The incident of a protective covering detaching from a vertical exhaust structure is a common occurrence resulting from severe weather conditions, age-related material degradation, or improper installation. For instance, high winds can exert significant force on the fixture, leading to its separation from the chimney structure.

Such an event compromises the integrity of the venting system, exposing it to rain, snow, debris, and nesting animals. This can lead to water damage within the home, flue blockage, and potentially hazardous conditions related to carbon monoxide buildup. Historically, these coverings were initially developed to prevent downdrafts and maintain efficient combustion, evolving over time to provide a wider range of protective functions.

The following discussion will address the potential causes of this detachment, explore subsequent risks, and outline appropriate remedial actions and preventative measures to ensure optimal chimney function and safety.

Preventative Measures Following Chimney Cap Detachment

The following outlines critical steps to be taken to mitigate risks associated with the separation of a chimney covering from its designated structure.

Tip 1: Immediate Inspection: Conduct a thorough visual assessment of the chimney and surrounding area. Document any visible damage to the chimney structure or nearby property.

Tip 2: Secure the Opening: If possible, temporarily cover the chimney opening with a durable, weather-resistant material to prevent immediate ingress of water and debris. Ensure this temporary covering does not obstruct the flue.

Tip 3: Internal Examination: Once safe access is possible, inspect the interior of the chimney flue for any obstructions, water damage, or signs of animal nesting. Debris accumulation can significantly reduce chimney draft.

Tip 4: Professional Assessment: Engage a qualified chimney sweep or professional installer to conduct a comprehensive inspection of the entire chimney system. Their expertise is crucial for identifying underlying structural issues.

Tip 5: Corrective Repairs: Based on the professional assessment, address any necessary repairs to the chimney structure, including masonry work, flue relining, or securing the base for the new protective covering.

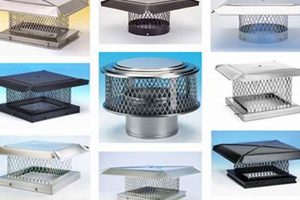

Tip 6: High-Quality Replacement: Select a replacement cap that is specifically designed for your chimney type and local climate conditions. Opt for durable materials resistant to corrosion and weather-related damage.

Tip 7: Professional Installation: Engage a qualified professional to install the replacement fixture. Proper installation is critical for ensuring a secure and lasting attachment, minimizing the risk of future detachment.

Adhering to these preventative measures and securing a swift professional assessment is essential to safeguard the functionality and safety of the chimney system and the building it serves.

Following these guidelines will ensure the secure re-establishment of the protective function for the chimney.

1. Wind Velocity

Wind velocity, characterized as the speed of air in motion, presents a significant external force acting upon chimney structures. Its intensity directly correlates with the probability of a protective covering detaching from the chimney.

- Aerodynamic Lift

Aerodynamic lift, generated by wind flowing over the surface of the chimney covering, exerts an upward force. If this lift force exceeds the gravitational force and the strength of the attachment mechanisms, the covering can become dislodged. The shape and orientation of the covering relative to the wind direction influence the magnitude of this lift.

- Shear Force

Wind exerts a shear force on the sides of the covering, creating stress on the fastening points. High wind velocity increases this shear stress, potentially leading to the failure of screws, bolts, or adhesive materials used to secure the covering to the chimney. Repeated exposure to shear stress can weaken the attachment over time.

- Turbulence and Gusts

Turbulent wind conditions and sudden gusts create fluctuating pressure zones around the chimney covering. These pressure variations can generate a “fluttering” effect, where the covering experiences rapid and repetitive stress. This repeated stress can lead to fatigue and eventual failure of the attachment points, especially in older or poorly maintained coverings.

- Vortex Shedding

At certain wind speeds, vortices (swirling air masses) can form and detach from the edges of the chimney covering. This vortex shedding creates oscillating forces on the covering, causing it to vibrate. Over time, these vibrations can loosen fasteners and weaken the structural integrity of the covering and its attachment to the chimney.

