This component serves as a protective covering for the top portion of a chimney structure, particularly when that structure is built with a framed enclosure. It effectively seals off the vulnerable area between the chimney flue and the surrounding chase, preventing water intrusion and potential damage. A common example involves its use atop a wood-framed chimney exterior clad in siding, where it provides a weatherproof barrier.

The installation of this protective element is critical to maintaining the structural integrity of the chimney and the building it serves. By preventing water from entering the chase, it mitigates risks like wood rot, mold growth, and deterioration of masonry. Historically, simpler methods were employed, often proving less durable and effective against the elements. Modern iterations, typically fabricated from durable metals, offer extended lifespans and superior protection, leading to reduced maintenance and repair costs over time.

The remainder of this article will delve into the specific materials used in construction, installation techniques, common problems, and preventative maintenance strategies related to these essential chimney components.

Essential Considerations for Optimal Performance

The following are crucial guidelines to ensure the longevity and effectiveness of this vital chimney component.

Tip 1: Material Selection. Prioritize durable, corrosion-resistant materials such as stainless steel or aluminum. These materials withstand harsh weather conditions and extend the component’s lifespan, minimizing the need for premature replacement.

Tip 2: Proper Sizing. Accurate measurement of the chimney chase is paramount. An improperly sized unit will fail to provide a watertight seal, negating its intended purpose and potentially leading to significant water damage.

Tip 3: Professional Installation. Engaging a qualified chimney professional is highly recommended. Correct installation ensures a secure fit, proper flashing, and effective sealing against the elements, preventing costly repairs down the line.

Tip 4: Regular Inspection. Conduct annual inspections to identify potential issues such as rust, corrosion, or damage from debris. Early detection allows for timely repairs, preventing minor problems from escalating into major structural concerns.

Tip 5: Seam and Joint Integrity. Pay close attention to the seams and joints during installation and subsequent inspections. Ensure they are properly sealed with a high-quality sealant to prevent water infiltration. Re-seal as needed.

Tip 6: Debris Removal. Routinely clear debris, such as leaves and twigs, from the surface. Accumulated debris can trap moisture and accelerate corrosion, compromising the component’s integrity.

Tip 7: Addressing Ponding. Design the unit with a slight slope to facilitate water runoff and prevent ponding. Standing water can contribute to corrosion and eventual failure of the unit.

By adhering to these guidelines, property owners can effectively protect their chimneys from water damage, ensuring structural integrity and avoiding costly repairs. These measures are essential for maintaining the long-term performance and safety of the chimney system.

The next section will present a conclusion to this discussion, summarizing the overall importance of the correct implementation and maintenance strategies outlined above.

1. Material Durability

Material durability is a paramount consideration in the construction and selection of this specific chimney component. Its location, exposed to the full range of environmental stressors, necessitates materials capable of withstanding prolonged exposure to moisture, temperature fluctuations, and potential chemical corrosion. Inadequate material selection directly compromises the lifespan and effectiveness of this crucial element.

- Corrosion Resistance

Corrosion is a primary threat to the longevity of a metal covering. Materials lacking inherent corrosion resistance, such as untreated steel, will rapidly degrade when exposed to rain, snow, and atmospheric pollutants. Stainless steel and aluminum alloys are frequently employed due to their superior resistance to oxidation and chemical attack. The specific alloy and protective coatings applied influence the component’s ability to resist pitting, rust, and structural weakening.

- Thermal Expansion and Contraction

Chimneys experience significant temperature variations due to flue gas emissions and external weather conditions. Materials must be capable of withstanding repeated cycles of expansion and contraction without fracturing or warping. Incompatible materials or poorly designed seams can lead to stress fractures and ultimately, failure of the component, creating pathways for water intrusion. Proper material selection considers the coefficient of thermal expansion for each material used in construction.

- Mechanical Strength

The protective element must possess sufficient mechanical strength to withstand wind loads, snow accumulation, and potential impact from debris, such as falling branches. Thin or inadequately supported materials may deform or collapse under stress, compromising the seal and allowing water to enter the chimney chase. Material thickness, support structure design, and fastening methods all contribute to the overall mechanical strength of the component.

- UV Resistance

Exposure to ultraviolet (UV) radiation from sunlight can degrade certain materials, particularly plastics and some coatings. Over time, UV exposure can cause discoloration, embrittlement, and cracking, compromising the material’s integrity and reducing its ability to provide effective protection. When selecting materials, consider those with inherent UV resistance or apply UV-resistant coatings to mitigate degradation.

