The process addresses damage to the protective covering found atop a chimney. This element, typically constructed from metal, helps prevent debris, animals, and precipitation from entering the flue. A common example includes replacing a rusted or dislodged cover on a residential chimney.

Maintaining the integrity of this component is essential for several reasons. It minimizes the risk of chimney blockage, which can lead to dangerous carbon monoxide buildup in the dwelling. Furthermore, a properly functioning one prevents water damage to the chimney structure itself, prolonging its lifespan and avoiding costly structural issues. Historically, these covers have been used to improve chimney draft and prevent backpuffing.

The subsequent sections will detail common types of damage observed, required tools and materials for addressing them, and considerations for when professional assistance becomes necessary.

Chimney Cap Maintenance Guidelines

These guidelines focus on ensuring the longevity and functionality of chimney covers, critical components for safe and efficient chimney operation.

Tip 1: Regular Inspection. Conduct visual examinations of the chimney cover at least twice annually, ideally in the spring and fall. Note any signs of rust, physical damage, or displacement.

Tip 2: Prompt Rust Mitigation. Address rust accumulation immediately. Minor surface rust can often be treated with a wire brush and protective coating, but extensive rust may necessitate component replacement.

Tip 3: Secure Mounting Verification. Confirm the chimney cover is firmly affixed to the chimney crown. Wind and weather can loosen mounting hardware, increasing the risk of detachment.

Tip 4: Debris Removal. Routinely clear any accumulated debris, such as leaves, twigs, or nests, from the area surrounding the chimney cover. Obstructions can impede proper ventilation and contribute to deterioration.

Tip 5: Professional Assessment. If uncertainty exists regarding the extent of damage or the appropriate action, consult a qualified chimney technician. Improper attempts at can exacerbate existing issues.

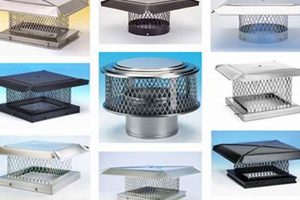

Tip 6: Material Selection. When replacing a chimney covering, opt for durable materials such as stainless steel or copper, which offer enhanced resistance to corrosion and weathering.

Tip 7: Spark Arrestor Maintenance. For covers incorporating spark arrestors, ensure the mesh remains clear and undamaged. Damaged spark arrestors pose a fire hazard.

Adhering to these guidelines will reduce the likelihood of chimney damage, mitigate potential safety risks, and optimize chimney performance.

The subsequent section will address common questions about related to specific chimney types and regional climate considerations.

1. Rust Prevention

Rust, a form of iron oxide, constitutes a significant threat to chimney cover longevity. The constant exposure to environmental elements, including moisture and acidic precipitation, accelerates the corrosion process in susceptible metals. Unprotected steel components, commonly employed in the construction of these covers, are particularly vulnerable. The formation of rust compromises the structural integrity of the component, ultimately leading to its failure. For example, a rusted chimney cover may develop holes, allowing rainwater and debris to enter the chimney flue, potentially damaging the chimney liner and fireplace.

Effective rust prevention involves several strategies. Selecting corrosion-resistant materials, such as stainless steel or copper, during installation is a primary measure. The application of protective coatings, specifically designed for metal surfaces exposed to high temperatures and corrosive environments, offers an additional layer of defense. Regular inspection and maintenance, including the removal of surface rust and the reapplication of protective coatings, extend the lifespan of the component. Neglecting rust prevention inevitably leads to costly replacements and potential safety hazards associated with compromised chimney function.

In summary, rust prevention is an indispensable element of comprehensive maintenance. Proactive measures, from material selection to consistent upkeep, are critical for preserving structural integrity, ensuring operational safety, and mitigating the long-term financial burdens associated with chimney infrastructure. Failure to prioritize corrosion resistance contributes to premature component failure and escalating maintenance requirements.

2. Animal Intrusion

The intrusion of animals into chimney systems presents a tangible threat to both property and occupant safety. Chimney caps serve as a primary defense against such incursions, and their integrity directly correlates with the effectiveness of this protection. The absence of a functional cover invites a range of complications, necessitating responsive measures.

- Nesting Obstructions

Birds, squirrels, and other small animals frequently construct nests within chimneys, leading to flue blockages. These obstructions impede the proper venting of combustion byproducts, increasing the risk of carbon monoxide poisoning. A damaged or missing cover provides easy access for nesting materials.

- Structural Damage

Animals can cause physical damage to the chimney’s interior structure. Persistent scratching and gnawing can compromise the integrity of the flue liner and mortar joints. This degradation accelerates water damage and can lead to costly repairs.

- Disease Transmission

Animals inhabiting chimneys can carry diseases and parasites. Their droppings and nesting materials introduce potential health hazards into the home environment. A properly installed cap minimizes exposure to these vectors.

