A vertical structure integrated within a building’s interior facilitates the controlled venting of combustion byproducts from heating appliances or fireplaces. These structures are designed to safely expel smoke, gases, and particulate matter away from the living space, contributing to indoor air quality and fire safety. The system typically comprises a flue, which is a duct or pipe that carries the exhaust, and a termination point, usually extending above the roofline.

Properly functioning venting systems are essential for efficient heating and the prevention of carbon monoxide poisoning. Their design and construction must adhere to stringent building codes and safety standards to ensure reliable performance and minimize risks associated with incomplete combustion. Historically, these internal structures have been central architectural features, influencing room layout and providing a focal point for social gatherings, especially in colder climates. Their presence signifies a reliable source of warmth and a fundamental component of domestic comfort.

The following sections will address topics related to selection criteria, installation procedures, maintenance practices, and the relevant safety regulations governing these critical building elements. Further discussion will explore the various materials used in their construction and common troubleshooting scenarios.

Tips for Maintaining Indoor Chimneys

Maintaining a functional and safe venting system is critical for any structure utilizing an indoor chimney. Adherence to these guidelines promotes efficiency, reduces the risk of fire, and ensures proper exhaust of combustion byproducts.

Tip 1: Schedule Annual Inspections. A qualified chimney sweep should inspect the system annually. This inspection identifies potential hazards like creosote buildup, blockages, and structural damage that may not be readily apparent.

Tip 2: Regular Cleaning is Essential. Frequency of cleaning depends on usage and fuel type. Wood-burning appliances require more frequent cleaning than gas-burning appliances. Creosote, a flammable byproduct of wood combustion, accumulates within the flue and poses a significant fire risk if not removed regularly.

Tip 3: Address Moisture Problems Promptly. Moisture intrusion can damage the chimney structure and accelerate deterioration. Leaks can occur due to damaged flashing, a cracked crown, or porous brickwork. Addressing these issues prevents more extensive and costly repairs in the future.

Tip 4: Ensure Proper Ventilation. Adequate airflow is crucial for efficient combustion and proper venting. Ensure that the damper is functioning correctly and is fully open when the appliance is in use. Avoid obstructions that may impede airflow within the room.

Tip 5: Utilize Seasoned Wood. Burning seasoned (dried) wood reduces creosote buildup compared to burning green or wet wood. Seasoned wood burns hotter and more efficiently, resulting in cleaner combustion.

Tip 6: Consider a Chimney Cap. Installing a chimney cap prevents rain, snow, leaves, and animals from entering the flue. This helps to maintain a clear and unobstructed venting system and protects against water damage.

Tip 7: Understand Appliance-Specific Requirements. Different heating appliances have unique venting requirements. Consult the manufacturer’s instructions to ensure the chimney is appropriately sized and configured for the specific appliance in use.

Consistent adherence to these maintenance practices ensures the safe and efficient operation of any interior venting system, safeguarding both the structure and its occupants from potential hazards.

The subsequent sections will delve into advanced troubleshooting techniques and detailed information regarding potential system upgrades.

1. Draft

Effective draft is paramount to the proper functioning of any indoor chimney system. It refers to the pressure differential that draws combustion gases up and out of the flue. This phenomenon relies on the principle that hot air rises; however, numerous factors influence the strength and consistency of the draft. Insufficient draft can result in smoke backdrafting into the living space, posing a significant health hazard due to carbon monoxide exposure and reduced indoor air quality. Conversely, excessive draft can lead to rapid burning of fuel, reducing efficiency and potentially causing damage to the appliance and the structure itself. Building height, chimney height, flue diameter, and external weather conditions all play critical roles in determining the overall draft performance.

The connection between draft and an indoor chimney is a cause-and-effect relationship. Inadequate chimney height, obstructions within the flue, or downdrafts caused by nearby structures can impede airflow, resulting in poor draft. For example, a chimney that is not tall enough to extend above the highest point of the roof may experience downdrafts, particularly in windy conditions. Similarly, the accumulation of creosote or debris within the flue can restrict airflow, reducing the draft’s effectiveness. A properly sized and maintained system facilitates the smooth and complete evacuation of combustion byproducts. Real-life examples include homes experiencing persistent smoke spillage upon fireplace startup, often indicating a draft problem caused by a cold flue or external wind pressure overcoming the natural buoyancy of the hot gases.

