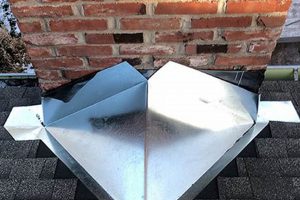

Flashing a chimney refers to the process of installing metal pieces to create a watertight seal where the chimney structure intersects with the roof. These metal components are strategically integrated with both the chimney’s masonry and the roofing materials to prevent water penetration. An example would be meticulously fitting metal sheets around the base of a brick chimney stack on a shingled roof, ensuring all joints are properly overlapped and sealed.

Proper chimney flashing is crucial for preventing water damage to the roof, attic, and interior of a building. Leaks around a chimney can lead to rot, mold growth, and structural deterioration. Historically, various materials and techniques have been employed, ranging from simple lead flashing in older constructions to more complex, multi-layered systems incorporating counter-flashing and step flashing. Effective flashing extends the lifespan of both the chimney and the surrounding roofing, minimizing costly repairs and maintaining the building’s overall integrity.

The following sections will detail the essential materials, tools, and step-by-step procedures involved in achieving a durable and reliable chimney flashing installation. This includes assessing the existing conditions, selecting appropriate flashing materials, preparing the chimney and roof surfaces, and executing the flashing installation with precision and attention to detail. Proper techniques for different roofing materials, such as asphalt shingles, tile, or metal, will also be addressed.

Chimney Flashing Best Practices

This section outlines essential guidelines for ensuring a durable and watertight chimney flashing installation.

Tip 1: Material Selection: Choose flashing materials compatible with both the chimney masonry and the roofing material. Galvanized steel, aluminum, or copper are common choices, each offering varying levels of corrosion resistance and aesthetic appeal. Match the thermal expansion properties of the flashing to those of the surrounding materials to prevent stress and potential failures.

Tip 2: Step Flashing Technique: Implement step flashing along the sides of the chimney where it intersects with the roof. Each piece of step flashing should be integrated with the individual roofing shingles, overlapping the shingle below and extending up the chimney’s side. This layered approach prevents water from running behind the flashing.

Tip 3: Counter-Flashing Integration: Incorporate counter-flashing into the chimneys mortar joints. This involves cutting grooves into the mortar, inserting the counter-flashing, and then sealing the joint with a high-quality sealant. The counter-flashing should overlap the step flashing, providing a two-tiered barrier against water intrusion.

Tip 4: Proper Overlap: Ensure adequate overlap between each piece of flashing. A minimum overlap of 2 inches is generally recommended to provide sufficient protection against water penetration due to wind-driven rain or snowmelt.

Tip 5: Sealing and Waterproofing: Utilize a high-quality, flexible sealant specifically designed for roofing applications. Apply sealant to all joints, seams, and penetrations in the flashing to create a watertight barrier. Select a sealant that is compatible with the flashing material and can withstand temperature fluctuations.

Tip 6: Chimney Crown Inspection: Inspect the chimney crown (the top surface of the chimney) for cracks or damage. A compromised crown can allow water to enter the chimney structure and compromise the flashing. Repair or replace the crown as needed before installing the flashing.

Tip 7: Regular Inspections: Conduct routine inspections of the chimney flashing, particularly after severe weather events. Address any signs of damage or deterioration promptly to prevent water damage and maintain the flashing’s effectiveness.

Adherence to these guidelines promotes a robust and long-lasting chimney flashing installation, safeguarding the building from water damage and ensuring the structural integrity of both the chimney and the roof.

The following sections will provide comprehensive information on chimney maintenance and damage prevention to further ensure the longevity of this vital element of the building.

1. Material Compatibility

Material compatibility is a foundational element for a successful chimney flashing installation. The selection of appropriate flashing materials must consider potential interactions with both the chimney masonry and the roofing material. Incompatibility can lead to accelerated corrosion, material degradation, and ultimately, flashing failure, negating its intended protective function. For instance, direct contact between aluminum flashing and dissimilar metals, such as steel or copper, in the presence of moisture can trigger galvanic corrosion, where one metal corrodes preferentially, weakening the flashing system. The consequences manifest as leaks, necessitating premature repairs and potential structural damage to the underlying roof and chimney.

The selection process should prioritize materials with similar electrochemical potentials or utilize isolating barriers to prevent direct contact between incompatible metals. Galvanized steel, while generally durable, can react negatively with certain types of treated lumber used in roof construction, causing corrosion of the steel. Copper flashing, though highly corrosion-resistant, may not be suitable for direct contact with aluminum roofing due to the risk of galvanic action. Instead, using similar materials like copper flashing with slate roofing will promote longevity of each, ensuring integrity between the parts.

