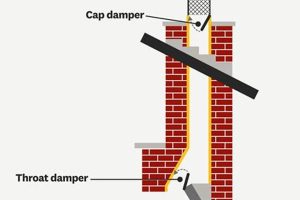

A protective barrier designed for installation at the top of a chimney, this component is typically constructed of wire or metal mesh. Its purpose is to prevent the entry of animals, debris, and burning embers into the chimney flue. Examples include models fabricated from stainless steel, copper, or galvanized steel, each offering different levels of durability and resistance to corrosion.

The installation of such a safeguarding device contributes significantly to maintaining the operational efficiency and safety of a fireplace or heating system. It mitigates the risk of chimney fires by preventing the accumulation of flammable materials such as leaves and twigs. Furthermore, it serves as a crucial deterrent against nesting birds and other wildlife, which can cause blockages and potential damage to the chimney structure. Historically, simpler forms of chimney protection have been employed, but modern versions provide enhanced protection and longevity.

The subsequent sections will delve into the selection criteria for these protective devices, installation methods, maintenance best practices, and a comparative analysis of available materials and designs.

Essential Considerations for Chimney Protection

The following recommendations are intended to assist in the effective selection, installation, and maintenance of protective chimney components. Adherence to these guidelines will contribute to the longevity and safe operation of the chimney system.

Tip 1: Material Selection: Prioritize stainless steel or copper construction. These materials offer superior resistance to corrosion and weathering compared to galvanized steel, resulting in a longer service life.

Tip 2: Mesh Size Evaluation: Ensure the selected product features a mesh size small enough to effectively exclude birds, squirrels, and other small animals. A mesh size of 1/4 inch or smaller is generally recommended.

Tip 3: Secure Attachment Mechanism: Verify the chosen component incorporates a robust and secure attachment mechanism. Options may include stainless steel screws, tension bands, or specialized clamps designed for chimney application.

Tip 4: Professional Installation: Consider professional installation, particularly for multi-story structures or chimneys with difficult access. Improper installation can compromise the effectiveness and structural integrity of the device.

Tip 5: Regular Inspection Schedule: Establish a regular inspection schedule, ideally twice annually (spring and fall), to assess the condition of the device. Check for signs of damage, corrosion, or debris accumulation.

Tip 6: Debris Removal Protocol: Implement a protocol for periodic debris removal. Accumulated leaves, twigs, and other materials can obstruct airflow and increase the risk of chimney fires.

Tip 7: Compatibility Verification: Ensure compatibility with existing chimney components, such as the flue liner and chimney cap. Incompatibility can lead to accelerated deterioration or reduced performance.

Properly selected and maintained protective chimney barriers offer significant advantages in terms of safety, efficiency, and structural preservation. Implementing these tips will maximize the return on investment and minimize the risk of chimney-related hazards.

The following sections will address common issues and troubleshooting strategies associated with chimney protection, as well as advancements in technology and design within this field.

1. Material Durability

Material durability represents a critical factor in the long-term effectiveness and functionality of chimney mesh screens. The selection of appropriate materials directly influences the ability of the screen to withstand environmental stressors, prevent degradation, and maintain its protective capabilities over extended periods. The consequences of selecting a material with inadequate durability can include premature failure, compromised safety, and increased maintenance requirements.

- Corrosion Resistance

Exposure to moisture, acidic precipitation, and temperature fluctuations necessitates materials with high corrosion resistance. Stainless steel and copper alloys are frequently employed due to their inherent ability to resist oxidation and degradation in harsh environments. The use of less resistant materials, such as uncoated carbon steel, can lead to rust formation, compromising the structural integrity of the screen and potentially resulting in failure.

- Thermal Stability

Chimneys experience a wide range of temperatures, from ambient conditions to the high temperatures associated with flue gases during fireplace or furnace operation. Materials must possess sufficient thermal stability to prevent warping, cracking, or other forms of heat-induced degradation. Materials with low melting points or high coefficients of thermal expansion are generally unsuitable for this application.

