Structures crafted from stone that serve as vertical conduits for expelling combustion gases from fireplaces, stoves, or furnaces are durable components of buildings. These masonry structures provide a necessary path for smoke and fumes to exit a dwelling, ensuring safe and efficient ventilation of heating appliances. The integration of rock materials into flue construction is a time-honored practice employed across various architectural styles.

The implementation of such designs offers numerous advantages, ranging from increased fire resistance and thermal mass to aesthetic appeal and historical significance. Their robust nature contributes to enhanced building longevity, while their ability to retain and radiate heat promotes energy efficiency. Historically, these constructions were vital features of homes, representing both functional necessity and displays of craftsmanship.

Subsequent sections will delve into the construction methods, maintenance considerations, and stylistic variations associated with these enduring architectural features, along with an overview of their impact on property value and their role in sustainable building practices. Further discussion will encompass modern adaptations and the integration of these features into contemporary home designs.

Stone Chimney Best Practices

Proper construction and maintenance are paramount to ensuring the safety, longevity, and optimal performance of these structures. Adherence to established guidelines minimizes the risk of fire hazards and structural deterioration.

Tip 1: Ensure Proper Flue Sizing. The flue’s dimensions must correspond to the connected appliance’s specifications to prevent backdrafting and ensure efficient exhaust of combustion gases. Consult relevant building codes and manufacturer recommendations.

Tip 2: Utilize Quality Mortar. Employ mortar specifically formulated for chimney construction to withstand high temperatures and resist deterioration from flue gases and moisture. Type N or Type S mortar is generally recommended.

Tip 3: Incorporate a Chimney Cap. A chimney cap prevents rain, snow, and debris from entering the flue, reducing the risk of water damage and blockages. It also helps deter birds and other animals from nesting inside.

Tip 4: Schedule Regular Inspections. Conduct annual inspections by a qualified chimney sweep to identify potential problems such as cracks, spalling, or creosote buildup. Early detection allows for timely repairs and prevents escalation of issues.

Tip 5: Address Water Intrusion Promptly. Water penetration is a major cause of deterioration. Seal cracks and replace damaged flashing to prevent moisture from compromising the chimney’s structural integrity. Waterproofing treatments can offer additional protection.

Tip 6: Remove Creosote Buildup Regularly. Creosote is a flammable byproduct of wood-burning. Regular cleaning by a certified chimney sweep is essential to reduce the risk of chimney fires.

Tip 7: Maintain Proper Clearance to Combustibles. Ensure that the chimney has adequate clearance from combustible materials such as wood framing and roofing. Building codes specify minimum clearance distances to prevent fire hazards.

Effective implementation of these guidelines promotes the safe and efficient operation. Consistent maintenance and adherence to construction best practices will maximize its service life and minimize potential risks.

The subsequent sections will provide a detailed analysis of repair techniques, material selection, and aesthetic considerations pertaining to these architectural components.

1. Structural Integrity of Stone Chimneys

Structural integrity forms the bedrock of a functional and safe chimney. This inherent stability ensures the chimney can withstand environmental stresses, thermal fluctuations, and the constant forces of gravity and wind, all while safely channeling combustion byproducts away from the dwelling. Compromised structural integrity can lead to catastrophic failure, posing significant safety risks and potential property damage.

- Mortar Joint Degradation

The mortar joints connecting individual stones are critical for distributing loads and resisting movement. Over time, exposure to freeze-thaw cycles, acidic flue gases, and water infiltration can degrade mortar, leading to cracking, crumbling, and eventual separation of stones. Failure to address mortar joint degradation compromises the chimney’s ability to resist lateral forces and vertical compression, increasing the risk of collapse. Repointing, the process of replacing deteriorated mortar, is essential for maintaining structural integrity.

- Foundation Settlement and Support

The chimney’s foundation must be stable and adequately sized to support its considerable weight. Differential settlement, where portions of the foundation sink unevenly, can induce stresses within the chimney structure, leading to cracking and instability. Furthermore, proper lateral support, achieved through anchoring to the building’s structure, prevents the chimney from swaying excessively in high winds. Insufficient foundation support or inadequate anchoring are major contributors to structural failure.

