The phenomenon describes the movement of air upwards through a flue or vent, driven by a temperature difference between the interior and exterior environments. This airflow is essential for the proper and safe operation of combustion-based heating appliances. For example, adequate venting is necessary to remove byproducts from a wood-burning stove or furnace.

A properly functioning system ensures efficient fuel combustion, reduces the risk of carbon monoxide poisoning, and minimizes the buildup of creosote, which can lead to chimney fires. Historically, its management was a crucial aspect of building design, influencing the placement and construction of fireplaces and heating systems for optimal performance and safety.

The following sections will detail the factors influencing this airflow, methods for troubleshooting common problems, and best practices for ensuring its consistent and effective performance.

Optimizing Chimney Ventilation

The following guidelines provide practical measures for maintaining optimal ventilation, ensuring safe and efficient operation of heating appliances.

Tip 1: Schedule Regular Inspections: A qualified professional should inspect the system annually. This preventative measure can identify potential obstructions, structural damage, or creosote buildup that can impede airflow and create safety hazards.

Tip 2: Maintain Cleanliness: Regular cleaning removes creosote and other debris that accumulate over time. The frequency depends on usage but generally should occur at least once per heating season to ensure unobstructed passage for gases.

Tip 3: Ensure Proper Appliance Sizing: An improperly sized appliance can produce excessive smoke and insufficient heat, leading to poor venting. Consult a professional to ensure the appliance is appropriately matched to the flue dimensions.

Tip 4: Address Downdrafts Promptly: Downdrafts, where air flows down the flue, can be caused by nearby obstructions, wind patterns, or negative pressure within the building. Implement solutions such as chimney extensions or draft inducers to reverse the airflow.

Tip 5: Seal Air Leaks: Air leaks in the building envelope can negatively affect the interior pressure, reducing the system’s effectiveness. Seal windows, doors, and other potential sources of infiltration to maintain a stable pressure differential.

Tip 6: Consider a Chimney Cap: A cap protects against rain, snow, and debris, preventing them from entering and obstructing the flue. It also helps prevent downdrafts caused by wind.

Tip 7: Burn Seasoned Wood: For wood-burning appliances, using seasoned wood with a moisture content below 20% minimizes smoke production and creosote buildup, contributing to more efficient combustion and a cleaner flue.

These measures contribute to a safer and more efficient heating system, reducing the risk of hazards and maximizing fuel efficiency.

The next section will address common troubleshooting steps to take when problems are suspected.

1. Temperature differential

The temperature differential is the primary driving force behind the phenomenon. This difference, existing between the flue gases inside and the ambient air outside, creates a pressure gradient that initiates and sustains the upward flow of air. Warmer, less dense gases within the flue naturally rise, displacing the cooler, denser air above. This displacement generates suction, drawing air and combustion byproducts upward and out of the structure. Without a sufficient temperature difference, this natural convection process weakens or ceases entirely, leading to poor venting and potential hazards.

The effectiveness of this principle is exemplified by comparing operation during peak heating season and milder weather. During winter, a substantial difference exists, ensuring strong and consistent venting. Conversely, during warmer periods, with a reduced contrast, venting may become sluggish, necessitating mitigation strategies such as pre-heating the flue. Moreover, design considerations in regions with extreme temperature fluctuations must account for these variations to maintain safe and effective operation year-round.

Understanding the critical role of temperature differences is essential for optimizing the performance and safety. By maintaining a sufficient differential through proper appliance selection, flue insulation, and addressing potential downdraft conditions, one can ensure efficient combustion, reduce the risk of carbon monoxide exposure, and mitigate the dangers associated with creosote buildup. Neglecting this fundamental principle compromises the integrity of the entire system.

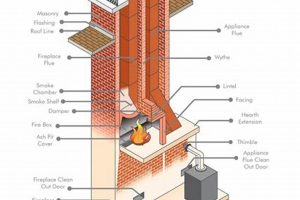

2. Flue Dimensions

Flue dimensions are a critical determinant of system performance. The internal size and shape of the flue directly influence the velocity and volume of gases, thereby impacting its effectiveness. An improperly sized flue can lead to inefficient combustion, increased creosote buildup, and potentially hazardous conditions.

