This component is typically a circular or oval-shaped tube inserted inside a flue. Its eight-inch dimension refers to its inner diameter, a common size used to accommodate the venting requirements of many wood-burning stoves, fireplaces, and other heating appliances. For example, a stove requiring an eight-inch outlet will necessitate a corresponding diameter for the inserted structure.

The integrity of the venting system is paramount for safe and efficient appliance operation. Installing this structure ensures that combustion byproducts are safely exhausted from the dwelling, preventing the leakage of dangerous gases like carbon monoxide. Its use can also improve draft, enhance heating efficiency, and protect the existing flue from corrosive elements. Historically, damaged flues were often repaired or replaced entirely; employing this method presents a more cost-effective and less disruptive alternative.

Detailed discussion of suitable materials, installation procedures, code compliance, and inspection protocols will follow. This discussion will further clarify crucial aspects pertaining to the selection, implementation, and maintenance of appropriate venting solutions.

Essential Considerations for Venting System Implementation

The proper implementation of a suitable venting solution is critical for home safety and appliance performance. Adhering to best practices during selection and installation ensures optimal operation and longevity.

Tip 1: Material Selection. Prioritize corrosion-resistant materials appropriate for the intended appliance and fuel type. Stainless steel alloys are often preferable due to their durability and resistance to the acidic byproducts of combustion. Example: Using a 316L stainless steel for wood-burning appliances due to its higher resistance to creosote.

Tip 2: Accurate Measurement. Precise measurement of the flue dimensions is essential before ordering components. Underestimating or overestimating the required length can lead to improper fit and compromised functionality. Example: Measure the entire length of the flue, including offsets, to ensure sufficient material is available for a continuous run.

Tip 3: Professional Installation. While DIY installation may seem appealing, engaging a certified professional installer is highly recommended. Proper installation requires specialized tools, knowledge of building codes, and expertise in ensuring a secure and airtight connection. Example: Hiring a technician certified by the Chimney Safety Institute of America (CSIA).

Tip 4: Code Compliance. Adherence to local and national building codes is mandatory. These codes dictate minimum safety standards and installation requirements. Failure to comply can result in fines, insurance complications, and potential safety hazards. Example: Verify that the chosen system is listed and labeled to UL 1777 or equivalent standards.

Tip 5: Regular Inspection. Schedule annual inspections by a qualified professional to identify potential problems such as corrosion, blockages, or structural damage. Early detection and repair can prevent costly repairs and ensure continued safe operation. Example: Using a chimney camera during inspections to identify internal damage not visible to the naked eye.

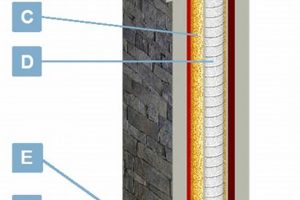

Tip 6: Proper Insulation. Consider insulating the venting structure to improve draft and minimize condensation, particularly in colder climates. This can enhance appliance efficiency and reduce creosote buildup. Example: Wrapping the exterior with a listed insulation blanket.

Careful selection, professional installation, and diligent maintenance of the venting solution are critical for safe and efficient operation. Neglecting these factors can compromise safety and lead to costly repairs.

The subsequent sections will address potential issues, troubleshooting, and advanced concepts related to venting system design and maintenance.

1. Diameter Consistency

Maintaining a consistent inner dimension throughout the entire venting pathway is essential for the proper function of an 8 chimney liner. Deviations from the specified diameter can negatively impact draft, combustion efficiency, and overall system safety.

- Draft Optimization

A consistent diameter ensures a smooth and uninterrupted flow of combustion gases. Reductions in diameter create bottlenecks, impeding airflow and potentially leading to backdrafting. Conversely, increases in diameter can dilute the exhaust gases, reducing buoyancy and weakening draft. The 8-inch specification represents an engineered balance for many appliances; altering this equilibrium disrupts the intended ventilation characteristics. Example: A reduction to a 6-inch section somewhere along the line will increase resistance to airflow and decrease overall draft.