- Mechanical Strength

The screen must withstand physical impacts from debris, animals, and environmental forces such as wind and ice. Materials with high tensile strength and resistance to deformation are preferred to ensure the screen maintains its shape and protective function. Thin or brittle materials are susceptible to damage and may require frequent replacement.

- UV Resistance

Prolonged exposure to ultraviolet (UV) radiation from sunlight can degrade certain materials, causing them to become brittle and lose their structural integrity. While less of a concern for metallic screens, the UV resistance of any non-metallic coatings or components should be considered, particularly in regions with high levels of solar radiation.

The interplay between these facets of material durability directly affects the overall performance and longevity of chimney protection. Selecting a chimney mesh screen that balances these considerations ensures effective and reliable protection against debris, animals, and other potential hazards, contributing to the safe and efficient operation of the chimney system.

2. Mesh Aperture Size

Mesh aperture size, referring to the dimensions of the openings within the wire or metal mesh of a chimney safeguard, directly influences its performance. Insufficiently small apertures permit the entry of birds, squirrels, and other small animals, negating the primary function of preventing chimney blockages and associated hazards. Conversely, excessively small apertures can restrict airflow, potentially affecting the draft and combustion efficiency of the fireplace or heating appliance. For example, a mesh with openings larger than 1/2 inch may allow smaller birds to nest within the chimney, while a mesh with openings smaller than 1/4 inch could impede proper ventilation in certain systems. The selection of an appropriate mesh aperture size represents a critical design consideration for effective chimney protection.

The practical significance of understanding the interplay between mesh aperture size and chimney function extends to preventing both immediate safety concerns and long-term structural damage. Blocked chimneys can lead to carbon monoxide buildup, increasing the risk of poisoning. Furthermore, trapped moisture and accumulated debris can accelerate the deterioration of the chimney liner and masonry. Regular inspection of the “chimney mesh screen,” with particular attention to the integrity and size of the mesh openings, provides a means to proactively identify and address potential issues before they escalate into costly repairs or hazardous conditions.

Achieving the optimal mesh aperture size requires a balance between exclusionary capabilities and adequate airflow. Industry standards and manufacturer recommendations often provide guidance on appropriate mesh sizes for various chimney configurations and geographic locations. While readily available pre-fabricated “chimney mesh screen” options offer convenience, custom solutions may be necessary for unique chimney dimensions or specific environmental challenges. In summary, careful consideration of mesh aperture size is essential for ensuring the reliable performance and safety of chimney protection systems.

3. Corrosion Resistance

Corrosion resistance is a paramount attribute of materials used in the construction of chimney mesh screens. The operational environment of a chimney exposes these screens to a combination of moisture, combustion byproducts, and varying temperatures, all of which can accelerate corrosive processes. The lifespan and effectiveness of a mesh screen are directly correlated with its ability to withstand these corrosive elements.

- Material Selection and Galvanic Corrosion

The choice of metal significantly impacts corrosion resistance. Stainless steel, particularly grades 304 and 316, exhibit superior resistance due to the formation of a passive chromium oxide layer. Conversely, galvanized steel, while offering initial protection, can corrode over time, especially when the zinc coating is compromised. Furthermore, the use of dissimilar metals in proximity can lead to galvanic corrosion, where one metal corrodes preferentially. For example, using aluminum fasteners with a steel screen in a damp environment will lead to the aluminum corroding.

- Exposure to Acidic Condensates

Combustion of fuels, especially those containing sulfur, generates acidic condensates that can attack the mesh material. These condensates form when flue gases cool, depositing corrosive acids on the screen surface. Materials with poor acid resistance will degrade rapidly under these conditions. Chimneys serving gas or oil-burning appliances are particularly susceptible to this form of corrosion, necessitating the use of highly resistant materials.

- Environmental Factors and Atmospheric Corrosion

Atmospheric conditions, including humidity, rainfall, and proximity to marine environments, influence the rate of corrosion. Coastal areas with high salt concentrations in the air significantly accelerate the corrosion of many metals. Even in less harsh environments, prolonged exposure to moisture and pollutants can lead to oxidation and degradation. Mesh screens in exposed locations are thus more vulnerable and require robust corrosion protection.

