Addressing moisture intrusion from a chimney structure involves identifying the source of the leak and implementing appropriate repairs. Failure to promptly resolve chimney leaks can lead to significant structural damage, including deterioration of masonry, wood rot, and potential mold growth within the building.

Maintaining a dry chimney contributes to the overall longevity of the structure and safeguards the interior environment from water damage. Historically, chimneys were built with simple designs that often lacked adequate protection against the elements, resulting in frequent leaks. Modern construction techniques and sealant technologies offer improved durability and water resistance.

The following sections detail common causes of chimney leaks and the methods employed to remediate them. These include inspecting the chimney crown, flashing, and brickwork, as well as addressing potential issues with the chimney cap or flue liner. Each of these areas requires careful evaluation and, if necessary, professional attention.

Remediation Strategies for Chimney Moisture Intrusion

The following strategies offer guidance on identifying and addressing sources of moisture ingress into a chimney structure. Employing these approaches can mitigate potential damage and maintain structural integrity.

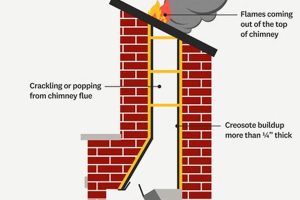

Tip 1: Inspect the Chimney Crown: The chimney crown, the concrete or masonry cap at the top of the chimney, is often the first line of defense against water penetration. Cracks or deterioration in the crown allow water to seep into the chimney’s interior. Repair or replacement of the crown may be necessary to restore its protective function.

Tip 2: Evaluate Flashing Integrity: Flashing, the metal sheeting installed at the intersection of the chimney and the roof, prevents water from running down the chimney’s exterior and entering the building. Damaged, corroded, or improperly installed flashing can lead to significant leaks. Careful inspection and repair, or replacement, is crucial.

Tip 3: Assess Brick and Mortar Condition: Over time, brick and mortar can deteriorate due to weathering and freeze-thaw cycles. Cracks, spalling (flaking), or crumbling mortar joints create pathways for water intrusion. Tuckpointing (replacing damaged mortar) and applying a masonry sealant can help prevent water from penetrating the chimney’s structure.

Tip 4: Examine the Chimney Cap: A chimney cap serves to prevent rain, snow, and debris from entering the flue. A missing or damaged cap can significantly increase the amount of water entering the chimney. Replacing or repairing the cap is a relatively simple, yet effective, measure.

Tip 5: Check the Flue Liner: The flue liner, which protects the chimney walls from corrosive combustion byproducts, can also be a source of leaks if it is cracked or damaged. Water can enter the chimney through these breaches. A thorough inspection and potential relining of the flue may be required.

Tip 6: Address Condensation Issues: In some cases, moisture within the chimney is not due to external leaks, but rather to condensation of combustion gases. Ensuring proper ventilation and insulation can reduce condensation buildup and prevent water damage.

Consistent monitoring and proactive maintenance are critical to preventing and addressing chimney leaks. Addressing these issues promptly can minimize damage and preserve the chimney’s structural integrity.

The subsequent sections provide more detailed information regarding specific repair techniques and preventative measures.

1. Crown Repair

The chimney crown, situated at the uppermost section of a chimney, functions as a protective barrier against environmental elements. Deterioration of this component frequently contributes to water infiltration, making its maintenance crucial when addressing chimney leakage issues. This section outlines key facets of chimney crown repair and their implications for resolving water intrusion problems.

- Material Degradation and Crack Formation

Chimney crowns are typically constructed from concrete or masonry. Over time, exposure to freeze-thaw cycles, precipitation, and temperature fluctuations causes these materials to crack and degrade. Cracks provide direct pathways for water to enter the chimney structure, leading to internal damage. Identifying and addressing these cracks is a primary step in preventing water intrusion.

- Importance of Proper Crown Design

A properly designed crown extends beyond the flue and incorporates a drip edge to direct water away from the chimney. Inadequate overhang or a missing drip edge allows water to run down the chimney’s sides, increasing the likelihood of moisture penetration. Ensuring the crown’s design is effective in diverting water is essential for long-term protection.

- Repair Techniques for Damaged Crowns

Minor cracks in a chimney crown can often be repaired using specialized patching compounds designed for masonry. These compounds fill the cracks, preventing water from entering. More extensive damage, such as crumbling or significant cracking, necessitates complete crown reconstruction. The appropriate repair technique depends on the severity of the deterioration.