- Appliance Performance

Heating appliances are designed to operate within specific parameters, including exhaust gas flow rates. A properly sized venting system, achieved through diameter consistency, allows the appliance to burn fuel efficiently and safely. Inconsistent diameters can lead to incomplete combustion, increased creosote buildup, and reduced heating output. Example: A wood stove with an 8-inch outlet requires a matching venting system to avoid inefficient burning and accelerated creosote formation.

- Creosote Management

Creosote, a flammable byproduct of wood combustion, tends to accumulate in areas where exhaust gases cool rapidly. Diameter inconsistencies can create such cooling zones, accelerating creosote deposition and increasing the risk of chimney fires. Maintaining an even diameter promotes a more consistent exhaust gas temperature, reducing creosote formation. Example: Bends or constrictions in the venting path can trap cooler exhaust gases, encouraging creosote buildup.

- Code Compliance and Safety

Building codes typically specify venting requirements based on appliance type and output. Deviations from these requirements, including diameter inconsistencies, can violate code and create safety hazards. Inspections often focus on ensuring proper sizing and continuity of the venting system. Example: Failure to maintain the required 8-inch diameter could result in a failed inspection and necessitate corrective action.

In summary, diameter consistency is a critical factor in ensuring the safe and efficient operation of a venting system utilizing an 8 chimney liner. Adhering to the specified diameter throughout the entire venting pathway is crucial for optimizing draft, maintaining appliance performance, managing creosote buildup, and complying with relevant building codes.

2. Material Durability

The selection of durable materials is paramount in the context of an 8 chimney liner due to the demanding operating conditions to which it is subjected. The primary function of a chimney liner is to safely vent combustion byproducts from heating appliances, exposing it to high temperatures, corrosive flue gases, and thermal cycling. Material failure can compromise the integrity of the chimney system, potentially leading to carbon monoxide leaks, chimney fires, or structural damage to the building. For example, a liner constructed from substandard steel may corrode prematurely due to exposure to acidic condensates from a high-efficiency furnace.

Stainless steel alloys, particularly 304 and 316L, are commonly used for 8 chimney liner construction due to their superior corrosion resistance and high-temperature strength. The choice between these alloys depends on the specific application and fuel type. For instance, 316L stainless steel is preferred for wood-burning appliances because it exhibits greater resistance to the corrosive effects of creosote. Proper material selection extends the lifespan of the liner, reducing the need for frequent replacements and minimizing long-term maintenance costs. A liner constructed from a robust material offers enhanced protection to the existing chimney structure, preventing deterioration caused by flue gas penetration.

In conclusion, material durability is a critical factor in the overall performance and longevity of an 8 chimney liner. The appropriate selection of corrosion-resistant materials, such as stainless steel, is essential for ensuring safe and reliable venting of combustion byproducts. Ignoring material durability can result in premature liner failure, posing significant safety risks and incurring substantial repair expenses.

3. Proper Installation

The effective operation of an 8 chimney liner hinges critically on proper installation techniques. Substandard installation undermines the inherent benefits of the liner, regardless of its material quality or design. Incorrect installation can lead to a multitude of problems, including compromised draft, leakage of combustion byproducts into the living space, accelerated corrosion of the liner itself, and an increased risk of chimney fires. For example, a liner that is not correctly sealed at the connections may permit carbon monoxide to infiltrate the dwelling, posing a serious health hazard.

Proper installation encompasses several key elements. First, the liner must be sized appropriately for the appliance it serves, ensuring that the internal diameter is sufficient to handle the exhaust flow. Second, all connections must be meticulously sealed to prevent leakage. Third, the liner must be adequately supported within the existing chimney structure to prevent sagging or collapse. Fourth, the space between the liner and the chimney walls should be properly insulated to maintain flue gas temperatures and minimize condensation. Finally, the termination of the liner at the top of the chimney must be designed to prevent water entry and ensure proper draft. Consider the case where an uninsulated liner in a cold climate experiences excessive condensation, leading to rapid creosote accumulation in a wood-burning system.

