A specialized covering designed to mitigate the effects of wind on chimney performance is a crucial element for efficient venting. These devices prevent downdrafts, where wind forces air back down the chimney, potentially disrupting heating systems and introducing smoke or dangerous gases into the living space. These often incorporate features such as directional cowls or strategically placed deflectors.

The employment of such a device offers several benefits, including improved draft consistency, reduced risk of backpuffing, and protection from debris and precipitation. Historically, these components evolved from simple rain guards to sophisticated designs incorporating aerodynamic principles. This evolution addresses challenges of inconsistent heating and safety hazards in structures exposed to strong or unpredictable wind patterns.

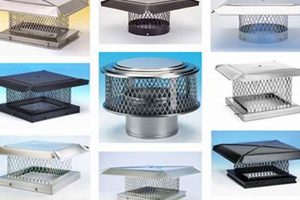

The following discussion will delve further into the materials used in their construction, installation considerations, and maintenance practices necessary for optimal performance and longevity of these protective devices. Different types of designs and their suitability for various chimney systems will also be explored.

Essential Considerations for Enhanced Chimney Performance

The following guidance focuses on selecting, installing, and maintaining protective chimney coverings, maximizing their effectiveness in adverse weather conditions.

Tip 1: Material Selection: Prioritize durable materials like stainless steel or copper, resistant to corrosion and extreme temperatures. Proper material ensures longevity and sustained performance in harsh environments.

Tip 2: Sizing Accuracy: Precisely measure the chimney flue’s dimensions before selecting a covering. Incorrect sizing compromises effectiveness and potentially obstructs airflow.

Tip 3: Professional Installation: Engage qualified professionals for installation. Correct installation guarantees secure attachment and optimal functionality, preventing premature failure.

Tip 4: Regular Inspection: Conduct routine visual inspections for signs of damage or deterioration. Early detection allows for timely repairs, preventing costly replacements.

Tip 5: Debris Removal: Regularly clear accumulated debris, such as leaves and branches, from the covering. Obstructions hinder airflow and reduce efficiency.

Tip 6: Local Building Codes: Adhere to all applicable local building codes and regulations. Compliance ensures safety and avoids potential penalties.

Tip 7: Consider prevailing wind direction: Some designs offer directional capabilities. Align the directional cowl with the prevailing wind for optimum protection.

Implementing these considerations ensures effective protection against downdrafts, improves heating system performance, and enhances overall safety.

The subsequent sections will cover common issues, troubleshooting, and advanced design features that optimize protective chimney covering performance.

1. Downdraft prevention

Downdraft prevention constitutes a primary function of a wind-resistant chimney termination device. Downdrafts occur when wind forces air down the chimney flue, disrupting the natural upward flow of exhaust gases. This phenomenon can introduce smoke, carbon monoxide, and other combustion byproducts into the living space, posing significant safety risks. The specialized cap mitigates this by employing aerodynamic principles or physical barriers to deflect wind away from the flue opening.

The effectiveness of the cap hinges on its design, which must account for prevailing wind patterns and chimney height. For instance, a chimney situated on the leeward side of a building is more susceptible to downdrafts due to turbulence. Similarly, inadequate chimney height can reduce draft and increase the likelihood of wind interference. A properly designed and installed termination device counteracts these effects, maintaining consistent upward airflow even under adverse wind conditions. Cases of residential buildings with fireplaces experiencing smoke spillage were often due to a lacking of efficient device for downdraft prevention.

In summary, downdraft prevention is not merely a desirable feature but a critical operational requirement of a wind-resistant chimney covering. Its implementation directly affects occupant safety and heating appliance performance. Selection and installation should prioritize designs that demonstrably minimize the impact of wind on chimney draft, ensuring reliable and safe operation. The interaction between the termination device and the existing chimney system requires careful assessment to optimize its protective capabilities.

2. Material Durability

Material durability constitutes a foundational element of an effective windproof chimney cap. The cap is constantly exposed to environmental stressors, including precipitation, extreme temperatures, and corrosive flue gases. Failure to withstand these conditions compromises the cap’s structural integrity and functional performance, leading to premature degradation and potential safety hazards. For example, a chimney cap constructed from low-grade steel may corrode rapidly in coastal environments or when exposed to acidic condensation from high-efficiency furnaces. This corrosion weakens the cap’s structure, potentially leading to collapse or detachment, thereby negating its windproof capabilities and creating a pathway for water and debris to enter the chimney.

