These protective coverings, typically circular in form, are installed atop chimney flues. Their primary function is to prevent precipitation, debris, and animals from entering the chimney. For example, a stainless-steel variant safeguards against corrosion while effectively blocking rainwater ingress.

Their utilization offers multiple advantages. They mitigate water damage within the chimney structure, thereby extending its lifespan and preventing costly repairs. Furthermore, they act as a barrier against nesting birds and other wildlife, precluding potential blockages and associated hazards like carbon monoxide backdraft. Historically, simpler versions served primarily as rain guards, evolving into more sophisticated designs offering comprehensive protection.

The following discussion will delve into the various materials used in construction, installation procedures, maintenance requirements, and selection criteria for these essential chimney components, providing a detailed overview for homeowners and professionals alike.

Essential Considerations for Chimney Termination Protection

Proper selection and maintenance of these components are crucial for optimal chimney performance and longevity. The following tips offer guidance on ensuring adequate protection against the elements and potential hazards.

Tip 1: Material Selection is Paramount. Choose materials resistant to corrosion, such as stainless steel or copper, particularly in coastal environments or regions with frequent acidic rainfall. A lower-grade material may degrade prematurely, requiring replacement.

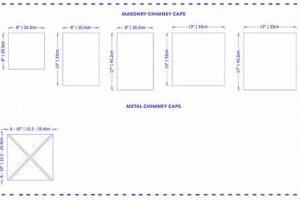

Tip 2: Sizing Must Be Precise. Ensure the selected component matches the flue’s diameter. An improperly sized unit will not provide adequate coverage, allowing moisture and debris to enter the chimney system.

Tip 3: Consider Mesh Size for Pest Control. If pest intrusion is a concern, select a model with a fine mesh screen. This prevents birds, squirrels, and other animals from nesting within the chimney, which can lead to blockages and hazardous conditions.

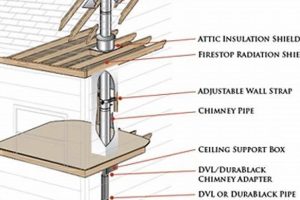

Tip 4: Professional Installation is Recommended. While DIY installation may seem appealing, engaging a qualified chimney sweep or contractor ensures proper attachment and sealing. Incorrect installation can compromise the unit’s effectiveness and structural integrity.

Tip 5: Regular Inspections are Essential. Conduct annual inspections to assess the condition of the covering. Look for signs of damage, corrosion, or debris accumulation. Promptly address any issues to prevent further deterioration.

Tip 6: Prioritize Draft Optimization. Certain designs can impede airflow. Opt for models with sufficient ventilation to maintain proper draft and prevent smoke backdraft into the dwelling.

Tip 7: Account for Aesthetic Considerations. While functionality is paramount, select a style that complements the architectural design of the residence. A visually appealing unit enhances curb appeal without sacrificing performance.

Implementing these measures ensures that the chimney system remains protected from external elements, promoting safety, efficiency, and longevity. Neglecting these aspects can lead to costly repairs and potential safety hazards.

The subsequent sections will provide detailed information on specific product features, regulatory requirements, and best practices for long-term chimney maintenance, complementing the guidance provided herein.

1. Material Durability

Material durability directly dictates the lifespan and protective efficacy of chimney termination components. The environment to which these components are exposedincluding precipitation, temperature fluctuations, and corrosive byproducts of combustiondemands robust materials capable of withstanding degradation over extended periods. For instance, a covering fabricated from low-grade galvanized steel in a coastal region will corrode rapidly due to salt exposure, leading to premature failure and necessitating replacement. This, in turn, exposes the chimney flue to the elements, potentially causing structural damage and compromising heating system efficiency.

Consider, conversely, a stainless-steel model. This alloy exhibits superior resistance to corrosion, maintaining its structural integrity and protective function even under harsh conditions. Its longevity translates to reduced maintenance costs and a sustained barrier against water infiltration, animal intrusion, and debris accumulation. Similarly, copper provides exceptional durability, developing a protective patina over time that further enhances its resistance to weathering. The choice of material, therefore, is not merely an aesthetic consideration but a critical determinant of long-term performance and cost-effectiveness.

In conclusion, the selection of durable materials is paramount in ensuring the prolonged functionality of chimney termination protection. Investing in high-quality materials, such as stainless steel or copper, mitigates the risk of premature failure, minimizes maintenance requirements, and safeguards the chimney system against environmental damage. Understanding this direct correlation between material durability and the component’s efficacy is crucial for homeowners seeking a reliable and long-lasting solution.

