A structure designed for containing a fire within a building, coupled with a vertical channel for exhausting combustion gases, represents a common architectural feature. The appliance serves as a focal point within a room while providing a means of supplemental heating. Early examples were primarily functional necessities, offering warmth and a location for cooking.

The presence of such a system can significantly enhance a property’s aesthetic appeal, creating an inviting and comfortable atmosphere. Historically, these installations played a vital role in residential heating before the advent of modern central heating systems. Beyond functional considerations, they often hold sentimental value, becoming a gathering place for families and a symbol of domesticity.

The following discussion will address key aspects related to the design, maintenance, and safety considerations associated with these systems. Topics to be covered include fuel types, efficiency factors, regulatory compliance, and best practices for ensuring optimal performance and minimizing potential hazards.

Enhancing Functionality and Safety

The following recommendations aim to optimize the performance and safety of systems designed to contain fire within a dwelling and vent exhaust externally.

Tip 1: Fuel Selection: Employ seasoned wood as the primary fuel source. Seasoning reduces moisture content, leading to more efficient combustion and decreased creosote buildup, a significant fire hazard.

Tip 2: Regular Inspection: Conduct annual professional inspections of the flue and firebox. Addressing minor issues promptly prevents escalation into costly repairs or dangerous situations.

Tip 3: Creosote Management: Schedule regular cleaning to remove creosote deposits. The frequency depends on usage and fuel type, but at least once per heating season is advisable.

Tip 4: Damper Operation: Ensure the damper functions correctly. A properly sealed damper prevents heat loss when the appliance is not in use and allows for controlled draft during operation.

Tip 5: Smoke Detector Maintenance: Verify that smoke detectors are functional and strategically located near the appliance. Replace batteries regularly to ensure reliable operation.

Tip 6: Carbon Monoxide Detection: Install a carbon monoxide detector in close proximity to the appliance. This provides early warning of potentially lethal gas leaks.

Tip 7: Proper Ventilation: Ensure adequate air supply to the room to support combustion. Insufficient ventilation can lead to incomplete combustion and the production of carbon monoxide.

These guidelines promote efficient operation, minimize risks, and contribute to the longevity of the system.

The subsequent section will delve into common maintenance procedures and troubleshooting techniques.

1. Design Considerations

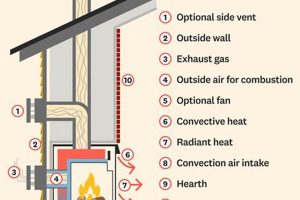

Design considerations exert a profound influence on the functionality and safety of an indoor fireplace with a chimney. The dimensions of the firebox, for instance, directly impact combustion efficiency and heat output. An improperly sized firebox may lead to incomplete combustion, resulting in increased smoke production and reduced heating effectiveness. Similarly, the flue dimensionsheight and cross-sectional areaare crucial for establishing adequate draft. Insufficient draft can cause backdrafting, where combustion gases enter the living space, posing a significant health hazard due to carbon monoxide exposure. Effective design balances these elements to optimize performance.

Material selection represents another critical design element. Fire-resistant materials, such as firebrick or cast iron, are essential for constructing the firebox to withstand extreme temperatures. The chimney liner materialtypically clay tile, stainless steel, or cast-in-place concretemust resist acidic corrosion from combustion byproducts. The aesthetic integration of the fireplace into the room’s architecture is also a design consideration. This includes selecting appropriate facing materialsstone, brick, tile, or woodand ensuring the overall design complements the room’s style. However, safety and functionality should always take precedence over purely aesthetic choices. A real-world example of poor design would be a fireplace with an undersized flue leading to smoke spillage into the room, whereas a well-designed system provides efficient heating and safe operation.

In summary, design considerations are integral to the successful operation of an indoor fireplace and chimney. Proper attention to firebox dimensions, flue sizing, material selection, and adherence to building codes are essential. Neglecting these design elements can result in reduced efficiency, potential safety hazards, and increased maintenance requirements. Therefore, a comprehensive understanding of these factors is paramount for both designers and homeowners seeking to incorporate a fireplace into their dwellings.

