The restoration of a deteriorated vertical structure that vents combustion gases from a fireplace, furnace, or other heating appliance involves dismantling the existing masonry and reconstructing it with new materials. This process addresses structural instability and compromised functionality, ensuring the safe and efficient expulsion of byproducts.

Such a comprehensive renovation is vital for maintaining property value and preventing potential hazards like carbon monoxide leaks and structural collapse. Historically, these structures were focal points of homes, and their integrity reflected the overall safety and well-being of the inhabitants. Their proper function ensures optimal heating system performance.

The subsequent sections will delve into the assessment of damage, the selection of appropriate materials, and the methodologies employed to execute this important construction undertaking.

Essential Considerations for Chimney Reconstruction

Prior to commencing with the restoration of a flue-venting structure, thorough planning and adherence to established construction practices are paramount for a safe and durable outcome.

Tip 1: Conduct a Comprehensive Inspection: A meticulous assessment of the existing structure is crucial. Identify the extent of the damage, including spalling bricks, cracked mortar joints, and any signs of water penetration. This informs the scope of the renovation and material requirements.

Tip 2: Ensure Proper Flue Sizing: Verify that the flue liner dimensions are appropriate for the connected heating appliance. An incorrectly sized flue can lead to inadequate draft and potentially hazardous combustion byproducts accumulating within the dwelling.

Tip 3: Utilize Compatible Materials: Employ masonry materials that are designed to withstand the high temperatures and corrosive elements associated with flue gas. Refractory mortar and fire-rated bricks are essential for the firebox and flue liner sections.

Tip 4: Employ Correct Mortar Techniques: Apply mortar using proper jointing techniques to ensure a watertight and structurally sound bond between the bricks. Avoid over-wetting the mortar, as this can compromise its strength and durability.

Tip 5: Implement Weatherproofing Measures: Install a chimney cap to prevent rainwater, snow, and debris from entering the flue. Consider applying a water repellent sealant to the exterior masonry to further protect against moisture damage.

Tip 6: Address Foundation Stability: Examine the chimney’s foundation for any signs of settling or cracking. Address any underlying foundation issues before commencing with the upper structure work.

Tip 7: Adhere to Local Building Codes: Ensure that the reconstruction project complies with all applicable local building codes and regulations. This may involve obtaining permits and undergoing inspections.

By meticulously following these guidelines, the restored chimney will provide safe and reliable venting for years to come, safeguarding both the structure and its occupants.

The concluding section will summarize the key aspects of chimney rebuilding and its significance in maintaining building integrity.

1. Structural Assessment

A structural assessment forms the critical foundation for any chimney reconstruction project. Prior to undertaking the dismantling and rebuilding process, a comprehensive evaluation of the existing chimney’s condition is imperative. This assessment serves to identify the precise extent of the damage, pinpoint the underlying causes of deterioration, and determine the necessary scope of work for a successful reconstruction. Without a thorough structural assessment, efforts at rebuilding risk addressing only superficial symptoms while leaving the root causes of failure unaddressed, leading to premature deterioration and potential safety hazards.

The assessment process includes a visual inspection for spalling, cracking, and mortar joint degradation. It also involves evaluating the chimney’s foundation for signs of settling or instability, which can compromise the structural integrity of the entire system. For instance, if water penetration is identified as a major contributor to the chimney’s deterioration, the reconstruction plan must incorporate measures to mitigate water damage, such as installing a chimney cap and applying a water-repellent sealant. Failure to address these issues during reconstruction can lead to a recurrence of the original problems.

In conclusion, a structural assessment is not merely a preliminary step but an integral component of rebuilding a chimney. Its importance lies in providing a clear understanding of the existing structure’s condition, guiding the selection of appropriate materials and techniques, and ensuring that the rebuilt chimney is structurally sound and capable of withstanding environmental stresses. By prioritizing a thorough assessment, homeowners and contractors can minimize risks, optimize resource allocation, and ensure a durable and safe outcome.

2. Material Selection

The selection of appropriate materials is paramount to the success and longevity of any chimney reconstruction project. The harsh conditions to which chimneys are exposed necessitate careful consideration of material properties and their compatibility with the intended application. Selecting substandard or inappropriate materials can lead to premature failure, posing safety risks and necessitating further repairs.