The selection of appropriate materials directly impacts the longevity and reliability of the chimney cap. Stainless steel alloys, particularly those containing molybdenum, offer superior resistance to corrosion and high-temperature oxidation, making them well-suited for demanding chimney environments. Copper, another durable option, exhibits excellent corrosion resistance and develops a protective patina over time, further enhancing its lifespan. Real-world case studies have demonstrated that chimney caps constructed from high-quality materials require less frequent maintenance and replacement, resulting in lower long-term costs and improved system safety. Therefore, the initial investment in durable materials represents a prudent strategy for ensuring the continued effectiveness of the windproof chimney cap.

In summary, material durability is not merely a superficial attribute but a critical determinant of a windproof chimney cap’s performance and lifespan. Selecting materials that can withstand environmental stressors and resist corrosion is essential for maintaining the cap’s structural integrity and safeguarding the chimney system. This understanding underscores the practical significance of specifying high-quality materials during the selection and installation process, thereby ensuring long-term reliability and minimizing the risk of failure. Neglecting this aspect can lead to accelerated degradation, compromised performance, and potential safety hazards, highlighting the importance of prioritizing material durability in chimney cap design and selection.

3. Proper Sizing

Accurate dimensional matching between a windproof chimney cap and the corresponding chimney flue is paramount for optimal functionality. Deviations from specified measurements compromise the cap’s intended performance, potentially negating its protective benefits.

- Effective Draft Control

An undersized cap restricts airflow, impeding draft and potentially causing smoke to back up into the living space. Conversely, an oversized cap may allow excessive wind penetration, negating its downdraft prevention capabilities. Correct sizing ensures optimal draft while minimizing wind-induced disturbances.

- Secure Mechanical Fit

A cap that is either too small or too large is less likely to form a secure connection with the chimney flue. An improperly fitted cap is vulnerable to displacement by high winds or heavy precipitation, defeating its protective purpose and potentially causing damage to the chimney structure.

- Prevention of Debris Ingress

Imprecise sizing creates gaps between the cap and the flue, allowing leaves, twigs, and other debris to enter the chimney. Accumulated debris obstructs airflow, increases the risk of chimney fires, and reduces heating system efficiency. Accurate sizing minimizes these vulnerabilities.

- Compliance with Building Codes

Many building codes stipulate specific requirements for chimney cap dimensions relative to flue size. Failure to comply with these codes can result in inspection failures, fines, and potential safety risks. Proper sizing ensures adherence to applicable regulations.

The interconnection between accurate chimney flue measurements and appropriately sized windproof chimney caps fundamentally dictates the system’s overall efficacy. Rigorous adherence to dimensional specifications enhances safety, maximizes performance, and ensures regulatory compliance.

4. Secure Installation

The integration of a windproof chimney cap is contingent upon a structurally sound and mechanically robust installation. A failure in secure attachment undermines the device’s intended function, irrespective of its inherent design advantages. Improper installation methods render the cap vulnerable to displacement by wind forces, rendering it ineffective at preventing downdrafts and admitting precipitation or debris. For example, a cap affixed with inadequate fasteners or an inappropriate sealing compound may detach during high-wind events, negating any protective benefits it might otherwise offer.

Proper installation protocols necessitate the use of corrosion-resistant fasteners, appropriate for the chimney material, and a high-temperature sealant to establish a weathertight seal. Furthermore, adherence to manufacturer specifications regarding attachment methods is essential. A competent installer will assess the chimney’s structural integrity before commencing installation, addressing any pre-existing weaknesses that could compromise the cap’s securement. Consider a case where a homeowner attempted a self-installation without proper training. The use of incorrect fasteners resulted in accelerated corrosion and subsequent detachment within a single heating season. This situation underscores the importance of skilled installation practices.

