A projecting structure of brick or stone, often found at the top of a building, creates a flue for smoke and gases to escape. This feature is achieved by progressively stepping out courses of masonry from the wall below, forming a bracket-like support for the chimney stack above. An example of this architectural element can be observed in vernacular buildings, where it serves a functional and decorative purpose.

This design offers several advantages. It allows for the construction of a wider chimney stack without increasing the footprint of the building at ground level. Historically, this was particularly important in areas with limited space or where property taxes were based on ground floor dimensions. Furthermore, the projecting feature can enhance the aesthetic appeal of a structure, adding visual interest and a sense of verticality. This technique has been employed across various architectural styles and periods.

The subsequent sections will delve into the specific construction techniques, regional variations, and maintenance considerations associated with this type of architectural detail. Understanding these aspects is crucial for the preservation and appreciation of buildings featuring this element.

Considerations for Structures Featuring Projecting Chimneys

The following points offer guidance regarding the care and maintenance of structures incorporating a chimney supported by stepped masonry. Proper attention to these details can ensure structural integrity and longevity.

Tip 1: Monitor for Cracks: Regularly inspect the brickwork or stonework for signs of cracking, particularly at the points where the masonry projects outwards. Cracks can indicate structural stress or water damage.

Tip 2: Assess Mortar Joints: Examine the mortar joints for deterioration, such as crumbling or missing mortar. Repointing may be necessary to prevent water infiltration and maintain structural stability.

Tip 3: Check for Water Damage: Look for signs of water damage, such as staining or efflorescence, on the surfaces of the feature and surrounding walls. Address any sources of water intrusion promptly.

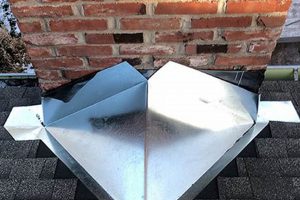

Tip 4: Ensure Proper Drainage: Verify that the chimney crown or cap is in good condition and effectively prevents water from entering the flue. Damaged or missing crowns can lead to significant water damage within the chimney structure.

Tip 5: Evaluate Structural Stability: Consult with a qualified structural engineer if there are concerns about the stability of the projecting feature, especially in areas prone to seismic activity or severe weather.

Tip 6: Consider Material Compatibility: When undertaking repairs, ensure that the replacement materials are compatible with the original construction materials to avoid differential expansion and contraction, which can lead to cracking.

Tip 7: Employ Professional Expertise: Engage experienced masons or contractors who are familiar with the techniques and challenges associated with repairing and maintaining structures featuring stepped masonry details.

Adhering to these recommendations will contribute to the preservation of these architectural elements and the overall integrity of the buildings they adorn. Timely intervention can prevent minor issues from escalating into costly and complex repairs.

The subsequent section will provide information on restoration techniques specific to historical chimneys with stepped supports.

1. Structural Projection

Structural projection is the defining characteristic of a chimney with a projecting support, directly impacting its form, function, and stability. The outward extension of the chimney stack beyond the vertical plane of the wall necessitates specific engineering and construction considerations to ensure its integrity.

- Load Transfer Mechanisms

The core principle of a projecting support involves the progressive transfer of the chimney’s weight outwards and downwards. Each course of masonry acts as a cantilever, distributing the load to the course below. The design must account for both vertical and horizontal forces to prevent overturning or shear failure. This mechanism dictates the maximum permissible projection relative to the wall thickness.

- Material Properties and Selection

The choice of materials is critical for a structurally sound projecting support. High compressive strength and resistance to weathering are essential. Traditionally, brick or stone were employed, selected for their durability and load-bearing capacity. Mortar composition also plays a vital role, providing adhesion and accommodating movement within the structure. Incompatible materials can lead to stress concentrations and premature deterioration.

- Construction Techniques and Geometry

Precise execution of masonry techniques is paramount in constructing a projecting support. Each course must be carefully laid and aligned to ensure uniform load distribution. The geometry of the projection, including the step-out distance and angle, influences the structural behavior of the assembly. Gradual, incremental projections minimize stress concentrations and enhance stability. Any deviations from established construction practices can compromise the integrity of the entire structure.

