Sealing a chimney structure permanently involves methods and materials designed to prevent airflow, moisture ingress, and debris entry for the long term. The objective is to effectively terminate the chimney’s function as a ventilation conduit. For instance, a complete closure might entail installing an impermeable cap at the chimney’s top, filling the flue with insulating material, and sealing the fireplace opening within the building.

Permanent chimney closures can offer several advantages, including reducing heat loss and improving energy efficiency within a building. It also mitigates the risk of water damage caused by rain or snow entering the chimney and potentially affecting the structure’s integrity. Historically, permanently sealing chimneys occurred when heating systems were upgraded, rendering the original chimney obsolete.

This discussion will outline the various techniques, required materials, and critical considerations for achieving a secure and lasting chimney termination. It will explore factors influencing the decision to implement a permanent closure, alongside the methods used to properly prepare for and execute the process.

Tips for Permanent Chimney Closure

Effective permanent chimney closure requires careful planning and execution to ensure a lasting seal and prevent future issues. The following tips provide guidance on key aspects of the process.

Tip 1: Conduct a Thorough Inspection: Prior to commencing any work, a complete inspection of the chimney’s interior and exterior is essential. Identify any structural damage, such as cracks or missing bricks, and address these issues before sealing the chimney. Neglecting existing damage can lead to further deterioration and compromise the closure’s integrity.

Tip 2: Select Appropriate Sealing Materials: Choose materials specifically designed for chimney closure that are durable, weather-resistant, and compatible with the chimney’s construction. Options may include expanding foam, concrete, or specialized chimney caps with sealing features. The choice depends on the chimney’s structure and the desired level of permanence.

Tip 3: Ensure Proper Ventilation (If Necessary): In some cases, complete sealing might not be appropriate due to building codes or ventilation requirements. Consult local regulations to determine if a partial closure with ventilation is required to prevent moisture buildup within the structure. This may involve installing a ventilated chimney cap or leaving a small opening for airflow.

Tip 4: Completely Fill the Flue: For a truly permanent closure, the chimney flue should be completely filled with a non-combustible insulating material, such as vermiculite or perlite. This prevents air movement and reduces the risk of condensation. Ensure the material is packed tightly to avoid settling over time.

Tip 5: Seal the Fireplace Opening: The fireplace opening must be securely sealed to prevent drafts and further enhance energy efficiency. Options include installing a custom-fitted fireplace plug, bricking up the opening, or using a durable, airtight sealant. Consider the aesthetic impact of the chosen method.

Tip 6: Consider Professional Assistance: If unsure about any aspect of the closure process, consult with a qualified chimney professional. They can assess the chimney’s condition, recommend the most appropriate sealing method, and ensure the work is completed safely and effectively.

Tip 7: Document the Closure: Maintain detailed records of the closure process, including photographs and material specifications. This documentation can be valuable for future reference or for potential buyers if the property is sold.

By following these tips, a permanent chimney closure can be achieved effectively, improving energy efficiency, preventing water damage, and ensuring the long-term integrity of the building.

The subsequent sections will explore specific techniques and best practices for implementing these tips, offering a more detailed guide to permanent chimney closure.

1. Assessment

A comprehensive assessment is the foundational step in any endeavor to permanently close a chimney. It determines the chimney’s current condition and informs the subsequent stages of the sealing process. Neglecting a thorough evaluation may lead to unforeseen complications and compromise the effectiveness of the permanent closure.

- Structural Integrity Evaluation

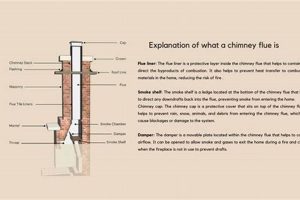

The physical structure of the chimney, both inside and outside, must be meticulously examined. This includes identifying cracks, loose bricks, deteriorated mortar, or any signs of water damage. Existing structural weaknesses need rectification before proceeding with the closure. For example, a severely cracked flue liner renders the chimney unsafe and necessitates repair or replacement. Failure to address such issues will result in the continued deterioration of the chimney even after it’s sealed.