Understanding and maintaining adequate draft is vital for safe and efficient heating. Ensuring the chimney is regularly inspected and cleaned, coupled with proper appliance selection and installation, is crucial. While natural draft is common, some systems utilize induced draft fans to enhance performance, particularly in challenging situations. Ignoring the importance of draft can lead to significant safety risks and operational inefficiencies. Therefore, a proactive approach to draft management is an essential aspect of responsible homeownership and building maintenance.

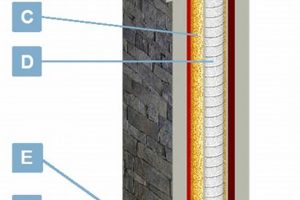

2. Flue Liner Integrity

Flue liner integrity is paramount to the safe and effective operation of any indoor chimney system. The flue liner, typically constructed of clay, metal, or concrete, serves as a protective barrier between the corrosive combustion gases and the surrounding chimney structure, often composed of brick or masonry. Its primary function is to contain these gases and prevent them from permeating the chimney walls, which can lead to structural damage and the release of harmful substances into the building’s interior. The integrity of the flue liner directly affects the durability of the chimney and the safety of the building occupants. For instance, a cracked or deteriorated liner allows acidic combustion products to attack the mortar joints, weakening the chimney’s structural stability. This deterioration can eventually lead to chimney collapse or allow carbon monoxide to seep into living spaces, posing a potentially lethal threat.

Compromised flue liners can also increase the risk of chimney fires. Cracks and gaps in the liner provide pathways for hot gases to come into direct contact with combustible materials in the surrounding walls, such as wood framing. Furthermore, damaged liners can impede the efficient flow of exhaust gases, leading to increased creosote buildup in wood-burning systems. Creosote is a highly flammable substance, and its accumulation significantly elevates the risk of a chimney fire. Real-world examples frequently highlight the devastating consequences of neglecting flue liner maintenance. Homes with older, unlined, or poorly maintained chimneys are statistically more prone to chimney fires and carbon monoxide incidents. The presence of visible cracks, spalling, or missing sections of the liner during a chimney inspection are clear indicators of a compromised system, demanding immediate attention.

In conclusion, maintaining flue liner integrity is not merely a matter of routine maintenance; it is a critical safety measure that safeguards the structural integrity of the chimney and protects building occupants from the dangers of carbon monoxide poisoning and chimney fires. Regular inspections and timely repairs are essential to ensure the continued safe and efficient operation of any indoor chimney system. Challenges in maintaining integrity often stem from aging materials and exposure to harsh combustion byproducts, emphasizing the importance of using appropriate materials and adhering to recommended maintenance schedules. The focus on flue liner health aligns directly with the overarching goal of promoting safe and responsible home heating practices.

3. Creosote Accumulation

Creosote accumulation is a significant safety hazard associated with indoor chimneys, particularly those serving wood-burning appliances. It results from the incomplete combustion of wood, where volatile gases condense as they cool within the flue. These condensates form a tar-like substance that adheres to the interior walls of the chimney. The chemical composition of creosote includes various organic compounds, making it highly flammable. Its presence in an indoor chimney creates a substantial fire risk, as even a small spark can ignite the accumulated deposits, leading to a potentially devastating chimney fire. Factors contributing to creosote buildup include the type of wood burned (softwoods tend to produce more creosote than hardwoods), the moisture content of the wood (wet wood burns less efficiently), and the operating temperature of the appliance (low temperatures promote condensation). A common real-life example is the homeowner who burns unseasoned wood in a low-burning fireplace, leading to rapid creosote accumulation and a heightened risk of chimney fire. Understanding the causes and consequences of creosote buildup is crucial for ensuring safe operation of an indoor chimney.

