A structure that has undergone inspection and verification to ensure it meets specific safety and performance standards is considered qualified. The purpose of this assessment is to confirm the integrity of the venting system, ensuring it operates efficiently and safely removes combustion byproducts from a heating appliance. For example, a flue system passing inspection according to a nationally recognized standard could be designated as meeting the requirements.

Verification of this systems condition is vital for preventing hazards like carbon monoxide poisoning and chimney fires. These evaluations also play a role in maintaining heating efficiency and ensuring compliance with local building codes and insurance requirements. Historically, reliance on visual inspection alone was common; modern practice increasingly emphasizes standardized assessments performed by trained professionals.

The subsequent sections will explore the inspection process in detail, examine the qualifications required of professionals conducting the assessment, and discuss the repair or maintenance procedures often associated with upholding these structures to meet mandated benchmarks.

Essential Advice for Maintaining Flue Systems

The following guidelines are intended to provide actionable insights for ensuring the safe and efficient operation of venting structures.

Tip 1: Schedule Annual Inspections: Routine evaluation by a qualified professional is crucial. This detects potential issues, such as cracks or blockages, before they escalate into hazardous situations.

Tip 2: Use Seasoned Wood: Burning wood with a moisture content below 20% reduces creosote buildup. Creosote is highly flammable and a leading cause of chimney fires.

Tip 3: Ensure Proper Ventilation: Confirm adequate airflow to the combustion appliance. Insufficient oxygen can lead to incomplete combustion and increased carbon monoxide production.

Tip 4: Maintain a Clean Flue: Regular cleaning removes creosote and other debris that accumulate over time. The frequency of cleaning depends on usage and fuel type.

Tip 5: Address Repairs Promptly: Any identified damage, such as crumbling brickwork or a damaged flue liner, requires immediate attention. Delaying repairs can compromise the structural integrity of the system.

Tip 6: Understand Appliance Compatibility: Ensure that the venting system is properly sized and rated for the specific heating appliance. Mismatched components can result in inefficient operation and safety hazards.

Adherence to these recommendations significantly minimizes risks associated with venting systems. Proactive maintenance promotes safety and optimizes performance.

The article’s concluding section summarizes the key points discussed and provides final recommendations for homeowners.

1. Inspection Protocol

Adherence to a defined inspection protocol is a prerequisite for chimney qualification. The protocol establishes the procedures and criteria used to assess the system’s condition and performance. A structured inspection identifies defects, deterioration, and code violations that compromise safety and efficiency. For instance, a Level II inspection, as defined by the National Fire Protection Association (NFPA) 211 standard, mandates a video scan of the flue liner. This process directly assesses the integrity of the liner, revealing cracks, separations, or obstructions that would be missed by a visual inspection alone. Failure to adhere to this protocol could result in overlooking significant hazards, negating the reliability of any subsequent evaluation.

Without a meticulous inspection, a structure may present a facade of acceptable condition while harboring latent dangers. Consider a scenario where a heating appliance is improperly vented. A proper protocol ensures that all connections, draft levels, and clearances are evaluated. Neglecting these steps increases the risk of carbon monoxide intrusion into the living space. An inspection protocol must also account for regional variations in building codes and environmental factors. Coastal areas, for example, require inspections that explicitly address corrosion caused by salt air.

Consequently, the inspection protocol is not merely a checklist but a comprehensive methodology for confirming safety and performance. Its consistent application promotes standardization across evaluations, enhancing the reliability of any assessment. Strict compliance is essential for ensuring that a structure genuinely meets established benchmarks and warrants being deemed qualified. The absence of a rigorous protocol undermines the integrity of the qualification process, potentially endangering occupants and property.

2. Structural Integrity

Structural integrity is paramount to the safe and effective operation of a venting system. It ensures the system can withstand operational stresses and environmental conditions without failure. In the context of flue qualification, maintained structural integrity minimizes the risk of hazards such as gas leaks, fire spread, and carbon monoxide intrusion.

- Material Degradation Resistance

The materials used in chimney construction must resist degradation from heat, moisture, and corrosive byproducts of combustion. For example, a clay flue liner that cracks due to thermal stress compromises its ability to contain combustion gases. Regular inspections and appropriate materials selection are vital to mitigate this type of degradation, therefore maintaining structural integrity is important.

- Mortar Joint Stability

Mortar joints are integral to the stability of masonry structures. Deterioration of mortar joints allows moisture penetration, which can lead to freeze-thaw damage and structural weakening. Repointing deteriorated joints and ensuring proper flashing prevent water intrusion and maintain the chimney’s structural soundness. Maintaining the mortar joint and performing regular structural checks are important.

- Foundation and Support Systems

The foundation and support systems bear the weight of the structure and must remain stable. Soil erosion, settling, or seismic activity can compromise these systems. Addressing foundation issues promptly, such as reinforcing the base or installing proper drainage, is crucial to prevent structural failure. Maintaining the support system will keep it in shape so it can function as intended.

