This architectural feature, frequently found in outdoor cooking areas, is designed to efficiently vent smoke and heat. Often constructed from brick, stone, or stucco, it typically integrates a wide base that tapers to a narrower flue. A common application includes enclosing a grilling or cooking surface, directing combustion byproducts upward and away from the user.

The value of this structure lies in its ability to create a more comfortable and controlled cooking environment. By channeling smoke effectively, it minimizes eye irritation and improves air quality in the immediate vicinity. Historically, similar designs have been utilized in various cultures for centuries, showcasing a universal need for effective smoke management in cooking and heating practices. The enduring appeal stems from functional design and aesthetic integration with outdoor living spaces.

The following sections will delve into the specific construction techniques, regional variations, and maintenance considerations associated with this type of outdoor structure. Further exploration will also cover materials selection, safety protocols, and optimal design considerations for maximizing both performance and longevity.

Tips for Optimal Performance

Maximizing the functionality and lifespan requires adherence to specific guidelines and best practices. These tips cover construction, usage, and maintenance to ensure safe and efficient operation.

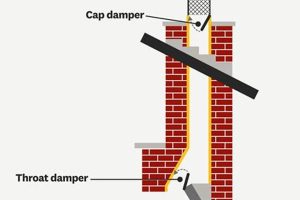

Tip 1: Ensure Proper Draft. The internal dimensions and flue height should be calculated to create sufficient draft. Inadequate draft results in smoke backflow, negating its purpose. Consult engineering guidelines or experienced builders to determine appropriate dimensions based on the firebox size.

Tip 2: Select Heat-Resistant Materials. Construction materials must withstand high temperatures and temperature fluctuations. Firebrick is a preferred material for the firebox, while durable stone or stucco can be used for the exterior. Avoid using combustible materials near the firebox.

Tip 3: Employ Proper Sealing Techniques. Gaps or cracks in the structure can compromise draft and create fire hazards. Use high-temperature mortar to seal joints and ensure a tight seal around the firebox. Regularly inspect and repair any cracks that develop.

Tip 4: Maintain Adequate Ventilation. The area surrounding it should be well-ventilated to prevent carbon monoxide buildup. Avoid using it in enclosed spaces without proper ventilation. Install a carbon monoxide detector in nearby structures.

Tip 5: Conduct Regular Cleaning. Soot and creosote buildup can restrict airflow and increase the risk of chimney fires. Schedule annual inspections and cleaning by a qualified chimney sweep. Remove ash and debris from the firebox regularly.

Tip 6: Use Seasoned Wood. Burning unseasoned wood produces excessive smoke and creosote. Use dry, seasoned wood to minimize smoke production and maintain efficient combustion. Store wood in a dry, well-ventilated area.

Implementing these recommendations will contribute to a safer and more enjoyable cooking experience, while also extending the lifespan. Careful planning and diligent maintenance are essential for optimal performance.

The subsequent sections will address regional design variations and advanced safety considerations. Continue reading to gain a comprehensive understanding of this outdoor structure.

1. Efficient Smoke Ventilation

Efficient smoke ventilation is a core functional requirement. Its design and construction directly influence the user experience and safety when using outdoor cooking areas incorporating it. Proper smoke management minimizes discomfort, improves air quality, and reduces potential health risks.

- Flue Design and Dimensions

The dimensions and shape of the flue directly impact the draft, determining how effectively smoke is drawn upwards and away. A wider base tapering to a narrower flue creates a natural convection current. Incorrect proportions can lead to smoke billowing back into the cooking area. Empirical calculations and regional building practices inform the optimal dimensions, taking into account typical fire size and local wind conditions. Insufficient flue height often results in poor smoke evacuation, requiring adjustments to the initial design.

- Material Composition and Heat Retention

The choice of materials, such as firebrick, stone, or stucco, impacts both heat retention and smoke flow. Materials must withstand high temperatures without cracking or degrading, which could create gaps that disrupt the airflow. Proper insulation prevents heat loss, contributing to a stronger updraft. Dense materials also influence the speed at which smoke cools, affecting its buoyancy and overall efficiency. Porous materials, if not properly sealed, can absorb smoke and odors over time, diminishing the cooking experience.

- Airflow Dynamics and Environmental Factors

Wind direction and surrounding structures significantly influence airflow around the structure. Strategic placement can leverage prevailing winds to enhance draft. Conversely, nearby buildings or trees can create downdrafts, impeding smoke ventilation. Local weather patterns and seasonal variations necessitate adaptive designs that accommodate changing wind conditions. Careful consideration of the surrounding environment is crucial for maximizing its effectiveness.