- Fire Hazard

Nesting materials are often highly flammable. Embers from a fireplace can ignite these materials, resulting in a chimney fire. A functional spark arrestor, typically integrated into the cover, prevents embers from escaping and igniting nearby combustibles, including nests.

The aforementioned complications underscore the importance of maintaining a secure and functional chimney cover. Regular inspections and prompt can effectively mitigate the risks associated with animal intrusion, ensuring both the structural integrity of the chimney and the safety of the building’s occupants. Failure to address these issues can lead to significant financial burdens and potential health consequences.

3. Water Damage

Water infiltration represents a significant threat to chimney structures, underscoring the critical role of chimney covers in mitigating potential harm. The chimney’s exposure to the elements renders it particularly vulnerable to precipitation, and the absence of a functional barrier accelerates deterioration. The subsequent points detail specific facets of water-related damage and their connection to proper cover maintenance.

- Mortar Deterioration

Water seeping into mortar joints initiates a freeze-thaw cycle, causing expansion and contraction that weakens the mortar. This process leads to cracks, crumbling, and eventual structural instability. A properly functioning cover diverts rainwater away from the mortar, prolonging its lifespan. Neglecting cover will accelerate mortar degradation and necessitate costly repointing.

- Flue Liner Degradation

Water intrusion corrodes metal flue liners and degrades clay tile liners. This damage compromises the liner’s ability to safely contain combustion byproducts, increasing the risk of carbon monoxide leakage and chimney fires. An intact cover protects the liner from direct exposure to rainwater, preserving its functionality.

- Interior Water Damage

Persistent water leaks through a damaged chimney can penetrate interior walls and ceilings, leading to staining, mold growth, and structural damage to surrounding building materials. A well-maintained cover prevents water from entering the chimney system, minimizing the risk of internal water damage and associated health hazards.

- Chimney Crown Degradation

The chimney crown, the concrete slab at the top of the chimney, is also susceptible to water damage. Cracks in the crown allow water to penetrate the chimney structure. A properly sized and installed cover protects the crown from direct exposure to precipitation, mitigating crack formation and extending its service life.

The interconnectedness of these issues highlights the necessity of proactive cover maintenance. Neglecting this essential component exposes the entire chimney structure to the detrimental effects of water, resulting in accelerated deterioration, compromised safety, and escalating costs. Regular inspection and timely action are paramount for preserving chimney integrity and preventing water-related damage.

4. Material Degradation

Material degradation directly impacts the lifespan and functionality of chimney covers, making regular repairs essential for structural integrity and operational safety. Understanding the primary modes of degradation is crucial for effective maintenance and component selection.

- Corrosion and Oxidation

Exposure to atmospheric elements, particularly moisture and acidic precipitation, leads to corrosion of metallic components. Oxidation, the chemical reaction with oxygen, results in rust formation on ferrous metals, weakening the structure. Examples include rusted steel covers exhibiting holes, allowing water ingress. Addressing corrosion through coatings or material replacement is a key aspect of chimney cover maintenance.

- Thermal Stress and Fatigue

Fluctuations in temperature, particularly during fireplace use, induce thermal stress within cover materials. Repeated expansion and contraction cycles lead to fatigue and cracking. Clay and concrete covers are susceptible to this type of degradation. Identifying and patching cracks early prevents further damage and potential structural failure.

- UV Radiation Damage

Prolonged exposure to ultraviolet (UV) radiation from sunlight causes degradation of polymeric materials used in coatings and sealants. UV radiation breaks down the chemical bonds in these materials, leading to discoloration, cracking, and loss of elasticity. This degradation compromises the protective properties of coatings and sealants, accelerating corrosion and water damage. Regular inspection and reapplication of UV-resistant coatings can mitigate this type of degradation.

- Biological Degradation

The accumulation of organic matter, such as leaves and bird nests, on chimney covers promotes biological degradation. Moisture trapped within the organic matter accelerates corrosion and provides a breeding ground for mold and mildew. These organisms can damage coatings and sealants, compromising their protective function. Regular cleaning and removal of organic matter are essential for preventing biological degradation and preserving chimney cover integrity.

These degradation modes illustrate the need for proactive maintenance strategies. Selecting appropriate materials resistant to specific environmental stressors, coupled with regular inspection and timely action, are crucial for extending the service life and ensuring the ongoing functionality of chimney covers.

5. Secure Attachment

The secure attachment of a chimney cap is paramount to its function and the overall integrity of the chimney system. A compromised attachment negates the benefits provided by the cap and can introduce further hazards.

- Wind Resistance

A primary function of secure attachment is to resist wind forces. High winds can dislodge improperly secured caps, rendering them ineffective and potentially causing damage to surrounding property. Mechanical fasteners, such as screws or bolts, must be appropriately sized and installed to withstand anticipated wind loads. Mortar alone is often insufficient for secure long-term attachment.