2. Proper Sizing

Accurate sizing is a non-negotiable aspect of chimney termination protection, directly impacting its functionality and effectiveness. A mismatched component, whether too small or too large, compromises its ability to safeguard the chimney flue and can lead to a cascade of negative consequences.

- Preventing Rain Ingress

An undersized covering fails to adequately shield the flue opening from precipitation. Rainwater entering the chimney can damage the interior brickwork, leading to spalling and structural weakening. Conversely, an oversized unit may allow wind-driven rain to bypass the protection. Correct sizing ensures complete coverage, channeling water away from the flue.

- Effective Debris Exclusion

Similar to rain protection, the size determines the barrier against debris. A unit that is too small might not fully cover the opening, allowing leaves, twigs, and other materials to enter. Too large and it could create gaps, again allowing debris to get inside. Proper fitting is necessary to create a sealed barrier.

- Ensuring Proper Draft

Sizing affects chimney draft. If a chimney termination is too small, it can restrict airflow and hinder proper combustion. This can lead to smoke backdraft into the dwelling, posing a safety hazard. An oversized unit can disrupt the natural draft pattern, potentially causing inefficient fuel burning. Optimal performance depends on precise dimensions.

- Secure and Stable Installation

A properly sized unit is essential for secure installation. If the unit is too small, it may not attach securely to the flue, increasing the risk of dislodgement during high winds or inclement weather. A model that is too large may require modification, potentially compromising its structural integrity. A correct fit ensures a stable and secure attachment.

In summation, proper sizing is fundamental to ensuring the effective performance. From safeguarding against water damage to maintaining optimal draft and ensuring secure installation, a correctly sized unit is vital for maximizing the benefits and minimizing the risks associated with chimney operation.

3. Pest Prevention

The installation of chimney round caps directly impacts the prevention of pest intrusion into a dwelling via the chimney flue. Chimneys, inherently vertical and often dark, provide an attractive nesting site for various animals, including birds, squirrels, raccoons, and bats. Unprotected flues represent an easily accessible entry point. The presence of nesting animals can lead to significant problems, ranging from noise and unpleasant odors to chimney blockages that can cause dangerous carbon monoxide backdraft. Pest prevention, therefore, becomes an essential consideration in chimney maintenance and safety. The effectiveness of chimney round caps in this context is contingent upon design and installation quality. A cap with a well-secured, appropriately sized mesh prevents access without impeding airflow.

Consider the scenario of a homeowner who neglects to install a suitable covering. Birds may construct nests within the flue, leading to a blockage that restricts ventilation. During the heating season, this restriction increases the risk of carbon monoxide poisoning, a potentially fatal hazard. Furthermore, the accumulation of nesting materials can create a fire hazard within the chimney itself. The financial implications extend beyond potential property damage. Removal of animal nests often necessitates professional services, incurring additional costs. Properly designed and installed covers mitigate these risks by physically barring pests from entering the flue. The mesh size must be small enough to exclude the target pests while allowing adequate draft for proper combustion.

In summary, pest prevention is a critical function of chimney round caps. These components serve as a physical barrier, preventing animals from accessing the chimney flue and creating hazardous conditions. The benefits of pest prevention include reduced risk of carbon monoxide poisoning, fire hazards, property damage, and the associated costs of pest removal. Integrating pest prevention measures into chimney maintenance through the use of appropriate round caps contributes to overall home safety and structural integrity.

4. Draft Optimization

Effective draft within a chimney system is paramount for safe and efficient appliance operation. The design and installation of chimney round caps significantly influence this draft, and therefore require careful consideration to prevent adverse effects on performance.

- Flue Area Obstruction

Improperly designed chimney caps can restrict the flue’s effective area, impeding the natural flow of combustion gases. This restriction may result in incomplete combustion, increased creosote buildup, and potentially hazardous backdrafting of carbon monoxide into the dwelling. An example is a cap with inadequate ventilation openings, which chokes the exhaust flow.

- Wind Effects and Downdraft Mitigation

Certain cap designs are specifically engineered to mitigate downdrafts caused by wind conditions. These designs employ directional vanes or angled surfaces to redirect wind flow, preventing it from entering the flue and disrupting the upward draft. However, poorly designed caps may exacerbate downdraft issues, leading to smoking problems.

- Height and Position Relative to Nearby Obstructions

The height and position of the chimney cap relative to surrounding structures, such as trees or adjacent buildings, can affect draft. A cap positioned too low may be subject to negative pressure zones created by wind flowing around these obstructions, hindering draft. Extending the chimney and cap height can often alleviate this issue.

