The process involves setting up a wood-burning stove in a location lacking a traditional flue. This necessitates the use of alternative venting systems to safely expel combustion byproducts. An example is utilizing a twin-wall flue system that exits through an exterior wall rather than vertically through a roof.

This approach offers flexibility in stove placement, bypassing the structural constraints of existing brick chimneys. It can be particularly beneficial in properties where a chimney is absent, damaged, or unsuitable for use, potentially reducing installation costs compared to chimney repair or construction. The advent of advanced flue technologies has made this a viable and increasingly popular option for home heating.

The following sections will detail the regulations, safety considerations, system options, and cost implications associated with creating a wood-burning heat source in the absence of traditional chimney infrastructure.

Guidance on Venting a Wood-Burning Stove Without a Traditional Flue

Consider these essential guidelines when implementing a heating solution that bypasses standard chimney systems. Adherence to these points is critical for safe and efficient operation.

Tip 1: Prioritize Regulatory Compliance: Confirm adherence to all local building codes and regulations pertaining to stove installation and venting systems. Obtain necessary permits before commencing any work.

Tip 2: Select an Approved Venting System: Ensure the venting system is specifically designed and certified for use with wood-burning stoves. UL or equivalent certification is paramount.

Tip 3: Calculate Flue Dimensions Accurately: Correct flue sizing is vital for optimal stove performance and safe exhaust removal. Consult manufacturer specifications or a qualified professional to determine the appropriate diameter and height.

Tip 4: Maintain Proper Clearances: Observe all mandated clearances between the stove, venting system, and combustible materials. These distances are crucial for preventing fire hazards.

Tip 5: Ensure Adequate Ventilation: Wood-burning stoves require sufficient air intake for combustion. Ensure the room has adequate ventilation to prevent negative pressure and potential backdrafting.

Tip 6: Install Carbon Monoxide Detectors: Install and maintain carbon monoxide detectors in the vicinity of the stove and in sleeping areas. Regular testing is essential.

Tip 7: Schedule Professional Inspection: Upon completion of the installation, arrange for a qualified professional to inspect the entire system. This inspection verifies correct installation and safe operation.

Careful planning and adherence to these guidelines are paramount for a safe and effective heat source. Ignoring these points can result in hazardous conditions.

The subsequent section will address troubleshooting common issues and maintaining the system for longevity.

1. Regulations and Permits

Compliance with local building codes and acquisition of necessary permits are non-negotiable prerequisites for any wood-burning stove installation, particularly when a traditional chimney is absent. These regulations safeguard public safety and ensure installations meet minimum performance standards.

- Building Codes and Standards

Local building codes often dictate specific requirements for the installation of solid fuel-burning appliances. These codes may stipulate allowable venting systems, clearance distances to combustible materials, and requirements for air supply. Failure to comply can result in fines, mandated removal of the installation, or voiding of homeowner’s insurance.

- Permitting Process

Obtaining a permit typically involves submitting detailed plans of the proposed installation to the local building department. The plans are reviewed to ensure compliance with applicable codes. Inspection of the completed installation by a building inspector is usually required before the stove can be legally used.

- Approved Appliance and Venting Systems

Regulations frequently mandate the use of certified appliances and venting systems. Certification, such as that provided by UL or similar organizations, signifies that the equipment has been tested and meets established safety standards. Using unapproved components can jeopardize safety and invalidate insurance coverage.

- Impact on Property Value

A properly permitted and installed wood-burning stove can enhance property value. Conversely, an unpermitted installation can create legal liabilities and negatively affect a property’s resale value. Potential buyers may be deterred by the prospect of rectifying unpermitted work.

The regulatory landscape governing solid fuel appliances emphasizes safety and code compliance. Adhering to these requirements not only protects occupants from potential hazards but also ensures the long-term integrity of the property. Engaging qualified professionals familiar with local codes is strongly recommended to navigate the permitting process and ensure a compliant installation.

2. Alternative Venting Systems

When a traditional chimney is absent, alternative venting systems become the critical component enabling the safe and effective expulsion of combustion byproducts from a wood-burning stove. The selection and installation of a suitable system are paramount for safe operation and regulatory compliance.

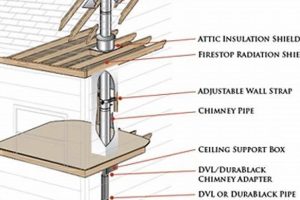

- Twin-Wall Flue Systems

Twin-wall flue systems are prefabricated, insulated metal pipes designed for exterior installation. These systems can vent a stove horizontally through a wall and then vertically up the exterior of the building, bypassing the need for a chimney. Their insulated design minimizes creosote buildup and maintains flue gas temperatures, promoting efficient drafting. An example is their use in modern homes with limited space for a traditional chimney. Improper installation can result in creosote accumulation and increased risk of chimney fires.