- Mortar Composition and Compatibility

The mortar used in chimney reconstruction must be specifically formulated for high-temperature applications and capable of withstanding the corrosive effects of flue gases. Portland cement-based mortars are generally unsuitable, as they can deteriorate rapidly when exposed to acidic combustion byproducts. Type N or Type S mortar, specifically designed for chimney construction, is recommended. Furthermore, the mortar must be compatible with the existing or replacement brick to ensure proper adhesion and prevent differential expansion issues that can lead to cracking.

- Brick Selection and Thermal Resistance

The brick used in chimney reconstruction must possess adequate thermal resistance to withstand the extreme temperature fluctuations within the flue. Firebrick, a specialized type of brick designed for high-temperature environments, is typically required for the firebox and flue liner sections. Standard clay brick may be suitable for the chimney’s exterior, provided it meets local building code requirements for durability and resistance to weathering. Consideration must also be given to the brick’s porosity and water absorption characteristics to minimize the risk of freeze-thaw damage.

- Flue Liner Materials and Size

The flue liner serves as a critical barrier, containing combustion gases and protecting the chimney structure from heat and corrosion. Common flue liner materials include clay tiles, cast-in-place concrete, and stainless steel. Clay tiles are a traditional option but are susceptible to cracking and spalling. Cast-in-place liners offer a more durable and seamless solution, while stainless steel liners provide excellent corrosion resistance and are suitable for a wide range of fuel types. The appropriate flue liner size must be determined based on the size and type of appliance being vented to ensure proper draft and prevent the buildup of hazardous gases.

- Chimney Cap Materials and Functionality

A chimney cap is essential for preventing rainwater, snow, debris, and animals from entering the flue. Common chimney cap materials include stainless steel, copper, and galvanized steel. Stainless steel caps offer the best combination of durability and corrosion resistance. The design of the chimney cap should also facilitate proper ventilation and prevent downdrafts. A properly installed chimney cap not only protects the chimney structure but also enhances the overall safety and efficiency of the venting system.

In conclusion, the strategic selection of materials is an indispensable facet of reconstructing a chimney. Choosing the right bricks, mortar, flue liner, and cap, based on their thermal properties, chemical resistance, and structural integrity, significantly contributes to the chimney’s performance and extends its service life. Strict adherence to material specifications, coupled with skilled workmanship, ensures a safe, reliable, and enduring chimney system.

3. Code Compliance

Adherence to local and national building codes is a non-negotiable aspect of rebuilding a chimney. These codes are designed to ensure public safety, prevent property damage, and promote energy efficiency. Non-compliance can result in fines, legal liabilities, and, more importantly, compromised structural integrity and increased risk of fire or carbon monoxide poisoning.

- Permitting Requirements

Most jurisdictions require permits for chimney reconstruction projects. Obtaining a permit necessitates submitting detailed plans and specifications to the local building department for review. This process ensures that the proposed work meets the minimum safety standards and complies with all applicable regulations. Failing to obtain the necessary permits can lead to work stoppages, fines, and potential legal action.

- Material Specifications and Standards

Building codes often specify the types of materials that can be used in chimney construction and their minimum performance standards. These specifications may cover brick, mortar, flue liners, and chimney caps. Using materials that do not meet these standards can compromise the chimney’s structural integrity and increase the risk of fire or deterioration. For example, codes may mandate the use of fire-rated bricks and refractory mortar for the firebox and flue liner sections to withstand the extreme temperatures of combustion.

- Construction Techniques and Safety Measures

Building codes also dictate specific construction techniques that must be followed during chimney reconstruction. These techniques may include proper bricklaying methods, mortar jointing requirements, and flue liner installation procedures. Safety measures, such as scaffolding requirements and worker protection protocols, are also typically addressed in building codes to minimize the risk of accidents during construction. Compliance with these techniques and safety measures is essential for ensuring a safe and durable outcome.