- Water Penetration and Freeze-Thaw Damage

Water penetration is a significant threat. When water infiltrates cracks in the stonework or mortar, it expands upon freezing, exerting tremendous pressure that can exacerbate existing cracks and dislodge stones. This freeze-thaw cycle is particularly damaging in colder climates, gradually weakening the chimney’s structure over time. Implementing preventative measures such as chimney caps, waterproofing treatments, and proper flashing is crucial for minimizing water penetration and preventing freeze-thaw damage.

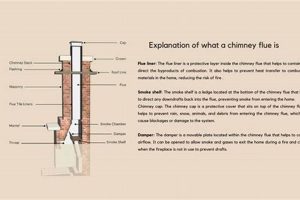

- Flue Liner Integrity

While not a direct component of the external stone structure, the integrity of the flue liner significantly impacts the chimney’s overall structural health. A damaged or deteriorated flue liner allows corrosive flue gases to penetrate the stonework, accelerating the degradation of mortar and potentially weakening the structural stones themselves. Ensuring a properly sized and maintained flue liner provides a protective barrier, safeguarding the chimney’s long-term structural integrity and preventing potentially hazardous gas leaks.

In essence, the structural integrity is a complex interplay of material quality, construction techniques, and ongoing maintenance. Neglecting any of these aspects can compromise the chimney’s stability and safety. Regular inspections and timely repairs are vital to preserving the structural integrity of stone chimneys, ensuring their continued functionality and mitigating potential risks.

2. Draft Efficiency

Draft efficiency, the capacity of a chimney to effectively remove combustion gases from a fireplace or heating appliance, is a critical factor influencing the safe and functional operation of stone chimneys. Its optimization ensures complete combustion, prevents backdrafting, and minimizes the accumulation of hazardous byproducts within the dwelling. Adequate draft is determined by various factors intrinsic to the chimney’s design and environmental conditions.

- Chimney Height and Cross-Sectional Area

Chimney height establishes the pressure differential needed to induce airflow. Greater height generally equates to stronger draft. However, the cross-sectional area of the flue must correspond to the appliance’s specifications. Undersized flues restrict airflow, while oversized flues can lead to cooling of exhaust gases, promoting creosote condensation and reducing draft efficiency. Proper sizing, based on appliance output and fuel type, is paramount.

- Flue Liner Material and Smoothness

The internal surface of the flue liner impacts airflow resistance. Smooth liners, such as those made of clay tile or stainless steel, reduce friction and facilitate efficient gas expulsion. Rough or deteriorated liners increase resistance, impeding draft and promoting creosote buildup. Regular inspection and maintenance of the flue liner are essential for preserving optimal draft performance.

- Chimney Location and Exposure to Wind

The chimney’s location on the roof and its exposure to prevailing winds significantly influence draft. Chimneys positioned on the leeward side of the roof may experience downdrafts, reversing the flow of gases. Tall trees or nearby buildings can also create wind turbulence, negatively impacting draft efficiency. Optimizing chimney placement, considering wind patterns and surrounding obstructions, is crucial for ensuring consistent performance.

- Temperature Differential and Stack Effect

The temperature difference between the hot flue gases and the cooler ambient air drives the stack effect, creating upward airflow within the chimney. A greater temperature differential results in stronger draft. However, excessive cooling of flue gases can reduce draft efficiency and promote creosote condensation. Insulating the chimney and ensuring proper combustion within the appliance help maintain optimal temperature differentials and maximize draft performance.

In summary, draft efficiency is a multifaceted consideration in stone chimney design and maintenance. Optimizing chimney height, flue liner characteristics, location, and temperature differential ensures the safe and effective removal of combustion gases, preventing hazards and maximizing heating appliance performance. Consistent monitoring and adherence to best practices are vital for maintaining optimal draft throughout the chimney’s lifespan.

