The apparatus, typically installed above a cooking range, functions to capture and expel airborne grease, smoke, odors, heat, and combustion products from the kitchen environment. An example of its function is the removal of steam and cooking smells during meal preparation, preventing their spread throughout the home.

Its primary purpose is to improve indoor air quality, reducing the risk of respiratory problems and preventing the buildup of grease and grime on kitchen surfaces. Historically, such systems have evolved from simple smoke shelves in open hearths to complex mechanical ventilation units, reflecting advancements in building design and indoor environmental control.

The following sections will detail the specific components, installation considerations, maintenance procedures, and performance metrics associated with this ventilation appliance, providing a comprehensive understanding of its functionality and application.

Essential Guidance for Optimal Performance

The following recommendations aim to enhance the effectiveness and longevity of the kitchen ventilation system. Adhering to these guidelines will contribute to improved air quality and a reduction in maintenance requirements.

Tip 1: Ensure Proper Sizing. The width of the unit should extend beyond the cooking surface to effectively capture rising effluents. Insufficient coverage can lead to the escape of smoke and grease into the surrounding environment.

Tip 2: Prioritize Ductwork Integrity. Utilize rigid metal ductwork with smooth interior surfaces to minimize airflow resistance. Flexible ductwork can impede airflow and accumulate grease, posing a fire hazard.

Tip 3: Maintain Adequate Exhaust Capacity. Select a unit with sufficient cubic feet per minute (CFM) rating based on the cooking style and range output. High-heat cooking requires greater exhaust capacity.

Tip 4: Implement Regular Filter Cleaning. Clean or replace the grease filters monthly, or more frequently with heavy usage, to maintain optimal airflow and prevent grease buildup. Clogged filters reduce efficiency and increase fire risk.

Tip 5: Conduct Periodic Duct Cleaning. Schedule professional duct cleaning every one to two years to remove accumulated grease and debris. This minimizes fire hazards and ensures efficient ventilation.

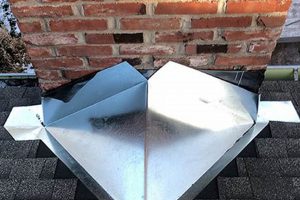

Tip 6: Monitor Backdraft Damper Function. Inspect the backdraft damper regularly to ensure it opens and closes freely, preventing outside air from entering the kitchen when the unit is not in use. A malfunctioning damper can lead to energy loss and drafts.

Tip 7: Consider Make-Up Air. In tightly sealed homes, installing a make-up air system may be necessary to compensate for the air exhausted by the unit. Insufficient make-up air can reduce ventilation effectiveness and create negative pressure within the home.

By implementing these practical strategies, homeowners can ensure the efficient operation, extend the lifespan, and maximize the safety benefits derived from this critical kitchen appliance.

The subsequent sections will address common troubleshooting issues and provide detailed instructions for replacement part selection, ensuring ongoing optimal performance.

1. Capture Efficiency

Capture efficiency, in the context of a kitchen ventilation apparatus, defines the apparatus’s ability to effectively contain and remove cooking-generated pollutants before they disperse into the surrounding environment. A high capture efficiency directly correlates with improved indoor air quality, reduced surface contamination from grease and particulate matter, and a decreased risk of respiratory irritation. The physical design and operational characteristics of the unit are the primary determinants of its capture efficiency. For instance, a unit extending beyond the perimeter of the cooking surface possesses an inherently superior capture area, minimizing the escape of fumes and smoke.

Several factors directly influence the capture efficiency. These include the hood’s depth and width, the angle of its sides, the airflow volume (CFM), and the distance between the cooking surface and the lower edge of the hood. Inadequate design in any of these areas can compromise capture efficiency. For example, a system installed too high above the cooking surface will allow pollutants to escape laterally, negating the benefits of the exhaust system. Similarly, insufficient airflow will fail to adequately draw contaminants into the filtration system. Real-world examples include the installation of undersized units in commercial kitchens, leading to visible grease accumulation on walls and ceilings, and increased complaints regarding odors and indoor air quality.