- Long-Term Performance and Maintenance

The projecting support is susceptible to environmental factors, including freeze-thaw cycles and wind loading. Regular inspection and maintenance are crucial for identifying and addressing potential problems. Cracking, mortar deterioration, and water infiltration can weaken the structure and accelerate its degradation. Timely repairs, such as repointing and crack sealing, are essential for preserving its long-term performance.

In summary, the structural projection represents a complex interplay of engineering principles, material properties, and construction techniques. A thorough understanding of these facets is necessary for designing, constructing, and maintaining chimneys that are both aesthetically pleasing and structurally sound.

2. Masonry Construction

Masonry construction forms the foundational basis of a chimney with projecting support. The stepped, outward projection, the defining characteristic, is achieved through carefully layered courses of brick or stone, each strategically placed to gradually extend beyond the vertical plane of the wall. Without sound masonry practices, the inherent structural vulnerabilities of the projecting element would lead to instability and eventual collapse. The choice of materials, mortar composition, and laying techniques directly impacts the load-bearing capacity and longevity of the projecting structure. For example, vernacular buildings in regions with readily available stone often feature chimneys constructed from locally sourced materials, showcasing adaptations in masonry techniques to suit the properties of the stone. The careful selection of mortar, balancing flexibility and strength, is crucial to accommodate thermal expansion and contraction and prevent cracking.

The effectiveness of masonry in the creation of a projecting chimney is also contingent on proper bonding patterns. These patterns, such as English bond or Flemish bond, interlock the bricks or stones, distributing the load evenly and preventing localized stress concentrations. The skillful execution of these patterns requires experienced masons who understand the nuances of material behavior and structural mechanics. Furthermore, the process of constructing the projecting element necessitates precise alignment and leveling to ensure stability. Any deviations from the intended geometry can compromise the load-bearing capacity and lead to differential settling or cracking. Real-world examples of well-preserved chimneys with projecting supports serve as testaments to the enduring quality of traditional masonry practices.

In summary, masonry construction is not merely a component of a chimney with projecting support but rather its very essence. A deep understanding of masonry principles and the application of appropriate techniques are indispensable for ensuring the structural integrity, durability, and aesthetic appeal of these architectural features. The challenges lie in selecting compatible materials, employing skilled craftsmanship, and maintaining the structure over time. This knowledge connects to the broader theme of preserving architectural heritage and understanding the interplay between materials, design, and construction in creating sustainable and aesthetically pleasing built environments.

3. Flue Functionality

Flue functionality represents a critical performance aspect of any chimney, including those with projecting masonry supports. The efficient and safe conveyance of combustion byproducts is paramount, ensuring proper ventilation and minimizing the risk of hazardous conditions. The design and construction of the flue must account for the specific characteristics of the chimney structure, including the potential for increased complexity introduced by the projecting support.

- Draft Optimization

The flue must generate sufficient draft to effectively exhaust combustion gases. Factors influencing draft include flue height, internal diameter, and insulation. Chimneys with projecting supports may experience localized turbulence or variations in flue gas temperature, potentially affecting draft performance. Careful consideration must be given to these factors during design to ensure adequate draft, particularly in regions with challenging climatic conditions or when using specific types of fuel.

- Thermal Performance

The flue liner must withstand high temperatures and prevent heat transfer to surrounding combustible materials. Insufficient insulation can lead to excessive heat loss, reducing draft efficiency and increasing the risk of condensation. In the context of a chimney with a projecting support, the increased surface area may amplify heat loss, necessitating enhanced insulation measures to maintain optimal thermal performance and prevent structural damage from freeze-thaw cycles.

- Creosote Management

In wood-burning appliances, incomplete combustion can result in the formation of creosote, a highly flammable substance that accumulates within the flue. Regular cleaning is essential to prevent creosote buildup and reduce the risk of chimney fires. The projecting support may create areas where creosote is more likely to accumulate, requiring more frequent inspections and cleaning to maintain flue safety. The design of the flue should facilitate access for cleaning and inspection.