In summary, proper installation is not merely a desirable adjunct to an 8 chimney liner; it is an indispensable requirement for safe and efficient operation. Neglecting installation best practices can negate the advantages of the liner and create significant safety risks. Therefore, engaging qualified professionals with demonstrated expertise in chimney liner installation is strongly recommended to ensure the long-term integrity and performance of the venting system. This is necessary, despite the difficulty or costs.

4. Code Compliance

Strict adherence to local and national building codes is a non-negotiable aspect of any 8 chimney liner installation. These codes exist to ensure public safety by mandating minimum standards for the venting of combustion appliances. Failure to comply with these regulations can result in significant consequences, ranging from failed inspections and required rework to potential liability in the event of a fire or carbon monoxide poisoning. For example, the International Residential Code (IRC) and the National Fire Protection Association (NFPA) standards provide specific guidelines on chimney sizing, material selection, installation methods, and clearance requirements. An 8 chimney liner installed without proper permits or without adhering to these prescribed guidelines immediately introduces a safety risk and legal liability.

The correlation between code compliance and the function of the 8 chimney liner is direct and causal. Codes dictate the acceptable materials for liner construction (often specifying stainless steel grades like 304 or 316L), the permissible methods of connecting liner sections, and the required clearances to combustible materials. These regulations are not arbitrary; they are based on decades of research and experience aimed at minimizing the hazards associated with venting flue gases. As an illustration, codes may specify that an 8 chimney liner serving a wood-burning appliance must be insulated to a certain R-value to reduce creosote buildup, thus mitigating the risk of a chimney fire. Similarly, the liner’s termination at the top of the chimney must conform to specific height and clearance requirements to ensure adequate draft and prevent downdrafts.

In conclusion, code compliance is an integral component of any 8 chimney liner project, acting as a safeguard against potential hazards and ensuring the system operates safely and efficiently. Neglecting code requirements, regardless of perceived cost savings or convenience, is a perilous gamble that can have severe repercussions. Therefore, consulting with qualified professionals who possess a thorough understanding of applicable codes is paramount to ensuring a compliant and safe 8 chimney liner installation.

5. Inspection Frequency

Regular inspection of an 8 chimney liner is crucial for ensuring its continued safety and operational efficiency. The frequency of these inspections is dictated by a combination of factors, including the type of fuel burned, the appliance used, and local building codes. Consistent evaluation mitigates risks associated with deteriorating venting systems.

- Fuel Type Impact

Different fuels produce varying amounts of creosote, soot, and corrosive byproducts. Wood-burning appliances, for instance, generate significantly more creosote than natural gas appliances. Consequently, 8 chimney liners serving wood-burning systems require more frequent inspections to detect and remove creosote buildup, minimizing the risk of chimney fires. Oil-burning appliances, on the other hand, may produce acidic condensates that can corrode the liner over time, necessitating inspections focused on identifying material degradation. Example: An 8 chimney liner for a wood stove should be inspected at least annually, while a liner for a gas furnace might be inspected every other year.

- Appliance Usage Patterns

The frequency with which a heating appliance is used directly impacts the rate at which its venting system deteriorates. A fireplace used only occasionally for ambiance will likely require less frequent inspections than a wood stove that serves as the primary heating source during winter months. Heavy usage accelerates the accumulation of creosote, soot, and other byproducts, increasing the likelihood of blockages, corrosion, and other problems that can compromise the 8 chimney liner’s integrity. Example: A vacation home with a rarely used fireplace may require inspection only every three to five years, while a home with a frequently used wood stove needs annual inspection.

