Establishing a safe and efficient venting system for a wood-burning appliance often necessitates passing a flue pipe through a building’s exterior wall. This procedure involves careful planning, adherence to building codes, and the use of approved components designed for high-temperature environments. The aim is to safely vent combustion byproducts away from the living space, mitigating the risk of fire and carbon monoxide poisoning.

Properly executed venting is crucial for optimal wood stove performance, ensuring efficient combustion and reducing creosote buildup. A well-installed system not only enhances heating efficiency but also significantly reduces the potential for hazardous conditions. Historically, improper venting has been a major cause of residential fires and carbon monoxide-related incidents, highlighting the necessity of adhering to stringent safety protocols.

The subsequent sections will detail the essential steps and considerations involved in creating a through-wall chimney system for a wood stove. This includes selecting appropriate materials, preparing the wall opening, installing the wall thimble, connecting the stove pipe, and ensuring proper sealing and insulation around the penetration point.

Essential Guidance for Through-Wall Wood Stove Chimney Installation

These guidelines address critical aspects of safely and effectively routing a wood stove chimney through an exterior wall.

Tip 1: Code Compliance: Verify all local and national building codes pertaining to wood stove and chimney installations before commencing any work. Specific requirements dictate clearances, materials, and installation methods.

Tip 2: Component Selection: Employ only listed and labeled components specifically designed for through-wall wood stove chimney installations. These typically include a listed wall thimble, connector pipes, and chimney pipes rated for high-temperature use.

Tip 3: Wall Thimble Installation: Ensure the wall thimble is correctly sized and installed according to the manufacturer’s instructions. This critical component protects combustible materials from the chimney’s heat.

Tip 4: Clearance to Combustibles: Maintain the minimum required clearance to combustible materials throughout the entire system, including around the wall thimble, connector pipes, and chimney pipes. Consult the appliance and chimney manufacturer’s specifications for specific clearance requirements.

Tip 5: Proper Sealing: Seal all joints between chimney components with high-temperature sealant to prevent flue gas leakage. This is essential for both safety and efficiency.

Tip 6: Chimney Support: Provide adequate support for the chimney system, particularly on the exterior of the building. Use appropriate bracing or supports to ensure stability and prevent stress on the wall thimble.

Tip 7: Professional Inspection: Upon completion of the installation, have the entire system inspected by a qualified professional chimney sweep or certified installer. This ensures compliance with safety standards and identifies any potential issues.

Adhering to these tips minimizes the risk of fire hazards, carbon monoxide exposure, and structural damage associated with through-wall wood stove chimney installations. Diligence and adherence to safety protocols are paramount.

The following section will explore the troubleshooting and maintenance associated with the through-wall wood stove chimney to ensure its safety.

1. Code Compliance

Adherence to building codes is paramount during the implementation of a through-wall wood stove chimney installation. These codes, developed by regulatory bodies and industry experts, establish minimum safety standards designed to mitigate the risks associated with combustion appliances. Code compliance is not merely a suggestion but a legal requirement, intended to protect occupants and property from potential hazards.

- Material Specifications

Building codes dictate the types of materials permitted for use in chimney systems. For example, codes typically require the use of listed and labeled stainless steel or equivalent materials for chimney liners and connectors, ensuring resistance to high temperatures and corrosive flue gases. Using non-compliant materials, such as standard galvanized steel, can lead to premature failure and potential fire hazards. Such stipulations are directly related to proper methods for how to install a wood stove chimney through wall

- Clearance Requirements

Minimum clearance distances between chimney components and combustible materials, such as wood framing, are strictly defined by code. These clearances prevent the transfer of heat to combustible surfaces, reducing the risk of fire. For instance, a common requirement is a minimum of two inches of clearance between a single-wall connector pipe and any combustible material, necessitating the use of a listed wall thimble to maintain this clearance when passing through a wall. This defines the methods of how to install a wood stove chimney through wall

- Installation Procedures

Building codes often outline specific installation procedures for chimney systems, including the proper methods for connecting chimney sections, supporting the chimney structure, and sealing joints to prevent flue gas leakage. For example, codes may require that chimney sections be joined with specific types of fasteners or that all joints be sealed with high-temperature sealant rated for chimney applications. Installation guidelines defines methods of how to install a wood stove chimney through wall.

- Inspection and Certification

Many jurisdictions require a professional inspection of wood stove and chimney installations to ensure compliance with building codes. This inspection typically involves verifying proper clearances, material specifications, and installation procedures. Upon successful inspection, a certification or permit may be issued, providing assurance that the installation meets the required safety standards. Inspections and certifications are crucial for knowing how to install a wood stove chimney through wall.