- Material Compatibility

The materials used in the flue construction must be compatible with the fuels being burned and resistant to the corrosive effects of combustion gases. Different fuels produce different byproducts, which can degrade flue liners over time. In chimneys with projecting supports, the potential for moisture accumulation and increased exposure to the elements may exacerbate corrosion. Careful selection of flue liner materials, such as stainless steel or clay tiles, is crucial for ensuring long-term durability and safety.

The various facets of flue functionality are inextricably linked to the design and construction of any chimney, but especially those with projecting masonry features. Optimizing draft, managing thermal performance, mitigating creosote buildup, and ensuring material compatibility are all essential for ensuring the safe and efficient operation of these structures, as well as prolonging their service life and reducing the potential for hazardous conditions or costly repairs.

4. Aesthetic Detailing

Aesthetic detailing, in the context of chimneys with stepped supports, transcends mere ornamentation; it represents an integral aspect of design that harmonizes functionality with visual appeal. This consideration extends beyond simple surface treatment, encompassing the careful selection of materials, proportioning of elements, and integration of decorative motifs. The resulting structure serves not only as a conduit for flue gases but also as a focal point that contributes to the overall architectural character of the building.

- Material Selection and Texture

The choice of brick or stone significantly influences the aesthetic quality of the feature. Variations in color, texture, and bonding patterns create visual interest and complement the surrounding architecture. For example, the use of contrasting brick colors can highlight the stepped projection, while textured stone adds a rustic character. The selection of materials must balance aesthetic considerations with durability and compatibility with the local climate.

- Proportion and Scale

The proportions of the projecting element relative to the overall building dimensions are crucial for achieving visual harmony. A chimney that is too large can overwhelm the structure, while one that is too small may appear insignificant. The degree of projection, the height of the stack, and the spacing between the stepped courses all contribute to the overall aesthetic balance. Careful consideration of these factors ensures that the element enhances rather than detracts from the building’s appearance.

- Decorative Elements

Additional ornamentation, such as corbel tables, caps, and moldings, can enhance the aesthetic appeal of the projecting feature. These elements add visual complexity and demonstrate the craftsmanship involved in the construction. The incorporation of decorative details should be consistent with the architectural style of the building, whether it is a simple, vernacular design or a more elaborate, formal style. The selection of appropriate decorative motifs reinforces the overall aesthetic theme.

- Shadow and Light

The stepped projection creates patterns of shadow and light that enhance the visual depth and interest of the chimney. The interplay of light and shadow changes throughout the day, adding dynamism to the architectural element. The design should consider the orientation of the building and the angle of the sun to maximize the impact of these effects. The texture of the materials and the detailing of the stepped courses further contribute to the interplay of shadow and light.

In summary, aesthetic detailing transforms a functional component into an architectural asset. By carefully considering material selection, proportion, ornamentation, and the interplay of light and shadow, the chimney with a projecting support can become a defining feature that enhances the visual appeal and architectural character of the building. These design considerations reflect a commitment to both functionality and aesthetics, demonstrating the potential for integrating practical elements into harmonious architectural compositions.

5. Weight Distribution

Weight distribution is a fundamental engineering principle governing the structural stability and longevity of stepped support chimneys. The outward projection of masonry necessitates a carefully balanced load transfer mechanism to prevent collapse. Uneven distribution of weight can lead to cracking, instability, and eventual failure of the structure.

- Cantilever Action

Each stepped course of masonry acts as a cantilever, supporting its own weight and the weight of the structure above. The load is transferred outwards and downwards to the supporting wall. The extent of the projection and the thickness of each course must be carefully calculated to ensure that the cantilever action is within safe limits. For example, historically, masons relied on empirical rules and local building traditions to determine the appropriate dimensions for stepped supports. Overly ambitious projections without sufficient supporting mass often resulted in structural instability.