The consequences of creosote accumulation extend beyond the immediate risk of fire. Over time, substantial deposits can restrict airflow within the flue, reducing the efficiency of the chimney and increasing the likelihood of smoke backdrafting into the living space. This can lead to indoor air pollution and expose occupants to harmful combustion byproducts, including carbon monoxide. Furthermore, the corrosive nature of creosote can degrade the chimney’s structural integrity, damaging the flue liner and mortar joints. Regular chimney inspections are essential for detecting creosote buildup and assessing the condition of the flue. Professional chimney sweeps employ specialized tools to remove creosote deposits, restoring the chimney’s proper function and reducing the risk of fire. Preventative measures, such as burning seasoned wood and maintaining proper airflow, can also help to minimize creosote accumulation. A real-world example highlights the homeowner’s neglect of inspections, where a severe chimney fire resulted from years of unchecked creosote buildup, causing extensive damage to the structure.

In conclusion, creosote accumulation is a serious concern for indoor chimney systems that requires proactive management. Its highly flammable nature poses a significant fire hazard, while its corrosive properties can damage the chimney structure. Regular inspections, professional cleaning, and preventative measures are essential for mitigating these risks and ensuring the safe and efficient operation of wood-burning appliances. Challenges in managing creosote accumulation include educating homeowners about proper burning practices and ensuring consistent chimney maintenance. Addressing this issue directly contributes to improved fire safety and reduced risks associated with indoor heating, and links directly to long term structural maintainence.

4. Proper termination

The proper termination of an indoor chimney is a critical component of its overall functionality and safety. It represents the point at which combustion byproducts are released into the atmosphere, and its design directly impacts the efficiency of the venting system and the potential for hazards.

- Height Above Roofline

The chimney termination must extend a sufficient height above the roofline and any nearby obstructions. This height is dictated by building codes and aims to ensure adequate draft and prevent downdrafts, where wind forces exhaust gases back into the chimney. Insufficient height can lead to smoke spillage into the dwelling. For example, a chimney located near a taller portion of the roof requires greater extension to avoid being affected by wind currents flowing over the higher structure.

- Spark Arrestor Installation

In areas prone to wildfires, or where mandated by local regulations, a spark arrestor is a crucial element of the chimney termination. It is a mesh screen designed to prevent embers and sparks from escaping the chimney and potentially igniting nearby vegetation or roofing materials. Without a spark arrestor, embers can be carried by wind, posing a significant fire hazard, especially in dry climates. A real-world scenario involves homes in wooded areas installing spark arrestors to minimize the risk of starting wildfires.

- Cap and Crown Condition

The chimney cap protects the flue from rain, snow, debris, and animals. The crown, a concrete or masonry slab at the top of the chimney, seals the top of the chimney structure and prevents water from entering the brickwork. Damage to either component can lead to water damage within the chimney, accelerating deterioration and potentially causing structural problems. A common example is a cracked crown allowing water to seep into the brick, causing it to spall and weaken over time.

- Material Compatibility

The materials used for the chimney termination must be compatible with the types of fuel being burned and the climate conditions. For instance, a metal chimney cap installed on a chimney venting a high-efficiency gas appliance might corrode due to the acidic nature of the exhaust gases. Similarly, a termination material that is not weather-resistant can deteriorate rapidly in harsh climates, leading to premature failure. Selecting materials appropriate for the specific application is essential for ensuring longevity and safety.

These facets highlight the interconnectedness of proper termination and the overall performance of an indoor chimney. Each aspect plays a role in preventing hazards, ensuring efficient venting, and protecting the chimney structure from damage. Neglecting any of these elements can compromise the safety and functionality of the entire system.

5. Air supply

Adequate air supply is intrinsically linked to the safe and efficient operation of an indoor chimney system. Combustion, the process that generates heat in fireplaces and heating appliances, requires a sufficient quantity of oxygen. If the air supply is restricted, incomplete combustion occurs, resulting in the production of carbon monoxide, a colorless, odorless, and potentially lethal gas. This incomplete combustion also leads to increased creosote buildup in wood-burning systems, further elevating the risk of chimney fires. A properly functioning venting system relies on a constant and adequate supply of air to ensure complete combustion and the effective removal of exhaust gases from the dwelling. For example, a tightly sealed modern home may inadvertently starve a fireplace of necessary air, causing smoke to backdraft into the room, a clear indication of insufficient air supply.