- Inspection Requirements

Many jurisdictions require inspections at various stages of chimney reconstruction to ensure compliance with building codes. These inspections may include a pre-construction inspection, a mid-construction inspection, and a final inspection. The purpose of these inspections is to verify that the work is being performed in accordance with the approved plans and specifications and that all applicable codes are being followed. Failure to pass these inspections can result in corrective action orders and delays in project completion.

In summary, strict adherence to building codes is not merely a formality but an essential component of rebuilding a chimney safely and effectively. Obtaining the necessary permits, using code-compliant materials, following prescribed construction techniques, and undergoing required inspections are all critical steps in ensuring that the rebuilt chimney meets the minimum safety standards and protects the building and its occupants from the hazards of fire and carbon monoxide poisoning.

4. Flue Integrity

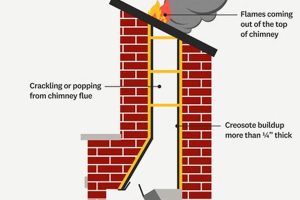

Flue integrity constitutes a cornerstone of any chimney rebuilding endeavor. The flue, serving as the conduit for combustion gases, directly impacts the safety and efficiency of the heating system. A compromised flue liner, characterized by cracks, spalling, or deterioration, presents several hazards, including the leakage of carbon monoxide into the dwelling, reduced draft efficiency, and the potential for chimney fires due to creosote buildup. Therefore, when rebuilding a chimney, the condition of the flue warrants meticulous attention and, in most cases, necessitates repair or replacement.

The connection between flue integrity and chimney rebuilding is one of cause and effect. Damage to the flue liner is often the primary driver for rebuilding the entire structure. Water penetration, freeze-thaw cycles, and the corrosive nature of flue gases progressively degrade the liner, leading to structural instability of the surrounding masonry. Real-world examples include instances where undetected cracks in the flue allowed carbon monoxide to seep into homes, resulting in serious health consequences. Similarly, deteriorated flue liners increase the risk of chimney fires, where hot embers escape through the breaches and ignite combustible materials within the chimney structure or nearby building elements. Neglecting the flue during chimney reconstruction is akin to addressing a symptom without treating the underlying illness; the problem will inevitably resurface.

In conclusion, the maintenance or restoration of flue integrity is inextricably linked to the decision and process of rebuilding a chimney. The practical significance of understanding this relationship lies in prioritizing the flue as a critical component during assessment and reconstruction. By ensuring the flue liner is structurally sound and appropriately sized for the heating appliance, chimney rebuilding achieves its primary goal: providing a safe, efficient, and durable venting system. Challenges in achieving flue integrity during rebuilding often arise from cost considerations or improper installation, underscoring the need for qualified professionals and adherence to established building codes. A focus on flue integrity ultimately reinforces the broader theme of safeguarding property and human life through responsible construction practices.

5. Weatherproofing

Effective weatherproofing is an integral component of chimney rebuilding, designed to mitigate the detrimental effects of environmental exposure and prolong the structure’s lifespan. Properly implemented weatherproofing measures safeguard against water damage, freeze-thaw cycles, and wind-driven debris, all of which can compromise the chimney’s structural integrity and functionality.

- Chimney Cap Installation

The chimney cap serves as the primary defense against precipitation, preventing rainwater and snow from entering the flue. The cap also inhibits the intrusion of birds, animals, and debris, which can obstruct the venting system and create fire hazards. Constructed from durable materials like stainless steel or copper, chimney caps are sized and installed to maximize protection while allowing for adequate draft. Neglecting this element during rebuilding leaves the chimney vulnerable to significant water damage, accelerating deterioration.

- Crown Construction and Sealing

The chimney crown, the concrete or masonry slab at the top of the chimney, is designed to shed water away from the flue and chimney walls. A properly constructed crown features a slight slope and overhang to prevent water from penetrating the masonry. Sealing the crown with a waterproof sealant further enhances its protective capabilities, preventing water absorption and subsequent freeze-thaw damage. Cracks or deterioration in the crown can lead to extensive water damage within the chimney structure, necessitating costly repairs.