- Material and Thermal Properties

The material of the chimney cap influences its thermal properties, which in turn affect draft. Metal caps can radiate heat, potentially cooling the flue gases and reducing draft. Insulated caps can help maintain flue gas temperature, promoting a stronger and more consistent draft.

The interplay between these facets highlights the critical role of chimney round caps in optimizing draft. Selecting a cap that balances protection from the elements with minimal airflow restriction is essential for ensuring safe and efficient operation of any fuel-burning appliance. A properly specified and installed cap contributes significantly to a well-functioning chimney system.

5. Weather Resistance

Weather resistance constitutes a fundamental attribute of chimney round caps, directly influencing their efficacy and longevity. These components are perpetually exposed to a spectrum of environmental stressors, including precipitation, temperature variations, ultraviolet radiation, and wind forces. The ability to withstand these elements without degradation is paramount to maintaining chimney system integrity and preventing costly repairs.

- Material Degradation Mitigation

Weather resistance dictates the selection of appropriate construction materials. Exposure to moisture can induce corrosion in ferrous metals, while ultraviolet radiation can degrade certain polymers. Materials such as stainless steel, copper, and specific high-temperature plastics are employed to resist these effects. For example, a stainless-steel cap inherently mitigates corrosion compared to a galvanized steel counterpart, extending its service life in a corrosive environment.

- Water Ingress Prevention

A primary function of chimney caps is to prevent water ingress into the flue. Weather-resistant designs incorporate features that effectively shed water away from the chimney opening, minimizing the potential for moisture-related damage. For instance, an overhanging lip or sloped top surface prevents rainwater from entering the flue, protecting the chimney lining and internal structure.

- Freeze-Thaw Cycle Resilience

In regions subject to freezing temperatures, water that penetrates the chimney structure can undergo freeze-thaw cycles, leading to cracking and spalling of brickwork. Weather-resistant chimney caps minimize water penetration, thereby reducing the risk of freeze-thaw damage. Materials with low water absorption rates are preferred in these climates.

- Wind Load Resistance

Chimney caps must withstand significant wind loads, particularly in areas prone to high winds or storms. Weather-resistant designs incorporate robust attachment mechanisms and aerodynamic profiles to minimize wind-induced stress. Caps constructed from heavier gauge materials and securely anchored to the flue are less susceptible to damage or dislodgement during extreme weather events.

The integration of these weather-resistant features into chimney round cap design ensures sustained protection against environmental elements. By mitigating material degradation, preventing water ingress, resisting freeze-thaw damage, and withstanding wind loads, these components contribute significantly to the longevity and safe operation of chimney systems.

6. Secure Installation

The longevity and effectiveness of chimney round caps are inextricably linked to secure installation practices. A properly installed cap provides reliable protection against weather elements, animal intrusion, and debris accumulation, while a poorly installed one is prone to failure, negating its intended benefits and potentially creating hazards. The consequences of inadequate attachment can range from minor inconveniences to significant structural damage and safety risks. For instance, a cap dislodged by high winds loses its protective function, allowing rainwater to saturate the chimney’s interior, leading to brickwork deterioration and potential water damage within the dwelling. Similarly, an unsecured cap poses a projectile hazard, especially in densely populated areas.

Several factors contribute to secure installation. These include selecting a cap of the appropriate size and design for the specific chimney flue, using durable and compatible fasteners, and ensuring a tight, weather-resistant seal. Furthermore, adherence to manufacturer specifications and local building codes is crucial. Professional installation by a qualified chimney sweep or contractor is often recommended, particularly for complex installations or in regions with stringent regulations. A real-world example highlights the importance of this: a homeowner attempting a DIY installation may inadvertently compromise the cap’s structural integrity or create gaps that allow moisture penetration, ultimately shortening the chimney’s lifespan and increasing the need for repairs.

In summary, secure installation is not merely an ancillary step but an integral component of chimney round cap functionality. It guarantees the cap’s ability to perform its protective role effectively over time. While challenges such as varying flue dimensions and complex roof geometries can arise, prioritizing proper installation practices is essential for realizing the full benefits of these chimney components and safeguarding the structural integrity and safety of the home. The broader theme underscores the significance of informed decision-making and adherence to best practices in all aspects of chimney maintenance.

7. Regular Inspection

Regular inspection forms a critical component of chimney maintenance, directly impacting the longevity and effectiveness of chimney round caps. These inspections serve to identify potential issues before they escalate into costly repairs or safety hazards, ensuring continued protection of the chimney system.