3. Material Durability

Material durability is a fundamental attribute that directly impacts the longevity, safety, and overall performance of rock-based chimneys. The selection of appropriate materials that withstand exposure to extreme temperatures, corrosive flue gases, and harsh weather conditions is essential for ensuring the structural integrity and continued functionality of these structures. Inadequate material durability results in accelerated deterioration, compromising the chimney’s ability to safely vent combustion byproducts and potentially leading to costly repairs or even structural failure.

The choice of stone type, mortar composition, and flue liner material are all critical determinants of long-term resilience. For example, chimneys constructed using porous or soft stone varieties are particularly susceptible to water absorption and subsequent freeze-thaw damage in colder climates. Similarly, the use of inappropriate mortar, lacking resistance to acidic flue gases, results in rapid degradation of mortar joints and subsequent structural weakening. Flue liners, traditionally made of clay, are increasingly being replaced with stainless steel due to their superior resistance to corrosion and thermal stress. The adoption of durable, high-quality materials translates directly into reduced maintenance requirements and extended service life, providing a significant return on investment over time. Real-world examples of historic chimneys, built with durable materials and proper construction techniques, demonstrate the potential for these structures to endure for centuries, serving as lasting testaments to the importance of material selection.

Ultimately, understanding the principles of material durability is paramount for both the design and maintenance of rock-built chimneys. Proper material selection, combined with sound construction practices and ongoing maintenance, ensures that these vital building components function safely and reliably for their intended lifespan. While initial cost considerations may influence material choices, the long-term benefits of utilizing durable, high-quality materials far outweigh the initial investment, preventing premature failure and safeguarding the structural integrity of the building.

4. Aesthetic Integration

Aesthetic integration, in the context of stone chimneys, refers to the harmonious blending of this functional structure with the overall architectural design of a building. The chimney ceases to be merely a utility; it becomes an integral visual component. The material, form, and detailing of the chimney must complement the style, scale, and texture of the building to achieve a cohesive and pleasing aesthetic result. A poorly integrated chimney can detract significantly from the overall appearance of a structure, regardless of its functional merits. Conversely, a well-designed chimney enhances visual appeal and adds character.

The importance of aesthetic integration is evident in various architectural styles. For example, a rustic stone house might feature a chimney constructed from locally sourced fieldstone, its irregular texture and earthy tones mirroring the natural surroundings. A formal Georgian-style home, on the other hand, might incorporate a chimney built from precisely cut limestone, its clean lines and symmetrical form reflecting the building’s inherent elegance. Failure to consider these stylistic nuances results in visual discord. The choice of stone type, mortar color, cap design, and even the chimney’s location on the roof all contribute to the overall aesthetic impact. Examples such as Frank Lloyd Wright’s designs, where the chimney often served as a central focal point, underscore the potential for chimneys to be architectural statements.

Understanding the practical significance of aesthetic integration in chimney design is critical for architects, builders, and homeowners. Careful consideration of material selection, form, and detailing ensures that the chimney not only functions effectively but also enhances the overall visual appeal of the building. Challenges can arise when attempting to integrate a chimney into an existing structure or when adhering to historical preservation guidelines. Nevertheless, prioritizing aesthetic harmony results in a more visually pleasing and valuable property. This principle is especially relevant in areas with strict architectural review boards or historic districts, where adherence to specific aesthetic standards is mandated. Therefore, aesthetic integration serves as a cornerstone of responsible and thoughtful building design.

5. Fire Resistance

Fire resistance, as a critical performance characteristic, directly relates to the ability of rock-constructed chimneys to withstand exposure to high temperatures and prevent the spread of fire. The inherent non-combustibility of stone materials provides a significant advantage in fire containment, minimizing the risk of structural collapse and limiting fire propagation to adjacent building elements. Effective fire resistance relies on a combination of material selection, construction techniques, and proper maintenance.