The connection between air supply and an indoor chimney manifests as a cause-and-effect relationship. Insufficient air results in incomplete combustion and the aforementioned hazards, while an adequate air supply promotes complete combustion, efficient venting, and reduced risk. Practical applications of this understanding include the installation of dedicated air vents near fireplaces, particularly in energy-efficient homes. These vents provide a direct pathway for outside air to enter the combustion chamber, ensuring sufficient oxygen for complete burning. Furthermore, understanding the importance of air supply informs best practices for appliance selection and installation. Manufacturers provide specific requirements for air supply, and adherence to these guidelines is essential for safe operation. Neglecting these considerations can have severe consequences, as evidenced by instances of carbon monoxide poisoning due to improperly vented appliances operating in air-starved environments.

In summary, air supply is a critical component of any indoor chimney system, directly influencing its safety and efficiency. Ensuring an adequate air supply is paramount for promoting complete combustion, preventing carbon monoxide production, reducing creosote buildup, and maintaining proper venting. The challenges lie in balancing the need for adequate air with the desire for energy efficiency, particularly in modern, tightly sealed homes. Addressing this challenge requires careful consideration of appliance requirements, proper installation techniques, and, where necessary, the implementation of dedicated air supply solutions. A proactive approach to air supply management is essential for promoting safe and responsible home heating practices and maintaining a healthy indoor environment.

6. Code Compliance

Strict adherence to building codes is non-negotiable when dealing with indoor chimney systems. These regulations are in place to safeguard building occupants from fire hazards, carbon monoxide poisoning, and structural failures. The codes address various aspects of chimney design, construction, installation, and maintenance, reflecting a comprehensive approach to safety.

- Material Specifications

Building codes specify the permissible materials for chimney construction, including flue liners, masonry, and connectors. These specifications ensure that materials can withstand high temperatures, corrosive combustion gases, and environmental factors without degrading or posing a safety risk. For example, codes may mandate the use of stainless steel flue liners for certain high-efficiency appliances due to their resistance to acidic condensate.

- Clearance Requirements

Codes dictate minimum clearance distances between the chimney and combustible materials such as wood framing and insulation. These clearances prevent the ignition of nearby materials due to radiant heat or direct contact with hot chimney surfaces. Failure to maintain proper clearances is a common cause of chimney fires, highlighting the importance of code compliance in this area. A real-life example would be ensuring the chimney is at least two inches away from any combustible framing.

- Chimney Height Regulations

Building codes establish minimum chimney height requirements based on roof pitch and proximity to adjacent structures. These regulations are designed to ensure adequate draft and prevent downdrafts, where wind forces exhaust gases back into the chimney. Insufficient chimney height can lead to smoke spillage into the dwelling. An illustrative case is a chimney needing to extend 3 feet above the highest point where it passes through the roof and be at least 2 feet higher than any structure within 10 feet.

- Inspection and Certification

Many jurisdictions require professional inspection and certification of indoor chimney systems during construction, renovation, or sale of a property. These inspections verify compliance with applicable codes and ensure that the chimney is safe and functioning properly. Certification provides assurance to homeowners and prospective buyers that the chimney meets established safety standards. This involves a qualified inspector checking dimensions, materials, and overall integrity.

These facets underscore the critical role of code compliance in ensuring the safety and functionality of indoor chimney systems. Adherence to these regulations minimizes the risk of fire, carbon monoxide poisoning, and structural failures, safeguarding building occupants and preserving property. Consistent enforcement and regular updates to building codes reflect an ongoing commitment to improving safety standards and addressing emerging challenges in chimney design and construction.