In summary, code compliance provides a framework for safe and effective through-wall wood stove chimney installations. Adhering to material specifications, clearance requirements, installation procedures, and inspection protocols minimizes the risks associated with wood stove operation and ensures the long-term safety of the building and its occupants. Failure to comply with these codes can result in fines, insurance complications, and, most importantly, increased risk of fire or carbon monoxide poisoning, highlighting the critical importance of understanding and adhering to all applicable regulations during the installation process.

2. Proper Clearances

Maintaining adequate clearances between chimney components and combustible materials is a fundamental safety requirement for any through-wall wood stove chimney installation. Insufficient clearances can lead to heat transfer to surrounding materials, potentially causing ignition and resulting in a structural fire. Therefore, understanding and adhering to specified clearance distances is a critical element.

- Heat Dissipation

Clearances allow for the natural dissipation of heat generated by the chimney. Without sufficient space, heat can build up, raising the temperature of nearby combustible materials to their ignition point. For example, if a wood stove connector pipe is installed too close to a wooden wall without proper insulation or shielding, the wood can slowly char and eventually ignite. Specified clearances are designed to prevent this accumulation of heat.

- Manufacturer Specifications

Clearance requirements are typically specified by both the wood stove and chimney component manufacturers. These specifications are based on rigorous testing and are designed to ensure safe operation. Deviation from these specifications can void warranties and, more importantly, compromise the safety of the installation. The manufacturer’s documentation serves as a primary guide during the installation process.

- Wall Thimble Functionality

In through-wall installations, the wall thimble is a critical component for maintaining proper clearances. The thimble acts as a barrier, isolating the chimney pipe from the combustible wall framing. Correct installation of the thimble, according to its listing, is essential to achieve the required clearances and prevent heat transfer to the wall structure. An incorrectly installed or improperly sized thimble negates its protective function.

- Material Properties

The required clearance distances can vary depending on the type of chimney component and the surrounding materials. Single-wall connector pipes, for example, typically require greater clearances than double-wall or triple-wall chimney pipes due to their higher surface temperatures. Similarly, the type of combustible material (e.g., wood, drywall, insulation) can influence the required clearance. Understanding these material properties is essential for ensuring a safe installation.

The aspects detailed show that proper clearance serves as a cornerstone in ensuring safety. Adhering to clearance specifications protects the surrounding structures from heat damage. Installation requires thorough understanding and precise execution to avert potential dangers, like wall fires.

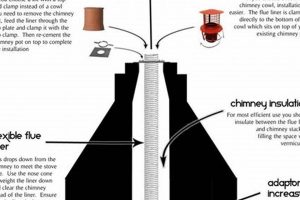

3. Thimble Installation

Thimble installation is an indispensable element within the overall process. The wall thimble serves as a firestop, creating a protective barrier where the chimney pipe penetrates the combustible wall structure. Without proper thimble installation, the heat radiating from the chimney pipe can directly contact and ignite the wall framing, resulting in a significant fire hazard. This direct connection highlights the causal link between thimble integrity and fire safety.

The correct thimble not only provides a physical separation but also facilitates the maintenance of required clearances between the chimney and combustible materials. For example, a listed wall thimble is engineered to maintain a specific air gap or employ insulation to reduce heat transfer. Improper installation, such as using an incorrectly sized thimble or neglecting to follow the manufacturer’s instructions, can negate these protective measures. This practical significance extends to code compliance, as building codes explicitly mandate the use of listed and labeled thimbles installed according to their listing. Consider a scenario where a homeowner attempts a DIY installation, omitting the wall thimble altogether; the resulting lack of protection drastically increases the risk of a fire, underscoring the importance of adhering to established safety standards.

In conclusion, the safe passage of a chimney pipe through a combustible wall is contingent upon the proper installation of a wall thimble. Addressing challenges such as ensuring correct sizing, alignment, and adherence to manufacturer specifications is critical. The connection between thimble installation and the safe operation of a wood stove system is direct and consequential, reinforcing the broader theme of prioritizing safety in all aspects of wood stove installation.

4. Component Selection

The selection of appropriate components is integral to the safe and effective implementation of a through-wall wood stove chimney system. Each component within the system serves a specific function, and the compatibility and quality of these components directly influence the overall performance and safety of the installation.

- Chimney Pipe Rating

Chimney pipes must be rated to withstand the high temperatures and corrosive byproducts of wood combustion. Selecting a pipe with an inadequate temperature rating can lead to premature degradation and potential fire hazards. For instance, using a B-vent pipe, designed for gas appliances, with a wood stove is a critical error, as it cannot withstand the higher temperatures produced by wood burning. The appropriate selection is stainless steel or its equivalent.

