A vertical structure designed to vent combustion byproducts from a heating appliance to the outside atmosphere is a critical component of many heating systems. This element facilitates the safe and efficient removal of exhaust gases, such as carbon monoxide, from fuel-burning appliances. Proper installation ensures the elimination of harmful substances from occupied spaces. An example of its application is evident in homes using wood-burning stoves or gas furnaces, where this structure provides the necessary ventilation for safe operation.

The importance of this venting system lies in its contribution to safety and indoor air quality. A properly functioning system prevents the buildup of dangerous gases, mitigating the risk of carbon monoxide poisoning. Historically, the design and construction of these systems have evolved, reflecting advancements in materials science and an increased understanding of combustion dynamics. The implementation of efficient and effective ventilation practices contributes to energy savings by optimizing combustion and reducing heat loss.

The following discussion will delve into various aspects of these venting structures, including material selection, design considerations, installation best practices, and maintenance procedures, with a focus on ensuring optimal performance and safety.

Important Considerations for Flue Systems

The following recommendations are provided to ensure the safe and efficient operation of combustion venting systems. Adherence to these guidelines is crucial for preventing hazards and maximizing system performance.

Tip 1: Material Selection. Select materials appropriate for the type of fuel being burned and the operating temperatures. Stainless steel liners are frequently recommended for gas and oil appliances, while heavier-gauge steel may be necessary for solid fuel-burning systems. Consult local building codes and manufacturer specifications to guarantee code compliance.

Tip 2: Proper Sizing. Ensure the flue is appropriately sized for the heating appliance. Undersized flues can lead to incomplete combustion and backdrafting, while oversized flues can result in condensation and corrosion. Consult the appliance manufacturer’s instructions or a qualified HVAC professional for sizing calculations.

Tip 3: Regular Inspections. Conduct annual inspections of the venting system for signs of deterioration, blockage, or damage. Look for cracks, rust, creosote buildup, or loose connections. Addressing issues promptly can prevent more serious problems and maintain system safety.

Tip 4: Professional Cleaning. Schedule professional cleaning of solid fuel-burning flues at least once per year, or more frequently if heavy usage occurs. Removing creosote buildup reduces the risk of chimney fires and improves draft. Gas and oil systems may also require periodic cleaning to remove soot and debris.

Tip 5: Maintaining Clearance. Maintain proper clearance to combustible materials. Refer to local building codes and manufacturer’s instructions for specific clearance requirements. Adequate clearance minimizes the risk of fires caused by heat transfer from the chimney to surrounding structures.

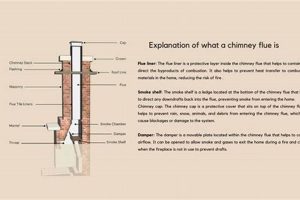

Tip 6: Cap Installation. Install a chimney cap to prevent rain, snow, and debris from entering the flue. Caps also help prevent downdrafts caused by wind and protect against animal entry.

Tip 7: Consider Draft. Proper draft is crucial for the safe and efficient operation of any flue. Evaluate the draft with combustion analysis equipment or conduct a smoke test with a qualified professional. If you have poor draft conditions, make sure the flue is warm to improve the draft.

Adherence to these guidelines will contribute to a safe, efficient, and durable venting system. Regular inspection and maintenance are key to maximizing the lifespan of the system and preventing costly repairs or hazardous conditions.

The following section will further elaborate on best practices for construction, repairs, and potential hazards associated with these systems.

1. Material Integrity

Material integrity is paramount to the safe and efficient operation of any combustion venting system. The components of these systems are subjected to extreme temperatures, corrosive combustion byproducts, and environmental stressors. Therefore, the selection and maintenance of appropriate materials are crucial for ensuring long-term performance and preventing hazardous conditions.

- Corrosion Resistance

Combustion processes generate acidic byproducts that can corrode metallic components. Materials used in these systems, such as stainless steel or specialized alloys, must exhibit high resistance to corrosion to prevent structural weakening and gas leaks. Failure to utilize corrosion-resistant materials can lead to premature system failure and the release of harmful gases into occupied spaces. For example, using standard galvanized steel in a high-efficiency furnace vent system will rapidly corrode, leading to potential carbon monoxide leaks.