- Flue Obstruction Identification

The chimney flue’s interior should be checked for obstructions like bird nests, debris accumulation, or creosote buildup. These blockages can impede proper sealing and may create fire hazards. An obstructed flue cannot be effectively insulated or sealed, undermining the purpose of permanent closure. Removal of all obstructions is, therefore, critical.

- Moisture Level Measurement

Determining the moisture content within the chimney structure is crucial, especially in regions prone to heavy rainfall or snowfall. High moisture levels can lead to mold growth, wood rot (if the chimney is connected to wooden elements), and deterioration of sealing materials. Addressing moisture issues prior to closure ensures the longevity of the sealed chimney. For instance, applying a waterproofing sealant to the exterior brickwork can mitigate future moisture penetration.

- Ventilation Requirements Verification

An assessment must also ascertain if other appliances, such as water heaters or furnaces, vent through the same chimney. Permanently sealing a chimney without proper assessment can lead to carbon monoxide buildup if other appliances are still using it as a flue. Consultation with a qualified HVAC technician is required to determine alternative venting solutions or to confirm that no other appliances are connected to the chimney being sealed.

The multifaceted assessment, incorporating structural integrity, flue obstruction, moisture levels, and ventilation requirements, forms the bedrock of a successful permanent chimney closure. This foundational understanding allows for informed decisions regarding materials, techniques, and regulatory compliance, ensuring a lasting and safe outcome.

2. Materials

The selection of appropriate materials is inextricably linked to the successful implementation of a permanent chimney closure. The materials employed directly influence the closure’s ability to withstand environmental stressors, prevent moisture intrusion, and provide effective insulation. Inappropriate material selection can lead to premature failure, necessitating costly repairs and potentially compromising the structural integrity of the chimney and adjacent building elements.

For instance, using a non-waterproof sealant on the chimney crown can result in water seepage, which, upon freezing and thawing, expands and cracks the sealant, creating pathways for moisture to enter the chimney. Conversely, employing a high-quality, waterproof sealant specifically designed for masonry ensures a durable barrier against water penetration, extending the lifespan of the closure. Similarly, the insulating material chosen to fill the flue affects the closure’s ability to minimize heat loss. Low-density materials provide less insulation, leading to higher energy bills, whereas dense, non-combustible materials like vermiculite or perlite provide superior insulation, reducing heat transfer and improving energy efficiency.

In conclusion, the choice of materials is not merely a perfunctory aspect but a pivotal determinant of a permanent chimney closure’s efficacy. Careful consideration of material properties, compatibility with existing chimney components, and resistance to environmental factors is paramount. Opting for high-quality, purpose-specific materials contributes significantly to a long-lasting, energy-efficient, and structurally sound chimney closure, mitigating the risks associated with improper material selection.

3. Ventilation

Ventilation plays a crucial role when considering a permanent chimney closure. Completely sealing a chimney without accounting for the potential impact on building ventilation can lead to unforeseen problems, affecting air quality and structural integrity. Assessing ventilation requirements is, therefore, a critical step in the planning process.

- Backdrafting Potential

Completely sealing a chimney can induce backdrafting in other fuel-burning appliances within the building if the chimney was previously part of a shared venting system. Backdrafting occurs when exhaust gases are drawn back into the building instead of being expelled, posing a significant carbon monoxide poisoning risk. A qualified HVAC technician should evaluate the venting system to ensure alternative pathways are available for all appliances before the chimney is sealed.

- Moisture Accumulation

Without adequate ventilation, moisture can accumulate within the sealed chimney structure, leading to mold growth, brick deterioration, and damage to adjacent building materials. This is especially pertinent in climates with high humidity or frequent precipitation. A viable solution involves installing a ventilated chimney cap, which allows for limited airflow while preventing rain and debris from entering. This mitigates moisture buildup while still effectively preventing the chimney from being used as a flue.