- Preventative Sealing and Waterproofing

Applying a waterproof sealant to a repaired or newly constructed chimney crown provides an additional layer of protection against water penetration. Sealants prevent water from being absorbed into the crown material, extending its lifespan and reducing the risk of future leaks. The application of a suitable sealant is a proactive measure in maintaining a dry chimney system.

In summation, crown repair encompasses material assessment, design evaluation, implementation of appropriate repair methodologies, and application of preventative measures. These interconnected elements of crown maintenance are integral to resolving chimney leaks and ensuring the structural integrity of the chimney system. Addressing the chimney crown directly contributes to effective moisture management.

2. Flashing Replacement

Compromised flashing is a common source of chimney leaks, rendering its replacement a critical component of remediating water intrusion. The metal flashing, installed where the chimney meets the roof, creates a watertight seal preventing rainwater from penetrating the roof structure and causing internal damage. Deterioration, improper installation, or physical damage to the flashing compromise its function, leading to leakage. Effective chimney leak remediation frequently necessitates complete flashing replacement.

Consider a scenario where a homeowner experiences water stains on the ceiling surrounding the chimney. An inspection reveals corroded and improperly sealed flashing. Attempts to patch the flashing prove ineffective due to the extent of the damage. Replacing the flashing with new, correctly installed material is essential to eliminate the leak and prevent further water damage. Improperly installed or aged flashing fails to properly divert water away from the chimney-roof intersection, allowing water to seep into the attic or living spaces. This, in turn, can lead to mold growth, wood rot, and compromised structural integrity of the roof.

Flashing replacement, therefore, represents a direct intervention to address a specific vulnerability in the chimney system. When properly executed, the new flashing establishes a reliable barrier against water intrusion, effectively resolving the leak. However, successful replacement requires careful attention to detail, including selecting appropriate materials, ensuring proper sealing, and integrating the flashing seamlessly with both the chimney and the roofing materials. The efficacy of flashing replacement as a solution is inextricably linked to the quality of the installation process.

3. Mortar Tuckpointing

Mortar tuckpointing plays a significant role in chimney leak remediation. As mortar deteriorates, the chimney’s structural integrity and its ability to repel water are compromised. Addressing failing mortar is therefore a fundamental step in resolving chimney leakage issues.

- Mortar Deterioration as a Water Entry Point

Over time, mortar joints between bricks or stones erode due to weathering, freeze-thaw cycles, and acid rain. This erosion creates cracks and voids, providing direct pathways for water to penetrate the chimney’s structure. Untreated, such deterioration allows water to seep into the interior of the building, leading to damage. Mortar tuckpointing, replacing the deteriorated mortar, effectively eliminates these entry points.

- Structural Integrity and Mortar Condition

The condition of the mortar directly impacts the structural stability of the chimney. Weakened mortar joints compromise the chimney’s ability to withstand wind loads and seismic activity. Water penetration accelerates this deterioration, further weakening the structure. Tuckpointing restores the mortar’s integrity, reinforcing the chimney and preventing collapse or further damage.

- Tuckpointing Techniques and Material Selection

Effective tuckpointing requires the removal of deteriorated mortar to a specified depth and the careful application of new mortar that matches the original in composition and color. Proper technique ensures a strong bond between the new mortar and the existing masonry. Using the wrong type of mortar can lead to accelerated deterioration and further leakage problems. Careful material selection is therefore essential for long-term success.

- Preventative Maintenance and Long-Term Protection

While tuckpointing addresses existing mortar damage, it also serves as a preventative measure. By restoring the mortar joints, the chimney’s resistance to water penetration is significantly improved. Regular inspections and timely tuckpointing can prevent minor mortar damage from escalating into major structural problems and costly repairs. Proactive maintenance extends the lifespan of the chimney and safeguards the building from water damage.

In summary, mortar tuckpointing is not merely an aesthetic repair; it is a critical intervention that addresses water intrusion, reinforces structural integrity, and provides long-term protection against chimney leaks. By focusing on the mortar joints, tuckpointing addresses a primary vulnerability of chimney structures and effectively contributes to a comprehensive solution for water damage prevention.