In summary, material compatibility is not merely a consideration but a prerequisite for effective chimney flashing. Failure to account for potential material interactions can result in costly repairs and compromised protection against water damage. Careful selection, proper installation techniques, and the use of appropriate isolating barriers are crucial for ensuring the long-term performance and reliability of the chimney flashing system.

2. Proper Overlap

Proper overlap is an indispensable element in the process of flashing around a chimney. It directly impacts the system’s ability to prevent water intrusion. Inadequate overlap creates vulnerabilities, allowing water to penetrate the roofing system via capillary action or driven by wind pressure. This penetration undermines the primary function of the flashing, leading to potential leaks, wood rot, and structural damage. The effectiveness of step flashing, counter-flashing, and base flashing hinges significantly on the degree of overlap implemented during installation. Insufficient overlap is a common cause of flashing failure and subsequent water damage around chimneys.

The practical application of proper overlap is demonstrated in the layering of step flashing along the sides of a chimney. Each piece of flashing must extend sufficiently over the shingle below to effectively divert water away from the chimney’s surface. Similarly, counter-flashing, embedded within the chimney’s mortar joints, must overlap the step flashing to provide a continuous, cascading barrier against water ingress. Real-world examples of flashing failures often reveal that inadequate overlap, rather than material failure, is the root cause of the problem. Correct overlap also contributes to the overall durability of the flashing system by providing a more robust barrier against the elements.

In conclusion, proper overlap is not a mere detail but a fundamental requirement for effectively flashing around a chimney. Insufficient overlap compromises the entire system, leading to water damage and costly repairs. Adherence to recommended overlap dimensions, combined with careful installation techniques, ensures a durable and watertight seal, protecting the structure from the detrimental effects of water intrusion. Challenges may arise in complex roof geometries, requiring additional planning and precision to achieve adequate overlap in all areas. Mastering the principles of proper overlap is critical for anyone involved in chimney flashing installation or maintenance.

3. Step Flashing

Step flashing is an integral component of chimney flashing systems. Its correct implementation is essential for achieving a watertight seal where a chimney intersects with a sloped roof. Without proper step flashing, water intrusion is highly probable, leading to potential damage to the roof structure and interior of the building.

- Individual Piece Integration

Step flashing comprises individual, L-shaped pieces of metal, typically aluminum, galvanized steel, or copper. Each piece is integrated with a single course of roofing material, such as shingles or tiles. This discrete application ensures that water is directed away from the chimney’s side and onto the adjacent roofing surface. An incorrect installation, bypassing integration with each shingle, can create direct paths for water penetration.

- Sequential Overlap

The effectiveness of step flashing relies on sequential overlap. Each piece must overlap the piece below it, creating a cascading effect that diverts water downwards and outwards. The amount of overlap is critical; insufficient overlap can allow water to wick upwards behind the flashing. Real-world examples demonstrate that neglecting adequate overlap often results in leaks, particularly during wind-driven rain.

- Complementary Counter-Flashing

Step flashing works in tandem with counter-flashing, which is embedded in the chimney’s mortar joints. Counter-flashing overlaps the top edge of the step flashing, providing a secondary barrier against water intrusion. This two-part system ensures a robust and reliable seal. Omitting counter-flashing compromises the effectiveness of the step flashing, as it leaves the upper edge vulnerable to water infiltration.

- Adaptation to Roof Slope

The installation of step flashing must account for the roof’s slope. Steeper slopes require more frequent step flashing pieces to maintain adequate coverage and prevent water from running horizontally behind the flashing. Failure to adjust the installation to the specific roof pitch can result in localized areas of vulnerability, particularly at the chimney’s corners.

The preceding components, when properly executed, demonstrate how step flashing contributes to an effective chimney flashing system. Its meticulous integration with the roofing material, strategic overlap, synergistic relationship with counter-flashing, and adaptation to roof slope are crucial for maintaining a watertight seal around the chimney and safeguarding the building from water damage.

4. Counter-Flashing

Counter-flashing represents a critical element in chimney flashing assemblies, directly influencing the overall effectiveness of preventing water intrusion. Its precise integration with step flashing and the chimney masonry is essential for achieving a durable and watertight seal.

- Mortar Joint Embedding

Counter-flashing is characterized by its integration into the chimney’s mortar joints. Grooves are cut into the mortar, allowing the counter-flashing to be inserted and sealed. This embedding ensures a secure and lasting connection between the flashing and the chimney structure. Examples of improper embedding can be seen where the mortar deteriorates, allowing water to infiltrate behind the flashing. This method makes it a necessity for how to flash around a chimney.