Ultimately, prioritizing high capture efficiency during appliance selection and installation is paramount for realizing the intended benefits of a kitchen ventilation system. This encompasses careful consideration of unit dimensions, airflow rates, and proper installation techniques. Recognizing the direct relationship between capture efficiency and indoor environmental quality is fundamental to ensuring a healthy and comfortable living space. Future designs should emphasize maximizing this efficiency to minimize the impact of cooking byproducts on indoor environments.

2. Airflow Capacity

Airflow capacity is a critical determinant of a chimney hood vent’s efficacy in removing airborne contaminants from a kitchen environment. Measured in cubic feet per minute (CFM), it quantifies the volume of air the system can exhaust, directly impacting its ability to capture smoke, grease, and odors generated during cooking.

- CFM Rating and Cooking Style

The CFM rating should correlate with the intensity of cooking. High-heat cooking, such as frying or stir-frying, necessitates a higher CFM rating to effectively capture the increased volume of pollutants produced. Insufficient CFM can result in incomplete removal, allowing contaminants to linger and deposit on surfaces.

- Ductwork Impact on Airflow

The ductwork system significantly influences the actual airflow achieved. Long, convoluted duct runs, or the use of flexible ductwork, introduce resistance, reducing the CFM delivered by the unit. Proper duct design is essential to minimize static pressure and maximize airflow efficiency.

- Make-Up Air Requirements

Exhausting air from a home creates negative pressure, potentially drawing in air from other sources. Tightly sealed homes may require a make-up air system to compensate for the exhausted air, ensuring the chimney hood vent operates at its designed CFM and prevents backdrafting of combustion appliances.

- Variable Speed Control

Variable speed control allows the user to adjust the airflow capacity based on the cooking activity. Lower speeds are suitable for simmering or light cooking, reducing noise and energy consumption, while higher speeds are reserved for intense cooking scenarios requiring maximum exhaust.

Collectively, these facets demonstrate that airflow capacity is not simply a matter of the unit’s CFM rating. It is a function of the entire ventilation system, encompassing ductwork design, make-up air considerations, and user control. Optimal performance hinges on a holistic approach to ventilation, ensuring the selected unit and its supporting infrastructure are appropriately matched to the specific cooking environment and practices.

3. Filtration Mechanisms

Filtration mechanisms constitute a crucial component of a chimney hood vent, directly impacting its efficiency in removing contaminants from the kitchen environment. Their primary function is to capture grease, particulate matter, and other airborne byproducts of cooking, preventing their accumulation within the ductwork and their release back into the living space. A properly functioning filtration system is essential for maintaining indoor air quality and reducing fire hazards associated with grease buildup. The absence or ineffectiveness of these mechanisms renders the chimney hood vent substantially less useful, leading to grease-laden surfaces and potential health concerns.

Various filtration technologies exist, each with its own advantages and disadvantages. Common examples include metallic mesh filters, baffle filters, and charcoal filters. Metallic mesh filters, often constructed from aluminum or stainless steel, are washable and reusable, providing a cost-effective solution for grease capture. Baffle filters, characterized by their intricate design of overlapping metal plates, offer improved grease removal efficiency compared to mesh filters. Charcoal filters, typically used in ductless chimney hood vents, absorb odors and some particulate matter, but require periodic replacement due to their limited capacity. The selection of an appropriate filtration mechanism depends on factors such as cooking style, frequency of use, and desired level of air purification. In commercial kitchens, where cooking is more intensive, high-efficiency baffle filters are often preferred to minimize grease accumulation and maintain compliance with fire safety regulations. Conversely, residential kitchens with lighter cooking demands may find metallic mesh filters sufficient.