- Early Detection of Damage

Regular inspections facilitate the early detection of damage to chimney round caps, such as corrosion, cracks, or physical impact from debris. Identifying these issues promptly allows for timely repairs or replacements, preventing further deterioration of the chimney structure. For example, a small crack in a cap can allow water to enter the flue, leading to freeze-thaw damage during colder months. Addressing the crack early can prevent significant structural damage.

- Assessment of Secure Attachment

Inspections verify the secure attachment of the cap to the chimney flue. Wind, weather, and thermal expansion/contraction can loosen the cap over time. A loose cap can become dislodged, rendering it ineffective and potentially creating a safety hazard if it falls. A thorough inspection includes checking the integrity of the fasteners and the seal between the cap and the flue.

- Identification of Obstructions and Debris Accumulation

Routine inspections reveal any obstructions or debris accumulation on or around the cap. Leaves, twigs, and animal nests can block the flue opening, impeding draft and potentially leading to carbon monoxide backdraft. Removal of such obstructions ensures proper ventilation and reduces the risk of hazardous conditions. A blocked cap is as ineffective as no cap at all, and potentially more dangerous.

- Evaluation of Material Condition

Regular inspection enables the evaluation of the material condition of the chimney round cap. Materials such as metal can corrode over time, especially in coastal environments or areas with acidic rainfall. Identifying corrosion early allows for protective coatings to be applied or for the cap to be replaced before structural failure occurs. Failure to address corrosion can lead to the cap collapsing into the flue, requiring extensive repairs.

In conclusion, consistent, scheduled inspection provides a proactive approach to chimney maintenance and is an indispensable component of ensuring the continued effectiveness of chimney round caps. These inspections safeguard against structural damage, prevent hazardous conditions, and extend the lifespan of the chimney system, providing peace of mind and minimizing long-term costs. Furthermore, these inspections can provide valuable data on the overall performance of the chimney system allowing for optimization and increased efficiency.

Frequently Asked Questions about Chimney Round Caps

This section addresses common inquiries regarding chimney termination protection, providing clear and concise answers to enhance understanding and inform decision-making.

Question 1: What constitutes the primary function of chimney round caps?

The primary function is to prevent the ingress of precipitation, debris, and animals into the chimney flue, thereby safeguarding the chimney structure and promoting safe and efficient operation.

Question 2: What materials are most suitable for chimney round caps in corrosive environments?

Stainless steel and copper are highly recommended for corrosive environments due to their superior resistance to rust and degradation caused by moisture, salts, and acidic compounds.

Question 3: How does incorrect sizing of a chimney termination component impact chimney performance?

An improperly sized unit can compromise draft, allowing rain and debris entry and potentially leading to unstable installation. Proper sizing is crucial for optimal functionality.

Question 4: What mesh size is recommended for preventing pest intrusion via the chimney flue?

A fine mesh screen with openings no larger than 1/4 inch is generally recommended to effectively deter birds, squirrels, and other small animals from entering the chimney.

Question 5: How often should chimney round caps be inspected for damage or deterioration?

Chimney termination protection should be inspected at least annually, ideally in conjunction with routine chimney cleaning and maintenance, to identify any signs of damage or deterioration.

Question 6: Does the design of chimney round caps influence chimney draft?

Yes, certain designs can impede airflow if not properly engineered. Select a model with sufficient ventilation to maintain proper draft and prevent smoke backdraft into the dwelling.

These questions and answers highlight the importance of proper selection, installation, and maintenance of chimney round caps in ensuring the safety and longevity of the chimney system. Ignoring these facets can potentially lead to significant hazards.

The subsequent section will delve into regulatory requirements and building codes pertaining to chimney termination protection, providing additional context for homeowners and contractors.

Conclusion

The preceding discussion has elucidated the critical role of chimney round caps in safeguarding chimney systems. Key considerations encompass material selection, proper sizing, pest prevention, draft optimization, weather resistance, secure installation, and regular inspection. Each of these elements contributes significantly to the overall performance and longevity of the chimney, preventing costly repairs and mitigating potential safety hazards.

The informed application of these principles is essential for maintaining the integrity and functionality of residential and commercial chimney systems. Diligence in the selection, installation, and maintenance of chimney round caps will ensure continued protection against environmental factors and structural degradation, promoting both safety and efficiency for years to come. Neglecting these vital components poses unnecessary risks and compromises the overall health of the building structure.