- Flue Area and Flow Rate

The cross-sectional area directly impacts flow rate. An undersized flue restricts the passage of gases, leading to back pressure and reduced efficiency. Conversely, an oversized flue may not heat adequately, resulting in slow-moving gases that cool prematurely, promoting creosote formation. Calculating the correct area is essential for optimal performance and safety.

- Flue Height and Momentum

Flue height contributes to the momentum of exhaust gases. A taller flue generates a greater pressure differential, enhancing the upward movement. However, excessive height can increase heat loss, reducing the overall system efficiency. The optimal height is determined by factors such as appliance type, climate, and surrounding structures.

- Flue Shape and Turbulence

Flue shape affects gas flow patterns. Circular flues generally promote smoother, more laminar flow compared to square or rectangular flues. Irregular shapes can induce turbulence, increasing resistance and reducing the overall efficiency. The shape should be selected to minimize turbulence and maximize flow.

- Flue Material and Heat Retention

The material impacts heat retention. Materials like clay flue tiles retain heat better than metal, contributing to a warmer flue and stronger flow. Proper insulation can further enhance heat retention, particularly in exterior flues. The choice of material should balance cost, durability, and heat retention properties.

These dimensional aspects are crucial in the effective functioning of the flue. Correctly specifying and maintaining the flue optimizes the system performance and reduces the risk of hazards. The proper size and shape is critical to the longevity and safety of any heating system that uses a flue for venting.

3. Obstruction-free passage

The unrestricted flow of gases is fundamentally linked to the effectiveness of a chimney. Obstructions within the flue impede this flow, diminishing the natural process and compromising the safe and efficient operation of heating appliances. This direct correlation highlights the indispensable role of maintaining a clear and unobstructed passage.

Various factors contribute to blockage formation. Creosote buildup, resulting from incomplete combustion of wood, gradually accumulates on flue walls, constricting the diameter. Debris such as leaves, nests, or animal remains can also physically obstruct the passage. Structural damage, like collapsed flue liners, presents significant impediment. The impact of these obstructions manifests as reduced venting, leading to smoke backdrafts into the living space, increased risk of carbon monoxide poisoning, and elevated potential for chimney fires. For instance, a chimney choked with creosote not only restricts exhaust but also serves as a readily combustible fuel source, amplifying the risk of a hazardous fire.

Understanding this critical connection underscores the importance of regular inspection and maintenance. Proactive measures, such as annual cleaning and timely repairs, are essential for ensuring unobstructed venting and the continuous safety of heating systems. Prioritizing the unobstructed passage is a fundamental aspect of responsible heating system management.

4. Ambient pressure

Atmospheric pressure, or ambient pressure, plays a subtle yet significant role in the dynamics of a venting system. This pressure, exerted by the weight of air above a given point, directly influences the movement of gases within the flue and the overall effectiveness of the system.

- Pressure Differentials and Airflow

The primary function of a chimney is to create a pressure differential. Lower pressure within the flue relative to the ambient pressure outside the structure facilitates the upward flow of combustion gases. Variations in atmospheric pressure due to weather patterns or altitude can affect the magnitude of this differential. High-pressure systems typically lead to increased downward force, potentially impeding flow, while low-pressure systems may enhance the natural process.

- Building Pressure Effects

The internal pressure within a building can be affected by ambient pressure. A tightly sealed building, coupled with the operation of exhaust fans or other appliances, may create negative pressure. This negative pressure can counteract the upward movement of gases in the flue, leading to backdrafting or reduced efficiency. Conversely, positive pressure within a building can augment the flow, although this is less common in residential settings.

- Altitude and its Impact

Altitude affects ambient pressure, as air density decreases with increasing elevation. At higher altitudes, the lower atmospheric pressure reduces the available oxygen for combustion and alters the pressure gradient within the flue. Systems in high-altitude regions require adjustments to ensure proper venting, often involving modifications to appliance settings or flue dimensions.

- Environmental Factors

Wind conditions and the presence of nearby structures influence ambient pressure around the chimney. Wind blowing across the top of a chimney can create a suction effect, enhancing the flow. However, tall buildings or trees can disrupt airflow patterns, creating localized areas of high or low pressure that adversely affect ventilation.

The interplay between ambient pressure and venting efficiency underscores the importance of considering environmental factors in heating system design and operation. Optimizing for consistent, safe venting requires an understanding of how atmospheric conditions and building characteristics impact the pressure differentials that drive the system.