- Mesh Coating and Surface Treatments

Application of protective coatings can enhance the corrosion resistance of chimney mesh screens. Powder coating, epoxy coatings, and ceramic-based treatments provide a barrier between the metal and the environment. However, the effectiveness of these coatings depends on their integrity and adhesion. Scratches or damage to the coating can create sites for localized corrosion to initiate. Regular inspection and maintenance of the coating are essential to preserving its protective function.

These interconnected aspects of corrosion resistance are critical for ensuring the long-term performance of chimney mesh screens. By selecting materials and coatings that are well-suited to the specific environmental conditions and combustion processes involved, it is possible to significantly extend the lifespan of the screen and maintain its intended function of preventing debris and animal intrusion into the chimney flue.

4. Installation Security

Installation security, with respect to chimney mesh screens, denotes the robustness and reliability of the attachment method used to affix the screen to the chimney structure. It is a critical factor determining the screen’s ability to withstand environmental forces, prevent dislodgement, and effectively perform its intended function of excluding debris and animals. Compromised installation security directly undermines the protective capabilities of the screen, potentially leading to significant safety hazards and costly repairs.

- Fastener Integrity

The selection of appropriate fasteners is paramount. Stainless steel screws, tension bands, or specialized clamps designed for chimney applications are typically employed. Fasteners must be resistant to corrosion and capable of maintaining their holding strength over time, despite exposure to temperature fluctuations and moisture. For example, using improperly sized or low-quality screws can result in loosening or breakage, allowing the screen to detach during high winds.

- Chimney Compatibility

The attachment method must be compatible with the specific chimney construction. Different chimneysmasonry, metal, or prefabricatedrequire distinct installation techniques. Attempting to force a screen designed for a round metal flue onto a square masonry chimney can compromise the integrity of both the screen and the chimney itself. Proper assessment of chimney geometry and material is essential before commencing installation.

- Weather Resistance

The installed screen must resist dislodgement from wind, snow, and ice accumulation. High winds can exert significant forces on the screen, particularly on chimneys located in exposed areas. In regions with heavy snowfall, the weight of accumulated snow can further strain the attachment points. The installation method should account for these weather-related stresses, incorporating features such as robust mounting brackets and secure fastening mechanisms.

- Professional Execution

While DIY installation is possible, professional installation is recommended, particularly for multi-story structures or chimneys with difficult access. Professional installers possess the expertise and equipment to ensure proper alignment, secure fastening, and adherence to safety codes. Improper installation can not only compromise the screen’s effectiveness but also create hazardous conditions for the installer. For example, attempting to install a screen from a precarious ladder position can lead to falls and serious injury.

These facets of installation security are inextricably linked to the overall performance and safety of chimney mesh screens. A properly installed screen, utilizing appropriate fasteners, compatible techniques, and accounting for environmental factors, provides reliable and long-lasting protection against debris and animal intrusion. Conversely, a poorly installed screen can create more problems than it solves, underscoring the importance of meticulous attention to detail and adherence to best practices during the installation process.

5. Debris Accumulation

Debris accumulation within a chimney poses a significant threat to both its structural integrity and operational safety. The presence of leaves, twigs, animal nests, and other foreign materials can obstruct the flue, impede proper ventilation, and create a fire hazard. The effectiveness of a chimney mesh screen in mitigating this threat is paramount, making the understanding of debris accumulation processes essential for informed screen selection and maintenance.

- Source and Composition of Debris

Debris entering a chimney originates from diverse sources, including airborne particles, falling foliage, and nesting animals. Its composition can range from dry, easily combustible materials like leaves and twigs to dense, damp substances like animal droppings and decomposed organic matter. The specific composition of debris influences its flammability, rate of decomposition, and potential to contribute to chimney blockages. For example, pine needles tend to be more flammable than oak leaves, and animal nests can harbor moisture that accelerates corrosion of the chimney liner.