- Prevention of Displacement

Secure attachment prevents the cap from shifting or becoming displaced due to vibrations from wind, seismic activity, or thermal expansion and contraction. Even minor displacement can create gaps, allowing water and animals to enter the chimney. Robust attachment methods, including the use of specialized adhesives and anchoring systems, are necessary to maintain a consistent seal.

- Material Compatibility

The attachment method must be compatible with the materials of both the chimney cap and the chimney crown. Dissimilar metals can lead to galvanic corrosion, weakening the attachment over time. Similarly, adhesives must be formulated to bond effectively with the specific materials involved and to withstand the temperature extremes encountered in chimney systems.

- Long-Term Durability

Secure attachment requires durable components and installation techniques designed to withstand the test of time. Fasteners must be corrosion-resistant, and adhesives must maintain their bond strength under prolonged exposure to environmental elements. Periodic inspections and maintenance are necessary to ensure the continued integrity of the attachment.

In conclusion, secure attachment is not merely an installation detail, but a critical factor in the performance and longevity of a chimney cap. Compromised attachment compromises the entire system, negating the protective benefits and potentially creating new hazards. Therefore, careful attention to materials, methods, and ongoing maintenance is essential.

6. Flue Obstruction

Flue obstruction represents a significant consequence of compromised chimney cap integrity. A damaged or absent chimney cap provides an entry point for debris, animals, and nesting materials, directly leading to blockage within the flue. This obstruction impedes the proper venting of combustion byproducts, creating a hazardous condition. For instance, a chimney cap missing for an extended period often accumulates leaves and twigs, forming a dense blockage that restricts airflow. Effectively, the primary function of a chimney cap is to prevent such obstructions, making maintenance and replacement crucial elements of overall chimney safety.

Addressing flue obstruction often necessitates the removal of the blockage, followed by chimney cap . Subsequent involves ensuring proper cap installation to prevent recurrence. Examples include using specialized tools to remove dense nests or hiring professionals to clear accumulated creosote exacerbated by poor ventilation. The practical significance lies in recognizing that a properly maintained chimney cap is a proactive measure, significantly reducing the likelihood of flue obstruction and related risks like carbon monoxide poisoning or chimney fires.

In summary, flue obstruction and chimney cap are intricately linked. Compromised covers invariably increase the risk of blockage, necessitating reactive measures. Prioritizing cap and maintenance is a proactive strategy, mitigating the potential for hazardous and costly obstructions. The long-term benefits of this approach outweigh the immediate costs, ensuring a safer and more efficient chimney system.

Frequently Asked Questions

The following questions address common concerns regarding chimney caps and their . These responses aim to provide clarity on important aspects of maintenance and safety.

Question 1: What constitutes a necessary chimney cap ?

Deterioration beyond minor surface rust, physical damage compromising structural integrity, or complete detachment necessitating replacement of the entire unit qualifies as necessary .

Question 2: What are the potential consequences of neglecting chimney cap ?

Neglecting can lead to water damage within the chimney structure, increased risk of chimney fires due to animal nesting and debris accumulation, and reduced efficiency of the chimney system.

Question 3: Can a homeowner perform chimney cap , or is professional assistance always required?

Minor can be performed by homeowners with appropriate skills and safety equipment. However, significant structural damage or difficult-to-access chimney caps necessitate professional intervention.

Question 4: How frequently should chimney caps be inspected for potential issues?

Chimney caps should undergo visual inspection at least twice annually, typically during spring and fall, to identify early signs of damage or deterioration.

Question 5: What materials are recommended for chimney cap replacements, and why?

Stainless steel and copper are recommended materials due to their superior resistance to corrosion and weathering compared to galvanized steel or other less durable options.

Question 6: Does insurance typically cover the cost of chimney cap ?

Insurance coverage varies depending on the cause of the damage. Damage resulting from covered perils, such as windstorms or falling debris, may be eligible for reimbursement, while damage due to neglect or normal wear and tear is generally excluded.

Properly functioning chimney caps are vital for maintaining chimney health and safety. Adherence to recommended inspection and procedures minimizes risks.

The subsequent section will delve into detailed step-by-step guides for various chimney cap procedures, emphasizing safety precautions and proper techniques.

Conclusion

This exposition has outlined the critical importance of chimney cap , encompassing inspection, maintenance, and component replacement. Key considerations include material selection, secure attachment, and the prevention of animal intrusion, water damage, and flue obstruction. Understanding these facets ensures the ongoing safety and efficiency of residential and commercial chimney systems.

Effective chimney cap are not merely a matter of property maintenance but a safeguard against potential hazards, including carbon monoxide poisoning and structural damage. Prioritizing diligent inspection and timely contributes to the longevity of the chimney infrastructure and the safety of building occupants, warranting serious consideration by all property owners.