The interplay of aerodynamic lift, shear force, turbulence, and vortex shedding demonstrates the multifaceted impact of wind velocity on chimney covering integrity. Understanding these forces is crucial for selecting appropriate attachment methods and materials to mitigate the risk of detachment in regions prone to high winds.

2. Material Degradation

Material degradation constitutes a significant contributing factor to the detachment of protective chimney coverings. Over prolonged exposure to environmental elements, the constituent materials of the fixture undergo deterioration, compromising their structural integrity and rendering them susceptible to failure under external forces. This degradation manifests in various forms, including corrosion of metallic components, embrittlement of plastics, and erosion of cementitious materials. For example, a steel chimney covering subjected to consistent moisture exposure will exhibit oxidation, progressively weakening the metal until it lacks the strength to withstand wind loads. Similarly, a plastic covering exposed to ultraviolet radiation becomes brittle, cracking and fracturing under stress.

The correlation between material degradation and the detachment is further amplified by inadequate maintenance practices. Lack of regular inspection and timely repair exacerbates the degradation process, accelerating the weakening of the covering’s attachment points. For instance, if mortar joints securing the covering to the chimney structure are allowed to crumble, the reduced bonding strength elevates the likelihood of displacement during periods of high wind. Furthermore, incompatible materials used in construction or repair can accelerate deterioration through galvanic corrosion or differential expansion and contraction.

In summary, material degradation represents a critical precursor to structural failure leading to instances of chimney coverings becoming dislodged. This process is compounded by environmental exposure and inadequate maintenance, emphasizing the need for regular inspections, appropriate material selection during installation or replacement, and proactive maintenance strategies to mitigate potential risks and ensure the long-term stability of chimney systems.

3. Flue Obstruction

Flue obstruction presents a critical element in understanding the consequences following an incident where a protective chimney covering becomes detached. A clear and unobstructed flue is essential for the safe and efficient venting of combustion byproducts. When a covering is missing, the likelihood of obstructions significantly increases, leading to potential hazards and reduced system performance.

- Debris Accumulation

Without a covering, the flue becomes directly exposed to external elements. Debris such as leaves, branches, and animal nests readily enter the flue, accumulating and creating blockages. This accumulation reduces the effective cross-sectional area of the flue, impeding the flow of gases. For example, a large bird’s nest can completely block a flue, leading to smoke back-up into the living space.

- Water Saturation

Rain and snow can enter the flue when a covering is absent, saturating any accumulated debris. This wet debris becomes heavier and more compact, further restricting airflow. Moreover, moisture can damage the interior of the chimney, accelerating deterioration. A flue blocked with saturated leaves and debris can significantly impede proper drafting, increasing the risk of carbon monoxide buildup.

- Animal Intrusion

The open flue presents an inviting entry point for animals such as birds, squirrels, and raccoons. These animals may build nests within the flue, causing significant blockages. Their presence not only restricts airflow but also introduces potential health hazards due to droppings and parasites. A raccoon nesting within a flue can completely obstruct it, leading to dangerous conditions when a fireplace or furnace is in use.

- Compromised Draft

Flue obstruction directly compromises the chimney’s ability to create a proper draft. The reduced airflow impedes the efficient removal of combustion gases, leading to incomplete combustion and increased levels of carbon monoxide. This can result in a backdraft, forcing harmful gases into the building. A severely obstructed flue may render a heating appliance unsafe to operate due to the risk of carbon monoxide poisoning.

These interconnected facets of flue obstruction underscore the urgency of addressing a missing chimney covering. Failure to promptly remove obstructions and reinstate protection can lead to significant safety hazards, structural damage, and reduced efficiency of heating appliances. Addressing this situation proactively is vital to ensure the safe and efficient operation of the chimney system.

4. Water Infiltration

The dislodgement of a chimney covering directly exposes the interior chimney structure to precipitation. Water infiltration, the ingress of rainwater or snowmelt into the chimney, becomes a primary consequence. This event initiates a cascade of detrimental effects, impacting the chimney’s structural integrity and operational efficiency. Brick and mortar chimneys, particularly those of older construction, are porous and vulnerable to water absorption.