- Building Code Mandates

Many jurisdictions have specific regulations regarding chimney inspections. These codes often mandate annual inspections for all chimneys and venting systems, regardless of fuel type or appliance usage. Compliance with these regulations is not only a legal requirement but also a crucial step in ensuring the safety of building occupants. Ignoring these mandates can result in fines, insurance complications, and potential liability in the event of a chimney-related incident. Example: Some municipalities require homeowners to obtain a certificate of inspection from a qualified chimney sweep before selling their property.

- Early Problem Detection

Regular inspections allow for the early detection of potential problems, such as cracks, corrosion, or blockages. Addressing these issues promptly can prevent them from escalating into more serious and costly repairs. Early detection also reduces the risk of chimney fires and carbon monoxide poisoning. An 8 chimney liner displaying signs of corrosion, for example, may need to be repaired or replaced before it completely fails. Example: A chimney sweep may identify a small crack in the liner during an inspection, allowing the homeowner to address it before it widens and compromises the liner’s structural integrity.

The established connection between inspection frequency and the operational effectiveness of an 8 chimney liner showcases the necessary actions for its maintenance and long life span. Appropriate inspection schedules ensure not only code compliance but also proactive risk mitigation, safeguarding the integrity of the venting system and the well-being of the occupants.

Frequently Asked Questions

This section addresses common inquiries concerning the selection, installation, and maintenance of venting systems with an eight-inch internal diameter.

Question 1: What is the purpose of an 8 chimney liner?

The structure serves primarily to contain and safely vent combustion byproducts from heating appliances to the outside atmosphere. It protects the existing masonry chimney from corrosive flue gases and improves appliance draft.

Question 2: When is an 8 chimney liner required?

It is generally required when an existing flue is damaged or undersized for a new appliance. It ensures a properly sized and sealed venting system, meeting safety standards.

Question 3: What materials are suitable for an 8 chimney liner?

Stainless steel alloys, such as 304 and 316L, are commonly used due to their resistance to corrosion and high temperatures. The specific alloy depends on the appliance and fuel type.

Question 4: Can an 8 chimney liner be installed as a DIY project?

While DIY installation may seem appealing, engaging a certified professional installer is highly recommended. Proper installation requires specialized tools, knowledge of building codes, and expertise in ensuring a secure and airtight connection.

Question 5: How often should an 8 chimney liner be inspected?

Annual inspections by a qualified professional are recommended. Fuel type, appliance usage, and local codes can influence the frequency. Inspections detect potential problems early.

Question 6: What are the potential consequences of neglecting an 8 chimney liner maintenance?

Neglecting maintenance can lead to creosote buildup, chimney fires, carbon monoxide leaks, and structural damage to the chimney. Regular maintenance prevents these hazards.

Understanding these key aspects promotes a safe and efficient heating system. Professional consultation remains advisable for informed decision-making and compliance.

The subsequent sections will delve into advanced topics related to chimney system design and troubleshooting.

8 Chimney Liner

This discussion has outlined the critical facets of the component with the eight-inch diameter. From material selection and proper installation to code compliance and inspection frequency, each element plays a vital role in ensuring the safe and efficient venting of combustion byproducts. The integrity of this element directly impacts the performance of heating appliances and the safety of building occupants. Neglecting any aspect of its implementation can lead to hazardous conditions, including chimney fires and carbon monoxide exposure.

Given the serious implications of a compromised venting system, responsible homeowners and building managers must prioritize the proper installation and maintenance. The long-term safety and efficiency of the heating system, and indeed the well-being of those within the structure, depend on diligent attention to these details. Therefore, continued education and adherence to best practices, coupled with professional assessment, are essential for safeguarding against potential hazards. Further investigation is always welcome to ensure the proper and up-to-date knowledge.

![Why Chimney Birds Matter: [Chimney Bird] Care Tips Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Why Chimney Birds Matter: [Chimney Bird] Care Tips | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/03/th-25-300x200.jpg)