- Temperature Tolerance

Venting systems experience a wide range of temperatures, depending on the type of fuel burned and the efficiency of the appliance. Materials must withstand these temperature fluctuations without degradation or deformation. High-temperature alloys and ceramic liners are often employed in systems handling high-temperature exhaust gases to maintain structural stability and prevent thermal stress failures. An example of temperature intolerance can be seen when an improper plastic is used for a high-efficiency venting pipe. The heat can weaken and melt the plastic.

- Structural Stability

The structural integrity of the materials must withstand the mechanical stresses imposed by the weight of the system, wind loads, and seismic activity. Materials with high tensile strength and resistance to cracking are essential for maintaining a safe and reliable system. Cracks or fractures can compromise the system’s ability to contain exhaust gases and can lead to structural collapse. For example, a chimney constructed with poorly mixed mortar can crumble over time, creating significant safety hazards.

- Resistance to Degradation from Combustion Byproducts

Besides acidic corrosion, other byproducts of combustion, such as creosote from wood-burning stoves, can degrade materials over time. Selecting materials that are resistant to the specific byproducts produced by the heating appliance is crucial for longevity and performance. Regular cleaning and maintenance are also essential for removing accumulated deposits and preventing material degradation. An example of degradation is when creosote buildup in a solid fuel chimney flue starts a chimney fire and cracks the flue liner.

The four previous points about material integrity illustrate the critical importance to selecting the right components. Each factor, from corrosion resistance to structural stability, plays a vital role in ensuring the safe and efficient operation of combustion venting systems. Proper material selection, combined with regular inspection and maintenance, minimizes the risk of system failures and protects occupants from potentially hazardous conditions. Neglecting material integrity can result in costly repairs, reduced system efficiency, and, more importantly, increased safety risks associated with carbon monoxide poisoning or structural collapse.

2. Proper Sizing

The dimensional configuration of a heater chimney, specifically its diameter and height, directly impacts the efficiency and safety of the connected heating appliance. Proper sizing ensures the adequate removal of combustion byproducts, mitigating the risk of carbon monoxide accumulation and promoting optimal combustion. An undersized flue restricts airflow, leading to incomplete combustion, backdrafting, and potential carbon monoxide spillage into the living space. Conversely, an oversized flue can cause excessive cooling of the exhaust gases, resulting in condensation of corrosive compounds and reduced draft, which can also lead to backdrafting. For instance, a wood-burning stove connected to a flue that is too small will produce excessive smoke and may fail to draw properly, resulting in smoke entering the room. Sizing discrepancies frequently arise during appliance upgrades when a new, more efficient appliance is connected to an existing venting system designed for a less efficient unit.

The sizing calculation necessitates consideration of several factors, including the appliance’s BTU input rating, the type of fuel used (natural gas, propane, oil, or wood), the height of the flue, and its geographical location (accounting for altitude and climate). Appliance manufacturers typically provide detailed guidelines for flue sizing, often presented in tables or nomographs. The International Fuel Gas Code (IFGC) and other relevant building codes offer standardized methods for calculating appropriate flue dimensions. These methods account for factors such as appliance input rating, flue height, and number of appliances connected to the same flue. Ignoring these guidelines can result in suboptimal performance, increased fuel consumption, and elevated safety risks. A common scenario is a homeowner replacing an old furnace with a high-efficiency model but failing to resize the chimney liner, resulting in condensation problems and potential damage to the chimney structure.

In summary, the correlation between appropriate sizing and heater chimney functionality is critical for both operational efficiency and safety. Adherence to manufacturer specifications and relevant building codes is essential for determining the correct flue dimensions. Neglecting proper sizing can lead to various problems, including carbon monoxide exposure, structural damage to the chimney, and reduced heating appliance performance. Engaging a qualified HVAC professional to assess and correctly size the venting system is advisable, particularly during appliance upgrades or when experiencing issues with draft or combustion. This understanding is the foundation of all chimney practices from a contractor’s point of view.

3. Draft Optimization

Draft optimization is a critical aspect of heater chimney design and performance, directly impacting the safe and efficient removal of combustion byproducts. Proper draft ensures that exhaust gases are effectively expelled from the heating appliance and vented to the exterior atmosphere, preventing backdrafting and potential carbon monoxide exposure.