2. Material Durability

Material durability is a critical factor in the long-term performance and safety of an indoor fireplace with a chimney. The extreme temperatures and corrosive byproducts generated during combustion place significant stress on the constituent materials. The firebox, subjected to direct flame and intense heat, requires materials capable of withstanding thermal shock and sustained high temperatures. Refractory brick, specifically designed for this purpose, exhibits superior resistance compared to standard brick. Failure to use appropriate materials in the firebox results in cracking, spalling, and eventual structural failure, necessitating costly repairs or complete replacement. The chimney liner, responsible for containing and venting combustion gases, faces a different set of challenges. Acidic compounds present in the flue gases can corrode the liner over time, weakening its structural integrity and potentially leading to gas leaks into the dwelling.

The choice of materials directly influences the service life of the system. For example, stainless steel liners offer superior corrosion resistance compared to traditional clay tile liners, especially when burning wood with high moisture content, which produces more acidic creosote. Similarly, using high-quality mortar specifically formulated for chimney construction minimizes the risk of mortar joint degradation and water infiltration. Water penetration, in turn, can accelerate the deterioration of the entire structure due to freeze-thaw cycles. Neglecting material durability can result in reduced efficiency, increased maintenance requirements, and potential safety hazards. A compromised chimney liner, for instance, allows combustion gases to escape into the building’s structure, increasing the risk of carbon monoxide poisoning.

In conclusion, material durability is not merely a desirable attribute but an essential component for the safe and efficient operation of an indoor fireplace with a chimney. Selecting appropriate, high-quality materials for the firebox, chimney liner, and mortar joints minimizes the risk of failure, extends the system’s lifespan, and ensures occupant safety. The initial investment in durable materials proves cost-effective over time by reducing maintenance and repair expenses and mitigating potential hazards associated with structural degradation.

3. Draft Performance

Draft performance represents a critical operational parameter for any indoor fireplace with a chimney. It dictates the efficient removal of combustion byproducts and ensures the safe and effective operation of the heating appliance. Inadequate draft leads to smoke spillage into the living space, posing health risks and reducing heating efficiency.

- Flue Height and Diameter

The height and diameter of the flue are fundamental determinants of draft performance. A taller flue generates a greater pressure differential between the indoor and outdoor environments, thereby increasing draft. Similarly, an appropriately sized diameter ensures adequate airflow without excessive cooling of the flue gases, which can reduce buoyancy. Undersized flues restrict airflow, while oversized flues allow rapid cooling, both leading to poor draft.

- Chimney Termination Height

The height of the chimney termination above the roofline significantly impacts draft performance. Building codes typically specify minimum heights to ensure that the termination is above any nearby obstructions, such as trees or adjacent buildings. Obstructions can disrupt airflow patterns and create downdrafts, causing smoke to enter the dwelling. Proper termination height minimizes the influence of external factors on draft stability.

- Flue Temperature

The temperature of the flue gases is a crucial factor affecting draft. Hotter gases are less dense and therefore more buoyant, creating a stronger draft. Factors that influence flue temperature include the fuel type, combustion efficiency, and insulation of the chimney. Insufficient insulation allows the flue gases to cool rapidly, reducing buoyancy and diminishing draft performance. Burning seasoned wood, which burns hotter and cleaner, helps maintain optimal flue temperature.

- Air Supply and Room Pressure

Adequate air supply to the firebox is essential for proper combustion and optimal draft performance. A lack of air can lead to incomplete combustion, producing more smoke and reducing flue gas temperature. Modern, tightly sealed homes can experience negative pressure, which can compete with the natural draft of the chimney, causing backdrafting. Providing a dedicated air supply to the fireplace can mitigate these issues and improve draft performance.

Optimizing draft performance in an indoor fireplace with a chimney requires careful consideration of flue dimensions, chimney termination height, flue temperature management, and adequate air supply. These factors interact to determine the efficiency and safety of the heating appliance. Addressing these elements ensures a reliable and comfortable heating experience while minimizing the risk of smoke spillage and carbon monoxide exposure.

4. Combustion Efficiency

Combustion efficiency in an indoor fireplace with a chimney directly correlates with both heating performance and environmental impact. Optimizing combustion minimizes fuel consumption, reduces particulate emissions, and maximizes heat output, enhancing the functionality and sustainability of the appliance.

- Fuel Type and Moisture Content

The type and condition of the fuel significantly influence combustion efficiency. Seasoned hardwoods, with a moisture content below 20%, burn cleaner and more completely than green or softwood. High moisture content reduces combustion temperature, leading to incomplete combustion and increased creosote production. Implementing dry, dense hardwoods maximizes heat release and minimizes harmful emissions in a fireplace setting.