- Wall Thimble Compatibility

The wall thimble must be compatible with both the chimney pipe and the wall construction. A mismatched thimble can compromise the required clearances to combustible materials, increasing the risk of fire. Ensure the selected thimble is specifically listed and labeled for use with the chosen chimney pipe and that its dimensions are suitable for the wall thickness. A thimble designed for a different type of chimney will not provide adequate protection.

- Connector Pipe Material

Connector pipes, which link the wood stove to the chimney system, must also be selected based on their ability to withstand high temperatures and resist corrosion. Single-wall and double-wall connector pipes offer varying levels of heat protection and must be chosen based on clearance requirements and stove manufacturer specifications. Using a standard, non-rated black stove pipe in close proximity to combustible walls would violate clearance requirements.

- Sealant and Fasteners

The sealant and fasteners used to connect chimney components must be rated for high-temperature applications and resistant to flue gas corrosion. Using inappropriate sealants or fasteners can lead to leaks, compromising the efficiency of the system and potentially allowing dangerous gases to enter the living space. High-temperature silicone sealant and stainless steel fasteners are commonly recommended.

Proper component selection directly correlates with safety and efficiency when installing a wood stove chimney through a wall. Employing correctly rated, compatible, and durable materials minimizes the risk of fire, carbon monoxide leaks, and structural damage, ultimately ensuring a safe and reliable heating system.

5. Secure sealing

Secure sealing within a through-wall wood stove chimney system is crucial for preventing the escape of harmful flue gases and maintaining optimal system performance. Compromised seals can lead to carbon monoxide leaks, reduced heating efficiency, and accelerated creosote buildup, all of which pose significant safety risks and operational challenges. Consequently, diligent attention to sealing procedures is paramount during installation.

- Joint Integrity

Each connection point within the chimney system, including joints between pipe sections and connections to the wall thimble and stove collar, represents a potential leak path. Proper sealing ensures that these joints are airtight, preventing the escape of flue gases into the living space. The application of high-temperature sealant, specifically formulated for chimney applications, is essential to maintain joint integrity over time. An improperly sealed joint, such as one lacking sufficient sealant or one where the sealant has deteriorated due to exposure to high temperatures, can allow dangerous gases to seep into the home.

- Sealant Application Techniques

The effectiveness of sealant depends not only on the type of sealant used but also on the application technique. Surfaces must be clean and dry before sealant is applied to ensure proper adhesion. The sealant should be applied in a continuous bead, completely filling the joint and creating an airtight seal. Over-application or under-application can both compromise the seal’s integrity. Following the sealant manufacturer’s instructions is critical for achieving a reliable and long-lasting seal.

- Material Compatibility

The selected sealant must be compatible with the materials used in the chimney system. Using an incompatible sealant can lead to premature degradation, loss of adhesion, and ultimately, a compromised seal. For example, using a silicone sealant that is not rated for high-temperature applications on a chimney connector pipe will result in the sealant breaking down and failing to maintain an airtight seal. Verify that the sealant is specifically formulated for use with the chimney pipe material and can withstand the operating temperatures of the wood stove.

- Inspection and Maintenance

Seals should be regularly inspected for signs of degradation or damage. Cracks, gaps, or discoloration in the sealant indicate a potential leak and should be addressed promptly. Damaged sealant should be removed and replaced with fresh sealant, following proper application techniques. Regular inspection and maintenance are essential to ensure the long-term integrity of the chimney system and prevent the development of hazardous conditions.

Given these considerations, secure sealing is not merely a peripheral step but a fundamental aspect of how to install a wood stove chimney through a wall safely and effectively. It represents a critical barrier against the dangers of flue gas leaks and ensures the overall reliability of the wood stove heating system. Neglecting proper sealing procedures can have severe consequences, underscoring the importance of prioritizing this aspect during installation and maintenance.

6. Chimney support

Chimney support is an essential element during a through-wall wood stove chimney installation, directly affecting the structural integrity and safety of the entire venting system. The chimney, extending vertically from the wall, is subject to gravitational forces, wind loads, and thermal expansion. Without adequate support, these forces can induce stress on the chimney components, leading to instability, joint separation, and potential collapse, especially exterior chimney. A structurally compromised chimney poses a significant hazard, increasing the risk of flue gas leaks, fire, and property damage. The proper method for chimney support ensures that the installed chimney remains stable and safe throughout its operational life.

The specific type of support required depends on factors such as the height of the chimney, the diameter of the pipe, and the local wind conditions. Common support methods include wall brackets, support boxes, and ground-mounted supports. Wall brackets are typically used for shorter chimneys, providing lateral support to the chimney as it extends upward from the wall. Taller chimneys require more substantial support, often involving a combination of wall brackets and a ground-mounted support. The load-bearing characteristics of the chosen support system must be sufficient to handle the weight of the chimney and any anticipated environmental loads. Inadequate support will result in stress fractures and, eventually, chimney failure.

