer viable and often more cost-effective alternatives while maintaining adequate performance. The selection of appropriate materials and installation techniques directly influences the long-term resilience of this building component.

Therefore, the following sections will delve into specific materials used, common causes of failure, detailed installation procedures, and preventative measures to ensure a watertight seal around a chimney structure, thereby mitigating potential risks associated with water infiltration.

Guidance on Chimney Flashing Repair and Replacement

This section provides focused guidance on maintaining a weathertight seal around a chimney, emphasizing critical aspects of flashing repair and replacement to prevent water damage.

Tip 1: Material Selection: Employ materials compatible with both the roofing material and the chimney construction. Dissimilar metals can cause galvanic corrosion, leading to premature failure. Stainless steel or aluminum flashing are generally suitable for a wide range of applications.

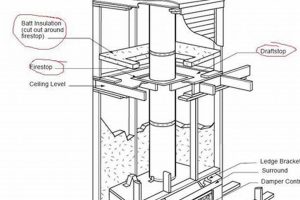

Tip 2: Proper Step Flashing Installation: Each course of roofing material requires individual step flashing pieces that are integrated with the base flashing. Overlapping each piece correctly is vital to channel water away from the chimney.

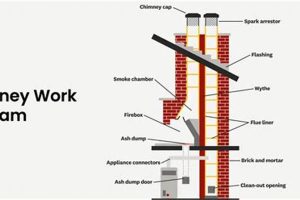

Tip 3: Counter Flashing Integration: The counter flashing must be embedded into the chimney’s masonry joints or properly attached to a pre-existing chase cover. This ensures a secure and watertight seal that prevents water from penetrating behind the step flashing.

Tip 4: Meticulous Sealing: Utilize a high-quality, flexible sealant specifically designed for roofing applications at all critical junctures, such as where the counter flashing meets the chimney masonry and where step flashing integrates with the roofing material. Avoid over-application, which can detract from the aesthetic appeal.

Tip 5: Regular Inspections: Conduct routine inspections of the flashing, especially after severe weather events, to identify any signs of damage, such as corrosion, cracks, or displaced pieces. Addressing minor issues promptly can prevent significant water intrusion.

Tip 6: Professional Consultation: For complex chimney designs or unfamiliar roofing systems, consult with a qualified roofing professional. Improper flashing installation can lead to costly repairs and potential structural damage.

Consistent adherence to these guidelines during flashing repair or replacement ensures long-term protection against water damage, preserving the integrity of the building’s structure and minimizing maintenance costs.

The subsequent sections will address common challenges encountered during flashing projects and offer advanced solutions for ensuring a durable and effective seal.

1. Material Compatibility

The selection of compatible materials is paramount when addressing chimney flashing, as incompatibility can lead to accelerated corrosion and subsequent flashing failure. This has direct implications for the effectiveness and longevity of the repair or replacement. For instance, pairing aluminum flashing with a copper roof can induce galvanic corrosion. The aluminum acts as the anode and corrodes preferentially, compromising the water-tight seal and necessitating premature intervention. Similarly, improper selection can impact the roof itself; runoff from copper flashing onto asphalt shingles will rapidly degrade the shingles.

In the context of a chimney, the objective is to create a barrier that withstands environmental stressors. Stainless steel flashing generally offers broad compatibility with various roofing materials, mitigating the risk of adverse reactions. However, local building codes and manufacturer recommendations should always be consulted to ensure compliance and optimize performance. The choice also extends to sealants; incompatible sealant can cause corrosion or lose elasticity. Therefore, a roofing-specific sealant compatible with both the flashing and roofing materials should be used.

In summary, material compatibility is not a mere suggestion but a fundamental requirement for achieving a durable and effective chimney flashing solution. Failure to consider compatibility can lead to costly repairs and further structural damage. Adherence to established guidelines and professional consultation are recommended to ensure optimal material selection and proper execution. The choice of appropriate materials is an investment in the long-term integrity of the chimney and the building it serves.