The interplay of these factors underscores the significance of prioritizing material durability when choosing a component for the chimney structure. Selection based solely on initial cost savings, without regard for long-term material performance, inevitably leads to premature failure, costly repairs, and potential damage to the building structure. Thus, investment in durable, high-quality materials is a critical element in ensuring the enduring protection and performance of the chimney system.

2. Proper Dimensions

Accurate sizing constitutes a foundational element in the successful installation and long-term performance of this protective chimney component. Inadequate or imprecise measurements negate the benefits of durable materials and professional installation, potentially leading to water intrusion and structural damage. The following facets highlight the critical aspects of dimensional accuracy.

- Chase Opening Measurement

The perimeter of the chimney chase opening must be precisely measured to ensure a snug, weatherproof fit. Undersized units fail to adequately cover the opening, leaving gaps for water penetration. Oversized units, conversely, may be unstable and difficult to secure, potentially leading to wind damage. Accurate measurements require precise tools and a thorough understanding of the chase geometry. For example, measuring each side multiple times and accounting for any irregularities in the construction is essential.

- Flue Extension Accommodation

The unit must accommodate any existing flue extensions or rain caps protruding from the chimney. Insufficient clearance can impede proper installation and potentially damage the flue system. Accurate measurement of the flue height and diameter is crucial to avoid interference. This often necessitates custom fabrication to ensure a perfect fit, especially with older or unusually configured chimneys.

- Slope and Drainage Considerations

Optimal performance requires a slight slope to facilitate water runoff and prevent ponding on the surface. This slope must be incorporated into the overall dimensions of the unit, ensuring adequate drainage without compromising the structural integrity. Insufficient slope leads to water accumulation, accelerating corrosion and material degradation. The slope angle should be carefully calculated based on the local climate and expected rainfall.

- Overlap and Flashing Integration

The dimensions must account for adequate overlap with surrounding roofing materials and flashing. Insufficient overlap creates vulnerabilities for water infiltration, especially during heavy rain or snow. Proper integration with existing flashing requires precise measurements and careful attention to detail. Flashing should extend sufficiently up the sides of the chimney and over the unit to provide a watertight seal. Inadequate flashing is a common cause of chimney leaks, even with a properly sized unit.

These considerations underscore the vital role of accurate dimensions. Deviation from precise measurements, even by a small margin, can compromise the entire system’s integrity. Meticulous attention to detail during the measurement and fabrication process is, therefore, indispensable for ensuring long-term protection and minimizing the risk of costly repairs.

3. Professional Installation

The longevity and effectiveness of a chimney chase pan are inextricably linked to the quality of its installation. While durable materials and accurate dimensions are prerequisites, improper installation negates these advantages, resulting in premature failure and potential structural damage. The complexities involved in achieving a weathertight seal and secure attachment necessitate the expertise of a qualified chimney professional.

Consider the scenario where a seemingly well-constructed unit is installed by an inexperienced individual. Improper flashing techniques, inadequate sealing of seams, or failure to properly fasten the pan to the chimney chase can create pathways for water intrusion. This, in turn, leads to wood rot, mold growth, and deterioration of the chimney structure. Conversely, professional installation ensures proper flashing, secure fastening, and meticulous sealing, providing a robust barrier against the elements. For instance, a certified installer understands the importance of using compatible sealants, applying them uniformly, and ensuring they adhere properly to both the pan and the surrounding materials. They will also possess the necessary tools and equipment to handle the pan safely and efficiently, minimizing the risk of damage during installation.

In summary, professional installation is not merely a desirable option but a critical component of a chimney chase pan’s overall performance. It transforms a potentially vulnerable point in the chimney structure into a reliably protected area, safeguarding the building from water damage and extending the lifespan of the chimney system. Neglecting this crucial step often proves to be a costly mistake in the long run, necessitating extensive repairs that far exceed the initial investment in professional services.

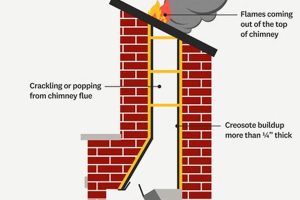

4. Seam Integrity

The structural integrity of a chimney chase pan is fundamentally contingent upon the integrity of its seams. Seams, representing junctures where separate pieces of material are joined, constitute inherent weak points susceptible to failure if improperly executed or maintained. The function of the pan, which is to prevent water intrusion into the chimney chase, directly relies on these seams remaining impermeable. A breach in seam integrity allows water to penetrate the chase, initiating a cascade of detrimental effects including wood rot, mold growth, and ultimately, structural degradation of the chimney and surrounding building elements. For example, a chase pan constructed with overlapping metal sheets secured solely by rivets, without proper sealing, is highly vulnerable. Expansion and contraction due to temperature fluctuations can loosen the rivets over time, creating gaps through which water can infiltrate.