- Overlap with Step Flashing

A primary function of counter-flashing is to overlap the top edge of the step flashing. This overlap creates a two-tiered barrier against water intrusion. Water that might make its way behind the shingles and step flashing is then directed away by the counter-flashing. The absence of proper overlap between these components negates the benefits of both, allowing water to penetrate the system.

- Material Compatibility Considerations

As with all flashing components, the material of the counter-flashing must be compatible with both the chimney masonry and the step flashing. Dissimilar metals can lead to galvanic corrosion, compromising the integrity of the seal. For instance, using aluminum counter-flashing with copper step flashing in a wet environment can accelerate corrosion. This consideration is key in executing how to flash around a chimney effectively.

- Sealing and Weatherproofing

The points where counter-flashing is embedded in the mortar joints require meticulous sealing to prevent water intrusion. A high-quality, flexible sealant is applied to fill any gaps and create a watertight barrier. Sealant failure, caused by age or environmental factors, can lead to water damage. Regular inspections and re-sealing are necessary to maintain the system’s effectiveness in how to flash around a chimney.

These facets highlight the interdependence of counter-flashing with other elements within a chimney flashing system. Proper material selection, meticulous installation, and regular maintenance of counter-flashing are essential for preventing water damage and ensuring the long-term integrity of the chimney and roof interface. Ultimately, the proper execution of how to flash around a chimney hinges on the correct application and integration of the counter-flashing component.

5. Sealed Joints

The integrity of sealed joints represents a critical determinant in the effectiveness of any chimney flashing system. The principle behind achieving a watertight seal in the context of “how to flash around a chimney” hinges on the understanding that flashing materials alone cannot provide complete protection against water intrusion. Gaps, however microscopic, at the intersections of flashing components, or between the flashing and the chimney or roofing materials, create pathways for water to penetrate the building envelope. This penetration can lead to significant and costly damage, including wood rot, mold growth, and deterioration of the chimney structure. Therefore, the creation of robust and durable sealed joints is not merely a supplementary step but an essential element in “how to flash around a chimney” correctly and effectively. The application of appropriate sealants and the meticulous attention to detail during this stage directly correlate with the long-term performance and reliability of the entire flashing system. Consider, for instance, the intersection between step flashing and counter-flashing; without a properly sealed joint, even the most meticulously installed flashing can fail to prevent water ingress, rendering the entire system ineffective.

The practical application of sealed joints involves selecting appropriate sealant materials, preparing the surfaces to be sealed, and executing the sealant application with precision. Sealant selection must consider the specific materials being joined, the environmental conditions to which the joint will be exposed, and the sealant’s long-term durability. Surface preparation is equally critical, as contaminants such as dirt, grease, or loose debris can compromise the sealant’s adhesion. Examples of real-world failures often demonstrate the consequences of neglecting these preparatory steps, resulting in premature sealant failure and subsequent leaks. A common mistake is using an incorrect sealant that hardens and cracks over time, failing to accommodate the expansion and contraction of the flashing materials due to temperature fluctuations. Properly executed sealed joints not only prevent water intrusion but also contribute to the overall longevity and aesthetic appeal of the chimney and roof interface.

In summary, the creation of sealed joints is an indispensable aspect of “how to flash around a chimney”. The application of sealant is a crucial element of how to flash around a chimney. Compromises in this area can negate the benefits of even the most carefully chosen and installed flashing materials. Effective sealing requires careful material selection, meticulous surface preparation, and precise application techniques. By prioritizing the integrity of sealed joints, one ensures the long-term performance and reliability of the chimney flashing system, safeguarding the building from water damage and associated structural issues. Addressing the challenges inherent in achieving durable sealed joints, such as selecting appropriate sealants and ensuring proper surface preparation, is essential for anyone undertaking chimney flashing installation or maintenance.

6. Chimney Condition

The state of the chimney structure directly influences the effectiveness and longevity of any flashing installation. Pre-existing damage or deterioration can compromise the flashing’s ability to create a watertight seal, rendering even the most meticulous installation efforts futile. A thorough assessment of the chimney’s condition is, therefore, a prerequisite for successful flashing around a chimney.

- Masonry Integrity

Cracked, crumbling, or spalling bricks and mortar joints provide direct pathways for water intrusion, circumventing the flashing altogether. Water can penetrate the chimney structure itself, leading to internal damage and accelerated deterioration. Addressing these masonry issues through repair or replacement is essential before proceeding with any flashing work, ensuring a sound substrate for the flashing to adhere to. A common example is failing to repair cracked mortar joints prior to flashing; the water continues to seep in, and will cause the corrosion from the inside.

