This outdoor cooking appliance is characterized by its vertical design, featuring a cylindrical body and a prominent stack. These devices are primarily used for low-and-slow cooking, imparting a distinct smoky flavor to food. An example of its application includes the preparation of barbecue ribs, where the controlled heat and smoke penetrate the meat over an extended period.

The benefits of utilizing this type of cooker are numerous. The upright configuration promotes even heat distribution, leading to consistent cooking results. Furthermore, the design allows for efficient smoke circulation, maximizing flavor infusion. Historically, these appliances represent a modern adaptation of traditional smoking techniques, offering a convenient and controllable method for achieving authentic barbecue flavors. Their use has expanded beyond backyard cooking to include professional catering and competitive barbecue events.

The subsequent sections will delve into the specific types of these vertical smokers, discussing their operational principles, maintenance requirements, and the various accessories that can enhance their performance. Furthermore, guidance will be provided on selecting the appropriate fuel type and mastering techniques for achieving optimal smoking results.

Tips for Optimal Use

Maximizing the performance and longevity of vertical barrel-style cookers requires careful attention to several key aspects. This section outlines crucial tips for achieving consistent results and maintaining the equipment.

Tip 1: Fuel Selection is Paramount: The type of fuel significantly impacts flavor and temperature control. Charcoal briquettes offer consistent, long-lasting heat, while lump charcoal provides a cleaner burn with a more pronounced smoky flavor. Wood chunks, strategically added, further enhance the aromatic profile.

Tip 2: Precise Temperature Management: Achieving and maintaining the desired temperature range is critical for low-and-slow cooking. Employing a reliable thermometer is essential. Adjusting the intake and exhaust vents regulates airflow, directly influencing the internal temperature.

Tip 3: Water Pan Utilization: Incorporating a water pan stabilizes the internal temperature and maintains humidity. This prevents meats from drying out during extended cooking sessions. Regularly monitor and replenish the water level.

Tip 4: Strategic Wood Placement: Position wood chunks directly on the hot coals for optimal smoke generation. Avoid overloading, as excessive smoke can result in a bitter taste. A few well-placed pieces are sufficient to impart a desirable smoky flavor.

Tip 5: Consistent Cleaning Practices: Regular cleaning prevents the accumulation of creosote and grease, which can negatively impact flavor and pose a fire hazard. After each use, remove ash and debris. Periodically clean the grates and internal surfaces.

Tip 6: Proper Ventilation is Key: Ensure adequate ventilation to maintain consistent airflow and prevent flare-ups. Avoid placing the equipment in enclosed spaces. Allow sufficient clearance around the vents.

Tip 7: Monitoring and Adjustments: Low-and-slow cooking requires patience and attention. Regularly monitor the internal temperature of both the cooker and the food. Make incremental adjustments to the vents as needed to maintain the target temperature.

By adhering to these guidelines, users can enhance their cooking experience, achieving consistently flavorful and tender results. Proper fuel selection, temperature management, and maintenance are fundamental to successful operation.

The subsequent section will explore different models and accessories, providing insights into selecting the right equipment for specific needs and preferences.

1. Vertical Airflow Dynamics

Vertical airflow dynamics are fundamental to the functionality of a vertical smoker, influencing temperature distribution, smoke circulation, and overall cooking performance. Efficient airflow is paramount for consistent results and optimal flavor infusion.

- Intake Vent Control

Intake vents, located at the base, regulate the amount of air entering the combustion chamber. Adjusting the intake directly affects the rate of fuel combustion and, consequently, the internal temperature. Insufficient intake restricts airflow, leading to low temperatures and incomplete combustion, while excessive intake results in rapid fuel consumption and potential temperature spikes. Controlling these vents allows for precise temperature management, crucial for low-and-slow cooking.

- Exhaust Vent Management

The exhaust vent, situated at the top of the stack, controls the rate at which smoke and heat exit the cooking chamber. Constricting the exhaust increases smoke concentration and internal temperature but can also lead to stale smoke and off-flavors. Conversely, fully opening the exhaust promotes rapid heat dissipation and reduces smoke intensity. Balancing intake and exhaust is essential for maintaining the desired temperature and smoke profile.

- Natural Convection Effects

The vertical design naturally promotes convection. As hot air rises from the fuel source, it circulates throughout the cooking chamber, distributing heat evenly. This natural convection minimizes hot spots and ensures consistent cooking. The height of the vertical structure enhances this effect, contributing to the cooker’s overall efficiency.