- Air Supply and Firebox Design

Adequate air supply is crucial for complete combustion. Firebox design, including air inlets and baffling systems, influences the mixing of air and fuel. Modern fireplaces often incorporate controlled air inlets to regulate the combustion rate and maximize efficiency. A well-designed firebox promotes turbulent airflow, ensuring sufficient oxygen for complete combustion and reducing the formation of carbon monoxide.

- Chimney Draft and Flue Management

Proper chimney draft is essential for removing combustion gases and supplying oxygen to the fire. Inadequate draft results in incomplete combustion and smoke spillage into the living space. Efficient flue management, including regular cleaning and inspection, prevents creosote buildup, which can impede airflow and increase the risk of chimney fires. Optimizing chimney draft through proper design and maintenance promotes efficient and safe combustion.

- Appliance Maintenance and Operational Practices

Regular maintenance and proper operational practices enhance combustion efficiency. Cleaning the firebox, ensuring proper damper operation, and employing appropriate firing techniques contribute to cleaner burning and reduced emissions. Consistent maintenance minimizes the buildup of ash and creosote, ensuring optimal airflow and combustion performance. Adopting responsible operational practices maximizes efficiency and extends the lifespan of the fireplace system.

These facets collectively underscore the importance of combustion efficiency in indoor fireplaces with chimneys. By addressing fuel selection, air supply, chimney draft, and maintenance practices, users can optimize heating performance, minimize environmental impact, and ensure the safe operation of the appliance.

5. Maintenance Schedule

The longevity, safety, and efficiency of an indoor fireplace with chimney are inextricably linked to a rigorous maintenance schedule. The accumulation of creosote, a byproduct of incomplete combustion, within the chimney poses a significant fire hazard. Regular cleaning, ideally conducted annually by a certified professional, mitigates this risk. Failure to adhere to a scheduled cleaning regime can result in creosote buildup, potentially leading to a chimney fire with devastating consequences. Furthermore, the accumulation of debris, such as leaves or bird nests, can obstruct the flue, impeding proper ventilation and leading to carbon monoxide accumulation within the dwelling. A planned maintenance approach directly addresses these potential hazards, ensuring safe operation.

Beyond safety concerns, a well-defined maintenance schedule extends the lifespan of the system. Components such as the firebox lining, damper, and chimney cap are subject to wear and tear from constant exposure to high temperatures and corrosive byproducts. Regular inspections, as part of the maintenance plan, allow for the early detection of damage, preventing minor issues from escalating into costly repairs. For instance, cracks in the firebox lining, if left unaddressed, can compromise the structural integrity of the entire fireplace. Similarly, a malfunctioning damper can significantly reduce heating efficiency, increasing fuel consumption and associated costs. Proactive maintenance, therefore, provides economic benefits through reduced repair expenses and optimized energy use.

In summary, a comprehensive maintenance schedule is not merely an optional task but an essential element for the safe and efficient operation of an indoor fireplace with chimney. Regular cleaning prevents fire hazards, while proactive inspections prolong the system’s lifespan and optimize performance. Neglecting this aspect can lead to significant safety risks and financial burdens, highlighting the critical importance of adherence to a planned maintenance program. The homeowner assumes responsibility for maintaining their fireplace and chimney or hires a certified professional for this task.

6. Safety Regulations

Safety regulations governing indoor fireplaces with chimneys are established to mitigate inherent risks associated with combustion appliances. These regulations address diverse aspects, ranging from installation standards to operational protocols and maintenance requirements. Failure to adhere to these safety regulations can lead to severe consequences, including structural fires, carbon monoxide poisoning, and property damage. Building codes, often informed by standards developed by organizations such as the National Fire Protection Association (NFPA), specify minimum clearances between the fireplace and combustible materials, flue sizing requirements, and proper chimney construction techniques. These measures are designed to prevent the spread of fire and ensure the safe venting of combustion gases. For instance, maintaining adequate clearance between the fireplace and wood framing minimizes the risk of ignition due to radiant heat transfer.

