This structure, commonly found above a cooking range, serves as a critical component in residential and commercial kitchens. It is designed to capture and expel smoke, grease, heat, and other airborne particles produced during cooking. Functioning as a localized exhaust system, it actively removes contaminants from the immediate area, contributing to improved indoor air quality. An example of its application is seen in professional kitchens, where high-volume cooking necessitates efficient ventilation.

The advantages of utilizing this system are multifaceted. Primarily, it minimizes the buildup of grease and grime on surrounding surfaces, thereby reducing cleaning frequency and effort. Furthermore, the extraction of heat contributes to a more comfortable working environment for kitchen staff. Historically, simpler forms of this technology have been employed for centuries to manage smoke from cooking fires; modern iterations enhance this fundamental principle through improved design and filtration.

Understanding the different types, installation considerations, and maintenance practices associated with this essential kitchen appliance will be the focus of the subsequent sections. This will include an exploration of factors influencing performance, regulatory requirements, and best practices for ensuring optimal operation and longevity.

Enhancing Performance and Longevity

Optimizing functionality and extending the lifespan requires adherence to established guidelines and best practices. The following recommendations outline crucial steps for ensuring consistent and efficient operation.

Tip 1: Prioritize Proper Installation: Adherence to manufacturer specifications during initial setup is paramount. Incorrect installation can significantly reduce efficiency and potentially create safety hazards.

Tip 2: Implement Regular Cleaning Schedules: Grease accumulation represents a significant fire risk and impedes airflow. Routine cleaning of filters and internal components is essential for maintaining optimal performance.

Tip 3: Select Appropriate Filter Types: Different filter types, such as mesh, baffle, and charcoal filters, cater to varying needs. Choosing the appropriate filter for the cooking style and frequency is vital for effective filtration.

Tip 4: Ensure Adequate Airflow: Confirming sufficient make-up air is available to replace the exhausted air prevents negative pressure within the dwelling. This ensures the system functions effectively and avoids drawing in unwanted odors or pollutants.

Tip 5: Conduct Periodic Inspections: Regular visual inspections of the entire unit can identify potential issues early on, such as damaged ductwork or faulty wiring. Addressing these problems promptly can prevent more significant damage.

Tip 6: Maintain Proper Ductwork: The ductwork should be free of obstructions and properly sized to accommodate the system’s exhaust capacity. Inadequate ducting restricts airflow and reduces efficiency.

Tip 7: Consider Professional Servicing: Schedule professional maintenance checks periodically. Qualified technicians can assess the system’s overall condition, perform necessary repairs, and ensure it operates safely and efficiently.

By implementing these preventative measures, the system’s overall effectiveness can be significantly enhanced, leading to improved indoor air quality and a reduced risk of fire hazards.

The subsequent sections will address common troubleshooting scenarios and provide guidance on selecting a suitable replacement unit when necessary.

1. Effective smoke removal

Effective smoke removal is a primary function and critical attribute of a chimney vent hood. The device’s capacity to eliminate smoke directly correlates with improvements in indoor air quality and mitigation of potential health hazards. Inadequate smoke removal leads to the accumulation of airborne particulate matter, which can exacerbate respiratory conditions and contribute to discomfort. A chimney vent hood, designed with appropriate capture area, fan power, and ducting, actively draws smoke away from the cooking surface, preventing its dispersal into the surrounding environment. This process is integral to maintaining a safe and healthy indoor living space.

The efficiency of smoke removal is contingent upon several factors. These include the size and design of the hood, the power of the exhaust fan (measured in cubic feet per minute, or CFM), and the presence of effective filtration systems. For instance, a commercial kitchen preparing large volumes of food requires a more powerful system than a residential kitchen with occasional light cooking. Furthermore, proper ductwork is essential to ensure unobstructed airflow, allowing the hood to effectively exhaust the smoke outside the building. Regular maintenance, including filter cleaning, is critical to sustained optimal performance.

In summary, effective smoke removal is not merely a desirable feature but a fundamental requirement of a functional chimney vent hood. Its importance is reflected in its direct impact on air quality, health, and safety. Understanding the factors that contribute to its efficiency, from design specifications to maintenance practices, is crucial for selecting, installing, and operating the system effectively. Prioritizing smoke removal capabilities during the selection process represents a proactive step towards ensuring a healthier and safer indoor environment.