4. Cap Installation

Chimney cap installation represents a crucial step in mitigating chimney leaks. The absence of a functional cap exposes the flue to direct precipitation, debris accumulation, and animal intrusion. Water entering the flue accelerates deterioration of the flue liner, mortar joints, and potentially damages connected heating appliances. Installing a properly sized and constructed cap addresses this vulnerability, effectively preventing a significant source of water entry. For instance, during periods of heavy rainfall, an uncapped chimney can collect substantial amounts of water, leading to interior leaks and structural damage over time. A cap acts as a barrier, deflecting rainwater and preventing it from entering the system.

The selection of an appropriate cap material is also important. Stainless steel caps offer superior durability and resistance to corrosion compared to galvanized steel or other materials. Furthermore, the cap’s design should facilitate adequate ventilation while preventing the ingress of rain and snow. A poorly designed cap may restrict airflow, leading to condensation issues within the chimney. Correct installation is paramount; a loose or improperly secured cap can be dislodged by wind, rendering it ineffective. Professional installation ensures a secure fit and long-term functionality, safeguarding the chimney from water damage.

In essence, chimney cap installation is a proactive measure that directly addresses a primary cause of chimney leaks. By preventing precipitation and debris from entering the flue, a well-installed cap contributes significantly to the overall health and longevity of the chimney structure. While other repairs, such as flashing replacement or tuckpointing, may address existing damage, cap installation serves as a preventative measure, reducing the likelihood of future leaks and associated structural problems.

5. Liner Inspection

A comprehensive chimney leakage assessment invariably necessitates a thorough inspection of the flue liner. The liner serves as a protective barrier, channeling combustion byproducts safely away from the building while shielding the chimney’s masonry structure from corrosive substances. Damage to the liner can precipitate or exacerbate leakage issues, making its condition central to determining appropriate remediation strategies.

- Identifying Cracks and Deterioration

Cracks, spalling, or other forms of deterioration within the flue liner provide direct pathways for water intrusion. Precipitation entering through the chimney top, or condensation forming within the flue, can seep through these breaches and into the chimney structure. Such damage can often be identified visually, using specialized cameras, or through smoke tests. Early detection of liner damage is critical in preventing further structural deterioration and associated leaks.

- Assessing Liner Material Compatibility

Flue liners are constructed from various materials, including clay tile, metal, or cast-in-place concrete. Each material possesses different properties and is suited for specific applications. Incompatibility between the liner material and the fuel type used in the appliance can lead to accelerated deterioration and subsequent leakage. Ensuring the liner material is appropriate for the intended use is a fundamental aspect of chimney maintenance and leak prevention.

- Evaluating Joint Integrity

Many flue liners, particularly those constructed from clay tile, consist of multiple sections joined together. The integrity of these joints is crucial for maintaining a watertight seal. Deteriorated or improperly sealed joints allow water to penetrate the liner and enter the chimney structure. Careful inspection of these joints is essential for identifying potential leak sources.

- Detecting Obstructions and Condensation Issues

Obstructions within the flue, such as animal nests or debris accumulation, can trap moisture and contribute to liner deterioration. Similarly, inadequate insulation or ventilation can lead to excessive condensation within the flue, accelerating corrosion and water damage. A thorough liner inspection should include assessment for obstructions and conditions that promote condensation buildup.

The insights gained from a comprehensive liner inspection are indispensable in formulating effective chimney leak remediation strategies. By identifying the specific nature and extent of liner damage, appropriate repairs, such as relining or patching, can be implemented to restore the chimney’s structural integrity and prevent further water intrusion. Neglecting the flue liner during a leakage assessment can result in incomplete repairs and recurring problems.

6. Waterproofing Application

Waterproofing application represents a proactive approach within chimney maintenance designed to prevent water intrusion. While other interventions address existing damage, waterproofing aims to enhance the chimney’s resistance to moisture penetration, thereby mitigating future leaks. Its application is considered a preventative measure, particularly after completing repairs such as tuckpointing or crown reconstruction.

- Selection of Appropriate Waterproofing Products

The efficacy of waterproofing hinges on selecting the correct product for the chimney’s materials. Masonry sealants, siloxanes, and other specialized coatings offer varying levels of protection and compatibility with different brick, stone, and mortar compositions. Improper selection can lead to ineffective waterproofing or, in some cases, damage to the chimney structure. Choosing a breathable sealant is often preferable to allow moisture vapor to escape from within the masonry, preventing freeze-thaw damage.