- Stack Effect and Natural Draft

The stack effect, driven by the temperature differential between the hot exhaust gases and the cooler ambient air outside, creates natural draft. Taller chimneys generally produce a stronger draft due to the increased height of the warm air column. The density difference is what causes air from the combustion process to rise out of the chimney. Inadequate chimney height or obstructions within the flue can impede the stack effect, resulting in weak draft. Older homes with tall, uninsulated chimneys can sometimes experience excessive draft, leading to increased heat loss and fuel consumption. This illustrates the need for balanced draft conditions.

- Mechanical Draft Systems

In situations where natural draft is insufficient, such as in buildings with short chimneys or in installations with complex venting configurations, mechanical draft systems may be necessary. These systems utilize fans or blowers to actively induce draft and ensure proper venting. Induced draft fans are positioned at the appliance outlet to pull exhaust gases through the flue, while forced draft systems push the gases through the chimney. Selection of a mechanical draft system requires careful consideration of the appliance’s exhaust requirements and the specific characteristics of the venting system to avoid over-pressurization or under-pressurization. For example, high-efficiency furnaces often require induced draft fans to overcome the resistance of long or complex venting runs.

- Chimney Liners and Draft Improvement

The internal surface of the chimney significantly influences draft characteristics. Rough or deteriorated chimney liners can impede airflow and reduce draft efficiency. Installing a smooth, appropriately sized chimney liner can improve draft and prevent the leakage of combustion gases through the chimney’s masonry structure. Stainless steel liners are commonly used due to their smooth surface and resistance to corrosion. For instance, relining an old brick chimney with a stainless steel liner can significantly improve the draft for a new high-efficiency furnace or wood-burning stove.

- Barometric Dampers and Draft Regulation

Barometric dampers are used in oil-fired heating systems to regulate draft and prevent excessive negative pressure within the chimney. These devices automatically adjust to maintain a consistent draft level, compensating for variations in atmospheric conditions and appliance operation. By introducing ambient air into the flue, barometric dampers prevent the appliance from drawing excessive air, which can reduce efficiency and increase fuel consumption. An improperly adjusted or malfunctioning barometric damper can lead to unstable combustion and increased emissions.

Effective draft optimization directly correlates with the safe and efficient operation of any heater chimney. Whether achieved through natural means, mechanical assistance, or careful attention to chimney liner and damper design, maintaining proper draft is essential for preventing hazardous conditions and maximizing the performance of the heating appliance. The connection is inextricable, and attention to draft is critical for any chimney system.

4. Code Compliance

Adherence to established building codes is a non-negotiable aspect of heater chimney installation and maintenance. These codes, developed and enforced by local, regional, and national authorities, establish minimum safety standards to protect occupants from potential hazards associated with combustion venting systems. Code compliance directly relates to the safe and efficient operation of the chimney, ensuring that it functions as intended without posing risks to health or property.

- Material Specifications and Standards

Building codes specify the types of materials acceptable for constructing heater chimneys, based on factors such as fuel type, appliance efficiency, and operating temperatures. These standards ensure that materials possess the necessary resistance to corrosion, heat, and structural stress. For instance, codes often mandate the use of stainless steel liners in chimneys venting high-efficiency gas appliances due to their corrosive exhaust. Failure to adhere to these material specifications can result in premature system failure, gas leaks, and fire hazards. For example, installing a single-wall vent pipe in an area requiring double-walled construction will cause a fire.

- Clearance Requirements to Combustible Materials

Building codes establish minimum clearance distances between the heater chimney and adjacent combustible materials, such as wood framing, insulation, and roofing. These requirements mitigate the risk of fires caused by heat transfer from the chimney to surrounding structures. Codes often specify different clearance distances based on chimney type, appliance fuel, and construction methods. Non-compliance with these clearance requirements is a leading cause of residential fires. If the improper clearance is not kept from combustibles, it could cause a structural fire.