2. Grease and odor filtration

Grease and odor filtration represent integral functions of a chimney vent hood, directly influencing indoor air quality and kitchen hygiene. The accumulation of airborne grease particles, a byproduct of cooking, presents a significant fire hazard and contributes to the degradation of kitchen surfaces. Simultaneously, cooking odors, if unmanaged, permeate throughout a dwelling, leading to unpleasant and persistent smells. Effective filtration systems within the hood actively capture these contaminants before they can circulate, thereby mitigating risks and maintaining a more sanitary environment. For example, without proper grease filtration, restaurant kitchens face an increased risk of duct fires and require more frequent and intensive cleaning.

The process of filtration typically involves a multi-stage approach. Grease filters, often constructed of mesh or baffle designs, trap larger grease particles. Activated carbon filters, on the other hand, target odors by absorbing volatile organic compounds (VOCs). The efficiency of these filters depends on several factors, including material composition, surface area, and airflow rate. Regular cleaning or replacement of these filters is crucial to maintaining their effectiveness. Neglecting this maintenance results in reduced airflow, diminished filtration capacity, and increased reliance on the hood’s blower to compensate, ultimately leading to premature component failure and increased energy consumption. Some advanced systems employ electrostatic precipitation or ultraviolet (UV) light to further enhance grease and odor removal.

In summary, grease and odor filtration are not merely ancillary features but essential components of a functional chimney vent hood. Their impact extends beyond simple convenience, affecting fire safety, air quality, and the overall longevity of the appliance and surrounding kitchen environment. Understanding the mechanisms of filtration, along with the importance of regular maintenance, empowers informed decision-making regarding hood selection and operational practices. This contributes to a safer, cleaner, and more comfortable indoor environment, whether in a residential or commercial setting.

3. Air quality improvement

The operation of a chimney vent hood is directly linked to air quality improvement within a kitchen environment. Cooking processes generate a multitude of airborne contaminants, including grease, smoke, combustion byproducts, and odors. These pollutants, if not effectively removed, can compromise indoor air quality, potentially impacting the health and well-being of occupants. The chimney vent hood, functioning as a localized exhaust system, actively captures and extracts these contaminants, preventing their dispersal throughout the dwelling. A properly functioning hood thus mitigates the accumulation of harmful airborne particles, promoting a healthier indoor environment.

The effectiveness of this system in achieving air quality improvement depends on several factors. The hood’s design, capture area, and exhaust fan capacity play critical roles. Insufficient capture area allows contaminants to escape into the surrounding space, negating the intended benefits. Similarly, an underpowered exhaust fan lacks the capacity to effectively remove pollutants, leading to their recirculation. Regular maintenance, including filter cleaning and ductwork inspection, is essential for sustained optimal performance. For example, a restaurant kitchen experiencing poor ventilation may encounter increased levels of carbon monoxide, impacting employee health and potentially violating workplace safety regulations.

In conclusion, the chimney vent hood serves as a vital component in the maintenance of acceptable indoor air quality within cooking environments. Its effective operation is contingent upon proper design, installation, and regular maintenance. By actively removing airborne contaminants, the system contributes to a healthier and more comfortable living space. Understanding the relationship between the chimney vent hood and air quality improvement is crucial for selecting, operating, and maintaining these systems effectively, ensuring their continued contribution to a healthier indoor environment.

4. Fire hazard mitigation

The integration of fire hazard mitigation is a fundamental aspect of a properly designed and maintained chimney vent hood system. Cooking activities, particularly those involving high heat and oil, generate flammable grease particles that become airborne. These particles, if not effectively captured, accumulate within the hood, ductwork, and surrounding surfaces, creating a significant fire risk. The primary function of the hood is to intercept these grease-laden vapors and channel them through filtration systems, preventing their build-up. Failure to adequately mitigate this risk can lead to catastrophic consequences, ranging from localized kitchen fires to structural damage and potential loss of life. For instance, a commercial kitchen neglecting regular cleaning of the hood and ductwork may experience a grease fire that rapidly spreads, causing extensive property damage and business interruption.

Effective fire hazard mitigation within a chimney vent hood system relies on several key components and operational practices. Grease filters, typically constructed of metal mesh or baffle designs, physically trap grease particles. Regular cleaning or replacement of these filters is crucial to maintaining their effectiveness. The ductwork connecting the hood to the exterior exhaust vent must be constructed of non-combustible materials and properly sized to accommodate the airflow requirements. Furthermore, compliance with relevant fire safety codes and regulations is essential to ensure the system meets minimum safety standards. Regular professional inspections are recommended to identify and address potential issues before they escalate into fire hazards. As an example, an incorrectly installed hood lacking proper clearances from combustible materials can readily ignite, underscoring the importance of adhering to installation guidelines.