Effective maintenance of filtration mechanisms is paramount for sustained performance. Regular cleaning or replacement of filters is necessary to prevent clogging, which reduces airflow and diminishes the chimney hood vent’s overall efficiency. Neglecting filter maintenance can lead to grease accumulation in the ductwork, increasing the risk of fire and requiring costly professional cleaning. Therefore, understanding the type of filtration mechanism present in a chimney hood vent and adhering to the manufacturer’s recommended maintenance schedule are essential for ensuring its safe and effective operation. The integration of advanced filtration technologies, such as self-cleaning filters or electronic air purifiers, represents a potential area for future improvement in chimney hood vent design, offering enhanced convenience and performance.

4. Ductwork Material

The selection of ductwork material exerts a significant influence on the performance and longevity of a chimney hood vent system. The material’s properties directly affect airflow efficiency, fire safety, and the accumulation of grease and other contaminants. Inappropriate material selection can lead to reduced ventilation effectiveness, increased fire risk, and premature system failure. For example, flexible ductwork, while easier to install, exhibits higher airflow resistance compared to rigid metal ductwork, resulting in diminished exhaust capacity. The texture and composition of the interior surface of the ductwork dictates the likelihood of grease accumulation. Rough surfaces provide more points of adhesion for grease particles, leading to a gradual buildup that restricts airflow and creates a potential fire hazard.

Rigid metal ductwork, typically constructed from galvanized steel or aluminum, represents the preferred choice for chimney hood vent systems due to its smooth interior surface, fire resistance, and durability. These materials minimize airflow resistance, allowing the system to operate at its designed CFM (cubic feet per minute) rating. Furthermore, metal ductwork is less susceptible to damage from heat and grease, reducing the risk of fire. Conversely, plastic ductwork is generally unsuitable for kitchen ventilation systems due to its flammability and tendency to deform under high temperatures. Flexible ductwork, while offering installation flexibility, introduces significant airflow restrictions and accumulates grease more readily, negating many of the benefits of a high-performance chimney hood vent. A real-world consequence of improper ductwork material is the accelerated deterioration of the ventilation system, resulting in frequent maintenance, reduced efficiency, and potential safety hazards.

Ultimately, the choice of ductwork material for a chimney hood vent represents a critical decision that directly impacts the system’s performance, safety, and lifespan. Prioritizing rigid metal ductwork, adhering to proper installation practices, and implementing a regular maintenance schedule are essential for ensuring optimal ventilation and minimizing the risks associated with grease accumulation and fire hazards. A comprehensive understanding of the material properties and their implications for system performance is paramount for homeowners and professionals alike.

5. Installation Height

Installation height, defined as the vertical distance between the cooking surface and the lower edge of a chimney hood vent, is a pivotal factor influencing the system’s effectiveness. Deviations from the manufacturer’s recommended height range can significantly compromise capture efficiency and overall performance.

- Optimal Capture Zone

The optimal capture zone is a spatial area directly above the cooking surface where the chimney hood vent is most effective at drawing in rising effluents. If installed too high, the hood vent allows pollutants to escape laterally, diminishing its ability to capture smoke, grease, and odors. Conversely, an installation that is too low can impede cooking activities and pose a potential fire hazard due to proximity to heat sources.

- Manufacturer Specifications and Code Compliance

Manufacturers provide specific height recommendations based on the design and airflow characteristics of the unit. Adherence to these specifications is essential for achieving optimal performance and maintaining warranty coverage. Furthermore, local building codes often stipulate minimum and maximum installation heights to ensure safety and compliance with ventilation standards.

- Impact on Airflow Dynamics

Installation height affects the airflow dynamics around the cooking surface. At the correct height, the chimney hood vent creates a focused updraft, effectively channeling pollutants into the filtration system. Excessive height disperses the airflow, reducing the system’s ability to capture airborne contaminants before they spread into the kitchen environment.