- Surface Preparation and Application Techniques

Proper surface preparation is paramount for successful waterproofing. The chimney surface must be clean, dry, and free of loose debris. Existing cracks or deteriorated mortar should be repaired before sealant application. The sealant should be applied evenly, following the manufacturer’s instructions to ensure complete coverage and penetration. Inadequate preparation or improper application techniques can compromise the sealant’s effectiveness and reduce its lifespan.

- Longevity and Maintenance of Waterproofing Treatments

Waterproofing treatments are not permanent and require periodic reapplication to maintain their protective properties. The lifespan of a sealant depends on environmental factors, such as exposure to sunlight, rain, and temperature fluctuations. Regular inspections can identify signs of sealant degradation, such as cracking or peeling, indicating the need for reapplication. Maintaining the waterproofing treatment ensures continued protection against water intrusion.

- Integration with Other Chimney Repair Strategies

Waterproofing application is most effective when integrated with other chimney repair strategies. For instance, after tuckpointing deteriorated mortar joints, applying a waterproofing sealant to the entire chimney surface provides an additional layer of protection. Similarly, after repairing a damaged chimney crown, sealing the crown helps prevent future water penetration. Combining waterproofing with other repairs maximizes the chimney’s resistance to moisture and extends its lifespan.

The strategic application of waterproofing treatments significantly contributes to preventing chimney leaks. By enhancing the chimney’s ability to repel water, waterproofing minimizes the risk of structural damage and internal water intrusion. When integrated with other repair and maintenance practices, waterproofing serves as a crucial component in ensuring the chimney’s long-term health and performance.

Frequently Asked Questions

The following addresses common inquiries regarding the identification, repair, and prevention of chimney leaks. The information provided aims to clarify essential concepts related to maintaining a dry and structurally sound chimney system.

Question 1: What are the primary indicators of a leaking chimney?

Indicators include water stains on ceilings or walls adjacent to the chimney, damp or crumbling brickwork, the presence of efflorescence (white, powdery deposits) on the chimney exterior, and a musty odor emanating from the fireplace or chimney area. Each of these signs suggests water is penetrating the chimney structure.

Question 2: Can a chimney leak be safely ignored if the amount of water intrusion appears minimal?

Ignoring a chimney leak, regardless of its perceived severity, is inadvisable. Even small amounts of water can lead to significant long-term damage, including wood rot, mold growth, and deterioration of the chimney’s structural components. Addressing leaks promptly prevents escalation of these issues.

Question 3: What is the expected lifespan of a chimney crown repair?

The lifespan of a chimney crown repair depends on factors such as the quality of materials used, the expertise of the installer, and environmental conditions. A properly constructed and sealed crown can last for 15 to 20 years. Regular inspections are essential to identify potential problems early.

Question 4: Is DIY flashing replacement recommended for a novice homeowner?

Flashing replacement requires specialized skills and tools to ensure a watertight seal. Improper installation can lead to more severe leaks and structural damage. Engaging a qualified professional is generally recommended for flashing replacement projects.

Question 5: How frequently should a chimney be inspected for potential leaks?

Annual chimney inspections are recommended to identify potential problems early. Inspections should be conducted by a qualified chimney sweep or a certified chimney inspector. Regular inspections allow for proactive maintenance and prevent costly repairs.

Question 6: Are there specific types of trees that should be avoided near a chimney to prevent damage or leaks?

Trees with aggressive root systems, such as willows and poplars, should be planted a safe distance from the chimney to prevent root intrusion into the foundation. Overhanging branches should also be trimmed to prevent debris accumulation on the chimney and potential damage from falling limbs during storms.

Prompt attention to chimney leaks is crucial for maintaining structural integrity and preventing water damage. Regular inspections and timely repairs are essential components of responsible home maintenance.

The subsequent section explores the long-term financial implications of neglecting chimney maintenance and the potential costs associated with extensive repairs.

Concluding Remarks

This discourse has illuminated key considerations in addressing chimney water intrusion, encompassing identification, remediation strategies such as crown repair and flashing replacement, preventative measures like waterproofing, and the importance of regular inspections. A multifaceted approach, tailored to the specific circumstances of the leak, remains paramount in ensuring long-term structural integrity.

Neglecting chimney maintenance carries significant financial and safety implications. Timely intervention, informed by professional assessment and executed with meticulous attention to detail, represents a prudent investment in preserving property value and safeguarding against potential hazards. The decision to address chimney leaks proactively mitigates escalating damage and associated costs, securing the chimney’s function for years to come.