The absorbed water undergoes freeze-thaw cycles in colder climates. During freezing, the water expands, exerting pressure within the brick and mortar matrix. This repeated expansion and contraction causes cracking and spalling of the masonry, weakening the chimney’s overall structure. Furthermore, water infiltration can lead to the deterioration of the flue liner, be it clay tile or metal. Cracks in the liner compromise its ability to safely vent combustion gases, potentially leading to carbon monoxide leakage into the building. The presence of moisture also promotes the growth of mold and mildew within the chimney, further degrading materials and posing health risks to building occupants. For instance, prolonged water exposure can dissolve the binding agents in mortar, leading to sections of the chimney collapsing, as observed in numerous cases following severe winter storms.

Therefore, the detachment of the protective covering precipitates water infiltration, resulting in structural damage, reduced venting efficiency, and potential health hazards. Mitigating these consequences necessitates prompt inspection and repair following a dislodgement event. Waterproofing measures and the installation of a suitable replacement will protect the chimney from further water-related damage and ensure its continued safe operation. Prioritizing this maintenance is crucial in preserving the long-term integrity of the chimney system.

5. Animal Intrusion

The absence of a chimney covering provides unrestricted access for various animal species to enter the chimney system. This intrusion poses significant risks to both the chimney’s functionality and the health of the building’s occupants. The open flue serves as an inviting habitat for animals seeking shelter and nesting sites.

- Nesting Materials and Blockage

Animals frequently construct nests within the flue, utilizing materials such as twigs, leaves, and debris. These nests can cause significant blockages, impeding the flow of combustion gases. For instance, a bird’s nest can substantially reduce the effective diameter of the flue, compromising draft and potentially causing smoke to back up into the living space. Accumulated nesting material also increases the risk of chimney fires.

- Structural Damage

Larger animals, such as raccoons and squirrels, may cause physical damage to the chimney structure. Their claws and teeth can damage flue liners, mortar joints, and other components. This damage can exacerbate existing issues, such as cracks caused by water infiltration, further weakening the chimney’s integrity. Nesting activities can also dislodge brickwork, requiring extensive and costly repairs.

- Health Hazards

Animal droppings and debris within the chimney introduce various health hazards. Bird and rodent feces can harbor pathogens and parasites, posing risks to human health if they enter the living space. Additionally, the presence of dead animals within the chimney creates unpleasant odors and sanitation concerns. Air quality may be significantly impacted if debris from the chimney enters the ventilation system.

- Chimney Draft Impairment

The presence of animals, nesting materials, and associated debris directly impairs the chimney’s ability to create a proper draft. This reduced draft efficiency compromises the safe and effective venting of combustion byproducts, increasing the risk of carbon monoxide buildup within the dwelling. Incomplete combustion due to poor draft can also lead to inefficient heating and increased fuel consumption.

These factors highlight the crucial importance of maintaining a properly installed chimney covering. The open access resulting from its absence invites animal intrusion, leading to a cascade of negative consequences ranging from structural damage and health hazards to impaired chimney function and increased safety risks. Timely repair or replacement of the protective fixture is essential to prevent these issues and ensure the continued safety and efficiency of the chimney system.

6. Carbon Monoxide Risk

The separation of a protective chimney covering directly elevates the risk of carbon monoxide (CO) poisoning. CO, an odorless and colorless gas produced by incomplete combustion, presents a severe health hazard when ventilation systems are compromised. The compromised state following such an event disrupts normal venting, potentially leading to dangerous CO accumulation within a dwelling.

- Impaired Draft and Ventilation

A missing chimney covering allows debris, animals, and precipitation to obstruct the flue. This obstruction impedes the natural draft essential for drawing combustion gases up and out of the chimney. Consequently, CO produced by furnaces, fireplaces, or other fuel-burning appliances may not be adequately vented, leading to a build-up within the living space. For example, a blocked flue from accumulated leaves can cause CO to backdraft into a home, even with a properly functioning appliance.

