These additions are self-contained heating units designed to be installed within an existing masonry fireplace. They typically feature a metal firebox surrounded by a decorative facade. As an example, a homeowner might choose to install one to improve the heating efficiency of their fireplace.

The inclusion of such a unit offers enhanced heating efficiency compared to traditional open fireplaces. They provide a more controlled and cleaner burn, reducing the amount of heat lost up the chimney and minimizing emissions. Historically, open fireplaces were primarily for ambiance; this type of addition transforms that aesthetic feature into a supplemental heat source.

The following sections will detail the types available, installation considerations, performance metrics, and maintenance requirements. This information is presented to provide a thorough understanding of these fireplace enhancements.

Chimney Insert Optimization

Effective utilization of these heating appliances necessitates adherence to specific guidelines. The following points outline best practices for maximizing efficiency and ensuring safe operation.

Tip 1: Size Appropriately. The selection process must prioritize dimensional compatibility. An incorrectly sized unit will operate inefficiently and potentially pose a safety hazard. Measure the existing fireplace accurately before purchase.

Tip 2: Prioritize Professional Installation. Installation is not a do-it-yourself undertaking. Qualified technicians possess the expertise to ensure proper venting and connection to the existing chimney flue, mitigating the risk of carbon monoxide exposure.

Tip 3: Select Fuel Wisely. The choice of fuel whether wood, gas, or pellets impacts performance and emissions. Consult the manufacturer’s specifications to determine the optimal fuel type for the chosen unit.

Tip 4: Conduct Regular Inspections. Annual inspections by a certified chimney sweep are crucial for identifying potential issues such as creosote buildup or flue blockages. Early detection prevents costly repairs and reduces the risk of chimney fires.

Tip 5: Maintain Proper Airflow. Adequate airflow is essential for efficient combustion. Ensure that air inlets are unobstructed and that the chimney damper is functioning correctly.

Tip 6: Understand Local Regulations. Compliance with local building codes and regulations is mandatory. Obtain the necessary permits and ensure the installation adheres to all applicable safety standards.

By following these guidelines, homeowners can optimize the performance of their heating appliance, ensuring safe and efficient operation throughout the heating season. Neglecting these key considerations may result in reduced efficiency, safety hazards, or costly repairs.

The subsequent sections of this document will address troubleshooting common issues and provide advanced maintenance techniques for sustained performance.

1. Fuel Type

Fuel type constitutes a primary determinant in the operation and selection of a unit designed for fireplace integration. The choice between wood, gas, and pellets fundamentally impacts heating efficiency, emissions profiles, maintenance requirements, and overall operational costs. For example, a wood-burning model necessitates manual fuel loading and ash removal, while a gas unit offers thermostat-controlled convenience. This selection also influences venting systems; wood requires a robust chimney lining to manage creosote buildup, whereas gas may permit direct venting in certain installations.

A practical consequence of selecting a specific fuel type lies in its environmental impact. Wood combustion generates particulate matter and greenhouse gases, although the carbon footprint may be considered neutral if sourced sustainably. Gas-fueled models typically produce lower particulate emissions but release carbon dioxide, contributing to climate change. Pellet units offer a middle ground, often utilizing biomass waste products and achieving relatively clean combustion with appropriate technology. Real-world scenarios demonstrate the impact: cities with prevalent wood-burning see elevated air pollution levels during winter months, prompting regulatory action.

In summary, the informed selection of fuel type is critical for optimal unit performance and environmental responsibility. While gas offers convenience and pellet units provide a sustainable alternative, wood requires diligent maintenance and responsible sourcing. Ultimately, the optimal choice balances heating needs with environmental concerns and lifestyle preferences. Understanding the implications of each fuel type is essential for achieving efficient and responsible home heating.

2. Heating Efficiency

Heating efficiency is paramount when considering these integrated heating systems, as it directly affects cost savings, environmental impact, and overall comfort levels. The inherent design of open fireplaces results in significant heat loss, making these modifications a critical improvement for maximizing usable heat output.

