This vertical structure, typically constructed of masonry or metal, facilitates the expulsion of combustion byproducts from a heating appliance or industrial process. It relies on differential air pressure, creating a draft to effectively vent gases away from the source and into the atmosphere. A well-constructed example ensures efficient and safe removal of potentially harmful emissions.

Effective venting systems are crucial for maintaining indoor air quality and preventing the buildup of dangerous gases, such as carbon monoxide. Historical context reveals a gradual evolution of designs, driven by advancements in understanding of thermodynamics and the need for improved safety and efficiency. These structures contribute significantly to public health and safety by minimizing the risk of exposure to hazardous substances.

The subsequent sections will delve into the specific design considerations, material selection, and performance characteristics that influence the overall effectiveness of these systems. Furthermore, regulatory compliance and best practices for maintenance and inspection will be examined to ensure continued safe and reliable operation.

Guidance for Optimized Performance

The following recommendations aim to enhance functionality and longevity. Adherence to these guidelines will contribute to safer and more efficient operation.

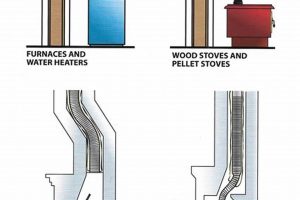

Tip 1: Ensure Proper Sizing: Dimensions must be calculated according to the connected appliance’s heat output and fuel type. Undersized structures can lead to backdrafting and incomplete combustion, while oversized ones may result in insufficient draft and condensation.

Tip 2: Maintain Structural Integrity: Regular inspections are critical to identify cracks, spalling, or other forms of deterioration. Prompt repairs prevent structural failure and potential hazards related to gas leakage or collapse.

Tip 3: Prioritize Liner Integrity: Liners protect the structure from corrosive flue gases. Damaged or deteriorated liners must be replaced to prevent deterioration of the surrounding masonry or metal.

Tip 4: Address Obstructions Promptly: Regular cleaning removes soot, creosote, and debris that can impede airflow. Obstructions increase the risk of chimney fires and carbon monoxide poisoning.

Tip 5: Implement Cap Installation: A cap prevents rainwater, snow, and debris from entering the structure. This reduces the risk of water damage, freeze-thaw cycles, and blockages.

Tip 6: Comply with Building Codes: All construction and repairs must adhere to local building codes and regulations. This ensures safety and compliance with established standards.

Tip 7: Consult Qualified Professionals: Engage certified professionals for complex repairs, installations, or inspections. Their expertise ensures that work is performed safely and effectively.

These recommendations provide a framework for maintaining efficient and safe operation. Implementing these practices minimizes risks associated with venting systems and promotes longevity.

The subsequent section will address common troubleshooting scenarios and solutions related to operational performance.

1. Draft Optimization

Draft optimization, the process of ensuring an adequate and consistent airflow through a venting structure, is intrinsically linked to the performance. It directly influences the efficiency of combustion by-product removal. Insufficient draft can lead to backdrafting, where harmful gases enter the occupied space, posing significant health risks. Conversely, excessive draft can result in rapid heat loss and decreased appliance efficiency. The design must therefore balance these competing factors to achieve optimal performance. For example, the height and diameter of the structure, coupled with prevailing wind conditions, significantly impact the resulting draft. A taller structure generally produces a stronger draft, but this must be calibrated to the specific appliance and fuel type to avoid over-drafting.

Consideration must be given to the thermal buoyancy of the flue gases. Hotter gases rise more readily, enhancing the draft effect. However, if the gases cool excessively before exiting, the draft will be reduced, potentially leading to condensation and creosote buildup, increasing the risk of chimney fires. Furthermore, external factors, such as the presence of nearby obstructions or variations in atmospheric pressure, can influence the draft. Properly designed and installed structures account for these variables to ensure consistent and reliable venting. In instances where natural draft is insufficient, mechanical draft inducers may be employed to augment airflow.

In summary, optimized draft is critical for safe and efficient operation. Achieving this requires a thorough understanding of fluid dynamics, thermodynamics, and the specific characteristics of the connected appliance and fuel. The design and installation must account for a wide range of factors to ensure reliable performance and minimize the risk of hazards associated with improper venting.

2. Material Durability

Material durability is a paramount consideration in the construction and maintenance of effective venting systems. The operating environment subjects these structures to extreme conditions, including high temperatures, corrosive combustion byproducts, and fluctuating weather patterns. The selection of appropriate materials directly influences the lifespan, safety, and overall performance. Inadequate material selection can lead to premature degradation, structural compromise, and the potential release of hazardous gases into the surrounding environment. For instance, the use of inappropriate mortar in masonry construction can result in spalling and cracking due to freeze-thaw cycles and acid condensation from flue gases, ultimately leading to structural instability.

