The process involves applying protective measures to a chimney structure to prevent water penetration. This often entails the use of sealants, coatings, or specialized materials designed to create a barrier against moisture. For example, applying a water-repellent sealant to the exterior brickwork is a common method.

Effective moisture control within this structure is crucial to prevent structural damage caused by freeze-thaw cycles, which can lead to cracking and deterioration of the brick or masonry. Furthermore, minimizing water entry safeguards the interior of the property from potential leaks, mold growth, and associated health hazards. Historically, methods have evolved from simple mortar repairs to advanced polymer-based solutions.

The following sections will detail the various causes of water damage to these structures, explore available protective materials and application techniques, and outline inspection and maintenance best practices to ensure long-term performance.

Essential Considerations for Chimney Moisture Protection

Optimal chimney longevity and functionality depend on diligent preventative measures. Employing the following strategies will significantly reduce the risk of water-related damage.

Tip 1: Conduct Regular Inspections: A qualified professional should inspect the chimney annually. This evaluation identifies potential issues such as cracked mortar, damaged flashing, or deteriorated brickwork before they escalate.

Tip 2: Address Cracks Promptly: Any visible cracks in the chimney’s masonry should be repaired immediately. Small cracks can be filled with appropriate patching compounds, while larger cracks may necessitate professional repointing.

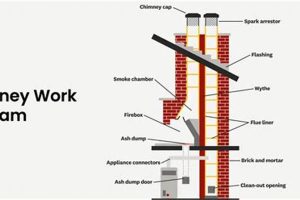

Tip 3: Install a Chimney Cap: A chimney cap prevents rainwater, snow, and debris from entering the flue. It also serves as a spark arrestor, enhancing fire safety.

Tip 4: Ensure Proper Flashing: The flashing at the base of the chimney, where it meets the roof, must be properly installed and maintained. Damaged or corroded flashing should be replaced to prevent water from seeping into the structure.

Tip 5: Apply a Water Repellent: A breathable, masonry-specific water repellent can be applied to the chimney’s exterior. This treatment allows moisture to escape while preventing water absorption.

Tip 6: Maintain Clear Drainage: Ensure that gutters and downspouts are functioning correctly to divert water away from the base of the chimney. Pooling water can exacerbate moisture problems.

Implementing these preventative actions protects the chimney structure, minimizes costly repairs, and contributes to overall home safety and value.

The subsequent section will explore material selection and application techniques in greater detail, providing a comprehensive guide for effective protection.

1. Material Permeability

Material permeability is a critical factor in ensuring the long-term effectiveness of chimney preservation efforts. The selection of impermeable materials can paradoxically exacerbate water damage. While the initial intention might be to create a watertight barrier, impermeable coatings trap moisture already present within the masonry, or allow water to enter but not escape. This trapped moisture undergoes freeze-thaw cycles, leading to internal stresses and the eventual cracking and spalling of the brick or stone. An example is the application of certain types of acrylic paints that, while providing a waterproof surface initially, prevent the chimney from “breathing,” thereby accelerating deterioration.

Conversely, employing materials with appropriate permeability characteristics facilitates the natural evaporation of moisture from within the chimney structure. Breathable sealants and coatings allow water vapor to escape while preventing liquid water from entering. Siloxane-based water repellents, for instance, penetrate the masonry and create a hydrophobic barrier without significantly impeding the movement of water vapor. This approach effectively minimizes the risk of internal moisture buildup and subsequent freeze-thaw damage. Proper mortar selection with compatible permeability characteristics is also essential for the chimney’s overall health.

Therefore, a thorough understanding of material permeability is essential for anyone undertaking chimney moisture protection. The optimal approach involves selecting materials that strike a balance between water repellency and breathability, ensuring the chimney remains dry while allowing for the natural dissipation of moisture. Incorrect material selection can lead to accelerated deterioration, emphasizing the practical significance of informed decision-making.

2. Flashing Integrity

Flashing, the metal sheeting installed at the intersection of the chimney and the roof, forms a crucial component in preventing water intrusion. Its primary function is to divert water away from vulnerable areas, ensuring a watertight seal and protecting the underlying structure from moisture damage. Compromised flashing can negate even the most comprehensive preservation efforts.