- Direct Vent Systems

While primarily used for gas appliances, direct vent systems may be adapted for certain wood-burning stoves. These systems draw combustion air from outside and exhaust directly to the exterior through a sealed, co-axial pipe. This configuration isolates the combustion process from the interior environment, enhancing safety. However, direct vent systems require careful matching to the stove’s specifications. Incompatible pairing can lead to inefficient combustion and potential carbon monoxide hazards.

- Through-the-Wall Systems

These systems involve venting the stove directly through an exterior wall using a short, specialized pipe. Due to their limited vertical rise, through-the-wall systems are typically suitable only for stoves designed for this type of venting. They often require careful consideration of prevailing wind patterns to prevent backdrafting. An example would be a small cabin where space is limited.

- Power Vented Systems

Power vented systems utilize a fan to actively exhaust flue gases. This can be beneficial in situations where natural draft is insufficient, such as long or complex vent runs. However, power vented systems require a reliable electricity supply, and failure during a power outage can compromise the stove’s operation. These are typically found in commercial settings for consistent exhaust.

The implementation of any alternative venting system demands strict adherence to manufacturer’s instructions and applicable building codes. A thorough understanding of the stove’s venting requirements and a careful assessment of the building’s characteristics are crucial for selecting and installing an appropriate system. Failure to do so can result in unsafe operating conditions and potential hazards.

3. Clearance Requirements

Adhering to specified clearance distances is paramount when installing a wood-burning stove in the absence of a traditional chimney. These requirements mitigate fire hazards and ensure safe operation, dictating the minimum separation between the stove, venting system, and combustible materials.

- Stove to Wall Clearances

Mandated distances between the stove body and nearby walls are crucial to prevent heat transfer from igniting combustible wall materials. These clearances vary based on stove model, wall construction, and the presence of heat shields. Failure to maintain these distances can lead to elevated wall temperatures, increasing the risk of fire. An example is maintaining a 36-inch clearance from an unprotected wall or reducing it with a certified heat shield.

- Venting System Clearances

Alternative venting systems, such as twin-wall flues, also have specific clearance requirements from combustible materials. These requirements apply to the entire length of the venting system, including horizontal and vertical runs. Insufficient clearance around the vent pipe can cause overheating and ignite nearby combustibles. For example, a double-wall flue pipe may require a 2-inch clearance to combustibles, while a single-wall pipe typically needs significantly more.

- Floor Protection

The floor beneath and around the stove must be protected with a non-combustible material to prevent embers or radiant heat from igniting the flooring. The size and type of floor protector are determined by the stove’s design and testing. Non-compliance may result in floor charring or ignition. An example would be using a listed floor protector extending 16 inches to the front and 8 inches to the sides of the stove.

- Corner Installations

Corner installations often present unique challenges in meeting clearance requirements. Reduced clearances may be permitted in corner installations if the walls are protected with appropriate heat shields or if the stove is specifically designed for corner placement. Ignoring corner-specific clearance guidelines can create concentrated heat zones and increase the risk of fire.

Compliance with all clearance requirements is critical for safe operation and code compliance. Consult the stove manufacturer’s instructions and local building codes to determine the specific clearance requirements for a given installation. Incorrect placement can compromise safety and invalidate insurance coverage, especially in installations lacking the inherent protection of a traditional chimney.

4. Ventilation adequacy

The operational safety and efficiency of a wood-burning stove, particularly when installed without a traditional chimney, hinge critically on adequate ventilation. This encompasses sufficient airflow to sustain combustion and prevent the buildup of hazardous gases within the dwelling. Inadequate ventilation impairs combustion, leading to incomplete burning of fuel and increased production of carbon monoxide, a colorless, odorless, and deadly gas. Moreover, insufficient air supply can result in backdrafting, where flue gases are drawn back into the living space instead of being exhausted through the venting system. For example, a tightly sealed modern home, designed for energy efficiency, may lack the natural air infiltration necessary to support a wood-burning stove’s combustion needs.

The primary cause of insufficient ventilation is often the presence of other appliances competing for air within the same space. Exhaust fans, clothes dryers, and central heating systems can create negative pressure, drawing air from the stove and impeding proper venting. Addressing this requires careful assessment of the home’s ventilation characteristics and implementation of corrective measures. This may involve installing a dedicated fresh air intake for the stove, ensuring a constant supply of oxygen for combustion. Another factor is the need to adhere to clearance and installation guidelines of alternative venting system. Failure to follow those could cause backdrafting.