The correlation between material selection and operational longevity is readily observable. Stainless steel liners, for example, offer superior resistance to corrosion from acidic condensates compared to traditional clay liners. Similarly, high-temperature alloys used in industrial applications provide enhanced resistance to thermal stress and chemical attack. Understanding the specific conditions to which the structure will be exposed, including fuel type, combustion temperature, and regional climate, is crucial for informed material selection. Furthermore, proper installation techniques and ongoing maintenance practices are essential to maximize the service life of the materials and ensure the system’s continued integrity. Failure to address material degradation promptly can result in costly repairs, potential safety hazards, and eventual system failure.

In conclusion, material durability represents a critical factor in the overall effectiveness and safety. A thorough understanding of material properties, environmental factors, and best practices for installation and maintenance is essential for ensuring long-term reliability and minimizing the risks associated with venting systems. The challenges associated with material degradation highlight the importance of proactive inspection and timely intervention to maintain structural integrity and prevent potentially hazardous situations.

3. Safety Standards

Safety standards are intrinsically linked to the design, installation, and maintenance of any chimney structure. The primary function is to safely vent combustion byproducts, and adherence to established codes is paramount in mitigating risks associated with fire hazards and carbon monoxide poisoning. These regulations dictate acceptable materials, construction techniques, and inspection protocols to ensure structural integrity and prevent the escape of harmful gases. For instance, building codes often specify minimum chimney height requirements to promote adequate draft and prevent downdrafting, which can force exhaust gases back into the building. Failure to comply with safety standards can result in catastrophic consequences, including structural collapse, chimney fires, and fatal carbon monoxide exposure.

The implementation of safety standards necessitates a multi-faceted approach, encompassing design specifications, material testing, and rigorous inspection procedures. Regular chimney inspections by certified professionals are essential to identify potential hazards, such as cracks, obstructions, or deteriorated liners. These inspections often employ specialized tools and techniques to assess the structural integrity and ensure compliance with current safety codes. Furthermore, ongoing maintenance, including routine cleaning and prompt repairs, is crucial for preventing the accumulation of creosote, a highly flammable substance that can lead to dangerous chimney fires. Real-world examples consistently demonstrate a direct correlation between adherence to safety standards and a reduction in chimney-related incidents.

In conclusion, safety standards constitute an indispensable element in the safe and efficient operation of these structures. The enforcement of these standards, coupled with diligent maintenance practices, significantly minimizes the risks associated with fire and carbon monoxide exposure. While challenges remain in ensuring consistent compliance and addressing the complexities of older installations, the continuous refinement and implementation of safety standards are essential for safeguarding public health and preventing chimney-related tragedies. A thorough understanding of these regulations and a commitment to proactive maintenance are vital for all stakeholders, from homeowners to building professionals.

4. Effluent Dispersion

Effluent dispersion, the process by which combustion byproducts are released and diluted into the atmosphere, is critically linked to the design and functionality. The effectiveness of this process directly impacts air quality and public health, influencing the environmental footprint of heating and industrial systems. Proper design and construction are therefore essential for ensuring adequate dispersion and minimizing the concentration of pollutants at ground level.

- Stack Height and Exit Velocity

Stack height directly influences dispersion by releasing effluents at a higher elevation, allowing for greater mixing with ambient air before reaching ground level. Exit velocity, the speed at which gases are discharged, affects plume rise and dispersion patterns. Insufficient stack height or exit velocity can result in localized pollutant concentrations that exceed acceptable levels. Industrial facilities, for example, employ taller structures to ensure emissions are adequately dispersed, preventing negative impacts on surrounding communities.

- Plume Dynamics and Atmospheric Conditions

Plume dynamics, the behavior of the effluent plume as it interacts with atmospheric conditions, affects the spread and dilution of pollutants. Factors such as wind speed, wind direction, and atmospheric stability influence the plume trajectory and mixing rates. Stable atmospheric conditions, characterized by minimal vertical mixing, can lead to trapped plumes and elevated ground-level concentrations. In contrast, unstable conditions promote vertical mixing and enhanced dispersion. Computational fluid dynamics (CFD) modeling is often used to simulate plume behavior and optimize design for varying atmospheric conditions.

- Particulate Matter and Gaseous Pollutants

Effluent streams contain both particulate matter (PM) and gaseous pollutants, each with distinct dispersion characteristics and environmental impacts. PM, consisting of solid particles, settles out of the plume at a rate dependent on particle size and density. Gaseous pollutants, such as sulfur dioxide (SO2) and nitrogen oxides (NOx), undergo chemical reactions in the atmosphere, forming secondary pollutants that contribute to acid rain and smog. The design of the chimney should consider the composition of the effluent stream and incorporate appropriate control technologies, such as scrubbers or filters, to minimize the release of pollutants.

- Regulatory Compliance and Air Quality Monitoring

Effluent dispersion is subject to stringent regulatory requirements aimed at protecting air quality and public health. Environmental agencies establish emission limits and mandate air quality monitoring to ensure compliance. Continuous emissions monitoring systems (CEMS) are often installed to track pollutant concentrations in real time. Exceedances of emission limits trigger corrective actions, such as equipment upgrades or process modifications. Facilities must demonstrate, through dispersion modeling and monitoring data, that their emissions do not pose a significant threat to air quality or human health.