- Flashing Installation and Maintenance

Flashing, typically made of metal, creates a watertight seal between the chimney and the roof. Proper flashing installation is crucial to prevent water from seeping into the attic or ceiling. Flashing should be properly integrated with the roofing material and sealed to prevent water intrusion. Regular inspection and maintenance of the flashing are essential to ensure its continued effectiveness. Deteriorated or improperly installed flashing is a common source of water leaks around chimneys.

- Masonry Sealing

Applying a waterproof sealant to the exterior masonry of the chimney helps to prevent water absorption and protect against freeze-thaw damage. The sealant should be specifically designed for masonry applications and applied according to the manufacturer’s instructions. While sealing can be beneficial, it’s essential to use a breathable sealant that allows moisture to escape from within the masonry. Non-breathable sealants can trap moisture, leading to internal damage and accelerated deterioration.

Weatherproofing strategies, when properly executed during chimney rebuilding, provide a robust defense against environmental stressors, extending the structure’s service life and minimizing the need for future repairs. The selection of appropriate materials and meticulous installation techniques are paramount to achieving long-term protection and ensuring the chimney’s continued functionality.

6. Foundation Stability

The stability of a chimney’s foundation is paramount to the overall structural integrity and longevity of the entire venting system. Rebuilding efforts focused solely on the above-ground structure are rendered ineffective, and potentially hazardous, if underlying foundation issues are ignored. A compromised foundation can lead to cracking, tilting, and eventual collapse of the chimney, regardless of the quality of the rebuilding work above.

- Soil Composition and Load-Bearing Capacity

The soil upon which the foundation rests must possess adequate load-bearing capacity to support the weight of the chimney. Unstable soil conditions, such as expansive clay or poorly compacted fill, can cause the foundation to settle unevenly. Soil testing is essential to determine the soil’s composition and load-bearing capacity, informing the design of the foundation and any necessary soil stabilization measures. Failure to account for soil conditions can result in foundation settlement and structural damage to the chimney.

- Frost Line Depth and Foundation Design

In regions subject to freezing temperatures, the foundation must extend below the frost line to prevent heaving and cracking due to freeze-thaw cycles. The frost line depth varies depending on the geographic location and soil type. The foundation design should incorporate appropriate footing dimensions and reinforcement to withstand the stresses imposed by frost heave. Inadequate frost protection can lead to significant foundation damage and structural instability.

- Water Drainage and Erosion Control

Proper water drainage away from the foundation is crucial to prevent erosion and hydrostatic pressure buildup. Poor drainage can saturate the soil, reducing its load-bearing capacity and increasing the risk of settlement. Erosion control measures, such as grading and retaining walls, may be necessary to protect the foundation from erosion. Addressing drainage issues is essential for maintaining long-term foundation stability.

- Existing Foundation Condition and Remediation

A thorough inspection of the existing foundation is necessary to identify any signs of cracking, settlement, or deterioration. Cracks should be assessed for their severity and potential impact on structural integrity. Settlement can be measured to determine the extent of the problem. Remediation measures, such as underpinning or soil stabilization, may be required to address existing foundation issues before rebuilding the chimney. Neglecting pre-existing foundation problems will undermine the success of the rebuilding project.

These facets underscore the direct link between a stable foundation and the success of chimney rebuilding. Ignoring foundation issues guarantees future structural problems and hazards, negating the investment in the above-ground reconstruction. Assessing and rectifying foundation problems is not merely a preliminary step, but an integrated aspect of ensuring the chimney’s long-term safety and stability. Proper foundation construction, incorporating appropriate soil analysis, frost protection, water management, and remediation techniques, provides a reliable base for rebuilding a chimney that can withstand environmental stresses and provide years of safe and efficient venting.

7. Qualified Expertise

The reconstruction of a chimney demands a level of proficiency that transcends basic construction skills. Engaging qualified expertise is not merely a precautionary measure; it is a fundamental requirement for ensuring structural integrity, code compliance, and long-term safety.

- Comprehensive Structural Assessment

Qualified professionals, such as licensed structural engineers or experienced chimney inspectors, possess the knowledge and tools to conduct a thorough assessment of the existing chimney’s condition. This includes identifying hidden damage, evaluating structural stability, and determining the appropriate scope of work. Their expertise minimizes the risk of overlooking critical issues that could compromise the rebuilt chimney’s integrity. For instance, an experienced professional can differentiate between superficial cracking and structural damage requiring immediate attention.