- Crown Condition

The chimney crown, the concrete or masonry slab at the top of the chimney, serves to protect the chimney flue from the elements. Cracks or deterioration in the crown allow water to enter the chimney, potentially damaging the flue liner and saturating the surrounding masonry. A damaged crown can also compromise the flashing seal where it meets the chimney. Repairing or replacing a damaged crown ensures that the flashing is not undermined by water entering from above and the integrity of how to flash around a chimney.

- Flue Liner Integrity

While not directly influencing the flashing installation itself, a damaged flue liner can contribute to moisture problems within the chimney. Condensation and rainwater entering the flue can saturate the masonry, potentially weakening the structure and compromising the flashing seal. Addressing flue liner issues ensures that the chimney is protected from internal moisture sources, which in turn supports the long-term effectiveness of the flashing, allowing for best execution of how to flash around a chimney.

- Chimney Height and Stability

The height and structural stability of the chimney also impact the flashing’s performance. A tall, unstable chimney may be subject to excessive movement, which can stress the flashing and compromise the seal. Similarly, a leaning chimney may create uneven stresses on the flashing, leading to premature failure. Addressing any stability issues prior to flashing ensures that the flashing is not subjected to undue stress and will fulfill its intended function for long duration of how to flash around a chimney.

These facets clearly demonstrate that the condition of the chimney is inextricably linked to the success of flashing. Addressing pre-existing damage and ensuring structural stability are essential steps in creating a durable and watertight flashing system. By attending to these aspects, the efforts to flash around a chimney are more likely to result in a long-lasting and effective solution, protecting the building from water damage and preserving the chimney’s structural integrity. Ultimately, a proper chimney condition sets the stage for the effective execution of how to flash around a chimney.

Frequently Asked Questions

This section addresses common inquiries regarding chimney flashing installation, maintenance, and troubleshooting. The information provided aims to offer clear and concise guidance based on industry best practices.

Question 1: What are the primary materials used for chimney flashing, and what are their respective advantages?

Common materials include galvanized steel, aluminum, and copper. Galvanized steel offers a balance of affordability and durability. Aluminum is lightweight and corrosion-resistant. Copper provides superior longevity and aesthetic appeal but is typically more expensive. The choice depends on budget, environmental factors, and aesthetic preferences.

Question 2: How often should chimney flashing be inspected for potential issues?

Chimney flashing should be inspected at least annually, ideally in the spring and fall. More frequent inspections are advisable after severe weather events, such as heavy rain, snowstorms, or high winds.

Question 3: What are the common signs of chimney flashing failure?

Signs of failure include water stains on ceilings or walls near the chimney, leaks in the attic, damaged or missing flashing components, and visible corrosion or rust on the flashing material.

Question 4: Is it possible to repair damaged chimney flashing, or is replacement always necessary?

The feasibility of repair depends on the extent of the damage. Minor damage, such as small tears or loose sealant, may be repairable. Extensive damage, widespread corrosion, or significant material deterioration typically warrants complete flashing replacement.

Question 5: Can chimney flashing be installed on any type of roofing material?

Chimney flashing can be installed on most roofing materials, including asphalt shingles, tile, metal, and slate. However, specific installation techniques and material compatibility considerations may vary depending on the roofing material.

Question 6: What is the typical lifespan of chimney flashing?

The lifespan of chimney flashing varies depending on the material, installation quality, and environmental conditions. Galvanized steel may last 10-20 years, aluminum 20-30 years, and copper 50 years or more with proper maintenance.

Proper installation, regular inspections, and timely maintenance are crucial for maximizing the lifespan and effectiveness of chimney flashing. Consult with a qualified roofing professional for assistance with any flashing-related concerns.

The subsequent section will provide a summary of the essential points discussed and offer guidance on selecting a qualified contractor for chimney flashing services.

Conclusion

This exploration of “how to flash around a chimney” has highlighted critical factors influencing its success. Material compatibility, proper overlap, strategic implementation of step and counter-flashing, secure sealed joints, and the pre-existing condition of the chimney structure collectively determine the long-term effectiveness of the flashing system. Deficiencies in any of these areas can compromise the integrity of the installation, leading to water damage and structural deterioration.

Effective chimney flashing is not merely a construction detail, but a critical safeguard for building integrity. Neglecting proper flashing techniques carries substantial risks. Therefore, property owners should prioritize meticulous flashing installation or entrust the task to qualified professionals. Proactive maintenance and prompt repairs are also paramount in preserving the flashing’s functionality, thereby protecting the building from costly water damage and ensuring its structural longevity. The significance of effective “how to flash around a chimney” strategies cannot be overstated in safeguarding property investments and ensuring structural safety.