7. Annual inspection

Annual inspection is a critical component of responsible indoor chimney ownership and maintenance. The systematic examination of the entire system, from the flue to the termination point, serves as a proactive measure against potential hazards and inefficiencies. Chimney systems are subject to wear and tear from heat, corrosive combustion byproducts, and environmental factors. Without regular inspection, underlying issues such as creosote buildup, flue liner damage, or structural deterioration may go unnoticed until they manifest as significant problems, including chimney fires or carbon monoxide leaks. The cause-and-effect relationship is clear: neglected inspection leads to undetected problems, which subsequently escalate into dangerous or costly situations. As a real-life example, homeowners who forego annual inspections may unknowingly allow creosote to accumulate to a dangerous level, creating a significant fire risk that could have been easily prevented with timely intervention.

The practical significance of annual inspection lies in its ability to identify and address minor issues before they become major problems. A qualified chimney sweep can detect cracks in the flue liner, assess the condition of the chimney crown, and evaluate the integrity of the flashing. These assessments allow for timely repairs, preventing water damage, structural instability, and the release of harmful gases into the living space. Moreover, annual inspections provide an opportunity to evaluate the efficiency of the chimney system and recommend measures to improve performance, such as flue cleaning or damper adjustments. Routine evaluation also allows for ensuring the system continues to meet existing building codes. The annual evaluation provides a snapshot of the systems current condition, but also historical trends if inspections are performed regularly, supporting preventative maintenance activities.

In conclusion, annual inspection is an indispensable element of indoor chimney care. It is not merely a recommendation but a necessary practice for ensuring the safety and well-being of building occupants and the structural integrity of the chimney. While the cost of an inspection may seem like an added expense, it pales in comparison to the potential costs and risks associated with neglecting this essential maintenance task. The challenge lies in educating homeowners about the importance of annual inspections and encouraging them to prioritize chimney maintenance as a vital component of homeownership. Ultimately, proactive inspection promotes a safer and more efficient heating environment.

Frequently Asked Questions

This section addresses common inquiries regarding internal venting systems, providing concise and informative answers to enhance understanding and promote safe operation.

Question 1: What is the primary function?

The primary function is to safely vent combustion byproducts, such as smoke and gases, from heating appliances and fireplaces to the outside atmosphere, preventing their accumulation within the living space.

Question 2: How often should an inspection occur?

An annual inspection by a qualified chimney sweep is recommended. This allows for the detection of potential hazards like creosote buildup, flue obstructions, and structural damage.

Question 3: What is the significance of a flue liner?

The flue liner protects the chimney structure from corrosive combustion gases and prevents carbon monoxide from seeping into the building’s interior. Maintaining its integrity is crucial for safety and structural stability.

Question 4: How does creosote accumulation impact function?

Creosote is a flammable byproduct of wood combustion that accumulates within the flue. Its presence increases the risk of chimney fires and can restrict airflow, leading to smoke backdraft and carbon monoxide exposure.

Question 5: What measures prevent operational problems?

Burning seasoned wood, ensuring proper ventilation, maintaining adequate clearances from combustible materials, and installing a chimney cap can help prevent problems and maintain efficient performance.

Question 6: Why is proper termination essential?

Correct termination ensures adequate draft, prevents downdrafts, and protects the chimney from weather damage. It should extend sufficiently above the roofline and include a spark arrestor where required.

These FAQs emphasize the importance of regular inspection, maintenance, and code compliance for the safe and effective operation of these systems.

The subsequent sections will explore advanced troubleshooting techniques and potential system upgrades.

Conclusion

This exploration has detailed the critical aspects of the indoor chimney, emphasizing its role in safe and efficient venting. Key points include the importance of annual inspections, the integrity of the flue liner, the management of creosote accumulation, proper termination techniques, and adequate air supply. Adherence to building codes and regulations is paramount. Neglecting any of these elements can compromise the system’s functionality and pose significant risks.

The information provided underscores the serious responsibility associated with owning and maintaining an indoor chimney. A proactive approach, encompassing regular maintenance and professional assessment, is essential to safeguarding occupants and preserving structural integrity. Future developments in chimney technology may offer enhanced efficiency and safety features, but fundamental principles of responsible ownership will remain unchanged.

![Why Chimney Birds Matter: [Chimney Bird] Care Tips Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Why Chimney Birds Matter: [Chimney Bird] Care Tips | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/03/th-25-300x200.jpg)