- Adherence to Building Codes and Regulations

Chimney reconstruction projects must comply with local and national building codes, which often specify material requirements, construction techniques, and safety standards. Qualified contractors are well-versed in these regulations and can ensure that the rebuilt chimney meets all applicable requirements. This mitigates the risk of code violations, fines, and potential legal liabilities. Lack of expertise in code compliance can result in hazardous construction practices and non-compliant venting systems.

- Proper Material Selection and Installation

The selection of appropriate materials is crucial for chimney reconstruction. Qualified professionals understand the properties of different masonry materials and can choose the most suitable options for the specific application. They also possess the skills and experience to install these materials correctly, ensuring a durable and weather-resistant structure. For example, using the wrong type of mortar or improperly installing the flue liner can lead to premature deterioration and safety hazards.

- Safe and Efficient Execution

Chimney reconstruction can be a complex and potentially dangerous undertaking, requiring specialized equipment and techniques. Qualified contractors have the necessary training and experience to perform the work safely and efficiently. This minimizes the risk of accidents, property damage, and delays. Their expertise in managing the project ensures that the reconstruction is completed on time and within budget.

In conclusion, employing qualified expertise in chimney reconstruction is an investment in safety, durability, and compliance. The knowledge, skills, and experience of trained professionals are essential for ensuring that the rebuilt chimney meets the highest standards of quality and provides reliable venting for years to come. Engaging less qualified individuals often results in increased risks, compromised structural integrity, and potentially devastating consequences.

Frequently Asked Questions

The following questions address common concerns and misconceptions regarding chimney rebuilding, providing factual and objective information.

Question 1: What are the primary indicators that a chimney requires rebuilding rather than repair?

Extensive structural damage, including widespread spalling, significant cracking affecting multiple courses of brick, and substantial mortar joint deterioration, typically necessitates rebuilding. Furthermore, foundation instability or severe flue liner damage may warrant complete reconstruction.

Question 2: How long does chimney rebuilding typically take?

The duration of a chimney reconstruction project varies depending on the chimney’s size, the complexity of the design, and weather conditions. However, a typical project can range from several days to a few weeks.

Question 3: What is the approximate cost associated with rebuilding a chimney?

Rebuilding expenses depend on the chimney’s dimensions, materials used, and labor rates. A comprehensive estimate requires a professional assessment, but costs can range from several thousand dollars to upwards of ten thousand.

Question 4: Is a permit required for chimney rebuilding?

Most jurisdictions mandate permits for chimney reconstruction to ensure compliance with building codes and safety regulations. Consult local building authorities to ascertain specific permitting requirements.

Question 5: What are the critical considerations when selecting a contractor for chimney rebuilding?

Verify the contractor’s licensing, insurance coverage, and experience in chimney reconstruction. Request references and examine previous work to assess their expertise and quality of workmanship.

Question 6: What preventative maintenance measures can prolong the lifespan of a rebuilt chimney?

Regular inspections, flue cleaning, chimney cap installation, and prompt repair of minor damage can significantly extend the chimney’s service life and prevent costly rebuilding projects.

Chimney rebuilding is a significant investment requiring informed decision-making and adherence to industry best practices. Proper planning and execution are crucial for ensuring a safe and durable outcome.

The subsequent section will summarize the key benefits of properly rebuilding a chimney and emphasize the importance of proactive maintenance.

Conclusion

The preceding discourse has illuminated the multifaceted nature of rebuilding a chimney, emphasizing the critical aspects of structural assessment, material selection, code compliance, flue integrity, weatherproofing, foundation stability, and the necessity of qualified expertise. It has highlighted the interconnectedness of these elements and their combined influence on the safety, efficiency, and longevity of the rebuilt structure.

Ultimately, rebuilding a chimney represents an investment in structural integrity and occupant safety. Proactive maintenance and timely intervention are crucial to prevent deterioration and avoid the extensive measures associated with full reconstruction. The commitment to maintaining a sound venting system safeguards property and protects lives, reinforcing the significance of responsible building practices.