5. Appliance compatibility

The operational effectiveness of a chimney is inextricably linked to appliance compatibility. This compatibility refers to the harmonious matching of a heating appliance’s exhaust requirements with the design and specifications of the venting system. A mismatch can result in suboptimal or hazardous conditions, directly affecting the establishment and maintenance of proper venting. The appliance’s fuel type, heat output, and exhaust gas volume are critical factors that must align with the flue’s dimensions, height, and material composition. For instance, connecting a high-efficiency gas furnace to an oversized flue designed for a traditional wood-burning fireplace can lead to inadequate heating of the flue, resulting in condensation, corrosion, and potential blockage. Proper sizing ensures that the exhaust gases maintain sufficient temperature to rise effectively and prevent the formation of corrosive byproducts.

One crucial aspect of appliance compatibility lies in adherence to manufacturer specifications and local building codes. These guidelines provide detailed instructions for selecting the appropriate flue size and type based on the specific appliance being installed. Furthermore, modern appliances often feature advanced venting technologies, such as direct venting or power venting, which necessitate specialized venting systems. Direct-vent appliances, for example, draw combustion air from outside and exhaust gases directly outdoors through a sealed system, eliminating the need for a traditional chimney. Power-vented appliances use a fan to assist with exhausting gases, allowing for longer vent runs and greater flexibility in appliance placement. Ignoring these specific venting requirements can compromise appliance efficiency, increase the risk of carbon monoxide exposure, and potentially void warranties.

In conclusion, appliance compatibility is a fundamental prerequisite for ensuring safe and effective operation. A lack of attention to this crucial aspect can negate the benefits of even the most well-designed venting systems. A comprehensive understanding of appliance exhaust characteristics, combined with adherence to established guidelines and codes, is essential for preventing problems and maintaining the long-term integrity and safety of both the heating appliance and the building it serves.

Frequently Asked Questions

The following questions address common concerns regarding the phenomenon and its impact on heating systems.

Question 1: What are the primary indicators of a poorly functioning chimney draft?

Indicators include smoke backdrafting into the living space, difficulty starting or maintaining a fire, a smoky odor inside the house, and excessive creosote buildup within the flue.

Question 2: How does the outside temperature influence chimney draft?

A significant temperature difference between the flue gases and the outside air promotes a stronger effect. Colder outside temperatures generally enhance venting, while warmer temperatures can weaken the process.

Question 3: Can a chimney be too tall, negatively impacting its performance?

Yes, an excessively tall chimney can lead to increased heat loss and reduced flue gas temperature, potentially weakening the upward flow and promoting creosote condensation.

Question 4: What role does a chimney cap play in maintaining proper function?

A chimney cap prevents rain, snow, and debris from entering the flue, protecting it from obstructions and water damage. It can also help prevent downdrafts caused by wind.

Question 5: Is professional inspection necessary, even if no obvious problems are apparent?

Annual professional inspection is recommended to identify potential problems, such as structural damage or hidden obstructions, before they become significant safety hazards.

Question 6: How does burning unseasoned wood affect chimney draft and overall safety?

Burning unseasoned wood produces excessive smoke and moisture, leading to increased creosote buildup and a higher risk of chimney fires. It also reduces the efficiency of the heating appliance.

These questions highlight the importance of understanding and maintaining a properly functioning system for safe and efficient heating.

The subsequent section will delve into troubleshooting common venting problems.

Chimney Draft

This exposition has detailed the critical role “chimney draft” plays in the safe and effective operation of combustion-based heating systems. The complex interplay of temperature differentials, flue dimensions, obstruction-free passages, ambient pressure, and appliance compatibility directly influences the ability of a flue to effectively exhaust combustion byproducts. A compromised or poorly managed system presents significant risks, including carbon monoxide poisoning and chimney fires, while also reducing heating appliance efficiency.

Therefore, diligent maintenance, regular inspections, and a thorough understanding of the factors affecting “chimney draft” are essential for all who utilize combustion appliances. Failure to address potential issues proactively can have serious consequences. Prioritizing proper venting not only ensures the comfort and safety of occupants but also contributes to the longevity and optimal performance of the heating system itself. Continued vigilance and adherence to best practices are paramount.