In summary, ventilation adequacy is an indispensable component of a safe and functional wood-burning stove installation, especially in the absence of a conventional chimney. Addressing ventilation concerns proactively prevents hazardous conditions and ensures efficient stove operation. The understanding of this cause-and-effect relationship underscores the need for professional evaluation and implementation of ventilation solutions tailored to the specific characteristics of the dwelling, to have a working install.

5. Carbon Monoxide Safety

The installation of a log burner without a chimney presents a heightened risk of carbon monoxide (CO) poisoning, necessitating stringent safety measures. Unlike installations with traditional flues, alternative venting systems and compromised draft conditions can increase the potential for CO to enter the living space.

- CO Production and Incomplete Combustion

Carbon monoxide is a byproduct of incomplete combustion, occurring when a fuel source, such as wood, does not burn completely due to insufficient oxygen. Stoves lacking proper ventilation or experiencing backdrafting are prone to increased CO production. For instance, a stove with a blocked or poorly designed venting system can lead to elevated CO levels in the home. The consequences can be severe, ranging from flu-like symptoms to death.

- Importance of CO Detectors

Carbon monoxide detectors serve as a critical line of defense against CO poisoning. These devices continuously monitor CO levels in the air and emit an audible alarm when dangerous concentrations are detected. Detectors should be installed in accordance with manufacturer’s instructions and building codes, typically near sleeping areas. Regular testing and battery replacement are essential. A malfunctioning or absent detector negates this vital safety measure.

- Venting System Integrity and Maintenance

The venting system’s integrity is paramount in preventing CO leakage. Regular inspection and maintenance are necessary to ensure that all connections are secure, and the system is free from obstructions. Creosote buildup can impede airflow and increase the risk of CO entering the living space. Professional chimney sweeps can identify and address potential venting problems. Neglecting maintenance can compromise the system’s ability to safely exhaust CO.

- Symptoms of CO Poisoning and Emergency Response

Recognizing the symptoms of CO poisoning is crucial for prompt intervention. Symptoms can include headache, dizziness, nausea, vomiting, confusion, and loss of consciousness. If CO poisoning is suspected, immediate evacuation of the premises and calling emergency services are essential. Delaying action can have fatal consequences. A well-informed household is better prepared to respond to a CO emergency.

These facets highlight the critical relationship between CO safety and the installation of a log burner lacking a conventional chimney. Vigilance, proper equipment, and proactive maintenance are indispensable for mitigating the inherent risks. The absence of a traditional flue necessitates a heightened awareness of potential CO hazards and a commitment to preventative measures.

6. Professional Inspection

Professional inspection constitutes a critical safeguard when implementing a log burner installation lacking a traditional chimney. This service ensures compliance with safety standards and regulatory requirements, mitigating potential hazards associated with improper installation practices.

- Code Compliance Verification

A certified inspector assesses the installation against applicable local building codes and manufacturer specifications. This includes verifying proper clearances to combustible materials, adherence to venting system guidelines, and the presence of required safety features. A failure to meet code requirements can result in mandatory remediation, fines, or invalidated insurance coverage.

- Venting System Assessment

The inspector evaluates the integrity and functionality of the alternative venting system. This assessment includes examining flue connections, assessing draft performance, and identifying potential obstructions or creosote buildup. A compromised venting system can lead to carbon monoxide leaks, chimney fires, or inefficient stove operation. For example, the inspector can confirm if the venting matches the requirements of your install, which is directly impacted from installing a log burner without a chimney.

- Combustion Air Adequacy

The inspector determines if sufficient combustion air is available to support proper stove operation. This involves assessing room ventilation and identifying potential sources of negative pressure, such as exhaust fans. Insufficient combustion air can result in incomplete burning of fuel, increased carbon monoxide production, and backdrafting of flue gases.

- Safety Feature Validation

The inspector verifies the proper installation and functionality of essential safety features, including carbon monoxide detectors, smoke detectors, and emergency shut-off mechanisms. A malfunctioning or absent safety feature can compromise the ability to detect and respond to hazardous conditions, having dire consequences given you’re installing a log burner without a chimney.

These inspections establish a baseline for ongoing safe operation and maintenance. The absence of a professional inspection after such an install increases the risk of undetected hazards and potential safety breaches, underscoring its importance in this context.

7. System maintenance

Consistent system maintenance is not merely advisable but critically necessary when a log burner is installed without a traditional chimney. The absence of a robust, naturally drafting chimney system places a greater burden on alternative venting solutions, increasing the likelihood of issues that, if unaddressed, can lead to hazardous conditions. A primary cause-and-effect relationship exists between neglected maintenance and compromised venting efficiency. Creosote accumulation, a byproduct of incomplete combustion, builds up more rapidly in systems lacking the strong updraft of a chimney. This buildup restricts airflow, reducing efficiency and elevating the risk of chimney fires and carbon monoxide backflow. For example, failing to clean a twin-wall flue system annually in such installations can reduce its venting capacity by 50% within just a few years, creating a significant safety hazard.