- Building Envelope Considerations

Modern, energy-efficient buildings often rely on tightly sealed envelopes to minimize heat loss. However, this can reduce natural ventilation and create negative air pressure within the building. If a chimney is sealed without considering the overall building ventilation strategy, it may exacerbate existing problems or create new ones. A balanced ventilation system, incorporating both intake and exhaust points, is essential to maintain healthy indoor air quality.

- Code Compliance

Local building codes and regulations may dictate specific ventilation requirements for chimney closures. These regulations may stipulate the need for a ventilated cap, the installation of alternative venting systems for existing appliances, or restrictions on the complete sealing of certain chimney types. Adherence to these codes is paramount to ensure the safety and legality of the chimney closure project. Failure to comply can result in fines or the requirement to reverse the work.

In summary, ventilation is not an optional consideration when pursuing a permanent chimney closure; it is an integral aspect that directly impacts the safety, air quality, and structural integrity of the building. Addressing potential ventilation issues proactively, through proper assessment, appropriate materials, and adherence to building codes, ensures a successful and long-lasting chimney closure project.

4. Sealing

The process of sealing constitutes a critical phase in permanently closing a chimney, directly influencing the effectiveness and longevity of the closure. It involves creating an airtight and watertight barrier to prevent airflow, moisture ingress, and debris entry into the chimney structure.

- Flue Closure Techniques

The chimney flue, acting as the primary conduit for airflow, requires a robust sealing method. Options include pouring a concrete plug at the base of the flue, installing an inflatable chimney balloon, or applying multiple layers of expanding foam. The selected technique should ensure a complete and lasting barrier. For instance, a concrete plug provides a rigid, impermeable seal, while expanding foam fills irregular spaces effectively. Improper flue closure can lead to drafts and moisture accumulation within the chimney.

- Crown Sealing Materials

The chimney crown, the top surface of the chimney, is susceptible to water penetration due to weathering and cracking. Applying a high-quality, waterproof crown sealant is essential to prevent water from entering the chimney structure. Materials like elastomeric coatings or specialized chimney crown sealants offer durable protection against the elements. Neglecting the crown sealant can result in freeze-thaw damage and accelerated deterioration of the chimney.

- Fireplace Opening Blockage

The fireplace opening must be effectively blocked to prevent drafts and minimize heat loss from the building. Options include installing a custom-fitted fireplace plug, bricking up the opening, or using a tightly sealed insert. The choice depends on aesthetic preferences and the desired level of permanence. For example, bricking up the opening offers a permanent and visually integrated solution, while a fireplace plug provides a removable option. A poorly sealed fireplace opening can negate the benefits of sealing the flue and crown.

- Material Compatibility Considerations

When selecting sealing materials, ensuring compatibility with the existing chimney structure is crucial. Using incompatible materials can lead to chemical reactions, adhesion failures, and accelerated deterioration. For instance, applying a sealant that is incompatible with the brick or mortar can cause it to peel, crack, or lose its waterproofing properties. Consulting material datasheets and seeking professional advice helps avoid these issues.

In summary, meticulous sealing, encompassing the flue, crown, and fireplace opening, with compatible and durable materials is paramount for achieving a successful and long-lasting permanent chimney closure. Comprehensive sealing efforts directly translate to improved energy efficiency, reduced moisture damage, and enhanced structural integrity. The absence of diligent sealing renders other aspects of the closure process less effective, highlighting its pivotal role in the overall endeavor.

5. Insulation

Insulation plays a crucial role in the effectiveness of permanently closing a chimney, as it directly influences energy efficiency and the prevention of moisture-related issues. Its proper implementation enhances the benefits of chimney closure beyond simply preventing its use as a flue.

- Minimizing Heat Loss

Insulating a permanently closed chimney significantly reduces heat loss through the chimney structure. Chimneys, even when not in use, can act as thermal bridges, allowing heat to escape from the building. Filling the flue with insulating material, such as vermiculite or perlite, minimizes this heat transfer. This reduction in heat loss contributes to lower energy consumption and improved overall energy efficiency within the building. Real-world examples include noticeable decreases in heating bills after insulating a closed chimney, especially in older homes with poorly insulated structures. The implications are clear: effective insulation maximizes the energy-saving benefits of chimney closure.