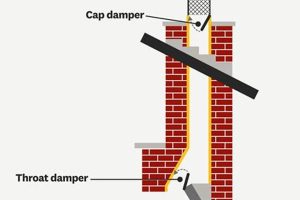

- Flue Liner Continuity

A continuous, intact flue liner contains combustion gases and prevents them from permeating the surrounding structure. Cracks, gaps, or misalignments in the liner compromise its effectiveness. Regular video scanning identifies liner defects, allowing for timely repairs or relining to maintain containment. An intact flue liner means that the system is properly sealed and functional.

Maintaining these facets of structural integrity is essential for a venting system to remain qualified. Regular inspections, prompt repairs, and the use of appropriate materials and construction techniques ensure the system operates safely and efficiently over its lifespan. Neglecting structural integrity can lead to hazardous conditions and jeopardize the integrity of the surrounding building structure and safety of the occupants. Therefore structural integrity is one of the most important aspects of the structural system.

3. Compliance Standards

The attainment of chimney system qualification is inextricably linked to adherence to established compliance standards. These standards, developed by organizations such as the National Fire Protection Association (NFPA) and Underwriters Laboratories (UL), specify minimum requirements for design, materials, construction, and performance. The systems verification hinges upon meeting these criteria. Failure to comply directly undermines the safety and effectiveness of the system, rendering it ineligible for qualified status.

For example, NFPA 211 dictates standards for chimney, fireplace, and venting systems, addressing aspects from flue sizing to clearance from combustible materials. UL 103 provides testing and certification protocols for factory-built chimneys, ensuring they withstand high temperatures and corrosive byproducts. A flue lacking proper clearance from combustible materials, as defined by NFPA 211, poses a significant fire hazard and would fail inspection. Similarly, a factory-built flue failing UL 103 testing for structural integrity or heat resistance would be deemed non-compliant and unsafe. Meeting these standards reduces fire risk and ensures compliance.

Ultimately, compliance standards serve as the foundation upon which confidence in the system’s safety and performance rests. Understanding and adhering to these standards is not merely a regulatory formality but a critical component of responsible design, installation, and maintenance. Without rigorous adherence to compliance standards, the designation of system verification becomes meaningless, potentially exposing occupants to preventable hazards. Standards help minimize risk and maximize safety.

4. Safety Verification

Safety verification is an indispensable element in the qualification process for a venting system. It confirms that the system meets established safety benchmarks and functions as intended, mitigating potential risks to occupants and property. This verification process is not merely a cursory check but a thorough evaluation that considers various factors.

- Combustion Byproduct Containment

Safety verification involves assessing the system’s ability to contain combustion byproducts, such as carbon monoxide and creosote. A qualified system must prevent these substances from leaking into living spaces or accumulating in a manner that poses a fire hazard. For example, a chimney with a cracked flue liner fails to contain combustion gases effectively, leading to potential carbon monoxide poisoning. Thus, verifying containment integrity is vital.

- Structural Stability Under Stress

Verification includes evaluating the system’s structural stability under operational stresses, including high temperatures, wind loads, and seismic activity. A system prone to collapse or material failure presents an immediate danger. For instance, a chimney lacking adequate reinforcement may crumble during an earthquake, posing a risk to nearby structures and occupants. Therefore, verifying structural resilience is crucial.

- Clearance from Combustible Materials

Safety verification necessitates confirming adequate clearance between the system and combustible materials, such as wood framing or roofing. Insufficient clearance can lead to ignition and fire spread. For example, a chimney improperly installed too close to a wood beam creates a fire hazard, particularly during extended use. Adhering to clearance requirements is a fundamental aspect of safety.

- Proper Draft and Ventilation

Verification involves assessing the system’s ability to maintain proper draft and ventilation, ensuring efficient removal of combustion gases. Inadequate draft can lead to back drafting, causing dangerous fumes to enter the building. For instance, a chimney blocked by debris or improperly sized can impede airflow, increasing the risk of carbon monoxide exposure. Validating proper draft is essential for safe operation.

These facets of safety verification are integral to the qualification of a venting system. A system failing to meet these criteria poses unacceptable risks and cannot be considered qualified. The comprehensive verification process ensures that the system operates safely and effectively, protecting occupants and property from potential hazards.

5. Professional Expertise

The attainment of verified status for a flue system is inextricably linked to the application of professional expertise. Flue systems are complex, with potential failure points requiring specialized knowledge to identify and mitigate. Untrained individuals often lack the skills to accurately assess structural integrity, code compliance, and operational safety. For example, a qualified professional, understanding principles of thermodynamics and material science, can assess the adequacy of draft, identify potential creosote buildup based on fuel type and usage patterns, and determine if the flue liner is appropriately sized for the connected appliance. The expertise to apply these skills and knowledge ensures proper validation.

The absence of professional oversight can lead to catastrophic consequences. Consider a homeowner who attempts to self-inspect and clean their flue. Without proper training, they might overlook subtle cracks in the flue liner, indicating structural compromise and potential carbon monoxide leakage. Similarly, incorrect cleaning techniques could damage the liner, exacerbating existing problems. Professional expertise, conversely, encompasses not only technical skills but also adherence to ethical standards and ongoing training. Qualified professionals are typically certified by recognized organizations, requiring them to stay abreast of changes in codes, technologies, and best practices. This ensures that assessments are conducted using current and validated methods.