- Combustion Efficiency and Fuel Type

The type of fuel used directly affects the amount and composition of the smoke produced. Seasoned hardwoods produce less smoke than green wood. Efficient combustion minimizes particulate matter and volatile organic compounds released into the atmosphere. The design should promote complete combustion by providing adequate oxygen supply to the fire. Modifications to the firebox, such as air inlets, can further optimize combustion efficiency and reduce smoke emissions.

Therefore, effective smoke ventilation is not merely a superficial design element; it is a complex interplay of flue design, material properties, environmental factors, and combustion management. Attention to these facets ensures a safer, more comfortable, and environmentally responsible cooking experience. Regional construction practices, refined over generations, reflect an understanding of these intricate relationships.

2. Material Heat Resistance

Material heat resistance is a critical factor in the construction and longevity of this outdoor architectural element. Due to the high temperatures generated within the firebox, the materials used must be capable of withstanding extreme thermal stress without significant degradation. Failure to select appropriate heat-resistant materials can result in structural failures, such as cracking, spalling, or complete collapse, posing a safety hazard and necessitating costly repairs. For instance, using standard brick instead of firebrick in the firebox will inevitably lead to premature deterioration due to the inability of standard brick to withstand prolonged exposure to high temperatures.

The selection process involves considering factors such as thermal conductivity, coefficient of thermal expansion, and resistance to thermal shock. Firebrick, known for its high alumina content, is commonly used for the inner lining due to its exceptional heat resistance. Stone, such as granite or volcanic rock, can be used for the exterior, provided it is properly sealed to prevent moisture absorption, which can exacerbate thermal stress. The mortar used in construction must also be heat-resistant to maintain the structural integrity of the joints. The practical application of this understanding is evident in the traditional designs found in various regions, where local materials with proven heat-resistant properties have been utilized for centuries.

In conclusion, material heat resistance is not merely a desirable attribute but an essential requirement for safe and durable operation. A thorough understanding of the thermal properties of different materials is crucial for successful construction and long-term performance. Ignoring this aspect can lead to structural failures, compromised safety, and increased maintenance costs, ultimately undermining the benefits this architectural element offers. Further research into advanced materials and construction techniques may enhance heat resistance and extend the lifespan.

3. Optimal flue dimensions

The functionality of a structure, specifically its smoke-venting capability, hinges critically on flue dimensions. Inadequate flue size restricts airflow, leading to smoke backflow and rendering the structure ineffective. Conversely, excessively large flues can dissipate heat too rapidly, weakening the draft and similarly causing smoke issues. Empirical data and regional building practices, refined over centuries, inform the ideal proportional relationship between the firebox and the flue’s cross-sectional area and height. For example, traditional designs in certain areas utilize a specific ratio derived from generations of practical experience, resulting in efficient smoke management for that region’s typical cooking practices and wind conditions. Deviations from these established ratios often lead to compromised performance, underscoring the direct cause-and-effect relationship between flue dimensions and smoke-venting efficiency.

The practical significance of understanding optimal flue dimensions extends beyond mere functionality. Proper smoke ventilation minimizes eye irritation and reduces the risk of respiratory problems associated with smoke inhalation. A well-designed flue enhances the overall cooking experience by creating a more comfortable and controlled environment. Furthermore, efficient smoke management reduces soot buildup on surrounding surfaces, minimizing maintenance requirements. A key component is the correct height of the flue relative to surrounding structures. Building codes often specify minimum flue heights to prevent downdrafts caused by nearby roofs or trees. Ignoring these codes and best practices can result in a structure that is both ineffective and potentially hazardous.

In summary, achieving optimal flue dimensions is paramount for the successful performance of this outdoor cooking structure. Challenges remain in adapting traditional designs to modern construction materials and techniques, as well as accommodating varying fuel types and cooking styles. However, a thorough understanding of airflow dynamics, heat transfer principles, and regional building practices provides a solid foundation for designing and constructing structures that are both functional and aesthetically pleasing. The integration of this understanding is crucial for the continued relevance and effectiveness of this traditional architectural element.

4. Structural Integrity

Structural integrity is fundamental to the safe and prolonged functionality of this specific outdoor architectural feature. Given its exposure to extreme temperatures, weather conditions, and potential physical stresses, a robust structural design and execution are paramount. Without adequate structural integrity, the element is susceptible to cracking, collapse, and other failures that could pose significant safety risks.