- Preventing Condensation

Insulation helps to maintain a consistent temperature within the chimney, reducing the likelihood of condensation. Temperature differentials between the inside and outside of the chimney can lead to moisture buildup, which can damage the chimney structure and promote mold growth. Insulating the flue helps to mitigate these temperature differences, reducing the risk of condensation. This is particularly important in climates with high humidity or significant temperature fluctuations. For example, insulating the chimney in a coastal region can prevent the accelerated deterioration of the masonry due to moisture-related issues. The implication is that proper insulation safeguards the chimney structure against moisture damage.

- Material Selection for Insulation

The choice of insulating material is critical for a permanent chimney closure. Materials should be non-combustible, resistant to moisture, and provide effective thermal insulation. Vermiculite, perlite, and mineral wool are commonly used options. Expanding foam can also be used, but it must be fire-rated and installed carefully to prevent expansion-related damage. The wrong choice of material, such as using flammable materials, can create a fire hazard. Real-life examples demonstrate the importance of selecting appropriate materials; improper material selection has led to chimney fires and structural damage. The implication is that the chosen insulation material directly affects the safety and longevity of the chimney closure.

- Complete Flue Fill vs. Partial Fill

For optimal results, the chimney flue should be completely filled with insulating material. Partial filling can create air pockets, which negate some of the insulating benefits and may allow for moisture accumulation. Complete filling ensures a consistent thermal barrier and minimizes the risk of condensation. Examples include situations where partially filled chimneys experienced increased heat loss compared to completely filled chimneys. The implication is that the thoroughness of the insulation directly impacts its effectiveness in minimizing heat loss and preventing moisture problems.

In conclusion, insulation is an indispensable component of “how to close off a chimney permanently.” Its role extends beyond simply blocking the flue; it actively contributes to energy efficiency, moisture control, and structural preservation. By carefully selecting appropriate materials and ensuring complete and thorough insulation, the benefits of chimney closure are maximized, resulting in a more energy-efficient, durable, and safe building.

6. Regulations

Adherence to local building codes and regulations is a non-negotiable aspect of permanently closing a chimney. These stipulations are in place to ensure safety, structural integrity, and compliance with established building standards. Ignoring these regulations can lead to legal repercussions, costly remediation, and potential safety hazards.

- Permitting Requirements

Many jurisdictions require a permit before undertaking any structural alterations to a building, including permanently closing a chimney. The permitting process involves submitting plans and documentation to the local building department for review and approval. This ensures that the proposed work meets all applicable codes and regulations. For instance, failing to obtain a permit can result in fines, stop-work orders, and the requirement to remove the completed work. The implication is that initiating a chimney closure without the necessary permits can lead to significant delays and financial penalties.

- Zoning Ordinances

Zoning ordinances may dictate specific requirements related to chimney modifications, particularly in historic districts or areas with aesthetic guidelines. These ordinances may restrict the type of materials that can be used, the visibility of the closure from public areas, or the preservation of certain architectural features. Violating zoning ordinances can lead to legal action and the requirement to restore the chimney to its original condition. For example, in a historic district, bricking up a chimney opening may be prohibited, requiring alternative closure methods that preserve the chimney’s external appearance. The implication is that understanding and complying with zoning ordinances is crucial for ensuring the legality and aesthetic compatibility of the chimney closure.

- Appliance Venting Regulations

If other appliances, such as water heaters or furnaces, vent through the same chimney, specific regulations govern how these appliances must be re-vented before the chimney can be permanently closed. These regulations are designed to prevent carbon monoxide poisoning and ensure the safe operation of the appliances. In many cases, a qualified HVAC technician must perform the re-venting work and certify its compliance with applicable codes. Ignoring these regulations can create a life-threatening hazard and result in legal liability. For instance, failing to properly re-vent a gas water heater can lead to carbon monoxide accumulating within the building. The implication is that addressing appliance venting regulations is paramount for ensuring the safety of building occupants.