- Combustion Technology

The type of combustion technology employed significantly impacts heating efficiency. Modern units utilize advanced combustion techniques, such as secondary combustion and catalytic converters, to ensure a more complete burning of fuel. This process reduces unburned hydrocarbons and carbon monoxide emissions, while simultaneously extracting more heat from the fuel. For example, a unit with secondary combustion can achieve efficiency ratings significantly higher than older models without this feature, resulting in lower fuel consumption and reduced environmental impact.

- Heat Exchange System

The heat exchange system is crucial for transferring heat from the firebox to the surrounding living space. Efficient designs incorporate large surface areas and optimized airflow patterns to maximize heat transfer. Some units employ a blower system to force air across the heated surfaces, accelerating the distribution of warm air. Inefficient heat exchangers can lead to significant heat loss up the chimney, negating the benefits of improved combustion. Proper maintenance of the heat exchanger, including regular cleaning, is essential to maintain peak performance.

- Insulation

Effective insulation minimizes heat loss through the unit’s surfaces and into the surrounding masonry. High-quality insulation materials, strategically placed around the firebox and venting system, reduce heat radiation and convection losses. Poor insulation results in lower overall efficiency and can contribute to uncomfortable temperature gradients within the room. The presence of air gaps or damaged insulation compromises heating efficiency and should be addressed promptly.

- Venting Design

The design of the venting system plays a critical role in maintaining heating efficiency and ensuring safe operation. Proper venting ensures adequate draft for efficient combustion and prevents the backflow of harmful gases into the living space. Oversized or improperly installed venting systems can lead to excessive heat loss, while undersized vents can cause incomplete combustion and increased creosote buildup. Adherence to manufacturer specifications and local building codes is essential for optimizing venting performance.

These facets underscore the multi-faceted nature of heating efficiency in the context of these fireplace enhancements. While combustion technology maximizes heat extraction, heat exchange systems ensure effective transfer, insulation minimizes heat loss, and venting design guarantees safe and efficient exhaust. Ultimately, a well-designed and properly maintained unit, incorporating these elements, offers a substantial improvement in heating efficiency compared to traditional open fireplaces, translating to cost savings, reduced environmental impact, and enhanced comfort.

3. Size Compatibility

Size compatibility constitutes a critical factor in the successful and safe integration of a fireplace enhancement into an existing masonry structure. The dimensions of the unit must align with the internal measurements of the fireplace opening to ensure proper fit and functionality. An undersized unit may result in inadequate heat distribution and compromised aesthetic appeal, while an oversized unit presents significant installation challenges and potential safety hazards, including improper venting and structural instability.

The implications of mismatched dimensions extend beyond mere aesthetics. Improper fit can impede airflow, leading to incomplete combustion and increased creosote buildup in the chimney. This creates a heightened risk of chimney fires and carbon monoxide exposure. Real-world examples abound where homeowners, attempting to force an incompatible unit into their fireplace, have experienced costly repairs, reduced heating efficiency, and, in some cases, dangerous safety issues. Professional installers prioritize accurate measurements and manufacturer specifications to mitigate these risks. These professionals are equipped to conduct thorough assessments of the existing fireplace, ensuring that the selected unit is appropriately sized for optimal performance and safety.

In conclusion, size compatibility is not merely a matter of convenience but rather a fundamental safety and performance consideration. Prioritizing accurate measurements, consulting with qualified professionals, and adhering to manufacturer guidelines are essential steps in ensuring a successful and safe installation. Neglecting this aspect can lead to significant financial repercussions, compromised safety, and diminished heating efficiency, underscoring the importance of meticulous attention to size compatibility in all unit installations.

4. Installation Complexity

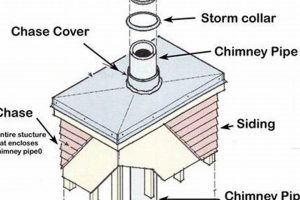

The integration of a new unit into an existing chimney system represents a multifaceted undertaking, and its complexity significantly impacts project cost, duration, and overall safety. Installation necessitates meticulous planning and execution to ensure code compliance, optimal performance, and the prevention of hazardous conditions. The degree of complexity varies considerably depending on the unit type (wood, gas, or pellet), the existing chimney’s condition, and local building regulations. For example, converting from an open fireplace to a gas-fueled unit often involves running gas lines, installing a dedicated flue liner, and ensuring proper ventilation. This heightened complexity demands specialized expertise and equipment, translating to increased labor costs and potential project delays.