In summary, fire hazard mitigation is an intrinsic element of chimney vent hood functionality. The system’s capacity to effectively capture and filter grease particles directly impacts the risk of fire incidents. Neglecting this aspect can lead to severe consequences, emphasizing the importance of proper design, installation, maintenance, and adherence to safety regulations. Prioritizing fire hazard mitigation within chimney vent hood systems is a proactive measure that safeguards property, protects lives, and ensures the safe operation of cooking environments.

5. Material construction quality

The material construction quality of a chimney vent hood directly influences its operational longevity, performance effectiveness, and overall safety. The harsh environment above a cooking surface exposes the appliance to high temperatures, corrosive grease vapors, and potential physical impacts. Therefore, the selection of durable and resistant materials is paramount to ensuring sustained functionality and preventing premature degradation. Inferior materials can lead to warping, corrosion, and structural failures, compromising the hood’s ability to effectively capture and exhaust contaminants. For example, a hood constructed of low-grade steel may corrode rapidly in a commercial kitchen environment, leading to costly repairs or replacement.

Stainless steel, a common material in high-quality hoods, offers superior resistance to corrosion, heat, and physical damage. The grade and thickness of the stainless steel further impact its durability. Thicker gauges provide increased strength and resistance to denting or warping. Powder-coated steel offers a more affordable alternative, but its long-term performance depends on the quality of the coating and its resistance to scratching and chipping. Internal components, such as the blower motor and wiring, should also be constructed of durable, heat-resistant materials to ensure reliable operation over extended periods. The selection of substandard internal components can result in premature failure and costly repairs. Furthermore, the quality of the welding and assembly processes significantly affects the structural integrity and longevity of the entire unit.

In conclusion, material construction quality is a critical determinant of a chimney vent hood’s overall value and performance. Selecting a hood constructed of durable, corrosion-resistant materials, such as high-grade stainless steel, and ensuring robust internal components will contribute to its longevity, operational effectiveness, and safety. Understanding the implications of material selection allows for informed decision-making, maximizing the return on investment and minimizing the risk of costly repairs or premature replacement. The choice of quality materials is not merely aesthetic; it is a fundamental factor in ensuring the hood functions reliably and safely for its intended lifespan, protecting both property and occupants.

6. Ductwork system compatibility

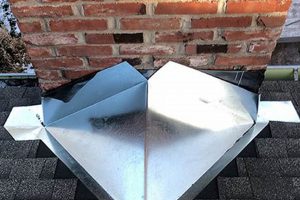

The performance of a chimney vent hood is inextricably linked to the compatibility of the associated ductwork system. The hood’s capacity to effectively remove smoke, grease, and odors hinges on its ability to exhaust those contaminants through properly sized and configured ductwork. An incompatible system, characterized by inadequate diameter, excessive length, or sharp bends, restricts airflow, diminishing the hood’s extraction efficiency. This impedance creates a backpressure that strains the blower motor, potentially leading to premature failure and increased energy consumption. A real-world example is a restaurant kitchen retrofit where a high-CFM hood is installed without upgrading the existing ductwork; the resulting lack of airflow renders the hood ineffective, failing to meet health and safety regulations.

Effective ductwork system compatibility entails several critical considerations. The duct diameter must align with the hood’s exhaust outlet size and the manufacturer’s specifications to ensure optimal airflow. The duct material should be non-combustible, such as galvanized steel, to minimize fire hazards. The length of the duct run should be minimized, and any necessary bends should be gradual to reduce airflow resistance. Furthermore, the ductwork must be properly sealed to prevent leaks, which can diminish the hood’s extraction efficiency and introduce contaminants into other areas of the building. In cases where ductwork is shared with other exhaust systems, careful consideration must be given to potential cross-contamination and pressure imbalances. Failure to address these factors can result in reduced indoor air quality, increased fire risk, and diminished energy efficiency.

In summary, ductwork system compatibility represents a crucial component of chimney vent hood performance. Inadequate ductwork negates the benefits of even the most powerful and sophisticated hood, compromising its ability to effectively remove contaminants and mitigate fire hazards. Therefore, careful consideration must be given to duct sizing, material selection, configuration, and maintenance to ensure optimal system performance and compliance with relevant safety standards. Addressing these factors proactively promotes a safer, healthier, and more energy-efficient cooking environment. Challenges in achieving compatibility often stem from existing building infrastructure or budgetary constraints, necessitating a thorough assessment of the trade-offs between performance, cost, and practicality.

7. Maintenance accessibility

Maintenance accessibility constitutes a critical design and operational parameter for chimney vent hoods. The degree to which components are readily accessible for cleaning, inspection, and repair directly impacts the long-term performance, safety, and lifespan of the appliance. Poorly designed systems, characterized by difficult-to-reach filters, concealed ductwork connections, or complex disassembly procedures, often suffer from neglect, leading to grease accumulation, reduced airflow, and increased fire risk. This correlation underscores the significance of prioritizing maintenance accessibility during the selection and installation phases. For instance, in densely packed commercial kitchens, hoods with easily removable filters and readily accessible blower compartments facilitate routine cleaning, preventing the build-up of flammable residues that could otherwise lead to a hazardous event.

