This entity represents a business or organization specializing in the maintenance, repair, and inspection of venting systems for fireplaces, furnaces, and other appliances. These entities typically offer services such as cleaning to remove creosote and other debris, structural repairs to brickwork or flue liners, and safety inspections to ensure proper operation and prevent hazards like chimney fires or carbon monoxide leaks.

The services provided are critical for both safety and efficiency. Regular maintenance helps prevent dangerous situations, extending the life of the chimney structure itself, and ensuring optimal performance of connected appliances. Historically, this type of specialized care was performed by general masons or sweeps, but the increasing complexity of heating systems and a greater awareness of safety standards have led to the development of dedicated companies with specialized knowledge and equipment.

With a foundational understanding of these specialized companies, the following sections will delve into the specifics of choosing a reputable provider, the range of services offered, and the essential considerations for maintaining a safe and efficient venting system.

Chimney Maintenance and Safety

The following guidelines are provided to promote the safe and efficient operation of chimney systems, minimizing potential hazards and ensuring longevity.

Tip 1: Schedule Annual Inspections. A qualified professional should inspect the chimney annually to assess its structural integrity and identify potential hazards such as cracks, blockages, or creosote buildup. Documentation of these inspections is crucial for insurance purposes and future reference.

Tip 2: Prioritize Regular Cleaning. Chimney cleaning removes combustible deposits like creosote, which is a primary cause of chimney fires. The frequency of cleaning depends on fuel type and usage, but at least annual cleaning is recommended.

Tip 3: Use Seasoned Wood Only. Burning unseasoned wood results in increased creosote production due to higher moisture content. Seasoned wood should have a moisture content of less than 20% and should be stored properly to prevent re-absorption of moisture.

Tip 4: Install and Maintain Carbon Monoxide Detectors. Carbon monoxide (CO) is a colorless, odorless gas that can be deadly. Install CO detectors on every level of the home, particularly near sleeping areas, and test them regularly.

Tip 5: Ensure Proper Ventilation. Adequate airflow is essential for efficient combustion and proper venting. Avoid blocking or obstructing vents and ensure that the chimney damper operates correctly.

Tip 6: Address Structural Issues Promptly. Cracks in the chimney structure or damaged flue liners compromise safety and efficiency. Address any structural issues immediately to prevent further deterioration and potential hazards.

Adherence to these guidelines can significantly reduce the risk of chimney fires, carbon monoxide poisoning, and other hazards, ensuring a safe and comfortable living environment.

The subsequent sections will delve into the selection of appropriate maintenance services and proactive measures for preserving the structural integrity of the chimney system.

1. Inspection and Assessment

The practice of inspection and assessment forms the cornerstone of responsible maintenance for chimney systems. Service entities specializing in this area offer a range of diagnostic procedures designed to identify potential safety hazards, structural deficiencies, and performance issues.

- Level 1 Inspections: Visual Scrutiny

This basic inspection, often performed during a routine cleaning, involves a visual examination of readily accessible components, including the chimney exterior, flue, and appliance connections. Its role is to identify obvious issues such as cracks, spalling brick, or loose connections. A residential home sale, for example, might involve a Level 1 inspection to confirm the chimney is apparently safe for use. The implications of neglecting this basic level are potential fire hazards or carbon monoxide leaks going unnoticed.

- Level 2 Inspections: In-Depth Examination

A Level 2 inspection is required when changes are made to the system, such as replacing the appliance or altering the fuel type. It involves a more comprehensive examination, potentially including video scanning of the flue to identify hidden cracks or obstructions. This type of inspection is also recommended when selling or purchasing a property. Failing to conduct a Level 2 inspection when required can lead to undetected structural flaws that could cause a chimney fire or carbon monoxide poisoning.