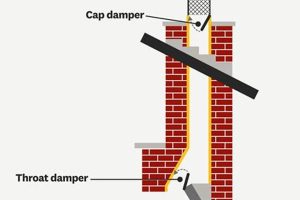

- Smoke Stack Functionality

The stack facilitates the removal of smoke and combustion byproducts, preventing the buildup of stale smoke within the cooking chamber. The height and diameter of the stack influence the draw, affecting the rate at which smoke is exhausted. A properly sized stack promotes efficient smoke removal while maintaining adequate smoke concentration for flavor enhancement.

In essence, understanding and manipulating vertical airflow dynamics is critical for mastering a vertical barrel-style cooker. By carefully managing intake and exhaust vents, leveraging natural convection, and ensuring proper smoke stack functionality, users can achieve consistent temperatures, optimal smoke infusion, and ultimately, superior cooking results. These principles form the foundation for successful low-and-slow barbecue.

2. Temperature Stability

Temperature stability is a critical factor in the effective utilization of vertical barrel-style cookers. Maintaining consistent internal temperature is essential for achieving optimal cooking results, particularly in low-and-slow barbecue techniques. Fluctuations in temperature can lead to uneven cooking, dryness, and compromised flavor profiles. Therefore, understanding the mechanisms that influence temperature stability within these devices is of paramount importance.

- Insulation Properties

The insulation properties of the cooker’s construction materials significantly influence temperature stability. Thicker-walled models, often constructed from heavy-gauge steel or ceramic, exhibit superior heat retention, minimizing temperature fluctuations in response to external environmental conditions. Insulated cookers require less fuel to maintain the desired temperature and are less susceptible to temperature swings caused by wind or ambient temperature changes. The absence of insulation leads to more volatile temperature behavior, demanding more frequent adjustments.

- Airflow Regulation

Precise control of airflow is instrumental in maintaining stable internal temperatures. The intake and exhaust vents govern the rate of combustion and the removal of heat and smoke. A delicate balance is necessary to achieve the desired temperature without excessive fuel consumption or oxygen deprivation. Uncontrolled airflow leads to rapid temperature fluctuations, making it difficult to maintain the low-and-slow cooking environment essential for barbecue. Monitoring and adjusting the vents based on internal temperature readings is crucial for stable operation.

- Water Pan Utilization

The presence of a water pan contributes to temperature stability by moderating temperature spikes and maintaining humidity. Water absorbs heat as it evaporates, preventing rapid temperature increases. The moisture-rich environment also helps to prevent the meat from drying out during extended cooking sessions. Regularly monitoring and replenishing the water level is essential for sustaining the stabilizing effect. The absence of a water pan increases the likelihood of temperature fluctuations and dryness.

- Fuel Source Consistency

The type and quality of fuel impact temperature stability. Charcoal briquettes offer a more consistent burn rate compared to lump charcoal, reducing temperature variations. However, lump charcoal produces a cleaner burn and imparts a more desirable smoky flavor. The choice of fuel depends on the user’s priorities, but consistency within a fuel type is crucial for minimizing temperature swings. Using a blend of fuels can also offer a compromise between burn rate and flavor profile. Utilizing consistently sized fuel pieces aids in predictable burn characteristics.

These interconnected elements collectively determine the temperature stability characteristics of vertical barrel-style cookers. By carefully considering these factors and implementing appropriate techniques, users can optimize their cooking processes, achieving consistent and high-quality results. Attention to insulation, airflow regulation, water pan utilization, and fuel source consistency are fundamental to mastering the art of low-and-slow barbecue using these devices.

3. Smoke Infusion Control

Smoke infusion control, as it pertains to vertical barrel-style cookers, is the ability to precisely regulate the quantity, quality, and duration of smoke exposure during the cooking process. This aspect is central to achieving desired flavor profiles in smoked foods. The design of these cookers, characterized by a vertical chamber and adjustable vents, directly influences the degree of control attainable over smoke infusion. Effective management of the airflow, fuel type, and wood selection allows the user to manipulate the smoke’s density and composition, thus influencing the final taste of the product. For example, using a mild wood like applewood with restricted airflow results in a light, sweet smoky flavor, suitable for poultry, while using hickory with open vents yields a stronger, more assertive smoke ideal for beef brisket.

Furthermore, smoke infusion control is intricately linked to the cooker’s temperature management. The temperature dictates the rate at which the wood smolders and releases its aromatic compounds. Low and consistent temperatures are crucial for generating a thin, blue smoke, which is indicative of efficient combustion and desirable flavor development. Overheating, on the other hand, produces thick, white smoke containing creosote and other undesirable compounds that can impart a bitter or acrid taste. Proper water pan utilization and precise vent adjustments contribute to maintaining the stable temperature environment necessary for optimized smoke infusion. The placement of wood chunks relative to the heat source and the timing of their introduction during the cooking process are additional factors that significantly influence the resulting smoke flavor. An uneven placement or late addition of wood can result in inconsistent smoke distribution, leading to localized areas of intense smoke flavor and others that are noticeably lacking.