- Material Non-Combustibility

The primary contribution to fire resistance stems from the non-combustible nature of stone itself. Unlike wood or other organic materials, stone does not readily ignite or contribute fuel to a fire. This inherent property limits the potential for chimney structures to act as ignition sources or contribute to fire spread. The selection of dense, less porous stone varieties further enhances this property, reducing the potential for heat absorption and subsequent thermal stress. Examples include granite, basalt, and certain types of sandstone known for their high-temperature stability. The implications are clear: selecting appropriate stone varieties significantly mitigates fire hazards associated with chimneys.

- Thermal Mass and Insulation

The thermal mass of stone contributes to fire resistance by absorbing and dissipating heat, slowing the rate at which the chimney’s exterior surfaces reach ignition temperatures. This insulation effect protects surrounding combustible materials from direct heat exposure, reducing the risk of fire spread to walls, roofing, or other structural components. The thickness of the chimney wall and the density of the stone material influence the degree of thermal protection. In practical terms, a thick stone chimney wall can provide a substantial buffer, delaying the onset of ignition in adjacent materials during a fire event.

- Mortar Joint Integrity under Thermal Stress

The integrity of mortar joints plays a crucial role in maintaining fire resistance. Mortar must withstand high temperatures without crumbling or losing adhesion, preventing the penetration of flames and hot gases through the chimney structure. The type of mortar used is critical; lime-based mortars, while historically common, are generally less fire-resistant than modern Portland cement-based mortars. Furthermore, proper joint filling and regular maintenance are essential to prevent cracks or voids that could compromise fire containment. The implications are that mortar joint integrity is as important as the rock itself.

- Flue Liner Protection and Containment

The flue liner, typically made of clay tile or stainless steel, provides an additional layer of fire protection by containing hot gases within the chimney and preventing direct contact with the stone structure. A properly installed and maintained flue liner minimizes the risk of cracks or breaches that could allow flames and hot gases to escape, potentially igniting surrounding combustible materials. Regular inspections and timely repairs of the flue liner are essential to maintaining this crucial fire safety barrier. In many instances, old chimneys which may look very safe may be compromised by a failed liner.

These facets illustrate the multi-faceted role that fire resistance plays in ensuring the safety and functionality of rock-built chimneys. By understanding the interplay of material properties, construction techniques, and maintenance practices, building professionals and homeowners can maximize the fire protection benefits offered by these structures. Implementing best practices related to material selection, mortar joint integrity, and flue liner maintenance is vital for maintaining fire-resistant characteristics throughout the chimney’s service life. Ignoring or delaying appropriate maintenance is very poor practice that can have disastrous consequences.

6. Moisture Protection

The long-term durability and structural integrity of rock chimneys are inextricably linked to effective moisture protection strategies. Water intrusion, in its various forms, constitutes a primary threat to these structures, accelerating deterioration and compromising their capacity to safely vent combustion byproducts. The porous nature of many stone materials, coupled with the presence of mortar joints, creates pathways for moisture penetration. This moisture, once absorbed, initiates a cascade of detrimental effects, ranging from freeze-thaw damage to chemical reactions that weaken the stone and mortar matrix.

The consequences of inadequate moisture protection are evident in numerous real-world examples. Efflorescence, the white powdery deposit on masonry surfaces, signifies the migration of soluble salts carried by water through the stone. These salts crystallize on the surface, causing surface staining and, more importantly, exerting expansive forces that can lead to spalling and surface erosion. In colder climates, the freeze-thaw cycle is particularly destructive. Water absorbed into the stone expands upon freezing, generating internal pressures that can fracture the material. Over time, repeated freeze-thaw cycles weaken the chimney structure, leading to cracks, dislodged stones, and eventual collapse. Furthermore, moisture facilitates the growth of biological organisms, such as mold and algae, which can contribute to surface staining and material degradation. Integrating effective flashing systems at the roof-chimney interface is critical to divert rainwater away from vulnerable areas. Applying breathable water repellents can reduce water absorption without trapping moisture inside the stone.