A primary determinant of installation complexity lies in the need for flue liner installation. Older chimneys often lack adequate lining or possess deteriorated liners that cannot safely accommodate the exhaust gases produced by modern units. Relining a chimney can be a labor-intensive process, requiring specialized tools and techniques to ensure a gas-tight seal and proper draft. Real-world instances highlight the consequences of neglecting this critical step: inadequate flue lining can lead to carbon monoxide leaks, chimney fires, and structural damage to the masonry. Furthermore, local building codes frequently mandate specific flue liner materials and installation methods, adding another layer of complexity to the process. Properly executed installations prioritize safety and compliance, often involving thorough inspections and pressure tests to verify the integrity of the venting system.

In conclusion, understanding the nuances of installation complexity is paramount for homeowners considering this home improvement project. Proper planning, qualified professional installation, and adherence to local building codes are essential for mitigating risks and ensuring a successful outcome. While the initial cost may appear higher than DIY attempts, the long-term benefits of a professionally installed unit including improved heating efficiency, enhanced safety, and reduced maintenance far outweigh the potential savings from cutting corners. Therefore, the careful assessment and management of installation complexity is not simply a procedural step but a critical investment in home safety and energy efficiency.

5. Venting Requirements

Adequate venting is paramount for the safe and efficient operation of any unit designed for insertion into an existing chimney. Proper venting ensures the removal of combustion byproducts, prevents the buildup of harmful gases, and maintains optimal draft for efficient fuel burning.

- Flue Liner Compatibility

The existing flue liner must be compatible with the fuel type and exhaust temperature of the unit being installed. Older, unlined chimneys or those with deteriorated liners pose significant safety risks, including carbon monoxide leakage and chimney fires. Upgrading to a properly sized, code-compliant flue liner is often a mandatory component of the installation process. For example, a gas unit typically requires a stainless steel or aluminum liner, while a wood-burning unit necessitates a heavier-duty liner capable of withstanding higher temperatures and corrosive byproducts.

- Draft Requirements

Sufficient draft is essential for the efficient removal of combustion gases. Inadequate draft can lead to backdrafting, where exhaust gases are drawn back into the living space, posing a serious health hazard. Chimney height, diameter, and proximity to surrounding structures all influence draft. Complex calculations are often necessary to determine the appropriate flue size and height for optimal venting. Instances of poor draft have resulted in carbon monoxide poisoning, highlighting the critical importance of proper draft assessment and correction.

- Termination Height and Location

The chimney’s termination point must meet specific height and location requirements to prevent downdrafts and ensure adequate dispersion of exhaust gases. Local building codes often dictate minimum distances from nearby structures, rooflines, and air intakes. Improper termination can result in smoke and odor issues for the homeowner and neighboring properties. Compliance with these regulations is crucial for maintaining air quality and preventing nuisance complaints.

- Inspection and Maintenance

Regular inspection and maintenance of the venting system are essential for ensuring continued safe and efficient operation. Creosote buildup in wood-burning systems, corrosion in gas systems, and obstructions from debris can all compromise venting performance. Annual inspections by a certified chimney sweep are recommended to identify potential problems and ensure that the venting system is functioning correctly. Neglecting maintenance can lead to dangerous conditions and costly repairs, emphasizing the need for proactive upkeep.

These multifaceted venting requirements underscore the complexity of unit installations. Compliance with building codes, proper flue liner selection, adequate draft, appropriate termination, and diligent maintenance are all critical for ensuring safe and efficient operation. Proper venting is not simply an ancillary concern but a fundamental aspect of unit integration, directly impacting the safety and well-being of the occupants.