- Sizing and Height Regulations

Building codes provide guidelines for determining the appropriate size and height of the heater chimney to ensure adequate draft and proper venting of combustion byproducts. These regulations take into account factors such as appliance BTU input rating, fuel type, and local climatic conditions. Undersized or improperly positioned chimneys can lead to backdrafting, carbon monoxide poisoning, and reduced appliance efficiency. For example, if the chimney does not have the minimum feet from the ridge line, the gas will not escape properly.

- Inspection and Maintenance Protocols

Building codes may outline inspection and maintenance requirements for heater chimneys to ensure ongoing safety and performance. These protocols often specify periodic inspections by qualified professionals to identify and address potential issues such as cracks, blockages, and creosote buildup. Regular maintenance, such as cleaning and repairs, is essential for preventing system failures and maintaining code compliance. The lack of this step is often seen in old homes before they go up for sale.

The connection between code compliance and heater chimney integrity is undeniable. Adhering to the provisions outlined in relevant building codes is paramount for ensuring the safety, efficiency, and longevity of combustion venting systems. Failure to comply with these codes not only exposes occupants to potential hazards but also can result in legal liabilities and insurance complications. Strict adherence to building code provides the best outcome.

5. Regular cleaning

Consistent removal of accumulated deposits from combustion processes within a heater chimney is essential for maintaining both operational efficiency and safety. Inadequate cleaning precipitates a range of detrimental effects, compromising the venting system’s integrity and posing potential hazards.

- Creosote Reduction and Fire Prevention

Creosote, a byproduct of incomplete combustion in wood-burning appliances, accumulates within the chimney flue. This substance is highly flammable, and its buildup significantly increases the risk of chimney fires. Routine cleaning removes creosote deposits, thereby mitigating this risk. Inadequate removal can lead to chimney fires, potentially spreading to the structure of the building itself. For example, homes with wood stoves that are never cleaned can easily catch fire.

- Draft Improvement and Efficient Ventilation

Accumulated soot, ash, and debris within the chimney obstruct airflow, reducing draft efficiency. This restriction impedes the proper venting of combustion gases, potentially leading to backdrafting and the release of harmful substances, such as carbon monoxide, into the living space. Regular cleaning removes these obstructions, optimizing draft and ensuring efficient ventilation. Poorly drafting systems can be lethal to building occupants. The effects of improper draft directly affect people’s lives.

- Corrosion Mitigation and System Longevity

Combustion byproducts, particularly those from fuel oil and gas appliances, can be corrosive. These substances can degrade the chimney liner and other components over time, leading to structural damage and reduced system lifespan. Regular cleaning removes these corrosive deposits, extending the life of the heater chimney. Homes in areas with high humidity are particularly susceptible to corrosive damage.

- Improved Appliance Performance and Fuel Efficiency

A clean heater chimney promotes optimal combustion within the connected appliance. Improved draft and efficient ventilation contribute to more complete combustion, resulting in increased appliance performance and reduced fuel consumption. Neglecting cleaning can lead to inefficient combustion, increased fuel costs, and higher emissions. An example of improved performance includes the time it takes to heat a room. If the system is optimized, the performance improves.

The multifaceted benefits of regular cleaning underscore its importance in maintaining the functionality and safety of a heater chimney. Adhering to a consistent cleaning schedule minimizes the risk of fires, improves draft efficiency, mitigates corrosion, and enhances appliance performance. These factors collectively contribute to a safer and more energy-efficient heating system.

6. Clearance Maintenance

Maintaining adequate clearance around a heater chimney is critical for fire safety and structural integrity. This practice involves ensuring that a specified distance is maintained between the chimney’s exterior surface and any combustible materials within the building. Proper clearance prevents the ignition of nearby materials due to heat transfer from the chimney, thereby reducing the risk of structural fires.

- Reduction of Fire Hazards

Adequate clearance minimizes the risk of heat transfer igniting combustible materials such as wood framing, insulation, or roofing materials. The heat generated by the combustion process can radiate through the chimney walls, potentially reaching temperatures high enough to ignite nearby combustibles if the clearance is insufficient. Maintaining the recommended clearance, as specified by building codes and manufacturer instructions, provides a buffer zone, reducing the likelihood of ignition. For example, loose insulation packed too closely around a chimney can easily ignite, leading to a structural fire. The effect of clearance drastically reduces fire hazard probability.