The factors influencing effluent dispersion underscore the significance of careful planning and design. These design considerations ensure that combustion byproducts are released in a manner that minimizes environmental impact and protects public health. Examples from real-world scenarios highlight the role of stack height, plume dynamics, and pollutant characteristics in determining the effectiveness of dispersion. The ongoing refinement of modeling techniques, monitoring strategies, and regulatory frameworks will contribute to continued progress in minimizing the environmental footprint.

5. Structural Integrity

Structural integrity is a foundational element for any chimney system, directly impacting its operational safety and longevity. The ability of a chimney to withstand external forces, such as wind loads and seismic activity, and internal stresses, including thermal expansion and corrosive flue gases, is crucial for preventing catastrophic failure. A compromised structure poses a significant risk of collapse, potentially causing property damage, injury, or loss of life. The materials used, construction methods employed, and ongoing maintenance practices all contribute to its structural robustness. A prime example of the consequence of neglecting structural integrity is the collapse of improperly maintained masonry structures due to freeze-thaw cycles, where water infiltrates cracks, expands upon freezing, and exacerbates the damage. Thus, a robust structure is not merely a desirable attribute but an essential characteristic that guarantees reliable performance and minimizes risks.

The practical implications of understanding the relationship between structural integrity and chimney performance extend to various aspects of building design and maintenance. Regular inspections, conducted by qualified professionals, are vital for identifying signs of deterioration, such as cracks, spalling, or leaning. Timely repairs, using appropriate materials and techniques, can prevent minor issues from escalating into major structural problems. Furthermore, the selection of appropriate lining materials is essential for protecting the structure from corrosive flue gases, prolonging its service life. For instance, stainless steel liners are often employed to safeguard masonry chimneys from the damaging effects of acidic condensates. Proper installation techniques, including adequate support and secure connections, are also crucial for ensuring long-term stability. Cases of chimney failure due to improper installation highlight the importance of adhering to established building codes and industry best practices.

In summary, structural integrity forms the backbone of reliable chimney operation, directly affecting its safety, efficiency, and lifespan. Addressing potential structural weaknesses through routine inspections, proactive maintenance, and appropriate material selection is paramount for preventing costly repairs, mitigating safety hazards, and ensuring the sustained performance. A comprehensive understanding of this relationship is essential for homeowners, building professionals, and regulatory authorities alike. The ongoing challenges in maintaining structural integrity, particularly in aging infrastructure, underscore the need for continued research and innovation in materials science, construction techniques, and inspection methodologies.

Frequently Asked Questions

The following addresses common inquiries regarding these chimney systems, providing insights into construction, maintenance, and regulatory aspects.

Question 1: What are the primary factors influencing the lifespan?

Lifespan is primarily determined by material quality, exposure to corrosive flue gases, and adherence to maintenance schedules. Regular inspections and prompt repairs are essential for maximizing longevity.

Question 2: How often should a chimney be inspected?

Inspections are recommended annually, or more frequently if the system experiences heavy use or is suspected of damage. Professional inspections can identify potential hazards before they escalate.

Question 3: What are the signs of structural deterioration?

Indications include cracks, spalling, leaning, and water damage. Any observed anomalies should be promptly evaluated by a qualified professional.

Question 4: Can these systems be repaired, or does complete replacement become necessary?

Many issues can be addressed through repairs, such as relining or masonry work. However, extensive damage or code violations may necessitate complete replacement to ensure safety and compliance.

Question 5: Are there specific building codes governing construction and maintenance?

Local building codes regulate the construction, alteration, and maintenance. Compliance with these codes is mandatory to ensure safety and prevent legal liabilities.

Question 6: What is the significance of a chimney liner?

A liner protects the surrounding masonry from corrosive flue gases and improves draft efficiency. Damaged or deteriorated liners should be replaced to prevent further deterioration.

These responses offer a foundational understanding of the core considerations. Routine maintenance and awareness of potential issues are critical for ensuring safe and reliable operation.

The subsequent section will delve into troubleshooting scenarios and their respective solutions.

Frechette Chimney

This discussion has illuminated the multifaceted aspects of this venting system. Structural integrity, material durability, effluent dispersion, safety standards, and optimized draft are inextricably linked to performance and longevity. Ignoring these fundamental elements increases the risk of failure, potentially leading to property damage, environmental harm, and loss of life.

A vigilant commitment to regular inspection, proactive maintenance, and adherence to regulatory guidelines remains paramount. Further research and development in materials science and design will continue to enhance safety and efficiency. The pursuit of improved venting technologies serves as a crucial endeavor to protect public health and safeguard the environment.

![Stone Chimneys: Repair, Build & Restore [Expert Tips] Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Stone Chimneys: Repair, Build & Restore [Expert Tips] | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/02/th-530-300x200.jpg)