System maintenance encompasses several key procedures: regular inspection of the venting system for damage or obstructions, creosote removal through professional chimney sweeping, and verification of proper stove operation. These actions directly affect the safety and longevity of the installation. Regular inspection can identify issues like corrosion or loose connections early, preventing costly repairs and safety breaches. Consider a scenario where a poorly sealed connection in the venting system allows flue gases to leak into the living space. Without routine inspection, this breach could go unnoticed for an extended period, exposing occupants to dangerous levels of carbon monoxide. The practical significance of this understanding is that homeowners must view system maintenance as an integral part of their heating strategy, not an optional extra.

In summary, system maintenance is an indispensable component of a log burner installation without a chimney. The effectiveness of alternative venting systems hinges on consistent care and upkeep. Ignoring maintenance requirements invites a range of potential problems, from reduced heating efficiency to life-threatening carbon monoxide exposure. Proactive maintenance is not only a matter of code compliance but a fundamental responsibility for ensuring the safety and well-being of occupants.

Frequently Asked Questions

This section addresses common inquiries and misconceptions regarding the installation of wood-burning stoves in the absence of a traditional chimney. Information provided is intended to clarify essential considerations and promote safe installation practices.

Question 1: Is it permissible to install a wood-burning stove without a chimney?

Installation is permissible, subject to strict adherence to local building codes and the implementation of an approved alternative venting system. These systems must meet specific safety standards and be installed according to manufacturer instructions and relevant regulations. Unauthorized installations are illegal and pose significant safety risks.

Question 2: What are the primary risks associated with bypassing a traditional chimney?

The absence of a chimney can lead to compromised draft, increased creosote buildup, and a higher risk of carbon monoxide intrusion into the living space. Alternative venting systems require meticulous installation and regular maintenance to mitigate these hazards. Failing to address these risks can result in chimney fires, carbon monoxide poisoning, or inefficient stove operation.

Question 3: What alternative venting systems are suitable for installations without a chimney?

Viable alternatives include twin-wall flue systems, direct vent systems, and, in some cases, through-the-wall systems. The suitability of each system depends on the stove’s specifications, building characteristics, and local code requirements. Professional consultation is advised to determine the most appropriate and safe option.

Question 4: How often should alternative venting systems be inspected and cleaned?

Alternative venting systems should be inspected at least annually, and more frequently if heavy stove usage occurs. Professional chimney sweeping is recommended to remove creosote buildup and ensure optimal draft. Neglecting regular maintenance can compromise venting efficiency and increase the risk of fire hazards.

Question 5: Are carbon monoxide detectors mandatory when installing a log burner without a chimney?

Carbon monoxide detectors are mandatory in most jurisdictions and are a critical safety measure, especially when a traditional chimney is absent. Detectors should be installed in accordance with manufacturer instructions and building codes. Regular testing and battery replacement are essential to ensure proper functionality. These measures add an important and critical layer when installing a log burner without a chimney.

Question 6: Can a homeowner install a log burner without a chimney independently?

While technically possible, independent installation is strongly discouraged. The complexity of venting requirements, building code compliance, and safety considerations necessitates professional expertise. Improper installation can result in hazardous conditions and legal liabilities. Engaging qualified professionals is advisable to ensure a safe and compliant installation.

The information provided herein emphasizes the need for diligent planning, adherence to safety regulations, and professional oversight when installing a log burner without a traditional chimney. Prioritizing safety and compliance safeguards both property and lives.

The subsequent section will offer a detailed guide to troubleshooting common issues encountered with alternative venting systems, focusing on preventative measures and corrective actions.

Conclusion

Installing a log burner without a chimney presents both opportunities and challenges. The preceding discussion outlined regulatory considerations, alternative venting systems, safety protocols, and maintenance requirements crucial for a successful and secure installation. From adhering to clearance requirements to ensuring adequate ventilation and carbon monoxide detection, each element contributes to minimizing potential hazards.

The decision to proceed demands careful evaluation of individual circumstances, strict adherence to applicable codes, and, most importantly, engagement of qualified professionals. A responsible approach to installing a log burner without a chimney ensures not only a functional heating solution but also the safety and well-being of occupants, reinforcing the necessity of informed decision-making and diligent execution.

![Protect Your Chimney: 9 Inch Round Chimney Cap [Debris Free] Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Protect Your Chimney: 9 Inch Round Chimney Cap [Debris Free] | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/02/th-483-300x200.jpg)