In summation, secure installation is not merely an ancillary step but an indispensable prerequisite for the successful deployment of a windproof chimney cap. Its direct influence on the cap’s stability, longevity, and functional efficacy mandates strict adherence to industry best practices and manufacturer guidelines. Neglecting this aspect exposes the system to premature failure, jeopardizing both property and safety. A properly installed cap ensures persistent performance, providing long-term protection against wind-induced issues and maintaining the integrity of the chimney system.

5. Debris Shielding

Effective debris shielding is an inherent characteristic of a well-designed windproof chimney cap, significantly impacting the system’s long-term performance and safety. Shielding prevents foreign materials from entering the chimney flue, safeguarding against blockages and potential hazards.

- Prevention of Chimney Obstruction

The accumulation of leaves, twigs, animal nests, and other debris can significantly impede the natural draft within a chimney. This obstruction may cause smoke to back up into the living space, posing a carbon monoxide poisoning risk. A properly designed shielding system prevents these materials from entering the flue, maintaining unobstructed airflow.

- Mitigation of Fire Hazards

Dry leaves and other combustible debris lodged within a chimney flue can ignite, resulting in a chimney fire. The presence of a debris shield significantly reduces the likelihood of such an event by preventing the accumulation of flammable materials. Regular removal of creosote and the presence of a debris shield work in tandem to improve safety.

- Protection Against Animal Intrusion

Chimneys provide an attractive nesting site for birds, squirrels, and other animals. These animals can block the flue, introduce parasites, and create unpleasant odors. A well-designed chimney cap with a suitable mesh or screen deters animal entry, preventing these problems.

- Reduction of Moisture Infiltration

Debris accumulating within the chimney flue can trap moisture, accelerating corrosion and deterioration of the chimney’s internal components. Effective shielding minimizes moisture infiltration by preventing debris from acting as a sponge, thereby extending the lifespan of the chimney structure.

The attributes of adequate debris shielding contribute significantly to the operational effectiveness and long-term durability of a windproof chimney cap. Preventing obstructions, mitigating fire hazards, deterring animal intrusion, and reducing moisture infiltration are critical functions that safeguard the integrity and performance of the entire chimney system.

6. Flue Draft Optimization

Flue draft optimization, the process of ensuring consistent and adequate upward airflow within a chimney, is inextricably linked to the functionality of a windproof chimney cap. An effective chimney cap serves not only to prevent downdrafts but also to enhance, or at least not impede, the natural draft necessary for efficient combustion and venting of exhaust gases. The cause-and-effect relationship is such that an improperly designed or installed cap can negate the positive effects of an otherwise well-functioning chimney system, leading to reduced heating appliance efficiency and increased risks of indoor air pollution.

The importance of flue draft optimization as a component of a windproof chimney cap lies in its ability to maintain consistent venting under varying wind conditions. For instance, a cap designed with an insufficient opening can restrict airflow, causing incomplete combustion and increasing creosote buildup, which heightens the risk of chimney fires. Conversely, a cap with excessive openings may allow wind to disrupt the draft, leading to intermittent backdrafts and reduced heating appliance performance. Real-life examples include instances where homeowners experienced increased fuel consumption and more frequent chimney cleaning after installing a cap that, while preventing downdrafts, failed to optimize the flue draft. Therefore, the integration of design features that promote upward airflow, such as strategically placed vents or aerodynamic cowls, is crucial for ensuring optimal flue draft optimization.

In conclusion, flue draft optimization is not merely a secondary consideration but a vital element of a comprehensive windproof chimney cap design. A balanced approach that combines downdraft prevention with the promotion of consistent upward airflow is essential for maximizing heating appliance efficiency, minimizing safety risks, and ensuring the long-term performance of the chimney system. Overlooking this aspect can lead to compromised venting, increased maintenance requirements, and potential health hazards, underscoring the practical significance of understanding the intricate connection between flue draft optimization and windproof chimney cap functionality.

7. Code Compliance

Adherence to prevailing building codes constitutes a non-negotiable aspect of integrating a windproof chimney cap into any structure. These codes, established by governing bodies, specify minimum performance standards for chimney systems, including requirements for termination devices. Code compliance directly affects building safety and is, therefore, legally mandated in most jurisdictions. Ignoring these regulations can lead to inspection failures, financial penalties, and, more significantly, compromised safety for building occupants.