2. Precise Installation

Precise installation is not merely an aspect of re-flashing a chimney; it is a prerequisite for its success and longevity. Failure to adhere to exacting standards during installation directly correlates with premature flashing failure, leading to water infiltration and potential structural damage. For example, incorrectly overlapping step flashing can create pathways for water penetration, particularly during wind-driven rain. This seemingly minor oversight can escalate into significant problems, necessitating further repairs and potentially compromising the building’s integrity. The interplay between the flashing, roofing material, and chimney structure demands meticulous attention to detail.

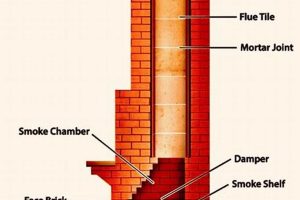

The significance of precise installation extends to the integration of counter flashing. If the counter flashing is not properly embedded into the mortar joints of the chimney or securely attached to a chase cover, it cannot effectively channel water away from the step flashing. This improper execution can result in water seeping behind the flashing, causing deterioration of the chimney masonry and internal framing. A real-world example involves a homeowner who, attempting a DIY re-flashing project, failed to adequately seal the counter flashing. Within a year, water damage was evident, leading to extensive mold growth and costly remediation.

In conclusion, the relationship between precise installation and chimney re-flashing is one of cause and effect. Imprecise installation acts as the direct cause of water infiltration, material degradation, and structural damage. The investment in skilled labor and attention to detail during the installation process represents a preventative measure against these adverse outcomes. Ultimately, understanding the criticality of precise installation is not just about following instructions; it’s about ensuring the long-term performance and protection of the building.

3. Weather Tightness

Achieving and maintaining weather tightness is the fundamental objective when addressing chimney flashing. A compromised seal invites water intrusion, leading to a cascade of potential structural and cosmetic issues. Therefore, any effort to re-flash a chimney must prioritize the establishment of a durable, impermeable barrier against the elements.

- Flashing Material Integrity

The chosen flashing material must possess inherent resistance to environmental degradation. Corrosion, cracking, or distortion of the flashing compromises its ability to prevent water penetration. For example, the use of substandard aluminum in coastal environments with high salt content can lead to rapid corrosion and subsequent leaks. The longevity of the seal is directly proportional to the durability of the chosen material.

- Seam and Joint Sealing

The points where individual pieces of flashing meet, whether through overlapping step flashing or connections with counter flashing, represent critical vulnerabilities. Effective sealing, achieved through appropriate sealant application and proper overlap techniques, is essential. Gaps or insufficient sealant application at these junctures create pathways for water intrusion, particularly during wind-driven rain or snow melt. A common failure point occurs where the step flashing meets the roofing material; if this seam is not properly sealed, water can wick under the flashing and into the underlying structure.

- Chimney-Flashing Interface

The connection between the flashing and the chimney masonry presents a unique challenge. Mortar deterioration, chimney settlement, or improper flashing embedment can disrupt this interface. Water can then penetrate behind the flashing and into the building. Regular inspection and maintenance of this interface are crucial to identify and address potential weaknesses before significant water damage occurs. For example, hairline cracks in the mortar around the counter flashing should be promptly sealed to prevent water infiltration.

- Roofing Material Integration

The flashing system must seamlessly integrate with the surrounding roofing material to ensure continuous water shedding. Incompatible roofing materials or improper flashing installation can disrupt this integration. For instance, if the flashing is not properly interwoven with the roofing shingles, water can be channeled underneath the shingles and behind the flashing. This scenario underscores the importance of adhering to established roofing practices and material compatibility guidelines to achieve a cohesive, weather-resistant system.

The facets discussed above highlight the multifaceted nature of achieving weather tightness in chimney flashing. Proper material selection, meticulous installation techniques, and routine maintenance are all essential components of a robust and reliable system. Failure to address any of these aspects can compromise the integrity of the seal, leading to costly repairs and potential structural damage. Therefore, when addressing chimney flashing, the primary focus should be on creating a barrier that withstands the constant barrage of environmental forces.