- Material Corrosion

Flashing is exposed to the elements, and over time, corrosion can occur. This process weakens the metal, creating gaps and openings through which water can penetrate. Common materials like aluminum or galvanized steel are susceptible to corrosion, especially in environments with high acidity or salt content. The presence of rust or pitting indicates a need for repair or replacement.

- Improper Installation

Even durable flashing materials are ineffective if improperly installed. Gaps, insufficient overlap, or incorrect sealing methods can create pathways for water to enter. The step flashing, base flashing, and counter flashing must be correctly integrated to form a continuous barrier against water ingress. Incorrect installation is a frequent cause of leaks around chimneys.

- Physical Damage

Flashing can sustain physical damage from falling debris, ice dams, or even strong winds. Dents, tears, or dislodged sections compromise the integrity of the seal. Regular inspection is essential to identify and address any physical damage promptly.

- Sealant Deterioration

Sealants are used to create a watertight bond between the flashing and the chimney or roofing materials. Over time, these sealants can dry out, crack, or lose their adhesion, allowing water to seep through. Regular inspection and reapplication of appropriate sealant are necessary to maintain the integrity of the flashing system.

The condition of chimney flashing directly impacts the effectiveness of the whole structure. Deteriorated or poorly installed flashing provides easy access for water, circumventing other preservation measures. Therefore, regular inspection, proper installation techniques, and timely repairs are crucial to maintaining chimney integrity and minimizing the risk of water damage.

3. Cap Installation

The installation of a chimney cap represents a primary defense against water intrusion, effectively reducing the amount of precipitation entering the flue. Without a cap, direct rainfall and snowfall can saturate the chimney’s interior, leading to various forms of damage.

- Moisture Reduction in the Flue

A properly installed cap significantly minimizes the amount of water entering the flue. This reduction prevents the saturation of interior masonry, which can lead to freeze-thaw damage and structural deterioration. For example, consider a chimney exposed to heavy rainfall without a cap; the flue can become saturated, accelerating the breakdown of mortar joints.

- Prevention of Animal Entry

Chimney caps not only deflect water but also prevent animals, such as birds, squirrels, and raccoons, from entering the chimney. Animal nests and debris can obstruct the flue, trapping moisture and creating a corrosive environment. A well-secured cap eliminates this entry point, maintaining a clear and dry flue.

- Deflection of Debris

Leaves, twigs, and other airborne debris can accumulate in an uncapped chimney, absorbing moisture and fostering decay. A cap with a mesh screen effectively blocks this debris, preventing clogs and promoting proper ventilation. This is particularly relevant in wooded areas where falling leaves are prevalent.

- Spark Arrestance

Many chimney caps incorporate a spark arrestor, a mesh screen designed to prevent embers from escaping the flue and potentially igniting nearby combustible materials on the roof. While primarily a fire safety feature, spark arrestors also contribute to moisture control by preventing the accumulation of flammable debris that could trap moisture.

The strategic incorporation of a chimney cap into the overall preservation strategy provides a comprehensive approach to water damage prevention. By addressing direct precipitation, animal entry, debris accumulation, and fire hazards, the cap contributes to the long-term health and functionality of the chimney.

4. Mortar Condition

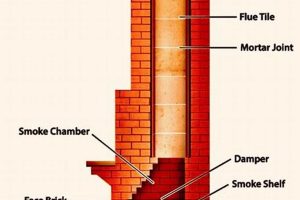

The condition of mortar within a chimney’s masonry structure is fundamentally linked to its overall resistance to water penetration. Deteriorated mortar joints provide direct pathways for moisture, undermining any external preservation measures.

- Mortar Degradation and Water Ingress

Cracked, crumbling, or missing mortar allows rainwater and melting snow to permeate the chimney’s structure. This ingress leads to internal saturation, freeze-thaw damage, and potential structural instability. For example, hairline cracks in mortar, often overlooked, can act as conduits for water that expands upon freezing, exacerbating the cracks and weakening the entire assembly.

- Composition and Permeability

The composition of the mortar itself influences its permeability. Incorrect mortar mixes, often too hard or dense for the surrounding brick or stone, can trap moisture and accelerate deterioration. Conversely, a softer, more permeable mortar allows for some moisture evaporation, reducing the risk of internal pressure buildup. The appropriate selection of mortar type, compatible with the existing masonry, is crucial for long-term preservation.