6. Safety Features

Safety features are integral to the design and functionality of these heating appliances, mitigating inherent risks associated with combustion and heat generation. These built-in safeguards protect occupants from hazards such as carbon monoxide poisoning, chimney fires, and accidental burns. Effective implementation of these features is crucial for ensuring safe and reliable operation.

- Carbon Monoxide Detection Systems

Carbon monoxide (CO) detectors are critical safety components integrated into many gas and pellet models. These devices continuously monitor CO levels in the surrounding air, providing an early warning in the event of a leak. Upon detecting elevated CO concentrations, the detector triggers an audible alarm, alerting occupants to the potential danger. Real-world examples demonstrate the life-saving potential of these systems, with numerous instances of CO detectors preventing serious illness or fatalities. Integration of a CO detection system is often mandated by building codes and represents a fundamental safety precaution.

- Overheat Protection Mechanisms

Overheat protection mechanisms safeguard against excessive temperatures that can lead to component failure, chimney fires, or structural damage. These systems typically employ temperature sensors that monitor the firebox or flue temperature. When temperatures exceed pre-set limits, the system automatically shuts down the unit or reduces fuel input, preventing further overheating. In wood-burning models, a common example is a bimetallic strip that controls airflow to the fire, limiting combustion when temperatures become excessive. The implementation of overheat protection minimizes the risk of uncontrolled fires and ensures safe operation under various conditions.

- Spark Arrestors

Spark arrestors are essential safety features incorporated into wood-burning models to prevent the escape of embers and sparks from the chimney. These devices consist of a mesh screen that covers the chimney outlet, effectively containing airborne particles and reducing the risk of starting fires on nearby roofs or vegetation. Spark arrestors are particularly crucial in areas prone to wildfires, where even a small ember can ignite dry brush and cause widespread damage. Regular inspection and cleaning of the spark arrestor are necessary to maintain its effectiveness and prevent clogging, which can impede draft.

- Automatic Shut-Off Systems

Automatic shut-off systems enhance safety by automatically terminating operation under certain conditions, such as power outages or malfunctions. These systems are commonly found in gas and pellet models, providing a fail-safe mechanism to prevent the uncontrolled release of fuel or exhaust gases. For example, a thermocouple in a gas unit senses the presence of a pilot flame and shuts off the gas supply if the flame is extinguished. Similarly, pellet units often feature sensors that detect auger jams or hopper overfills, triggering an automatic shut-off to prevent damage and ensure safe operation. Automatic shut-off systems provide an added layer of protection, minimizing the risk of accidents and equipment failures.

These safety features represent critical investments in the well-being of occupants and the protection of property. While these safety measures can greatly reduce the risk of accidents, they should not be considered a replacement for regular maintenance and proper operation. Responsible use, combined with these integrated safety features, ensures these heating solutions can provide warmth and comfort without compromising safety.

7. Aesthetic Design

Aesthetic design plays a significant role in the selection and integration of fireplace enhancements. Beyond mere functionality, the visual appeal of these units contributes substantially to the overall ambiance and aesthetic harmony of the living space. Consequently, manufacturers offer a diverse range of designs to complement various architectural styles and homeowner preferences.

- Material Finishes and Textures

Material finishes and textures are pivotal in shaping the visual identity of a unit. Options range from traditional cast iron with intricate detailing to modern stainless steel with clean lines. The choice of material finish influences the perceived formality and warmth of the fireplace. For example, a dark, textured cast iron finish might evoke a rustic charm suitable for a country-style home, while a sleek, brushed stainless steel finish aligns with contemporary aesthetics. The material’s texture also impacts light reflection and tactile appeal, contributing to the overall sensory experience.

- Door and Facade Styles

The door and facade design directly influences the unit’s visual prominence within the room. Door styles range from arched designs with ornate detailing to minimalist glass fronts that showcase the fire. Facade styles encompass a wide spectrum, including raised panels, brick patterns, and smooth, seamless surfaces. A real-world example would be the use of a custom-built facade to seamlessly integrate the unit with an existing stone fireplace surround, maintaining the original architectural character of the space.