- Level 3 Inspections: Invasive Investigation

Level 3 inspections are the most comprehensive and are typically performed when a significant hazard is suspected. They involve removing portions of the chimney structure, such as drywall or brickwork, to gain access to concealed areas. This inspection type is indicated when a Level 1 or 2 inspection reveals substantial damage or a suspected problem. An example would be investigating after a chimney fire to assess the full extent of the damage. Ignoring the need for a Level 3 inspection after suspected severe damage can result in continued use of an unsafe chimney, endangering the occupants of the building.

- Performance Testing: System Efficiency

In addition to visual and structural inspections, some specialists offer performance testing to assess the overall efficiency and draft of the chimney system. This may involve measuring flue gas temperatures, draft pressures, and carbon monoxide levels. Poor performance can indicate blockages, leaks, or improper appliance connections. Corrective actions identified through performance testing can improve heating efficiency and reduce the risk of carbon monoxide exposure.

These facets of inspection and assessment directly relate to the value offered by the specialized service providers. Through thorough investigation and accurate diagnosis, these entities enable informed decision-making regarding necessary repairs and maintenance, ultimately contributing to the safety and longevity of chimney systems and the buildings they serve.

2. Creosote Removal

Creosote removal is a critical service offered by specialized companies, addressing a significant hazard associated with solid fuel-burning appliances. Its connection to these providers is foundational, representing a core competency essential for safe and efficient chimney operation.

- Formation Mechanisms

Creosote forms as a byproduct of incomplete combustion when burning wood or other solid fuels. Unburnt gases, smoke, and particulate matter condense within the chimney flue as they cool. Factors such as low flue temperatures, restricted airflow, and burning unseasoned wood accelerate creosote accumulation. Specialized entities possess the expertise to diagnose and mitigate these contributing factors. For instance, recommending proper wood seasoning techniques or identifying airflow obstructions can prevent excessive creosote buildup.

- Stages of Creosote

Creosote exists in three distinct stages. Stage one is a flaky, soot-like deposit. Stage two is a hard, tar-like substance. Stage three is a glazed, highly flammable coating. The composition and flammability increase with each stage. Companies utilize specialized tools and techniques to remove creosote at each stage, selecting appropriate methods to minimize damage to the chimney structure. For example, chemical treatments may be used to modify the structure of glazed creosote, making it easier to remove mechanically.

- Removal Techniques

Service providers employ various techniques for creosote removal, including manual sweeping with brushes and scrapers, power sweeping with rotary cleaning tools, and chemical treatments to loosen hardened deposits. The choice of technique depends on the type and amount of creosote present, as well as the construction materials of the chimney flue. Improper removal techniques can damage the flue liner, necessitating costly repairs. Therefore, employing qualified professionals is essential.

- Safety Implications

Creosote is highly combustible, and its accumulation poses a significant fire hazard. Chimney fires can damage the chimney structure, spread to adjacent building materials, and endanger occupants. Regular creosote removal minimizes this risk. Furthermore, the smoke and gases released during a chimney fire can contain toxic compounds, including carbon monoxide. Professional entities not only remove creosote but also educate homeowners about fire safety and carbon monoxide detection.

The importance of creosote removal underscores the value of specialized chimney service providers. Their expertise and equipment are essential for maintaining safe and efficient chimney systems, protecting property and lives from the hazards associated with creosote accumulation. Neglecting this aspect of chimney maintenance can have severe consequences, highlighting the need for regular professional inspections and cleaning.

3. Structural Repair

Structural repair represents a fundamental service provided by organizations specializing in chimney maintenance. Deterioration due to weathering, age, or chimney fires compromises the integrity of the structure, impacting both safety and operational efficiency. The expertise of chimney care specialists is essential in diagnosing and rectifying these issues, ensuring the continued safe function of the venting system.