- Ergonomic Considerations

The installation height should also accommodate ergonomic considerations for the user. The hood vent should not obstruct the user’s line of sight or impede their ability to comfortably access the cooking surface. Striking a balance between optimal capture efficiency and user ergonomics is crucial for a functional and satisfactory installation.

In summary, the installation height is not merely a physical measurement but a critical parameter that governs the performance and safety of a chimney hood vent. Proper installation requires careful adherence to manufacturer specifications, consideration of local building codes, and an understanding of the airflow dynamics involved. Failing to address these factors can result in a compromised ventilation system that fails to adequately protect indoor air quality and mitigate fire hazards.

6. Noise Level

The acoustic output of a kitchen ventilation system, quantified as the noise level, constitutes a significant factor influencing user satisfaction and overall kitchen environment comfort. Excessive noise from a chimney hood vent can detract from the cooking experience and contribute to auditory fatigue.

- Fan Motor Design and Construction

The design and construction of the fan motor are primary determinants of noise generation. Motors with poorly balanced impellers or inadequate vibration dampening produce increased levels of noise. Real-world examples include units with audible motor hum or vibration transmitted to the surrounding cabinetry, resulting in an unpleasant auditory experience.

- Airflow Velocity and Turbulence

Airflow velocity through the ductwork and internal components contributes to noise generation. Higher airflow velocities, while increasing exhaust capacity, can also create turbulent airflow, resulting in whistling or rushing sounds. Systems with poorly designed duct transitions or restrictive filters exacerbate this effect.

- Material Selection and Vibration Dampening

The materials used in the construction of the chimney hood vent and its ductwork influence noise transmission. Lightweight materials or those lacking adequate vibration dampening properties amplify noise. Installation techniques that minimize contact between the unit and surrounding structures can mitigate vibration-induced noise.

- User Perception and Sound Quality

User perception of noise is subjective and influenced by the quality of the sound produced. A low-frequency rumble may be perceived as more intrusive than a higher-frequency hiss of equal decibel level. Manufacturers often strive to minimize undesirable sound characteristics to improve user satisfaction.

Collectively, these elements highlight the multifaceted nature of noise generation in chimney hood vents. Minimizing noise levels requires a holistic approach, encompassing careful motor design, optimized airflow dynamics, appropriate material selection, and an understanding of user perception. The ongoing development of quieter and more efficient ventilation technologies is essential for enhancing the kitchen environment and improving the overall cooking experience.

7. Maintenance Schedule

A structured maintenance schedule is essential to ensure the sustained efficacy and safety of a chimney hood vent system. Neglecting routine maintenance leads to diminished performance, increased fire risk, and potential equipment failure. Adherence to a prescribed schedule safeguards the investment in the system and maintains a healthy kitchen environment.

- Filter Cleaning/Replacement Frequency

The frequency of filter cleaning or replacement directly impacts airflow and grease accumulation. Metallic mesh filters require monthly cleaning under normal usage; baffle filters may extend to quarterly cleaning. Charcoal filters, prevalent in ductless systems, necessitate replacement every three to six months. Failure to maintain filters results in restricted airflow, reduced capture efficiency, and elevated fire hazard. Real-world examples include kitchen fires originating from grease-laden filters and compromised air quality due to recirculated pollutants.

- Ductwork Inspection and Cleaning

Periodic inspection of ductwork for grease buildup is critical. Professional duct cleaning, recommended every one to two years, removes accumulated grease, preventing airflow obstruction and reducing fire risk. Visual inspection can reveal obvious grease accumulation, while airflow measurements can indicate hidden obstructions. A neglected ductwork system experiences reduced ventilation effectiveness, increased energy consumption, and heightened fire potential.

- Motor and Fan Blade Assessment

Annual assessment of the motor and fan blades ensures proper operation. Lubrication of motor bearings, if applicable, reduces friction and extends motor life. Cleaning fan blades removes accumulated dust and grease, maintaining optimal airflow. Unusual noises or vibrations indicate potential motor or fan blade issues requiring professional attention. Failure to address these issues leads to reduced airflow, increased noise, and potential motor failure.