Enforcement of safety regulations typically falls under the purview of local building inspectors, who review construction plans and conduct on-site inspections to verify compliance. Permits are often required for new fireplace installations or modifications to existing systems, allowing inspectors to ensure that work adheres to applicable codes. Furthermore, some jurisdictions mandate periodic inspections of fireplaces and chimneys, particularly in rental properties, to identify potential hazards. The practical significance of these regulations is evident in the reduced incidence of fireplace-related incidents in areas with rigorous enforcement. Conversely, areas with lax enforcement often experience a higher frequency of chimney fires and carbon monoxide exposures. A real-world example is the adoption of carbon monoxide detector requirements in response to increased awareness of the dangers of incomplete combustion. These regulations, coupled with public education campaigns, have demonstrably reduced carbon monoxide-related fatalities.

In conclusion, safety regulations constitute a critical component of indoor fireplace with chimney systems, safeguarding lives and property by minimizing inherent risks. Adherence to these regulations, through proper installation, maintenance, and operational practices, is paramount. Challenges remain in ensuring consistent enforcement and promoting widespread awareness of safety protocols. Continuous monitoring and adaptation of safety regulations are necessary to address evolving technologies and construction practices. Ultimately, a comprehensive approach to safety, encompassing regulatory oversight, professional expertise, and responsible homeowner behavior, is essential for the safe and sustainable use of indoor fireplaces.

Frequently Asked Questions

The following addresses common inquiries regarding the design, operation, and maintenance of indoor fireplaces equipped with chimneys. The intent is to provide clear, concise answers to frequently encountered questions related to these systems.

Question 1: What are the key considerations when selecting a fuel source for an indoor fireplace?

Optimal fuel selection involves prioritizing seasoned hardwoods with a moisture content below 20%. Seasoning reduces moisture, promoting more efficient combustion and minimizing creosote buildup, a significant fire hazard. Avoid softwoods and unseasoned wood, as they contribute to increased smoke production and accelerated creosote accumulation.

Question 2: How frequently should an indoor fireplace and chimney be inspected by a professional?

Annual professional inspections are recommended to identify potential issues, such as cracks in the firebox, deterioration of the chimney liner, or obstructions within the flue. Early detection of these problems prevents escalation into costly repairs or dangerous situations.

Question 3: What are the primary signs of a chimney fire, and what immediate actions should be taken?

Indicators of a chimney fire include a roaring sound, dense smoke emanating from the chimney, or visible flames extending from the chimney top. In the event of a chimney fire, evacuate the premises immediately and contact emergency services. Do not attempt to extinguish the fire without professional assistance.

Question 4: What is the purpose of a chimney liner, and what materials are commonly used for its construction?

The chimney liner serves to protect the chimney structure from the corrosive effects of combustion gases and to contain the gases for safe venting. Common liner materials include clay tile, stainless steel, and cast-in-place concrete, each offering varying degrees of durability and resistance to corrosion.

Question 5: What steps can be taken to improve the heating efficiency of an indoor fireplace?

Enhancing heating efficiency involves several strategies, including ensuring proper damper operation, sealing air leaks around the fireplace, and utilizing a fireplace insert or blower to circulate heated air into the room. These measures maximize heat output and minimize heat loss.

Question 6: What are the potential health risks associated with improper fireplace operation, and how can these risks be mitigated?

Incomplete combustion can result in the production of carbon monoxide, an odorless, colorless gas that poses a serious health hazard. Mitigation strategies include ensuring adequate ventilation, using seasoned wood, and installing a carbon monoxide detector in close proximity to the fireplace.

In summary, understanding key aspects of fuel selection, maintenance, safety regulations, and efficient operation is paramount for ensuring the safe and effective use of an indoor fireplace with chimney. Consistent adherence to recommended practices minimizes risks and maximizes the benefits of this heating appliance.

The subsequent section will provide information on troubleshooting common fireplace problems.

Conclusion

The preceding discussion has presented a comprehensive overview of the indoor fireplace with chimney, encompassing design elements, material considerations, operational parameters, maintenance protocols, and relevant safety regulations. These facets are essential to understanding the intricate relationship between performance, safety, and longevity of such systems. A thorough comprehension of each element facilitates informed decision-making regarding installation, operation, and upkeep.

The safe and efficient utilization of an indoor fireplace with chimney necessitates diligent adherence to established guidelines and protocols. Continued education and proactive maintenance are critical to minimizing risks, optimizing performance, and ensuring the enduring value of this architectural feature. Future advancements in fireplace technology and evolving building codes will further shape best practices, requiring ongoing awareness and adaptation.