- Repointing and Joint Integrity

Repointing, the process of replacing deteriorated mortar, is a necessary maintenance task for preserving chimney integrity. Properly executed repointing restores the water-resistant barrier provided by intact mortar joints. However, improper repointing techniques, such as using incompatible mortar or failing to thoroughly clean the joints, can negate the benefits and even accelerate deterioration.

- Chemical Attack and Erosion

Acid rain and other environmental pollutants can chemically attack mortar, causing it to erode and weaken over time. This erosion creates voids and pathways for water penetration. In industrial areas or regions with high levels of air pollution, the rate of mortar deterioration is often accelerated, necessitating more frequent inspections and maintenance.

Consequently, maintaining the integrity of mortar joints is a critical aspect of chimney preservation. Addressing mortar deterioration through appropriate repointing techniques, selecting compatible materials, and mitigating chemical attack are essential strategies for minimizing water penetration and prolonging the life of the chimney structure.

5. Sealant Application

Sealant application directly impacts the efficacy of chimney preservation efforts. The strategic application of appropriate sealants to vulnerable areas minimizes water intrusion, thereby protecting the structure from moisture-related damage. Sealants create a barrier that prevents water from penetrating cracks, joints, and other potential entry points, safeguarding the chimney’s integrity. The absence of effective sealant application often leads to accelerated deterioration, necessitating costly repairs. As an example, consider the area where the chimney cap meets the flue; without a properly applied sealant, rainwater will seep into the chimney’s interior, causing damage to the firebox, flue liner, and surrounding masonry.

The selection of suitable sealant types is critical. Different materials possess varying properties regarding adhesion, flexibility, and resistance to weathering. Silicone-based sealants, for example, offer excellent flexibility and water resistance but may not be suitable for all substrates. Polyurethane sealants exhibit superior adhesion and durability but may be more rigid. A thorough assessment of the chimney’s materials and environmental conditions is essential to determine the optimal sealant for the application. Furthermore, proper surface preparation, including cleaning and priming, ensures adequate sealant adhesion and long-term performance. Neglecting these factors can result in premature sealant failure and renewed water intrusion.

In summary, sealant application represents a key component of chimney preservation strategies. The careful selection and application of appropriate sealants to vulnerable areas establish a protective barrier against water intrusion, preventing damage to the chimney’s structure and prolonging its lifespan. However, the effectiveness of sealants relies on proper material selection, surface preparation, and application techniques. Addressing these factors is essential to maximize the benefits of sealant application and minimize the risk of water-related damage.

6. Inspection Frequency

The regularity with which a chimney is inspected directly correlates with the long-term success of any water protection strategy. The structure is subject to constant environmental stressors, making proactive identification of vulnerabilities essential. Neglecting regular examinations invites progressive water damage, ultimately undermining protective measures.

Annual assessments conducted by qualified professionals allow for the early detection of subtle issues such as hairline cracks in mortar, minor flashing damage, or the initial stages of sealant degradation. These seemingly insignificant problems can rapidly escalate into major water intrusion points if left unaddressed. For example, a small crack in the chimney crown, unnoticed during a period of neglect, can widen over subsequent freeze-thaw cycles, leading to significant water saturation of the underlying masonry. Similarly, a partially detached section of flashing can allow water to seep behind the roofing materials, causing hidden damage that is costly to repair. Regular checks allow for the implementation of targeted repairs, preventing the need for extensive and expensive renovations. The chimney is a large investment; protect that investment through regular inspections.

In conclusion, inspection frequency serves as a cornerstone of effective protection. Consistent monitoring enables the timely identification and remediation of vulnerabilities, preventing minor issues from evolving into major structural problems. While initial preservation efforts may involve the application of sealants and protective coatings, their longevity is contingent upon a commitment to routine inspection and maintenance. Therefore, a proactive approach, characterized by regular assessments, is paramount to ensuring the long-term effectiveness of water protection measures.

7. Professional Expertise

The successful implementation of chimney moisture protection strategies is inherently linked to the involvement of qualified professionals. The complexity of chimney construction, combined with the diverse range of potential failure points, necessitates specialized knowledge and experience for accurate assessment and effective remediation.