- Ensuring Proper Air Circulation

Maintaining clearance allows for adequate air circulation around the chimney. This ventilation dissipates heat and prevents the buildup of excessive temperatures in the surrounding materials. Proper airflow helps regulate the temperature of the chimney’s exterior surface, reducing the potential for heat-related damage to nearby structures. Restricted airflow can lead to increased temperatures and accelerate the degradation of combustible materials. An example of this is seen in enclosed chimney chases where inadequate ventilation leads to overheating and potential fire hazards. Proper spacing, according to relevant codes, increases air circulation and prevents overheating.

- Preventing Material Degradation

Sustained exposure to high temperatures can degrade combustible materials over time, reducing their ignition point and increasing their susceptibility to fire. Maintaining clearance minimizes this long-term degradation, preserving the fire-resistant properties of surrounding building components. Over time, the continuous heat transfer can dry out wood framing and insulation, making them more prone to ignition. Proper maintenance involves regular inspection of the clearance zone to ensure that no combustible materials have been placed too close to the chimney. An example is the drying out of wood over time due to close proximity with chimney heat.

- Compliance with Building Codes

Building codes establish minimum clearance requirements for heater chimneys to ensure the safety of building occupants and property. Adherence to these codes is essential for meeting safety standards and avoiding legal liabilities. Code compliance typically involves verifying that the chimney is installed and maintained according to specified clearance distances, as well as conducting regular inspections to identify any potential violations. Failure to comply with clearance requirements can result in fines, insurance complications, and increased risk of fire. The importance of code compliance cannot be understated as it is essential for the health and safety of those in the area.

The relationship between clearance maintenance and heater chimney safety is direct and consequential. By reducing fire hazards, ensuring proper air circulation, preventing material degradation, and complying with building codes, maintaining adequate clearance around a heater chimney contributes significantly to the overall safety and structural integrity of the building. The importance of this practice is such that continuous monitoring is encouraged to ensure compliance and peace of mind.

7. Effective Capping

Proper termination of a heater chimney with a well-designed cap is critical for the system’s overall performance, longevity, and safety. The cap serves as a primary defense against external elements and hazards, directly impacting the chimney’s ability to function as intended.

- Prevention of Precipitation Entry

A properly installed chimney cap effectively prevents rain, snow, and ice from entering the flue. Moisture intrusion can lead to corrosion of the chimney liner, deterioration of masonry, and water damage to the connected appliance. In freezing climates, accumulated water can freeze and expand, causing structural damage to the chimney. A chimney without a cap is particularly vulnerable to water damage, which can accelerate the deterioration process and compromise the chimney’s integrity. The impact of precipitation on an uncapped chimney is a slow but guaranteed failure.

- Exclusion of Debris and Animal Intrusion

A chimney cap acts as a barrier against debris such as leaves, twigs, and nests, which can obstruct the flue and impede proper draft. Additionally, the cap prevents animals, such as birds, squirrels, and raccoons, from entering the chimney and creating nests that can block the venting system. Blockages caused by debris or animals can lead to backdrafting and the accumulation of dangerous gases within the living space. An uncapped chimney is an open invitation to all sorts of unwanted intrusions.

- Spark Arrestance and Fire Safety

For chimneys serving solid fuel-burning appliances, such as wood stoves and fireplaces, a spark arrestor cap is essential for preventing the emission of sparks and embers into the surrounding environment. These caps feature a mesh screen that contains sparks, reducing the risk of starting wildfires or igniting nearby combustible materials. Homes in wooded areas are at increased risk of fire from sparks emitted from uncapped chimneys. The absence of a spark arrestor is a significant fire hazard.

- Draft Stabilization and Downdraft Mitigation

Certain chimney cap designs can help stabilize draft and mitigate downdraft issues caused by wind conditions or nearby obstructions. These caps are designed to deflect wind and create a more consistent airflow through the chimney, reducing the likelihood of backdrafting and ensuring proper venting of combustion gases. Homes located in areas with strong winds or tall buildings may benefit from specialized caps designed to improve draft stability. Stabilization is crucial for consistent and safe flue operation.