The causes of structural damage are varied. Freeze-thaw cycles can lead to cracking and spalling of brickwork. Moisture penetration accelerates deterioration, particularly in older chimneys lacking adequate weather protection. Chimney fires, resulting from creosote buildup, generate intense heat that weakens the structure and damages flue liners. Without timely intervention, these problems escalate, potentially leading to collapse or dangerous gas leaks. For instance, a homeowner might experience water damage in the attic due to a cracked chimney crown, or notice crumbling brickwork on the chimney exterior. Addressing these issues requires specialized skills in masonry repair, flue liner replacement, and weatherproofing.

In summary, structural repair is an integral component of comprehensive maintenance services. Its effectiveness hinges on accurate diagnosis, appropriate repair techniques, and the expertise of qualified professionals. By addressing structural deficiencies promptly, these specialists ensure the longevity, safety, and efficient operation of chimney systems, protecting property and occupants from potential hazards.

4. Flue Liner Integrity

Flue liner integrity is intrinsically linked to the services offered by specialized chimney maintenance companies. The flue liner, a critical component of a chimney system, acts as a barrier protecting the chimney structure and surrounding building materials from the corrosive byproducts of combustion and high temperatures. Its primary function is to safely vent exhaust gases from heating appliances to the outside atmosphere, preventing carbon monoxide leaks and chimney fires. Compromised flue liners negate this protection, leading to potential structural damage, health hazards, and increased fire risk, thereby necessitating the intervention of entities specializing in chimney care.

These specialized service providers address flue liner issues through inspection, repair, and replacement. Inspection methods range from simple visual checks to advanced video scanning to identify cracks, breaches, or deterioration. Repair options include patching minor damage or applying specialized coatings to seal cracks. In cases of extensive damage, complete flue liner replacement becomes necessary, a complex process requiring specialized equipment and expertise. Failure to maintain the integrity of the flue liner has significant consequences. For example, a cracked liner allows corrosive gases to penetrate the chimney structure, leading to deterioration of brickwork and mortar joints. Carbon monoxide, a colorless and odorless gas, can leak into the living space, posing a severe health risk to occupants. Additionally, a compromised liner increases the risk of chimney fires as hot gases come into direct contact with combustible building materials. Real-world examples include homes experiencing unexplained water damage due to rainwater penetration through cracked chimneys and instances of carbon monoxide poisoning linked to faulty flue liners.

Maintaining flue liner integrity is thus a fundamental aspect of responsible home maintenance. Regular inspections and timely repairs performed by qualified chimney care companies are essential for ensuring the safety and efficiency of heating systems. The understanding of this connectionbetween the structural soundness of the flue liner and the expertise required for its maintenanceis crucial for homeowners to prioritize safety and protect their property. This emphasizes the importance of chimney inspections as a way of maintaining home safety.

5. Preventative Maintenance

Preventative maintenance constitutes a proactive strategy for preserving the integrity and functionality of chimney systems, an approach intrinsically linked to the services offered by specialized chimney care companies. This proactive approach aims to minimize the occurrence of significant structural issues and safety hazards, thereby extending the lifespan of the chimney and related appliances.

- Moisture Control Measures

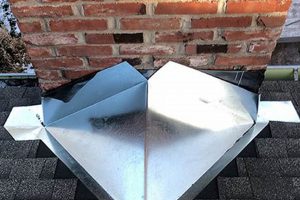

The implementation of moisture control strategies is paramount in preventative maintenance. Water penetration accelerates the deterioration of chimney structures, leading to cracking, spalling, and damage to the flue liner. Chimney care companies address this through the application of waterproofing sealants, installation of chimney caps to prevent rainwater entry, and repair of damaged crowns or flashing. A homeowner might, for example, experience recurring leaks that damage interior walls; addressing the root cause through professional waterproofing can prevent further structural deterioration and costly repairs.

- Regular Cleaning Protocols

The scheduled removal of creosote and other debris is a core element of preventative maintenance. Accumulation of these materials increases the risk of chimney fires and reduces the efficiency of the venting system. Chimney care companies offer regular cleaning services, utilizing specialized tools and techniques to safely remove deposits without damaging the chimney structure. Failure to adhere to cleaning schedules can result in dangerous chimney fires, highlighting the importance of professional intervention.