- Impact on Airflow and Combustion

Accumulated debris restricts airflow within the chimney flue, reducing the draft and potentially leading to incomplete combustion. This can result in the buildup of carbon monoxide, a colorless and odorless gas that poses a serious health risk. Furthermore, restricted airflow can cause backdrafting, where combustion gases are forced back into the living space. The severity of these effects depends on the volume and density of the debris accumulation, as well as the design and dimensions of the chimney.

- Contribution to Chimney Fires

Creosote, a flammable byproduct of wood combustion, accumulates on the inner walls of the chimney flue. The presence of debris accelerates creosote buildup by providing a surface for it to condense and adhere to. Accumulated creosote, combined with dry debris, creates a highly combustible mixture that can ignite, leading to a chimney fire. These fires can spread rapidly, causing significant damage to the chimney structure and potentially igniting surrounding building materials.

- Screen Maintenance and Debris Removal

Regular inspection and cleaning of chimney mesh screens are essential for preventing excessive debris accumulation. Screens should be inspected at least twice annually, in the spring and fall, to assess the extent of debris buildup. Accumulated debris should be removed promptly, using a brush or vacuum cleaner. Neglecting screen maintenance can compromise its effectiveness, allowing debris to bypass the screen and enter the chimney flue. In cases of heavy debris accumulation, professional chimney cleaning services may be required.

The interconnectedness of these factors underscores the importance of a proactive approach to debris management within chimneys. A well-maintained chimney mesh screen, coupled with regular inspections and cleaning, provides a critical line of defense against the hazards associated with debris accumulation, ensuring the safe and efficient operation of the chimney system.

6. Animal Intrusion Prevention

Animal intrusion prevention is a primary function of chimney mesh screens, directly impacting the safety and operational efficiency of a chimney system. Unimpeded access by animals can lead to a range of problems, from chimney blockages to property damage. Implementing effective strategies to deter animal entry is, therefore, a critical aspect of chimney maintenance.

- Species-Specific Deterrents

Different animal species require different deterrent strategies. For example, a mesh screen with smaller apertures is necessary to exclude smaller birds such as sparrows, while larger openings may be sufficient to deter larger animals like raccoons. Understanding the prevalent species in a given geographic area is crucial for selecting the appropriate mesh size and installation methods. Failure to account for species-specific behaviors can render the mesh screen ineffective.

- Chimney Blockage and Ventilation Impairment

Nesting birds and other animals can construct nests within the chimney flue, obstructing airflow and impairing ventilation. This obstruction can lead to carbon monoxide buildup within the dwelling, posing a significant health risk. Furthermore, restricted airflow can reduce the efficiency of fireplaces and heating systems. A properly installed and maintained mesh screen prevents animal nesting, preserving the chimney’s ventilation capacity and mitigating the risk of carbon monoxide poisoning.

- Structural Damage and Nesting Materials

Animals can cause structural damage to the chimney by dislodging bricks, damaging the flue liner, or introducing corrosive nesting materials. Bird droppings, for example, contain uric acid that can erode masonry over time. The presence of nesting materials can also trap moisture, accelerating the deterioration of the chimney structure. A mesh screen prevents animal entry, safeguarding the chimney from these forms of damage and prolonging its lifespan.

- Material Degradation and Longevity

The effectiveness of animal intrusion prevention is contingent upon the durability and longevity of the mesh screen material. Inferior materials can corrode, degrade, or become damaged by animals, compromising their ability to exclude entry. Selecting corrosion-resistant materials like stainless steel and ensuring secure installation are essential for maintaining the long-term effectiveness of the mesh screen in preventing animal intrusions. Regular inspection and prompt repair of any damage are also crucial.

The aforementioned points underscore the integral connection between animal intrusion prevention and chimney mesh screens. The implementation of a robust, species-appropriate, and well-maintained mesh screen is an essential step in preserving the safety, efficiency, and structural integrity of a chimney system. The consequences of neglecting this aspect of chimney maintenance can be significant, ranging from minor inconveniences to serious safety hazards.