Consider the practical implications of compromised seam integrity in various environmental conditions. In regions experiencing heavy snowfall, accumulated snow melting on the pan’s surface can exert prolonged hydrostatic pressure on the seams. Similarly, in areas prone to frequent freeze-thaw cycles, water that has penetrated minute seam imperfections can expand upon freezing, exacerbating the breaches and accelerating material deterioration. These scenarios highlight the necessity of employing robust seam construction techniques such as welding, soldering, or the application of high-quality, elastomeric sealants designed to withstand environmental stresses. Regular inspection and maintenance of seams, including resealing when necessary, are essential for preventing water intrusion.

In conclusion, seam integrity is not merely a detail but a critical determinant of a chimney chase pan’s effectiveness. Understanding the cause-and-effect relationship between seam quality and water resistance, supported by tangible examples of environmental impact, underscores the practical significance of prioritizing seam construction and maintenance. While durable materials and proper dimensions are important, they are rendered ineffective if the seams fail to maintain a watertight barrier. Prioritizing seam integrity is therefore indispensable for ensuring the long-term protection of the chimney and the building it serves.

5. Debris Removal

Debris removal is an indispensable aspect of chimney maintenance, directly impacting the functionality and longevity of the protective component covering a framed chimney structure. Accumulation of organic material and other foreign objects compromises the pan’s intended performance, necessitating regular clearing to prevent related issues.

- Moisture Retention

Debris, such as leaves, twigs, and pine needles, traps moisture against the surface of the pan. Prolonged moisture exposure accelerates corrosion, particularly in pans constructed from less resistant materials. The damp environment created by accumulated debris also fosters the growth of mold and mildew, which can further degrade the pan’s coating and structural integrity. In colder climates, trapped moisture can freeze and thaw, causing expansion and contraction that weakens the pan’s seams and overall structure. For example, a pan perpetually covered in wet leaves will corrode much faster than one that is regularly cleared.

- Obstructed Drainage

Debris accumulation obstructs the designed drainage pathways on the pan, leading to water ponding. Standing water increases the risk of leaks and further accelerates corrosion. Obstructed drainage can also lead to ice dam formation during winter months, potentially damaging the roof and chimney structure. A pan designed with a slight slope for water runoff becomes ineffective when clogged with debris, negating its intended purpose.

- Pest Infestation

Accumulated debris provides an attractive habitat for insects, birds, and other pests. Nests constructed from debris can further obstruct drainage and contribute to moisture retention. Animal activity can also cause physical damage to the pan, such as punctures or dislodged flashing. For example, birds nesting within accumulated debris may peck at the pan’s surface, compromising its protective coating and creating entry points for water.

- Increased Weight Load

Heavy accumulation of debris, particularly when saturated with water or snow, increases the weight load on the pan. This added stress can cause deformation, sagging, or even collapse, especially in older or poorly supported pans. The increased weight also puts additional strain on the chimney structure itself. A pan designed to withstand normal weather conditions may fail under the added burden of excessive debris accumulation.

The synergistic effect of moisture retention, obstructed drainage, pest infestation, and increased weight load underscores the critical importance of regular debris removal. Neglecting this simple maintenance task can lead to significant damage, necessitating costly repairs or even complete pan replacement. Therefore, incorporating debris removal into a routine chimney maintenance schedule is essential for preserving the integrity and extending the lifespan of the chimney component.

6. Water Runoff

Effective water runoff is a critical design consideration for any protective covering of a chimney chase. This principle ensures that precipitation is efficiently diverted away from vulnerable areas, preventing water intrusion and mitigating potential damage to the chimney structure and the building it serves. The proper management of water runoff extends the lifespan of the covering and contributes to the overall integrity of the chimney system.

- Slope Angle and Direction

The angle and direction of the slope are primary determinants of effective water runoff. An insufficient slope promotes water ponding, increasing the risk of corrosion and material degradation. Conversely, an excessively steep slope may compromise structural stability. The optimal slope angle should be calculated based on regional precipitation patterns and the specific material properties of the covering. The runoff direction should be designed to channel water away from sensitive areas such as the chimney flue and the surrounding roof. For example, a properly designed pan should feature a gradual slope directing water towards a gutter system or designated drainage point.