- Accurate Diagnosis and Assessment

Professionals possess the expertise to accurately diagnose the causes of water intrusion. This involves a thorough inspection of the chimney structure, including the crown, flue, flashing, and mortar joints. They can identify subtle signs of damage that might be overlooked by a layperson, such as hairline cracks or early stages of material degradation. A professional assessment ensures that protection efforts are targeted to the specific vulnerabilities of the chimney, rather than relying on generic solutions. For example, they may use moisture meters to detect hidden water damage behind seemingly intact surfaces.

- Material Selection and Compatibility

Professionals are knowledgeable about the various protective materials available, including sealants, water repellents, and mortar types. They understand the properties of these materials and their compatibility with different chimney construction materials. Selecting the wrong material can lead to accelerated deterioration or even structural damage. Professionals can recommend the appropriate materials based on factors such as the chimney’s age, construction type, and local environmental conditions. For instance, using an impermeable sealant on a brick chimney can trap moisture and exacerbate freeze-thaw damage.

- Proper Installation Techniques

The effectiveness of protection measures depends on proper installation techniques. Professionals are trained in the correct application methods for sealants, flashing, and other protective materials. They understand the importance of surface preparation, adhesion, and proper sealing to create a durable and watertight barrier. Improper installation can render even the best materials ineffective. An example is the incorrect installation of flashing, which can create pathways for water intrusion despite the use of high-quality materials.

- Safety and Compliance

Chimney work often involves working at heights and dealing with potentially hazardous materials. Professionals are trained in safety procedures and equipped with the necessary safety equipment to perform the work safely. They are also familiar with local building codes and regulations related to chimney construction and repair. Engaging a professional ensures that the work is performed safely and in compliance with all applicable regulations.

The multifaceted nature of chimney preservation underscores the value of engaging professionals. Their expertise in diagnosis, material selection, installation techniques, and safety ensures that efforts are effective, durable, and compliant with industry standards. Relying on professional expertise minimizes the risk of costly mistakes and maximizes the lifespan of the chimney structure.

Frequently Asked Questions

This section addresses common inquiries regarding the preservation of chimney structures against water damage, offering concise and authoritative responses.

Question 1: What are the primary indicators of water damage affecting a chimney?

Evidence of water damage can manifest as spalling brick, crumbling mortar joints, efflorescence (white, powdery deposits), interior water stains, or a musty odor emanating from the chimney area.

Question 2: How frequently should a chimney undergo professional inspection for water damage?

A professional inspection is recommended on an annual basis. Early detection of potential issues is crucial for preventing extensive and costly repairs.

Question 3: Is it possible to effectively mitigate water damage through do-it-yourself methods, or is professional intervention always required?

While minor repairs, such as patching small cracks, may be addressed through do-it-yourself methods, significant water damage or structural issues necessitate the expertise of a qualified professional.

Question 4: What sealant types are recommended for preserving a chimney structure?

Breathable, masonry-specific sealants, such as siloxane-based water repellents, are typically recommended. These sealants allow for moisture evaporation while preventing water ingress. The incorrect sealant can cause damage.

Question 5: What role does the chimney cap play in preserving against water damage?

A chimney cap prevents direct rainfall, snowfall, and debris from entering the flue, significantly reducing the risk of internal moisture saturation and subsequent damage.

Question 6: How does the deterioration of mortar joints contribute to water damage within a chimney structure?

Deteriorated mortar joints provide direct pathways for water intrusion, leading to internal saturation, freeze-thaw damage, and potential structural instability. Damaged mortar is detrimental to the structures integrity.

The information presented emphasizes the importance of proactive maintenance, professional assessment, and the appropriate selection of materials for ensuring the long-term integrity of chimney structures.

The subsequent section will address specific techniques and materials used for protecting chimney structures.

Concluding Remarks on Waterproofing a Chimney

This exploration has detailed the multifaceted nature of safeguarding chimney structures from water damage. Key considerations include material permeability, flashing integrity, cap installation, mortar condition, sealant application, and inspection frequency. These elements are not isolated but interconnected, forming a comprehensive approach to preservation. The information provided underscores the importance of proactive maintenance, professional assessment, and the selection of appropriate materials.

Neglecting chimney protection can lead to substantial structural damage and costly repairs. It is crucial to recognize the long-term value of routine inspections and preventative measures. Prioritizing these strategies ensures the continued functionality, safety, and longevity of the chimney, ultimately safeguarding the entire property from the detrimental effects of water intrusion.