Proactive moisture protection measures are crucial for preserving rock chimneys. Regular inspections should identify and address potential sources of water intrusion, such as cracked mortar joints, damaged flashing, or deteriorated chimney caps. Repointing deteriorated mortar joints with appropriate materials prevents water penetration and restores structural integrity. Applying breathable water repellents provides a barrier against moisture absorption while allowing water vapor to escape, preventing moisture buildup within the stone. Ensuring proper drainage around the chimney base prevents water from wicking up into the structure. While challenges exist in balancing moisture protection with the need for breathability, the long-term benefits of prioritizing moisture control far outweigh the potential risks. By implementing effective strategies, building professionals and homeowners can safeguard the longevity and structural integrity, minimizing the risk of costly repairs and ensuring continued safe operation for decades to come.

Frequently Asked Questions About Rock-Based Chimneys

This section addresses common inquiries regarding the construction, maintenance, and performance characteristics of structures built with rock materials. The information provided aims to offer clarity on crucial aspects of these systems.

Question 1: What factors influence the cost of constructing one?

The expense is determined by several variables: the type of material employed (e.g., granite, limestone, fieldstone), the complexity of the design, the height of the structure, site accessibility, and labor costs in the specific geographic region. Elaborate designs using premium materials invariably result in higher project expenditures.

Question 2: How often should it be inspected for safety?

Annual inspections by a qualified chimney sweep are recommended. More frequent inspections may be necessary if the heating appliance is used extensively or if there are known issues, such as water leaks or visible damage. Regular inspections facilitate early detection of potential hazards and prevent costly repairs.

Question 3: What are the signs of potential structural problems?

Indicators of structural issues include: visible cracks in the stonework or mortar joints, spalling (flaking or crumbling of the stone), leaning or tilting of the chimney, efflorescence (white powdery deposits) on the surface, and water leaks inside the building near the chimney. Any of these signs warrants immediate evaluation by a qualified professional.

Question 4: Can damaged ones be repaired, or does it need to be replaced?

Repair is often feasible for localized damage, such as deteriorated mortar joints or cracked stones. However, extensive structural damage, such as foundation settlement or widespread spalling, may necessitate replacement. A thorough assessment by a qualified professional determines the most appropriate course of action.

Question 5: What type of mortar is best suited for rock chimney construction and repair?

Type N or Type S mortar is generally recommended. These mortar types offer a balance of compressive strength, flexibility, and water resistance. The specific mortar mix should be compatible with the type of stone being used and should comply with relevant building codes and standards.

Question 6: How can water damage be prevented?

Preventive measures include: installing a chimney cap to prevent rain and snow from entering the flue, ensuring proper flashing at the roof-chimney interface to divert water away from the structure, applying a breathable water repellent to the stonework, and promptly repairing any cracks or deteriorated mortar joints. Regular maintenance is essential for preventing water damage.

The longevity and safe operation hinge on consistent maintenance and timely repairs. Addressing potential issues promptly mitigates risks and prevents extensive structural deterioration.

The following section will provide detailed insights into advanced restoration techniques.

Stone Chimneys

This exploration has underscored the enduring significance of these structures, from their fundamental role in safely venting combustion gases to their aesthetic contributions to architectural design. The examination has illuminated critical aspects, including structural integrity, draft efficiency, material durability, aesthetic integration, fire resistance, and moisture protection, emphasizing the interconnectedness of these factors in ensuring optimal performance and longevity.

The information presented serves as a foundational resource for building professionals and homeowners seeking to understand, maintain, and appreciate the enduring value of these vital architectural components. Continued vigilance in adhering to best practices, coupled with a commitment to regular inspection and timely repair, will safeguard the structural integrity and functionality for generations to come. The preservation of these structures is not merely a matter of historical significance; it is a commitment to safety, efficiency, and architectural heritage.

![Top Premium Chimneys Reviews - [Year]: Quality Chimney Work Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Top Premium Chimneys Reviews - [Year]: Quality Chimney Work | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/02/th-517-300x200.jpg)