- Material Selection and Load-Bearing Capacity

The choice of materials directly influences the overall structural integrity. Firebrick, stone, and reinforced concrete are commonly used due to their high compressive strength and heat resistance. The design must account for the weight of the structure itself, as well as any additional loads imposed by wind, snow, or seismic activity. Improper material selection, such as using standard brick instead of firebrick in high-temperature areas, can lead to premature failure. Local building codes often specify minimum load-bearing requirements to ensure structural safety.

- Foundation Stability and Ground Conditions

A stable foundation is critical for preventing settling or shifting, which can compromise the structure’s integrity. The foundation must be designed to withstand the weight of the element and distribute it evenly over the underlying soil. Ground conditions, such as soil type and moisture content, must be carefully assessed to determine the appropriate foundation design. In areas with unstable soil, pilings or other reinforcement measures may be necessary to ensure long-term stability. Neglecting foundation stability can result in cracks, tilting, or even collapse.

- Jointing and Mortar Integrity

The joints between individual masonry units are weak points in the structure, and their integrity is crucial for preventing water infiltration and structural failure. High-quality mortar, specifically formulated for high-temperature applications, must be used to ensure a strong and durable bond. Proper jointing techniques, such as full mortar beds and head joints, are essential for maximizing the structural integrity of the joints. Regular inspections and maintenance are necessary to identify and repair any cracks or deteriorated mortar.

- Reinforcement and Support Systems

In some cases, reinforcement may be necessary to enhance the structural integrity of a particularly large or complex structure. Steel reinforcing bars, embedded in the mortar, can provide additional tensile strength and resistance to cracking. Support systems, such as buttresses or arches, can be used to distribute loads and reduce stress on critical areas. These reinforcement and support systems are particularly important in regions prone to seismic activity or extreme weather conditions.

These interconnected facets highlight the importance of a holistic approach to structural design and construction. By carefully considering material selection, foundation stability, jointing integrity, and reinforcement strategies, it is possible to construct structures that are safe, durable, and aesthetically pleasing. The durability of existing historical examples underscores the value of adhering to sound engineering principles and time-tested construction practices. Ignoring structural integrity considerations can lead to significant safety hazards and costly repairs, ultimately diminishing its intended functionality and aesthetic value.

5. Regional Design Variations

The form and function of this cooking structure exhibit notable regional variations across Mexico, reflecting the diverse climates, available materials, and culinary traditions. These variations are not merely aesthetic; they represent adaptations optimized for local conditions and usage patterns.

- Material Sourcing and Construction Techniques

The availability of local materials profoundly influences construction techniques. In Oaxaca, clay-rich soils support the production of terracotta structures, often featuring intricate, handcrafted details. Conversely, mountainous regions favor stone, resulting in more robust and monolithic constructions. Coastal areas might utilize brick due to its accessibility and resistance to humidity. These material choices dictate construction methods, ranging from traditional adobe layering to skilled stonemasonry.

- Climatic Adaptations and Ventilation Strategies

Design adaptations address specific climatic challenges. In hot, arid regions, smaller fireboxes and taller flues promote rapid heat dissipation and efficient smoke removal. Regions with high rainfall necessitate larger overhangs to protect the firebox and cooking area from the elements. Ventilation strategies vary, with some designs incorporating adjustable dampers to control airflow based on prevailing wind conditions. The orientation of the structure is frequently aligned with the dominant wind direction to maximize draft.

- Functional Specialization and Culinary Practices

Regional culinary practices shape the functional design. Structures in regions known for slow-cooked dishes often feature larger fireboxes capable of sustaining low, consistent heat for extended periods. In contrast, areas specializing in grilling or roasting may prioritize designs that facilitate high-temperature searing. The size and shape of the cooking surface, as well as the inclusion of features like built-in ovens or smokers, reflect specific regional culinary preferences.

- Aesthetic Embellishments and Cultural Significance

Beyond functional considerations, aesthetic embellishments contribute to the cultural significance of the design. Structures may be adorned with intricate tilework, colorful stucco, or hand-painted murals, reflecting local artistic traditions. The placement of the structure within the outdoor space, its relationship to other architectural elements, and its overall integration with the surrounding landscape contribute to its cultural identity. In some communities, the construction of the structure is a communal event, symbolizing social cohesion and shared heritage.

These regional design variations underscore the adaptability and enduring relevance of the design. As both a functional cooking tool and a cultural artifact, it continues to evolve, reflecting the diverse landscapes, traditions, and lifestyles of Mexico. The variations highlight the interplay between environmental constraints, culinary needs, and aesthetic expression. The study of these variations provides insights into the rich cultural tapestry of Mexico and the ingenuity of its artisans.