- Early Detection and Repair

Preventative maintenance encompasses routine inspections to identify minor issues before they escalate into major problems. Chimney care companies conduct thorough examinations of the chimney structure, flue liner, and related components, detecting early signs of deterioration, such as cracks, loose bricks, or damaged mortar joints. Addressing these issues promptly prevents further damage and avoids costly repairs in the future. For instance, identifying and repairing a small crack in the flue liner can prevent carbon monoxide leaks and potential structural damage.

- Component Assessment and Upgrades

Periodic evaluation of chimney components, such as dampers, caps, and connectors, forms part of preventative maintenance. Chimney care companies assess the condition of these components and recommend upgrades or replacements as needed to ensure optimal performance and safety. Replacing a damaged chimney cap can prevent water intrusion and animal infestation, extending the life of the chimney and preventing related problems.

These facets of preventative maintenance underscore the significance of proactive care in preserving chimney systems. Through the provision of specialized services, entities focused on chimney maintenance play a critical role in mitigating risks, extending the lifespan of chimney structures, and ensuring the safety of residential and commercial properties. Embracing a preventative approach minimizes the potential for costly repairs, hazardous conditions, and system inefficiencies, emphasizing the value of regular engagement with qualified chimney care professionals.

Frequently Asked Questions Regarding Chimney Maintenance

The following frequently asked questions address common concerns and misconceptions about chimney maintenance, providing clarity and guidance for responsible homeowners.

Question 1: How frequently should a chimney be inspected?

Chimneys should undergo annual inspections by qualified professionals. More frequent inspections may be necessary for chimneys connected to appliances used daily or those exhibiting signs of damage or malfunction.

Question 2: What constitutes a Level 1, Level 2, and Level 3 chimney inspection?

A Level 1 inspection is a visual examination of readily accessible chimney components. A Level 2 inspection includes a video scan of the flue and is required upon changes to the system or property transfer. A Level 3 inspection involves invasive investigation, removing portions of the chimney structure to access concealed areas.

Question 3: Why is creosote removal important, and how often should it be performed?

Creosote is a highly combustible byproduct of wood burning. Regular removal minimizes the risk of chimney fires. The frequency depends on fuel type and usage, but at least annual cleaning is generally recommended.

Question 4: What are the indicators of a damaged flue liner, and what are the potential consequences?

Indicators include cracks, missing sections, and visible deterioration. Consequences range from carbon monoxide leaks and structural damage to increased risk of chimney fires.

Question 5: What are the benefits of installing a chimney cap?

Chimney caps prevent rainwater entry, animal intrusion, and debris accumulation, protecting the chimney structure and preventing blockages.

Question 6: How can homeowners ensure they are hiring a qualified chimney service provider?

Verify certifications from organizations such as the Chimney Safety Institute of America (CSIA), check for proper insurance coverage, and request references from previous clients.

These frequently asked questions highlight the significance of proactive chimney maintenance and the role of qualified professionals in ensuring safe and efficient operation.

The subsequent section will provide guidance on selecting a reputable service provider, emphasizing the importance of expertise, certifications, and customer testimonials.

Conclusion

This exploration of entities specializing in chimney maintenance has underscored the vital role they play in safeguarding homes and ensuring efficient heating system operation. From conducting thorough inspections to performing necessary repairs and preventative measures, these specialized businesses address critical safety concerns. Their services are not merely cosmetic; they are integral to protecting property and lives from the inherent dangers associated with chimney systems.

The continued reliance on professional services for chimney maintenance is paramount. Homeowners are encouraged to prioritize regular inspections and necessary repairs, understanding that diligent care ensures both safety and the long-term structural integrity of their homes. The specialized knowledge and skills offered by companies focused on venting systems are invaluable for responsible homeownership.