The practical implications of maintenance accessibility extend beyond fire safety. Systems that are easy to service encourage regular upkeep, ensuring sustained optimal performance and minimizing energy consumption. Clean filters and unobstructed ductwork improve airflow, reducing the strain on the blower motor and lowering electricity bills. Furthermore, easy access to internal components simplifies troubleshooting and repairs, minimizing downtime and associated costs. Manufacturers are increasingly incorporating design features that enhance maintenance accessibility, such as tool-free filter removal, hinged access panels, and standardized component interfaces. These advancements reflect a growing recognition of the importance of facilitating routine maintenance, empowering users to proactively address potential issues before they escalate into significant problems. Compliance with relevant safety codes and regulations often mandates regular inspections and cleaning of chimney vent hood systems, further emphasizing the importance of maintenance accessibility.

In conclusion, maintenance accessibility is not merely a convenience feature but a fundamental requirement for ensuring the long-term functionality, safety, and efficiency of chimney vent hoods. Systems designed with accessibility in mind promote regular upkeep, mitigating fire hazards, optimizing performance, and minimizing operational costs. Prioritizing this aspect during the selection, installation, and operational phases constitutes a proactive approach to risk management and responsible ownership. Addressing potential challenges related to maintenance accessibility, such as limited access to ductwork or complex disassembly requirements, necessitates careful planning and coordination to ensure that the system can be effectively maintained throughout its lifespan.

Frequently Asked Questions About Chimney Vent Hoods

The following section addresses common inquiries regarding chimney vent hoods, providing concise and informative answers to enhance understanding of their functionality and maintenance requirements.

Question 1: What constitutes an appropriate CFM (cubic feet per minute) rating for a chimney vent hood?

The required CFM rating depends on the cooking style and range size. A general guideline suggests a minimum of 100 CFM per linear foot of range width. High-heat cooking, such as frying or wok cooking, necessitates higher CFM ratings.

Question 2: How frequently should chimney vent hood filters be cleaned or replaced?

Filter cleaning frequency depends on cooking frequency and volume. Metal mesh filters should be cleaned monthly, while charcoal filters typically require replacement every three to six months. Inspections should be conducted regularly to assess filter condition.

Question 3: What are the common signs that a chimney vent hood is not functioning correctly?

Indications of malfunction include inadequate smoke or odor removal, excessive noise, grease buildup around the hood, and the presence of flickering lights. A professional inspection is recommended for comprehensive diagnosis.

Question 4: Does a chimney vent hood require professional installation?

While some installations may be suitable for experienced DIYers, professional installation is generally recommended, especially for ducted systems. Proper installation ensures compliance with building codes and optimal performance.

Question 5: What type of ductwork is recommended for a chimney vent hood?

Smooth, rigid metal ductwork is preferred to maximize airflow efficiency and minimize fire hazards. Flexible ductwork should be avoided due to its increased airflow resistance and potential for grease accumulation.

Question 6: Are there any specific safety precautions to observe when using a chimney vent hood?

Never operate the hood without filters in place. Regularly clean the hood and ductwork to prevent grease buildup. Ensure the hood is properly grounded and connected to a dedicated electrical circuit. Do not store flammable materials near the cooking surface.

Proper understanding and adherence to these guidelines promote the safe and effective operation of chimney vent hoods.

The subsequent sections will delve into specific troubleshooting scenarios and provide guidance on selecting a replacement unit when necessary.

Conclusion

This exploration of the chimney vent hood has illuminated its multifaceted role in ensuring both safety and operational efficiency within cooking environments. From smoke and grease removal to air quality improvement and fire hazard mitigation, the system’s contribution extends beyond simple convenience. Material construction quality, ductwork compatibility, and maintenance accessibility have been identified as critical parameters influencing long-term performance and reliability. Understanding these aspects is paramount for informed decision-making during selection, installation, and routine upkeep.

Continued adherence to established best practices, including regular cleaning, professional inspections, and compliance with relevant safety codes, is essential for maximizing the benefits and minimizing the risks associated with chimney vent hood operation. A proactive approach to maintenance and a commitment to quality contribute to a safer, healthier, and more sustainable indoor environment for both residential and commercial applications. The significance of this technology in safeguarding property and protecting occupants necessitates a continued emphasis on its proper implementation and responsible operation.