- Compromised Appliance Efficiency

The disruption of airflow due to a missing chimney covering affects the combustion process within the appliance. Incomplete combustion results in increased CO production. This is particularly critical in older, less efficient appliances that rely on a consistent draft for optimal performance. A furnace struggling to vent properly will produce elevated levels of CO, compounding the risk when ventilation is already compromised.

- Flue Liner Degradation

The lack of a covering exposes the flue liner to weather elements. Water infiltration and freeze-thaw cycles can degrade the liner, creating cracks and breaches. These breaches allow CO to leak directly into the building’s structure, bypassing the intended venting path. Deteriorated flue liners are a common factor in CO incidents, especially in older homes where regular inspections are neglected.

- Backdrafting

Negative pressure within a home, caused by exhaust fans or tightly sealed construction, can exacerbate the risk. The compromised venting, combined with negative pressure, can cause backdrafting the reversal of airflow in the chimney. This forces CO and other combustion gases back into the living space. Modern energy-efficient homes, while beneficial in other respects, can increase the risk of backdrafting if chimney systems are not properly maintained.

These interconnected factors underscore the critical importance of promptly addressing a missing chimney fixture. The elevated risk of CO poisoning necessitates immediate inspection and repair to ensure the safe and efficient venting of combustion byproducts. The installation of CO detectors throughout the home provides an additional layer of protection but should not be considered a substitute for proper chimney maintenance.

Frequently Asked Questions Regarding Detached Chimney Coverings

The following addresses common inquiries related to incidents where a protective chimney fixture has become dislodged, offering insights into potential causes, risks, and necessary actions.

Question 1: What factors typically contribute to chimney covering detachment?

Several factors can precipitate such an event. High winds, material degradation due to weathering, improper initial installation, and structural damage to the chimney itself are common causes.

Question 2: What immediate steps should be taken upon discovering a detached fixture?

The chimney opening should be temporarily covered to prevent further water or debris entry. A comprehensive inspection of the chimney structure and surrounding area should be conducted to assess any visible damage.

Question 3: Is it possible to temporarily repair the covering, or must it be completely replaced?

Temporary repairs are generally discouraged, as they may not provide adequate protection and could pose a safety risk. A complete replacement with a properly sized and installed covering is the recommended course of action.

Question 4: What potential hazards arise if a missing chimney covering is not promptly addressed?

Significant hazards include water damage to the chimney and building interior, flue blockage from debris or animals, reduced heating efficiency, increased risk of carbon monoxide exposure, and accelerated deterioration of the chimney structure.

Question 5: What are the key considerations when selecting a replacement chimney covering?

The covering material should be durable and resistant to corrosion and weather-related damage. It should also be appropriately sized for the chimney flue and designed to prevent downdrafts and animal intrusion. Professional guidance is recommended for selecting the appropriate fixture.

Question 6: How often should a chimney be inspected to prevent future incidents of covering detachment?

Annual chimney inspections are highly recommended. Regular inspections can identify potential issues, such as material degradation or loose attachments, before they lead to more significant problems.

Prompt action and appropriate maintenance are critical to mitigate the risks associated with detached protective coverings and ensure the safe and efficient operation of the chimney system.

The subsequent section details the selection and installation of a suitable replacement, emphasizing the importance of professional expertise.

Conclusion

The preceding analysis has detailed the cascading consequences initiated when a chimney cap blew off. From compromised structural integrity and increased risk of water damage to potential carbon monoxide exposure and animal intrusion, the ramifications extend beyond mere inconvenience. The disruption to the chimney’s designed functionality necessitates immediate and informed action.

The information presented underscores the critical importance of proactive chimney maintenance and swift remediation following any incident of protective covering detachment. Neglecting these concerns invites escalating hazards, ultimately jeopardizing the safety and well-being of building occupants. Continued vigilance and adherence to best practices remain paramount in ensuring the long-term integrity and performance of chimney systems.