- Exterior Surface Cleaning and Inspection

Regular cleaning of the exterior surfaces maintains aesthetic appeal and prevents grease accumulation. Inspecting the exterior for damage, corrosion, or loose connections ensures structural integrity and electrical safety. Corrosion can compromise the unit’s structural integrity, while loose connections pose electrical hazards. Neglecting exterior maintenance leads to aesthetic degradation, potential safety risks, and reduced equipment lifespan.

These facets underscore the importance of a comprehensive maintenance schedule for chimney hood vents. Consistent adherence to these guidelines ensures optimal performance, minimizes safety risks, and extends the lifespan of the system, ultimately safeguarding the investment and maintaining a healthy kitchen environment. The absence of a structured maintenance plan precipitates performance degradation, safety hazards, and premature equipment failure.

Frequently Asked Questions

The following addresses common inquiries regarding the selection, installation, and maintenance of kitchen ventilation systems. The information presented aims to clarify misconceptions and provide a practical understanding of these appliances.

Question 1: What constitutes an adequate CFM (cubic feet per minute) rating for a residential chimney hood vent?

The requisite CFM rating is contingent upon the cooking style and range output. High-heat cooking methods necessitate a greater CFM rating. As a general guideline, a CFM rating of 100 CFM per linear foot of range width is considered a minimum standard.

Question 2: Is flexible ductwork an acceptable alternative to rigid ductwork for chimney hood vent installations?

Flexible ductwork is generally discouraged due to its increased airflow resistance and propensity for grease accumulation. Rigid metal ductwork provides superior airflow and fire safety. The use of flexible ductwork can significantly reduce the effectiveness of the ventilation system.

Question 3: How frequently should the filters in a chimney hood vent be cleaned or replaced?

Metallic mesh filters should be cleaned monthly with regular use. Baffle filters may require cleaning quarterly. Charcoal filters, employed in ductless systems, necessitate replacement every three to six months. Neglecting filter maintenance reduces airflow and increases fire risk.

Question 4: Does the installation of a chimney hood vent require a make-up air system?

In tightly sealed homes, a make-up air system may be necessary to compensate for the air exhausted by the hood vent. Insufficient make-up air can reduce ventilation effectiveness and create negative pressure within the home, potentially causing backdrafting of combustion appliances.

Question 5: What is the appropriate installation height for a chimney hood vent above the cooking surface?

The recommended installation height typically ranges from 28 to 36 inches above the cooking surface. Refer to the manufacturer’s specifications for precise recommendations. Deviations from the specified height can compromise capture efficiency and ergonomic considerations.

Question 6: How can noise levels from a chimney hood vent be minimized?

Select a unit with a low sones rating. Ensure proper ductwork installation to minimize airflow turbulence. Employ vibration-dampening techniques to reduce noise transmission. The quality of the fan motor and the overall design of the unit significantly influence noise generation.

These FAQs serve as a fundamental guide for addressing common concerns regarding chimney hood vents. Proper selection, installation, and maintenance are crucial for ensuring optimal performance and a healthy kitchen environment.

The subsequent section will delve into specific troubleshooting scenarios and offer guidance on selecting replacement parts for ongoing maintenance.

Conclusion

This exposition has detailed the multifaceted aspects of the apparatus, encompassing its functionality, essential components, installation parameters, and maintenance protocols. Proper utilization of a ventilation system is crucial for maintaining indoor air quality and mitigating potential fire hazards associated with cooking byproducts. The parameters outlined herein serve as a foundation for informed decision-making regarding selection, implementation, and upkeep.

Effective kitchen ventilation remains a critical aspect of building design and residential safety. Continued adherence to best practices and technological advancements in this field will contribute to healthier living environments and reduced fire risks. Prioritizing proper installation and diligent maintenance of the apparatus represents a significant investment in the well-being of occupants and the longevity of the structure itself.