Proper chimney support ensures that the venting system remains stable, secure, and capable of safely conveying combustion byproducts away from the living space. Employing appropriate support methods, selected based on the chimney’s dimensions and environmental conditions, is paramount. The absence of adequate support compromises the structural integrity of the entire chimney system, increasing the risk of hazardous conditions. Correct installation of chimney support protects the investment in the wood stove and safeguards the property from fire. Therefore, the process should be viewed as integral for how to install a wood stove chimney through wall.

7. Professional inspection

The independent assessment by a qualified professional represents a crucial validation step following a wood stove chimney installation. This inspection serves to confirm adherence to safety standards and building codes, providing assurance that the system operates as intended and poses minimal risk to occupants and property.

- Code Compliance Verification

A certified inspector possesses in-depth knowledge of local and national building codes pertaining to wood stove installations. The inspector will verify that the installation adheres to these codes, including required clearances to combustibles, proper chimney height, and approved materials. This ensures legal compliance and mitigates potential fire hazards arising from code violations.

- Component Integrity Assessment

The inspection includes a thorough evaluation of all chimney components, such as the chimney pipe, wall thimble, and connector pipes. The inspector assesses these components for signs of damage, corrosion, or improper installation. Identifying compromised components allows for timely repairs or replacements, preventing potential failures that could lead to flue gas leaks or chimney fires.

- Draft Performance Evaluation

An inspector will assess the chimney’s draft, which is the upward flow of air through the chimney that carries away combustion byproducts. Insufficient draft can result in smoke backdrafting into the living space, increasing the risk of carbon monoxide poisoning. The inspector uses specialized instruments to measure draft and identify any obstructions or design flaws that may impede proper airflow. This ensures efficient and safe venting of combustion gases.

- Safety Feature Validation

The inspector validates the functionality of critical safety features, such as smoke detectors and carbon monoxide detectors, ensuring that they are properly installed and operational. These devices provide early warning of potential hazards, allowing occupants to take prompt action in the event of a fire or carbon monoxide leak. This is to make sure the process to how to install a wood stove chimney through wall is successful

The professional inspection integrates directly with how to install a wood stove chimney through wall, effectively merging installation practices with professional evaluation. The inspection not only ensures adherence to safety standards but also provides homeowners with confidence in the proper functioning of their wood stove system. It serves as a final safeguard, confirming that the installation has been completed correctly and that the system is safe for operation. This added level of safety provides homeowners peace of mind when using their heating system.

Frequently Asked Questions

The following questions address common concerns and misconceptions regarding establishing a through-wall wood stove chimney system, focusing on safety and regulatory compliance.

Question 1: Is a permit required for a through-wall wood stove chimney installation?

Building codes mandate permits for such installations in most jurisdictions. The purpose is to ensure adherence to safety standards. Contacting the local building department before starting any work is vital.

Question 2: Can standard metal ductwork be used for a wood stove chimney?

Standard ductwork is unsuitable. Only listed and labeled chimney components specifically designed for high-temperature wood-burning appliances should be used. Standard ductwork lacks the necessary heat resistance.

Question 3: What is the correct height for a chimney extending above the roof?

Chimney height must comply with the “3-2-10 rule.” The chimney must extend at least 3 feet above the highest point where it passes through the roof and at least 2 feet higher than any structure within 10 feet.

Question 4: How often should a wood stove chimney be inspected?

Chimneys should be inspected at least annually by a qualified professional. More frequent inspections may be necessary depending on the frequency of wood stove use.

Question 5: What is the purpose of a spark arrestor on a chimney?

A spark arrestor prevents embers from escaping the chimney and potentially igniting nearby combustible materials. It is often required in areas prone to wildfires.

Question 6: Can a wood stove chimney be installed near electrical wiring?

Maintaining adequate clearance between the chimney and electrical wiring is essential. Building codes specify minimum clearance distances to prevent heat from damaging the wiring.

These responses highlight the importance of following established safety guidelines and regulations when implementing a through-wall wood stove chimney installation. Failure to adhere to these guidelines can result in hazardous conditions and code violations.

The subsequent section explores the troubleshooting and maintenance associated with through-wall wood stove chimneys to ensure its continued safety.

Conclusion

Throughout this exploration, the procedures for a through-wall wood stove chimney installation have been detailed, with an emphasis on code adherence, component selection, and maintenance protocols. Maintaining proper clearance, secure sealing, and adequate support systems are key aspects to ensuring safe operation.

Prioritizing these procedures minimizes the risk of fire and carbon monoxide exposure, and failure to adhere to safety practices poses significant dangers. Diligence during installation is paramount to protect lives and property, serving as a reminder of responsible heating practices.