- Stress Concentration

The points where the masonry projects outwards are subject to increased stress concentrations. These areas are particularly vulnerable to cracking and deformation under load. Proper design and construction techniques must mitigate stress concentrations by distributing the weight evenly across the stepped courses. For example, the use of high-strength mortar and the precise alignment of bricks or stones can help to minimize stress concentrations and improve the structural integrity of the projecting element.

- Material Properties

The weight distribution capabilities of a stepped support chimney are directly influenced by the properties of the materials used. High compressive strength and resistance to weathering are essential for withstanding the sustained loads and environmental stresses. The type of stone or brick, the composition of the mortar, and the presence of any reinforcing elements all contribute to the overall load-bearing capacity of the structure. For instance, the selection of porous materials can lead to water absorption and subsequent freeze-thaw damage, compromising the weight distribution mechanism and weakening the chimney.

- Foundation Settlement

Uneven foundation settlement can disrupt the weight distribution within a stepped support chimney, leading to structural distress. Differential settling places additional stress on certain areas of the projection, potentially causing cracking and instability. Proper site preparation, soil compaction, and foundation design are crucial for ensuring uniform support and preventing settlement-related problems. Regular monitoring of the chimney for signs of settlement, such as cracks or tilting, is also essential for early detection and mitigation of potential issues.

The interaction between cantilever action, stress concentration, material properties, and foundation settlement collectively determines the long-term performance of weight distribution within a stepped support chimney. A thorough understanding of these factors is crucial for the design, construction, and maintenance of these architectural features, ensuring their structural stability and preserving their historical significance. Examples of failures due to inadequate weight distribution serve as cautionary tales, highlighting the importance of proper engineering and construction practices.

Frequently Asked Questions

The following questions address common inquiries regarding the design, construction, and maintenance of structures featuring projecting masonry elements at their apex.

Question 1: What is the primary structural advantage of a chimney utilizing stepped masonry for support?

The stepped configuration allows for a wider chimney stack above without increasing the footprint of the structure at ground level. This is particularly advantageous in situations where space is constrained or property taxes are assessed based on ground-floor dimensions.

Question 2: How does the use of stepped masonry impact the long-term stability of a chimney structure?

Properly designed and constructed stepped features distribute the weight of the chimney stack outwards and downwards, reducing stress concentrations on the supporting wall. This contributes to enhanced stability and longevity compared to chimneys that rely solely on vertical support.

Question 3: What are the most common causes of deterioration in chimneys with stepped support?

Exposure to the elements, particularly freeze-thaw cycles and wind-driven rain, can lead to mortar deterioration, cracking, and water infiltration. Lack of proper maintenance, such as regular cleaning and inspection, can also accelerate deterioration.

Question 4: What types of maintenance are essential for preserving the integrity of a stepped chimney?

Regular inspections to identify cracks, mortar deterioration, and water damage are crucial. Repointing of deteriorated mortar joints, sealing of cracks, and ensuring proper drainage from the chimney crown are essential maintenance practices.

Question 5: Are there specific building codes that govern the construction or repair of chimneys with stepped masonry?

Local building codes may address specific requirements for chimney construction, including material specifications, structural stability, and fire safety. It is essential to consult with local building officials and qualified professionals to ensure compliance with applicable codes.

Question 6: When should a structural engineer be consulted regarding a chimney with stepped support?

A structural engineer should be consulted if there are concerns about the stability of the structure, particularly in areas prone to seismic activity or severe weather. Also, consult if significant cracking, bulging, or other signs of structural distress are observed.

Proper understanding of these key elements ensures the ongoing functionality and longevity of structures utilizing projecting features.

The subsequent section will provide a detailed examination of case studies involving restoration projects of historic chimneys with stepped supports.

Conclusion

This exploration of the corbelled chimney has highlighted its functional and aesthetic importance in architectural history. The design, reliant on precise masonry and an understanding of weight distribution, presents both challenges and opportunities for preservation. Proper maintenance and informed restoration are crucial for safeguarding these structures.

The corbelled chimney serves as a tangible link to past construction practices and design sensibilities. Continued research, diligent preservation efforts, and informed construction choices will ensure that these architectural features endure for future generations, providing insights into the ingenuity and craftsmanship of the past.