In conclusion, mastery of smoke infusion control is essential for realizing the full potential of vertical barrel-style cookers. This control is not merely a matter of adding wood; it involves a holistic understanding of airflow dynamics, temperature management, wood selection, and combustion processes. By carefully manipulating these elements, the user can consistently produce smoked foods with nuanced and well-balanced flavor profiles. However, challenges remain in accurately predicting smoke flavor outcomes due to the variability in wood composition and environmental conditions. Continuous experimentation and meticulous documentation are necessary for developing a reliable framework for achieving desired smoke infusion results.

4. Fuel Efficiency

Fuel efficiency is a critical performance metric for vertical smokers, directly influencing operational costs and environmental impact. The design of a vertical smoker, specifically its insulation and airflow management, fundamentally determines its fuel consumption. Improved insulation minimizes heat loss, reducing the amount of fuel required to maintain consistent cooking temperatures. Precise control over airflow ensures efficient combustion, maximizing heat generation from a given quantity of fuel. Inefficient designs, characterized by poor insulation and uncontrolled airflow, necessitate the use of larger fuel quantities to achieve the desired cooking temperatures, resulting in elevated operational costs and increased emissions. The financial implications are significant, particularly for frequent users or commercial establishments. From an environmental perspective, decreased fuel consumption translates to a reduction in greenhouse gas emissions and resource depletion, aligning with sustainable practices.

The practical significance of understanding fuel efficiency in vertical smokers is evident in the selection process. Consumers can evaluate models based on their documented or observed fuel consumption rates, factoring this into their overall cost assessment. Features such as tightly sealed doors, adjustable vents, and thick-walled construction indicate potential fuel savings. Furthermore, employing proper operational techniques, such as preheating the smoker efficiently and avoiding unnecessary door openings, can further enhance fuel efficiency. The choice of fuel also plays a role, with certain fuel types, such as well-compacted charcoal briquettes, offering a more consistent and longer burn time compared to others, leading to reduced fuel requirements. Real-world examples demonstrate the tangible benefits: insulated vertical smokers can often maintain consistent temperatures for extended periods using significantly less fuel compared to non-insulated models, leading to lower operating expenses over time.

In summary, fuel efficiency represents a key consideration in the design, selection, and operation of vertical smokers. Improved fuel efficiency not only translates to reduced operational costs but also minimizes environmental impact. The interplay between design features, operational techniques, and fuel selection dictates the overall fuel consumption rate. By prioritizing fuel efficiency, users can optimize their smoking experience while contributing to sustainable resource management. However, accurately measuring and comparing fuel efficiency across different models remains a challenge due to variations in testing methodologies and environmental conditions. Therefore, continued research and standardization efforts are necessary to provide consumers with reliable information for informed decision-making.

5. Construction Material Integrity

Construction material integrity is a paramount consideration in the design and longevity of chimney smokers. The materials employed directly influence the smoker’s ability to withstand high temperatures, resist corrosion, and maintain structural stability over extended periods of use. The selection of appropriate materials is therefore critical for ensuring safe and efficient operation.

- Steel Gauge and Composition

The gauge and composition of the steel used in the body and firebox significantly affect the smoker’s durability. Thicker gauge steel provides greater heat retention and resistance to warping under high temperatures. The inclusion of alloys, such as stainless steel or heat-resistant coatings, enhances corrosion resistance, particularly in humid environments. Lower-quality steel is prone to degradation, leading to structural failure and potential safety hazards. The long-term performance of a smoker is directly correlated with the quality of steel used in its construction. Examples include models utilizing 7-gauge steel offering increased longevity compared to those employing thinner 18-gauge steel.

- Welding Quality and Technique

The quality and technique of welding used to join the smoker’s components are crucial for structural integrity. Poorly executed welds can create weak points susceptible to cracking or failure under thermal stress. Consistent, high-quality welds ensure a robust and leak-proof construction, preventing heat loss and maintaining even temperature distribution. Welding techniques, such as MIG or TIG welding, offer varying degrees of strength and precision. Substandard welding leads to premature failure of the smoker, compromising its functionality and safety. Real-world instances of weld failure have demonstrated catastrophic structural compromise during high-temperature operation.

- Grate Material and Design

The grates, which directly support the food during the smoking process, must be constructed from materials capable of withstanding high temperatures and repeated use. Common materials include porcelain-coated steel, cast iron, and stainless steel. Cast iron grates offer excellent heat retention but are susceptible to rusting if not properly maintained. Stainless steel grates are corrosion-resistant and easy to clean but may not retain heat as effectively. The design of the grates, including their thickness and spacing, influences heat distribution and airflow within the cooking chamber. Inadequate grate material or design can result in uneven cooking and premature failure of the grates themselves. The choice of grate material should consider both performance characteristics and ease of maintenance.