4. Joint Integrity

Joint integrity is a critical factor in the effectiveness of chimney flashing, directly influencing its ability to prevent water intrusion. In the context of re-flashing a chimney, ensuring robust and well-sealed joints between flashing components, and between the flashing and the chimney structure, is paramount. Weak or improperly sealed joints provide direct pathways for water to penetrate, negating the purpose of the flashing. For example, if step flashing pieces are not adequately overlapped and sealed, rainwater can wick beneath them, leading to deterioration of the underlying roof sheathing. Similarly, failure to properly seal the joint between the counter flashing and the chimney masonry allows water to seep behind the flashing and damage the chimney itself. Therefore, joint integrity is not merely an incidental consideration but a fundamental component of successful chimney re-flashing.

The materials used to create and maintain joint integrity also play a significant role. High-quality sealants designed for exterior applications, capable of withstanding temperature fluctuations and UV exposure, are essential. The improper choice of sealant, or its inadequate application, can lead to premature failure of the joints. This manifests as cracking, peeling, or loss of adhesion, creating openings for water entry. Furthermore, the preparation of the surfaces prior to sealant application is equally important. Clean surfaces, free of dirt, debris, and old sealant, provide a proper bonding surface for the new sealant, ensuring a durable and watertight seal. A case in point is a building where an attempt was made to re-flash the chimney without first removing old, crumbling sealant. The new sealant failed to adhere properly, resulting in persistent leaks and the eventual need for a complete re-flashing project.

In conclusion, joint integrity represents a crucial aspect of re-flashing a chimney. It directly impacts the system’s capacity to prevent water damage and maintain structural integrity. Careful attention to detail during the installation process, coupled with the use of appropriate materials and techniques, is essential for ensuring long-term performance. Neglecting joint integrity effectively renders the entire flashing system ineffective, resulting in costly repairs and potential safety hazards. Thus, the importance of robust and well-sealed joints cannot be overstated when undertaking a chimney re-flashing project.

5. Regular Inspection

Regular inspection of chimney flashing serves as a critical preventative measure, mitigating the need for extensive re-flashing projects. Proactive assessment allows for the early detection of minor issues, preventing their escalation into significant structural problems. This approach not only preserves the integrity of the chimney and roof but also minimizes long-term costs associated with repairs and water damage.

- Early Detection of Corrosion

Routine examination reveals signs of corrosion on flashing materials before structural integrity is compromised. Identifying rust on steel flashing or white oxidation on aluminum can prompt targeted interventions, such as localized sealant application or component replacement, precluding the need for complete re-flashing. Left unaddressed, corrosion weakens the material, leading to leaks and potential damage to surrounding structures.

- Identification of Sealant Deterioration

Regular inspections expose cracks, peeling, or separation in sealant around flashing joints. Timely re-application of sealant prevents water infiltration that can rot underlying wood and damage interior spaces. Sealant failure often occurs due to UV exposure and temperature fluctuations. Ignoring these signs can lead to significant water damage requiring extensive and costly remediation beyond just re-flashing.

- Detection of Physical Damage

Inspections reveal physical damage to flashing caused by weather events, such as high winds or ice accumulation. Bent, torn, or dislodged flashing components compromise the water-tight seal and necessitate immediate repair or replacement. For example, a tree branch falling on the roof can damage flashing, creating an entry point for water. Early detection allows for prompt action, preventing water damage and the need for a full re-flashing project.

- Assessment of Mortar Joint Integrity

For chimneys with masonry construction, inspections assess the condition of mortar joints surrounding the flashing. Deteriorated mortar can create pathways for water to penetrate behind the flashing. Re-pointing or sealing the mortar joints restores the integrity of the chimney structure and prevents water intrusion. Delaying this maintenance can lead to significant deterioration of the masonry, necessitating extensive repairs in addition to re-flashing.

The multifaceted benefits of regular inspection highlight its importance in maintaining the efficacy of chimney flashing. These inspections serve not only to identify existing problems but also to prevent future issues, minimizing the likelihood of needing extensive re-flashing. Consistent monitoring and prompt action represent a proactive approach to preserving the structural integrity of a building and mitigating the financial impact of water damage.