- Flame Presentation and Visibility

The presentation and visibility of the flame contribute significantly to the ambiance created by the unit. Some models feature large glass viewing areas that provide an unobstructed view of the fire, while others employ smaller, more discreet windows. The flame characteristics, such as color, height, and movement, can also be manipulated through design features. For instance, a gas-fueled unit may utilize ceramic logs arranged to create a realistic and visually appealing flame pattern. Enhancing flame visibility serves to strengthen the ambiance and mood.

- Integration with Existing Dcor

Successful aesthetic design necessitates seamless integration with the existing dcor of the room. The unit’s color, style, and scale should complement the surrounding furniture, wall coverings, and architectural elements. In cases where the existing dcor is traditional, a unit with classic lines and a dark finish may be the most appropriate choice. Conversely, a contemporary space might benefit from a unit with a minimalist design and a light, neutral color palette. Achieving aesthetic harmony requires careful consideration of the room’s overall design theme and the unit’s ability to enhance, rather than detract from, the existing visual appeal.

These aspects underscore the importance of aesthetic design as an integral consideration in fireplace enhancements. By carefully selecting a unit that complements the existing dcor, homeowners can enhance the visual appeal of their living space while enjoying the functional benefits. Thus paying attention to these details in their decision making will be beneficial to the space.

Frequently Asked Questions About Chimney Inserts

The following questions address common concerns and misconceptions surrounding the selection, installation, and operation of these fireplace enhancements. These answers are intended to provide clear and concise information to homeowners considering this type of upgrade.

Question 1: What is the typical lifespan of these fireplace additions?

The lifespan varies depending on fuel type, usage frequency, and maintenance practices. However, a properly installed and maintained unit can be expected to last between 15 and 20 years.

Question 2: Can it be self-installed?

While technically possible, self-installation is strongly discouraged. Professional installation ensures compliance with building codes, proper venting, and safe operation, mitigating the risk of carbon monoxide poisoning and chimney fires.

Question 3: Are all units compatible with every existing fireplace?

No. Size compatibility is critical. The dimensions of the unit must align with the internal measurements of the fireplace opening to ensure proper fit and functionality. Consult manufacturer specifications and seek professional advice to determine compatibility.

Question 4: How often should a chimney be inspected after installing this kind of heat appliance?

Annual inspections by a certified chimney sweep are recommended. These inspections identify potential issues such as creosote buildup, flue blockages, and structural damage, preventing costly repairs and reducing the risk of chimney fires.

Question 5: What fuel types are typically compatible?

Common fuel types include wood, gas, and pellets. The choice of fuel impacts heating efficiency, emissions, and maintenance requirements. Consult the manufacturer’s specifications to determine the optimal fuel type for the chosen unit.

Question 6: Does installing this heating source qualify for energy efficiency tax credits?

Tax credits and incentives vary by location and are subject to change. Consult federal, state, and local government resources to determine eligibility for available programs. Review manufacturer certifications to ensure compliance with energy efficiency standards.

Understanding these key aspects facilitates informed decision-making. Prioritizing safety, proper installation, and regular maintenance ensures optimal performance and longevity.

The following section addresses advanced maintenance techniques and troubleshooting common issues for sustained performance.

Chimney Inserts

This exploration has elucidated critical aspects of fireplace enhancements, ranging from fuel type and heating efficiency to installation complexity and aesthetic design. Meticulous attention to detail in each of these areas is essential for maximizing performance, ensuring safety, and optimizing homeowner satisfaction. The long-term benefits of a well-chosen and properly installed unit extend beyond mere heating capabilities, encompassing increased property value and enhanced home comfort.

Ultimately, the decision to integrate chimney inserts should be predicated on a thorough understanding of individual needs, existing fireplace conditions, and adherence to established safety protocols. Responsible implementation transforms an existing fireplace from an inefficient amenity into a valuable source of supplemental heat, contributing to both energy savings and a more sustainable living environment. Therefore, due diligence and professional guidance are paramount in navigating the complexities of this home improvement endeavor.