The multifaceted benefits of effective chimney capping demonstrate its crucial role in maintaining a safe and efficient heating system. By preventing precipitation entry, excluding debris and animals, arresting sparks, and stabilizing draft, a well-designed cap protects the chimney from external threats and ensures its continued functionality. The investment in a quality chimney cap is a worthwhile measure for preserving the integrity of the chimney and safeguarding the well-being of building occupants. Proper capping increases the life and function of the entire chimney system.

Frequently Asked Questions

The following questions address common inquiries and misconceptions regarding heater chimneys. The information provided aims to offer clarity and guidance on best practices for ensuring safe and efficient operation.

Question 1: What is the expected lifespan of a heater chimney?

The lifespan is contingent upon several factors, including material composition, fuel type, and maintenance practices. Stainless steel liners, when properly maintained and used with compatible fuel, can last upwards of 20 years. Masonry chimneys, however, may require more frequent repairs or relining depending on the severity of environmental exposure and combustion byproducts. Routine inspections are essential for identifying potential issues and extending the chimney’s service life.

Question 2: How frequently should a heater chimney be inspected?

A heater chimney should undergo annual inspection by a qualified professional. Solid fuel-burning systems necessitate more frequent inspections, particularly during periods of heavy use. Inspections should assess the structural integrity of the chimney, identify any blockages or creosote buildup, and evaluate the condition of the chimney liner. Promptly addressing identified issues prevents further deterioration and maintains system safety.

Question 3: What are the signs of a failing heater chimney?

Indications of a failing system include visible cracks in the masonry, spalling bricks, water leaks, excessive creosote buildup (for solid fuel systems), and poor draft. Unusual noises, such as rattling or whistling, may also indicate structural damage or blockage. Carbon monoxide detectors should be installed to alert occupants to the presence of odorless, potentially lethal gas leaks.

Question 4: Can multiple appliances be vented into a single heater chimney?

Multiple appliances can be vented into a single flue under certain conditions, provided that the chimney is appropriately sized to accommodate the combined exhaust volume and that the appliances are compatible. Building codes regulate this configuration, and it is critical to consult with a qualified HVAC professional to ensure code compliance and safe operation. Improperly sized or configured multi-appliance venting systems can lead to backdrafting and carbon monoxide poisoning.

Question 5: What is the significance of a chimney liner?

A chimney liner provides a protective barrier between the corrosive combustion gases and the chimney’s structural components. Liners prevent the deterioration of masonry, improve draft, and enhance safety. Damaged or deteriorated liners should be repaired or replaced promptly. Stainless steel and clay tile liners are commonly used, each with its own advantages and disadvantages depending on the specific application.

Question 6: What role does the chimney cap play in system operation?

The chimney cap protects the flue from precipitation, debris, and animal intrusion. It also can prevent downdrafts and spark emissions from solid fuel appliances. A properly installed and maintained cap extends the lifespan of the chimney and enhances its overall performance.

These FAQs highlight the importance of routine inspection, maintenance, and code compliance in ensuring the safe and efficient operation of heater chimneys. Consulting with qualified professionals and adhering to best practices is essential for mitigating risks and maximizing system longevity.

The following section will delve into the environmental impact of heater chimneys and potential mitigation strategies.

Heater Chimney

The preceding discussion has explored the critical elements of heater chimney systems, emphasizing material integrity, sizing, draft optimization, code compliance, regular cleaning, clearance maintenance, and effective capping. These aspects are not merely theoretical considerations but are essential to the safe and efficient operation of any combustion venting system. A failure to address any of these components compromises the integrity of the overall system, increasing the risk of fire, carbon monoxide exposure, and structural damage.

Given the inherent risks associated with combustion byproducts, diligent adherence to established safety protocols and building codes is paramount. The ongoing maintenance and professional inspection of heater chimney systems are not optional conveniences but critical responsibilities. Prioritizing these preventative measures safeguards property and, more importantly, protects human life. Ignoring these responsibilities will lead to disaster, so it is important to maintain the chimneys.

![Stone Chimneys: Repair, Build & Restore [Expert Tips] Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Stone Chimneys: Repair, Build & Restore [Expert Tips] | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/02/th-530-300x200.jpg)