The stipulations within building codes regarding chimney caps often address aspects such as minimum height above the roofline, materials of construction, and mesh size (when applicable). For example, some codes mandate that chimney caps be constructed of corrosion-resistant materials like stainless steel or copper to ensure longevity and structural integrity in harsh weather conditions. Furthermore, the mesh size of spark arrestors, often integrated into windproof chimney caps, is frequently regulated to prevent the escape of embers while maintaining adequate airflow. Deviations from these requirements, even if seemingly minor, can have cascading effects on the overall chimney system performance and safety. Homes failing fireplace inspections commonly violate chimney cap code. For example, using low quality material that rusts, or the improper height of the cap above the chimney and roofline.

In summary, code compliance is not merely a bureaucratic hurdle but a fundamental prerequisite for the safe and effective operation of a windproof chimney cap. It ensures that the cap meets minimum performance standards, promotes long-term durability, and safeguards building occupants from potential hazards associated with malfunctioning chimney systems. Therefore, thorough familiarity with local building codes and strict adherence to their provisions are essential for any construction or renovation project involving chimney termination devices. Strict adherence to code ensures the cap’s longevity and ability to perform it’s duty, ultimately protecting the building occupants and contents.

Frequently Asked Questions

This section addresses common inquiries regarding the selection, installation, and maintenance of windproof chimney caps. Information provided aims to clarify technical aspects and facilitate informed decision-making.

Question 1: What differentiates a standard chimney cap from a windproof model?

A standard chimney cap primarily protects against rain and debris. A windproof chimney cap incorporates specialized design features, such as directional cowls or internal deflectors, to actively counteract the negative effects of wind on chimney draft.

Question 2: Can a windproof chimney cap be installed on any type of chimney?

Compatibility depends on the chimney’s construction and flue dimensions. A professional assessment is recommended to determine the appropriate cap design and ensure a secure, code-compliant installation. Certain chimney types may necessitate custom solutions.

Question 3: How does a windproof chimney cap prevent downdrafts?

These caps utilize aerodynamic principles to redirect wind currents away from the flue opening. This creates a low-pressure zone above the chimney, promoting upward draft and preventing wind from forcing air down the flue.

Question 4: What materials are best suited for a windproof chimney cap in coastal environments?

Stainless steel (316 grade) or copper are recommended due to their superior resistance to corrosion from salt air. Galvanized steel is generally unsuitable for coastal applications due to its susceptibility to rust.

Question 5: How often should a windproof chimney cap be inspected and maintained?

Annual inspections are advisable. Debris should be removed as needed, and any signs of corrosion or damage should be addressed promptly. Professional chimney sweeps often include cap inspection as part of their service.

Question 6: Does installing a windproof chimney cap guarantee the complete elimination of downdrafts?

While these caps significantly reduce downdrafts, complete elimination cannot be guaranteed in all situations. Chimney height, surrounding structures, and extreme weather conditions can still influence draft performance. Optimal performance is dependent on correct selection, installation, and maintenance.

Effective windproof chimney cap functionality hinges on proper product selection, professional installation, and adherence to recommended maintenance practices. Consult qualified chimney professionals for personalized guidance.

The following section will delve into troubleshooting common issues related to windproof chimney caps, addressing potential performance concerns and offering practical solutions.

Windproof Chimney Cap

The preceding discussion has provided a comprehensive overview of the windproof chimney cap, encompassing its definition, benefits, selection criteria, installation considerations, and maintenance requirements. Crucial aspects, including material durability, proper sizing, secure installation, debris shielding, flue draft optimization, and code compliance, have been thoroughly examined. The information presented underscores the significance of these devices in maintaining safe and efficient chimney operation, particularly in environments prone to adverse wind conditions.

Given the critical role that a properly functioning windproof chimney cap plays in safeguarding property and ensuring occupant well-being, diligent attention to the aforementioned details is paramount. Consult qualified professionals for expert guidance and services related to chimney system design, installation, and maintenance. Prioritizing quality and adherence to industry best practices ensures the long-term reliability and effectiveness of this essential component.