7. Airflow Maintenance

Airflow maintenance constitutes a critical operational parameter directly influenced by the design and condition of a chimney mesh screen. The primary function of a chimney is to facilitate the efficient expulsion of combustion byproducts, relying on a consistent and unimpeded flow of air. A mesh screen, while designed to prevent the ingress of debris and animals, must also allow for adequate ventilation to ensure proper draft and prevent the accumulation of hazardous gases within the dwelling. A mesh screen with excessively small apertures, or one obstructed by accumulated debris, can impede airflow, leading to incomplete combustion and the potential for carbon monoxide buildup. For instance, a homeowner who installs a screen with an overly fine mesh to prevent bird entry may inadvertently reduce the chimney’s draft, leading to smoke spillage into the living space during fireplace use.

The choice of material and the frequency of maintenance are directly related to airflow maintenance. Materials prone to corrosion or degradation can reduce the effective open area of the mesh screen, further restricting airflow over time. Similarly, the accumulation of leaves, twigs, and other debris on the screen surface can progressively diminish ventilation. Regular inspections and cleaning are therefore essential to ensure that the screen does not become a significant impediment to airflow. As an example, a chimney in a wooded area may require more frequent cleaning of its screen than one in an open environment to prevent leaf accumulation from restricting ventilation.

Effective airflow maintenance is, therefore, a balancing act. The chimney mesh screen must provide adequate protection against unwanted intrusions while simultaneously allowing for the unrestricted passage of combustion gases. Careful selection of mesh size, material, and adherence to a regular maintenance schedule are crucial factors in achieving this balance. Neglecting airflow maintenance can compromise the safety and efficiency of the entire chimney system, underscoring the practical significance of this understanding for homeowners and chimney professionals alike.

Frequently Asked Questions Regarding Chimney Mesh Screens

The following section addresses common inquiries and misconceptions concerning chimney mesh screens, providing clarity on their purpose, selection, and maintenance.

Question 1: What is the primary function of a chimney mesh screen?

The primary function is to prevent the entry of animals, debris, and burning embers into the chimney flue, thereby mitigating the risk of chimney fires and blockages.

Question 2: What materials are recommended for chimney mesh screen construction?

Stainless steel and copper are preferred due to their superior corrosion resistance and longevity compared to galvanized steel or aluminum.

Question 3: What mesh size is most effective for animal exclusion?

A mesh size of 1/4 inch or smaller is generally recommended to prevent the entry of birds, squirrels, and other small animals.

Question 4: How often should a chimney mesh screen be inspected?

It is advisable to inspect the screen at least twice annually, preferably in the spring and fall, to assess its condition and remove any accumulated debris.

Question 5: Is professional installation of a chimney mesh screen necessary?

While DIY installation is possible, professional installation is recommended, especially for multi-story structures or chimneys with difficult access, to ensure proper alignment and secure fastening.

Question 6: What are the potential consequences of neglecting chimney mesh screen maintenance?

Neglecting maintenance can lead to debris accumulation, reduced airflow, chimney fires, and potential damage to the chimney structure, compromising both safety and efficiency.

In summary, chimney mesh screens play a vital role in maintaining chimney safety and functionality. Proper selection, installation, and regular maintenance are crucial for maximizing their effectiveness.

The subsequent section will explore advanced technologies and emerging trends in chimney protection.

Chimney Mesh Screen

This exploration of the chimney safeguard underscores its critical role in maintaining the structural integrity and operational safety of chimney systems. From material selection and installation security to debris accumulation prevention and airflow maintenance, each aspect contributes directly to the overall effectiveness of these protective devices. The integration of durable materials, appropriate mesh sizing, and secure attachment methods are essential for preventing animal intrusion, mitigating fire hazards, and promoting efficient ventilation.

The adoption of a proactive approach to chimney protection, including regular inspections and maintenance, is not merely a matter of routine; it is a crucial investment in safeguarding property and lives. As technology and design continue to evolve, ongoing vigilance and informed decision-making will remain paramount in ensuring the sustained performance and reliability of the chimney mesh screen in safeguarding homes and structures from potential hazards.