6. Professional Expertise

The successful execution of a chimney re-flashing project hinges significantly on the application of professional expertise. The inherent complexity of roof-chimney interfaces, variations in roofing materials, and the potential for unforeseen structural issues necessitate a level of skill and knowledge often beyond the scope of a typical homeowner. Attempting this type of project without adequate experience can lead to improper installation, resulting in water leaks, structural damage, and ultimately, increased costs. For instance, incorrect installation of step flashing, a common error made by inexperienced individuals, can create pathways for water intrusion, leading to rot and mold growth within the building’s structure.

Professional expertise ensures correct material selection, adherence to building codes, and the implementation of proper installation techniques. A qualified roofing contractor understands the nuances of different roofing materials and their compatibility with various flashing options. They are also equipped to identify and address underlying structural issues, such as deteriorated mortar joints or damaged roof sheathing, that may compromise the effectiveness of the re-flashing project. Consider a scenario where a homeowner attempts to re-flash a chimney without addressing underlying mortar deterioration. While the new flashing may initially appear to be effective, water can still penetrate through the compromised mortar joints, leading to ongoing damage and the need for further repairs.

In conclusion, engaging a professional for chimney re-flashing is an investment in the long-term integrity of the building. The expertise provided ensures a properly executed project, minimizing the risk of water damage and structural issues. While DIY attempts may seem cost-effective initially, the potential for errors and subsequent repairs often outweigh the perceived savings. Thus, leveraging professional expertise is not merely an option, but a critical component of a successful chimney re-flashing endeavor, safeguarding the building from costly and potentially dangerous water damage.

Frequently Asked Questions About Reflashing Chimneys

The following section addresses common inquiries regarding chimney flashing, offering guidance on maintenance, repair, and replacement.

Question 1: What are the primary indicators that a chimney requires reflashing?

Evidence of water stains on ceilings or walls adjacent to the chimney, visible corrosion or damage to the existing flashing, and leaks during or after rainfall are key indicators that the chimney may require reflashing.

Question 2: Is it possible to reflash a chimney as a do-it-yourself project?

While technically feasible, reflashing a chimney is generally recommended for experienced professionals due to the potential for improper installation, leading to water damage and structural issues. Furthermore, work at heights introduces safety risks.

Question 3: What is the typical lifespan of chimney flashing?

The lifespan of chimney flashing varies depending on the material used, environmental conditions, and installation quality. Generally, properly installed flashing can last from 20 to 30 years, although corrosion or physical damage can shorten this lifespan.

Question 4: What are the common materials used for chimney flashing?

Common materials include aluminum, galvanized steel, stainless steel, and copper. Each material offers different levels of durability, corrosion resistance, and cost. Stainless steel and copper are typically preferred for their longevity.

Question 5: How often should chimney flashing be inspected?

Chimney flashing should be inspected at least once a year, preferably in the spring and fall, to identify any signs of damage or deterioration. Inspections are particularly important after severe weather events.

Question 6: What are the consequences of neglecting damaged chimney flashing?

Neglecting damaged chimney flashing can lead to significant water damage, including rot, mold growth, structural deterioration, and costly repairs. Furthermore, water intrusion can compromise the integrity of the chimney itself.

Properly functioning chimney flashing is crucial to maintaining a watertight seal and preventing structural damage. Routine inspections and prompt repairs are essential.

The subsequent section will delve into the long-term maintenance strategies for chimney flashing and overall chimney health.

Conclusion

This exploration has underscored the critical role of chimney flashing in maintaining a building’s structural integrity and preventing water damage. From material selection and precise installation to consistent inspections and the judicious application of professional expertise, each facet contributes to a robust defense against environmental stressors. Effective flashing creates a lasting barrier against water infiltration, protecting the underlying structure from rot, mold, and costly repairs. Failure to address flashing vulnerabilities can result in significant damage, compromising both the building’s physical health and its financial value.

Therefore, a proactive approach to chimney flashing maintenance is paramount. Building owners and managers should prioritize regular inspections, prompt repairs, and, when necessary, complete replacements to ensure long-term protection. By understanding the importance of each element involved in creating a watertight seal, and by investing in quality materials and skilled labor, individuals can protect their properties and secure the well-being of those within. A well-maintained chimney flashing system is not merely a component of the building; it is a safeguard against the destructive power of water, ensuring structural longevity and peace of mind.