6. Regular maintenance

The operational efficiency and lifespan of this outdoor architectural element depend significantly on consistent upkeep. The exposure to high temperatures, soot, and external weather conditions necessitates a proactive approach to maintenance. Neglecting scheduled maintenance leads to a cascade of negative consequences, including reduced draft, increased fire risk, and structural degradation. For instance, creosote buildup within the flue restricts airflow, hindering efficient smoke removal and increasing the likelihood of chimney fires. The direct result is a compromised cooking experience and a potential safety hazard. Therefore, consistent maintenance forms an essential component of its continued usability.

Specific maintenance tasks include regular cleaning of the firebox to remove ash and debris, annual inspections of the flue for creosote buildup, and prompt repair of any cracks or damaged mortar. Using appropriate cleaning tools and techniques is critical to prevent further damage to the structure. The frequency of these tasks depends on usage patterns and fuel type. Structures used frequently with resinous wood require more frequent cleaning than those used occasionally with seasoned hardwoods. Practical application of this understanding involves implementing a scheduled maintenance program, documenting inspections, and addressing any issues promptly. Failure to adhere to this practice can result in costly repairs and premature failure.

In summary, regular maintenance is not merely a supplementary activity, but an integral component of ensuring the longevity, safety, and efficiency of this outdoor cooking structure. The challenges involve educating users about the importance of maintenance and providing accessible resources for performing these tasks. By emphasizing the connection between consistent upkeep and long-term benefits, it’s possible to promote a culture of responsible ownership and ensure the continued enjoyment of this architectural element for generations to come. Addressing these maintenance needs secures both functionality and cultural relevance.

Frequently Asked Questions

The following questions address common inquiries regarding the construction, maintenance, and performance aspects of this outdoor architectural element. The responses are intended to provide clear and concise information to ensure safe and effective utilization.

Question 1: What is the optimal flue height for efficient smoke ventilation?

Optimal flue height is determined by several factors, including the size of the firebox, the surrounding landscape, and local wind conditions. Generally, a flue height that extends at least two feet above any structure within ten feet is recommended to prevent downdrafts. Consult local building codes for specific requirements.

Question 2: What type of mortar should be used for construction?

A high-temperature mortar specifically formulated for masonry fireplaces and chimneys is essential. These mortars are designed to withstand extreme heat and prevent cracking or crumbling. Avoid using standard mortar, as it is not suitable for high-temperature applications.

Question 3: How often should the structure be cleaned?

Cleaning frequency depends on usage patterns and fuel type. If the structure is used frequently or if resinous woods are burned, cleaning should be performed at least once a year. Regular inspections are recommended to assess the buildup of creosote and soot.

Question 4: What are the signs of structural damage that require immediate attention?

Signs of structural damage include cracks in the masonry, spalling or crumbling brick, and loose or missing mortar. These issues can compromise the structural integrity and pose a safety hazard. Immediate repair is recommended to prevent further damage and ensure continued safe operation.

Question 5: Can this structure be used indoors?

This structure is designed for outdoor use only. Using it indoors can lead to dangerous carbon monoxide buildup and pose a significant health risk. Ensure adequate ventilation when operating the structure outdoors.

Question 6: How can the draft be improved if smoke is billowing back into the cooking area?

Several factors can contribute to poor draft. Ensure the flue is free of obstructions, such as bird nests or debris. Increasing the height of the flue may improve draft in some cases. Consulting a qualified chimney professional is recommended to diagnose and address complex draft issues.

The information presented here provides a general overview of common considerations. Consulting with qualified professionals is recommended for specific design, construction, and maintenance needs.

The subsequent section will explore safety protocols associated with the utilization of these structures.

Conclusion

This exploration has detailed the multifaceted nature of the mexican chimney, encompassing design principles, construction techniques, regional adaptations, maintenance requirements, and safety protocols. The structure’s effectiveness hinges on a confluence of factors, including optimal flue dimensions, heat-resistant materials, structural integrity, and consistent upkeep. Variations across regions highlight the adaptability of the basic design to local climates, resources, and culinary traditions. Adherence to established building codes and best practices is paramount for ensuring safe and efficient operation.

Understanding these aspects is essential for anyone considering building or maintaining a mexican chimney. Further research into advanced materials and design innovations is encouraged to enhance performance and longevity. The continued appreciation for this architectural element depends on a commitment to responsible construction and diligent maintenance, ensuring that it remains a functional and aesthetically pleasing feature of outdoor living spaces for years to come.