- Hardware Durability

The durability of the smoker’s hardware, including hinges, handles, and fasteners, is often overlooked but is essential for long-term functionality. Hardware constructed from low-quality materials is prone to corrosion, breakage, and failure under stress. Stainless steel or coated hardware offers enhanced resistance to environmental degradation. The design and construction of hinges, in particular, are critical for ensuring smooth and reliable door operation. Failure of hardware components can compromise the usability and safety of the smoker. Regular inspection and maintenance of hardware are necessary to prevent premature failure. For instance, replacing standard steel hinges with stainless steel alternatives can significantly extend their lifespan.

These interconnected elements underscore the importance of construction material integrity in chimney smokers. The selection of high-quality materials, coupled with skilled craftsmanship, ensures a durable, safe, and efficient cooking appliance. Neglecting material integrity can lead to premature failure, posing safety risks and necessitating costly repairs or replacements. Therefore, thorough evaluation of construction materials and techniques is essential when selecting a chimney smoker.

Frequently Asked Questions

The following addresses common inquiries regarding the operation, maintenance, and performance characteristics of vertical barrel-style cookers, often referred to as chimney smokers. These answers aim to provide clear and concise information for informed decision-making and optimal utilization.

Question 1: What is the optimal temperature range for low-and-slow cooking within a chimney smoker?

The generally accepted temperature range for low-and-slow cooking in these appliances is between 225F (107C) and 275F (135C). This range promotes even cooking and allows for maximum smoke penetration, resulting in tender and flavorful results. Deviations from this range may necessitate adjustments to cooking times and techniques.

Question 2: How frequently should the water pan be refilled during a long smoking session?

The water pan’s water level should be monitored and replenished every 2-3 hours, or more frequently if the ambient temperature is high or the cooking session is prolonged. Maintaining an adequate water level is crucial for temperature stability and preventing the meat from drying out.

Question 3: What are the key indicators of clean versus dirty smoke, and how does each affect flavor?

Clean smoke, often described as thin and blue, indicates efficient combustion and imparts a desirable smoky flavor. Dirty smoke, characterized by thick, white plumes, suggests incomplete combustion and can impart a bitter or acrid taste due to the presence of creosote and other undesirable compounds. Ensuring adequate airflow and using properly seasoned wood are essential for generating clean smoke.

Question 4: How often should a chimney smoker be cleaned, and what cleaning methods are recommended?

A chimney smoker should be cleaned after each use to remove ash and debris. A more thorough cleaning, including scrubbing the grates and internal surfaces to remove grease and creosote buildup, is recommended every 3-4 cooking sessions. Avoid using harsh chemicals; a mixture of warm water and mild detergent is generally sufficient. Regular cleaning is crucial for maintaining optimal performance and preventing fire hazards.

Question 5: What factors contribute to temperature fluctuations within a chimney smoker, and how can they be mitigated?

Temperature fluctuations can be caused by several factors, including changes in ambient temperature, wind gusts, variations in fuel consistency, and improper vent adjustments. Mitigating these fluctuations involves using an insulated smoker, providing wind protection, utilizing consistent fuel, and making small, incremental adjustments to the intake and exhaust vents.

Question 6: Is it necessary to use a dedicated smoker thermometer, or can the built-in thermometer be relied upon?

While built-in thermometers can provide a general indication of temperature, they are often inaccurate. Using a dedicated, calibrated smoker thermometer is highly recommended for precise temperature monitoring, ensuring consistent cooking results. Position the thermometer near the food being cooked, rather than relying solely on the dome thermometer.

In summary, understanding these frequently asked questions provides a foundation for successful operation of a vertical barrel-style cooker. Careful attention to temperature management, smoke control, and maintenance practices will result in consistent and flavorful results.

The subsequent section will explore advanced techniques and troubleshooting tips for resolving common challenges encountered during the smoking process.

Chimney Smoker

This exploration has elucidated the operational principles, maintenance requirements, and critical performance factors associated with the vertical barrel-style cooker. Precise temperature control, smoke infusion management, fuel efficiency, and construction material integrity have been identified as essential elements governing its effective utilization. The preceding analysis underscores the necessity for users to possess a comprehensive understanding of these aspects to achieve consistently favorable results.

Ultimately, the successful application of the “chimney smoker” relies on the operator’s commitment to continuous learning and meticulous execution. Further investigation into advanced techniques and innovative designs is encouraged to refine the art of low-and-slow cooking and maximize the potential of this versatile appliance. The pursuit of knowledge in this domain promises to elevate culinary endeavors and unlock new dimensions of flavor and texture.