- Fire Safety Codes

Fire safety codes often dictate requirements for chimney closures, particularly regarding the use of non-combustible materials and the prevention of fire hazards. These codes may specify the types of insulation materials that can be used, the methods for sealing the flue, and the requirements for maintaining fire separation between the chimney and adjacent building components. Non-compliance with fire safety codes can increase the risk of fire and compromise the structural integrity of the building. For example, using flammable materials to seal a chimney can create a fire hazard if the chimney is exposed to heat from nearby appliances or external sources. The implication is that adhering to fire safety codes is essential for preventing fire-related risks associated with chimney closures.

In summary, navigating the regulatory landscape is an indispensable part of permanently closing a chimney. From obtaining the necessary permits to complying with zoning ordinances, appliance venting regulations, and fire safety codes, adherence to these requirements is crucial for ensuring the legality, safety, and structural integrity of the project. Neglecting these regulations can lead to significant repercussions, underscoring the importance of thorough research and compliance. The final objective in “how to close off a chimney permanently” is a seal that lasts and complies with all applicable laws and rules.

Frequently Asked Questions About Permanent Chimney Closure

This section addresses common inquiries and misconceptions regarding the process of permanently sealing a chimney, providing clear and concise information to assist in informed decision-making.

Question 1: Is it permissible to completely seal a chimney, or are ventilation provisions always required?

The necessity of ventilation depends on local building codes and the presence of other appliances utilizing the chimney flue. If no other appliances vent through the chimney and local codes permit, a complete seal is possible. However, verification with local authorities is crucial.

Question 2: What materials are deemed suitable for permanently sealing a chimney flue?

Appropriate materials include concrete, vermiculite, perlite, and expanding foam specifically designed for chimney applications. The chosen material should be non-combustible, durable, and resistant to moisture.

Question 3: How can potential moisture accumulation within a sealed chimney be mitigated?

Installing a ventilated chimney cap allows for limited airflow, preventing rain and debris entry while minimizing moisture buildup. Ensuring the chimney crown is properly sealed also helps to prevent water penetration.

Question 4: What steps should be taken if asbestos is suspected within the chimney structure?

If asbestos is suspected, immediate cessation of work and consultation with a certified asbestos abatement professional are mandatory. Asbestos removal requires specialized equipment and procedures to prevent fiber release.

Question 5: What are the potential consequences of failing to obtain necessary permits for a permanent chimney closure?

Failure to obtain required permits can result in fines, stop-work orders, and the potential requirement to remove the completed work. Compliance with local building codes is essential.

Question 6: Is professional assistance recommended for completing a permanent chimney closure?

Consultation with a qualified chimney professional is advisable, particularly if structural damage is present or uncertainties exist regarding the appropriate closure method. Professional expertise ensures safety and effectiveness.

In summary, permanent chimney closure requires meticulous planning, appropriate materials, and strict adherence to local regulations. Prioritizing safety and seeking professional guidance when needed are paramount.

The subsequent section will present a concise checklist for those undertaking this project, serving as a guide to critical considerations.

Permanent Chimney Closure

The preceding discussion has elucidated the critical factors involved in how to close off a chimney permanently. From initial assessment to regulatory compliance, each step necessitates careful consideration to ensure a safe, effective, and lasting result. The emphasis on structural integrity, appropriate materials, ventilation, and meticulous sealing underscores the complexity of the process.

While the prospect of permanently terminating a chimney’s function offers advantages in terms of energy efficiency and structural preservation, a thorough understanding of the associated responsibilities is paramount. Prioritizing safety and seeking professional guidance where uncertainty exists remains the cornerstone of a successful endeavor. The responsible execution of a permanent chimney closure safeguards both the building and its occupants, contributing to a more sustainable and secure environment.

![Top Premium Chimneys Reviews - [Year]: Quality Chimney Work Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Top Premium Chimneys Reviews - [Year]: Quality Chimney Work | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/02/th-517-300x200.jpg)