Therefore, the involvement of certified professionals is not merely a procedural formality but a fundamental requirement for ensuring flue safety and performance. Reliance on untrained individuals or superficial inspections undermines the entire qualification process, potentially jeopardizing occupants and property. Proper professional oversight is a key aspect of chimney system safety, and it is important to only use experts for the inspection. The challenges of achieving universal adherence to this principle remain, particularly in regions with limited access to qualified professionals. However, promoting awareness of the importance of expert evaluation is crucial for minimizing risks and promoting informed decision-making among homeowners.

6. Performance Benchmarks

Performance benchmarks are quantifiable metrics that define acceptable levels of operational effectiveness for a flue system. They serve as critical indicators of efficiency, safety, and longevity. In the context of certified chimney systems, these benchmarks are not merely aspirational goals but rather mandatory thresholds that must be consistently met to maintain qualified status. Failure to meet these established performance metrics invalidates the certification, potentially exposing occupants to hazards and negating compliance with building codes. For instance, a benchmark might specify a minimum flue draft necessary for proper venting of combustion byproducts, measured in Pascals. A system exhibiting insufficient draft, as determined through diagnostic testing, would fail to meet the required benchmark, indicating a potential for carbon monoxide back drafting.

The connection between performance benchmarks and verification is direct and consequential. Benchmarks dictate the parameters that are evaluated during inspection and testing, informing decisions regarding system approval or rejection. Practical application involves using specialized instruments to measure relevant performance characteristics, such as flue gas temperature, creosote accumulation rates, and structural stability under simulated stress conditions. Data collected during these assessments are then compared against established benchmarks to determine compliance. Another example could be the amount of allowable creosote buildup after a specific period of use. The accumulation rate must fall below a defined level to minimize the risk of chimney fires. A system exceeding this threshold necessitates immediate cleaning and potentially further investigation to identify the underlying cause of excessive creosote formation.

In summary, performance benchmarks represent an objective and quantifiable measure of a flue system’s ability to function safely and effectively. They are a cornerstone of the qualification process, providing a clear basis for evaluating system compliance and ensuring consistent operational standards. Challenges exist in establishing universally accepted benchmarks that account for regional variations in climate, fuel types, and building construction practices. However, ongoing research and refinement of these metrics are essential for maintaining public safety and promoting responsible flue system management, leading to effective system qualification.

Frequently Asked Questions about Verified Flue Systems

The following questions address common inquiries regarding qualified venting systems and their importance in residential safety.

Question 1: What constitutes a “certified” flue system?

Answer: A “certified” flue system is one that has undergone inspection and has been verified by a qualified professional to meet established safety and performance standards, such as those set by NFPA or UL. This indicates compliance with building codes and reduces potential hazards.

Question 2: Why is qualification of a flue system necessary?

Answer: Qualification is essential for preventing hazards such as carbon monoxide poisoning and chimney fires. These systems are responsible for safely venting combustion byproducts, and any compromise to their integrity can have severe consequences.

Question 3: How often should a flue system undergo evaluation?

Answer: It is recommended that a flue system be inspected at least annually by a qualified professional. More frequent inspections may be necessary depending on usage and fuel type.

Question 4: What qualifications should a professional possess to conduct an inspection?

Answer: A qualified professional should hold certifications from recognized organizations such as the Chimney Safety Institute of America (CSIA) or have equivalent credentials demonstrating expertise in chimney inspection and maintenance.

Question 5: What are the potential consequences of neglecting flue system maintenance?

Answer: Neglecting maintenance can lead to creosote buildup, structural deterioration, and increased risk of carbon monoxide leaks and chimney fires. These issues can compromise the safety of the building and its occupants.

Question 6: What recourse is available if a flue system fails inspection?

Answer: If a flue system fails inspection, necessary repairs or replacements should be undertaken promptly by a qualified professional. Failure to address identified issues can have significant safety implications.

These frequently asked questions offer essential insight to maintaining a properly qualified and safe venting system. Regular inspections, appropriate maintenance, and informed decision-making are paramount.

The following section will provide a comprehensive guide to selecting a qualified professional for a flue system inspection.

Certified Chimney

This exploration of “certified chimney” has underscored its critical role in safeguarding properties and lives. The discussion illuminated the importance of professional expertise, structural integrity, adherence to compliance standards, rigorous safety verification, and the achievement of established performance benchmarks. Each element contributes to a reliable venting system, mitigating risks associated with combustion byproducts and potential structural failures.

Given the inherent dangers associated with compromised venting systems, diligent adherence to these principles is non-negotiable. Prioritizing qualified inspections and prompt remediation of identified issues are paramount for maintaining a safe living environment. The long-term implications of neglecting these precautions can be catastrophic, emphasizing the significance of proactive management and informed decision-making regarding chimney system maintenance and qualification.