- Material Surface Properties

The surface properties of the materials used in construction significantly influence water runoff efficiency. Smooth, non-porous surfaces facilitate rapid water shedding, reducing the likelihood of moisture retention. Conversely, rough or porous surfaces can trap water, promoting corrosion and the growth of mold or mildew. The application of protective coatings can enhance the water-repellent properties of the covering material. Consider a stainless steel pan coated with a hydrophobic sealant, which will exhibit superior water runoff compared to an uncoated steel pan.

- Drainage Outlet Design

The design and placement of drainage outlets are crucial for effectively channeling water away from the covering. Outlets should be adequately sized to accommodate peak runoff volumes during heavy precipitation events. They should also be strategically positioned to prevent water from pooling or accumulating in specific areas. Clogged or undersized outlets can lead to water backup and potential leaks. An effective drainage system might incorporate a series of strategically placed weep holes or a fully integrated gutter system, depending on the size and design of the covering.

- Integration with Flashing Systems

Seamless integration with existing flashing systems is essential for preventing water intrusion at the interface between the covering and the surrounding roof. Flashing should be properly lapped and sealed to create a watertight barrier. Inadequate flashing can negate the benefits of effective water runoff, allowing water to penetrate the chimney chase despite the presence of a properly sloped covering. The flashing material should be compatible with both the covering material and the roofing material to ensure long-term durability and prevent corrosion due to dissimilar metal contact.

These interconnected elements illustrate the comprehensive approach necessary for managing water runoff effectively. Failure to adequately address any of these factors can compromise the integrity of the covering and increase the risk of water damage. By prioritizing proper slope angle, selecting appropriate surface materials, designing efficient drainage outlets, and seamlessly integrating with flashing systems, ensures lasting protection and minimizes potential maintenance requirements. It demonstrates a commitment to long-term performance and structural integrity of the chimney system.

Frequently Asked Questions Regarding Chimney Chase Pans

The following addresses common inquiries concerning these critical chimney components, their function, and their maintenance.

Question 1: What constitutes the primary function?

The principal role is to provide a weatherproof barrier, preventing water intrusion into the chimney chase, thereby protecting the internal structure from moisture damage.

Question 2: What materials are appropriate for the construction of one of these components?

Durable, corrosion-resistant materials, such as stainless steel or aluminum, are recommended. These materials withstand environmental stressors and prolong the component’s lifespan.

Question 3: How is proper sizing determined for this chimney component?

Accurate measurement of the chimney chase opening is paramount. The component must adequately cover the opening to prevent water infiltration, necessitating precise dimensions.

Question 4: Is professional installation necessary for this chimney component?

Engaging a qualified chimney professional for installation is highly recommended. Proper installation ensures a secure fit, correct flashing, and effective sealing against the elements.

Question 5: What are the key maintenance requirements for this chimney component?

Regular inspection and debris removal are essential. Inspections identify potential issues, while debris removal prevents moisture retention and accelerated corrosion.

Question 6: What are the consequences of neglecting to maintain the seam integrity of this component?

Compromised seam integrity allows water to penetrate the chimney chase, leading to wood rot, mold growth, and potential structural damage to the chimney and surrounding building elements.

In summary, meticulous attention to material selection, accurate sizing, professional installation, and routine maintenance are crucial for maximizing the lifespan and effectiveness of these components.

The subsequent section will elaborate on potential issues and troubleshooting strategies related to this specific chimney component.

Chimney Chase Pan

This article has explored the fundamental importance of the chimney chase pan as a protective element against water damage in framed chimney structures. From material selection to installation techniques and ongoing maintenance, each aspect contributes to the overall effectiveness and longevity of this critical component. Proper implementation safeguards against wood rot, mold growth, and the potential deterioration of both the chimney itself and the surrounding building materials. The details discussed underscore the necessity of a comprehensive approach that considers the environmental stressors specific to each installation.

The decision to invest in a high-quality, professionally installed, and diligently maintained chimney chase pan represents a commitment to preserving the structural integrity and long-term value of the property. Neglecting this critical element exposes the building to significant risks and potentially costly repairs. Prioritizing this component is a proactive step towards ensuring the enduring stability and safety of the entire chimney system.