A ceramic or earthenware component utilized in chimney construction forms a protective internal layer within the flue. Its primary function is to contain and direct the products of combustionsmoke, gases, and particulate matteraway from the building and into the atmosphere. These sections are typically installed during the initial chimney build or can be retrofitted into existing structures.

The incorporation of this safeguarding element is critical for several reasons. It prevents corrosive byproducts of combustion from damaging the chimney’s masonry, thereby extending its lifespan and structural integrity. Furthermore, it significantly reduces the risk of carbon monoxide infiltration into the living space, enhancing occupant safety. Historically, their use became widespread as heating appliances became more efficient and produced more concentrated and potentially harmful exhaust.

Therefore, a properly functioning interior safeguard is essential for safe and efficient chimney operation, influencing factors such as draft, code compliance, and the choice of appropriate fuels. The subsequent sections will delve into the specifics of inspection, repair, alternative materials, and the regulatory landscape governing their application.

Essential Guidance

The following comprises crucial recommendations concerning the selection, maintenance, and lifespan optimization of flue safeguards.

Tip 1: Regular Inspection is Paramount: Conduct annual inspections, preferably by a qualified chimney sweep, to identify cracks, spalling, or mortar deterioration. Early detection prevents costly repairs and potential hazards.

Tip 2: Material Compatibility Matters: Ensure the chosen liner material is compatible with the type of fuel burned. Wood-burning systems, for instance, generate different byproducts than gas or oil-burning appliances, requiring appropriate resistance to acid and creosote buildup.

Tip 3: Proper Sizing is Critical: The flue size must correspond to the appliance it serves. Undersized flues can lead to poor draft and carbon monoxide buildup, while oversized flues can contribute to creosote condensation.

Tip 4: Promptly Address Damage: Cracks or gaps compromise the liner’s integrity and allow harmful gases to escape. Damaged sections necessitate professional repair or replacement to restore safe operation.

Tip 5: Consider Professional Installation: Retrofitting a liner, particularly within an existing chimney, often requires specialized tools and knowledge. Employing a certified technician ensures proper installation and compliance with relevant codes.

Tip 6: Maintain Cleanliness: Regular cleaning removes creosote, soot, and debris that can accumulate and obstruct the flue, reducing efficiency and increasing the risk of chimney fires.

Tip 7: Document All Inspections and Repairs: Maintaining a detailed record of inspections, cleanings, and repairs provides a valuable reference for future maintenance and potential insurance claims.

Adherence to these guidelines facilitates the preservation of chimney functionality, mitigation of safety risks, and extension of the lifespan, thereby minimizing expenses associated with significant remediation.

The subsequent segment will address the legal and regulatory framework surrounding chimney and venting system standards.

1. Material Composition

The performance and longevity of a ceramic interior flue component are inextricably linked to its material composition. The specific type of clay, its purity, and the firing process significantly influence the finished product’s ability to withstand the harsh conditions within a chimney flue. Impurities within the clay matrix can create weak points, leading to premature cracking and degradation when exposed to high temperatures and corrosive combustion byproducts.

For instance, variations in clay composition impact the liner’s resistance to acids formed during the combustion of fossil fuels. Liners manufactured from a clay with insufficient acid resistance will deteriorate more rapidly, potentially compromising the chimney’s structural integrity and creating a safety hazard. The firing process, particularly the maximum temperature reached and the duration of the firing cycle, affects the liner’s density and overall strength. Under-fired clay remains porous and susceptible to moisture absorption, while over-fired clay can become brittle. A proper firing regime is essential for optimal performance.

Therefore, a thorough understanding of the material properties of the clay used in its production is crucial for assessing the suitability and expected lifespan of the safeguarding element. Proper selection, based on material composition, can significantly reduce the risk of chimney failure and ensure safe and efficient venting of combustion gases.

2. Structural Integrity

The stability and durability of a chimney system are intrinsically linked to the structural integrity of its internal safeguarding element. A compromise in this internal component’s soundness directly threatens the overall safety and functionality of the entire chimney structure, impacting both its capacity to safely vent combustion byproducts and its long-term viability.

- Resistance to Thermal Stress

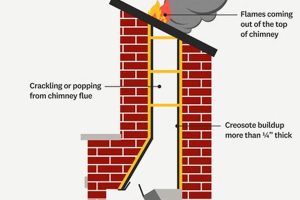

Frequent and rapid temperature fluctuations within a chimney flue induce thermal stress. The ability of the clay liner to withstand these cycles without cracking or spalling is crucial. Inadequate thermal resistance leads to material fatigue, compromising its structural integrity and creating pathways for flue gas leakage. For example, a liner exposed to a sudden temperature spike during a chimney fire can develop severe cracks, necessitating immediate repair or replacement.

- Mortar Joint Stability

The joints between individual liner sections are potential weak points in the system. Deterioration of the mortar due to moisture, acid exposure, or freeze-thaw cycles can compromise the liner’s integrity. Weakened mortar joints allow flue gases to escape and can lead to structural instability of the chimney stack. Consider a chimney exposed to years of rainwater infiltration; the resulting mortar degradation can cause sections to shift and create hazardous gaps.

- Impact Resistance

While not typically subjected to direct impact, a flue liner can be damaged by falling debris or improper cleaning techniques. The clay’s inherent ability to resist cracking or shattering under these conditions is vital. A liner struck by a dislodged brick or a heavy chimney cleaning tool can sustain damage that, while not immediately apparent, can gradually worsen over time, eventually compromising its structural integrity.

- Resistance to Corrosive Byproducts

The combustion process generates various acidic and corrosive byproducts. The liner’s ability to resist degradation from these substances is critical to maintaining its structural integrity. Liners exposed to prolonged acid exposure will gradually weaken and erode, eventually compromising their ability to contain flue gases and protect the surrounding chimney structure. The use of improper fuels, such as unseasoned wood, can exacerbate this corrosive effect.

These facets collectively underscore the critical role of structural integrity in ensuring the long-term performance and safety of a clay chimney flue safeguarding element. The selection of high-quality materials, proper installation techniques, and regular inspections are essential for preserving this integrity and preventing costly and potentially hazardous chimney failures.

3. Thermal Resistance

Thermal resistance, the measure of a material’s ability to impede the flow of heat, is a critical property of a ceramic internal component within a chimney system. This characteristic directly impacts the efficiency and safety of the chimney’s operation. A liner with inadequate thermal resistance allows excessive heat transfer to the surrounding combustible materials of the building. This heat transfer elevates the risk of chimney fires, as combustible materials near the chimney reach their ignition point. The effectiveness of this thermal property determines the degree to which the liner can contain high temperatures during flue operation, thereby minimizing the potential for heat-related hazards. For example, improperly rated flue components in wood-burning stoves have been linked to structural fires due to insufficient heat protection.

The thermal resistance of this product is directly influenced by the clay’s composition, density, and the manufacturing process. Higher density materials, achieved through proper firing techniques, generally exhibit superior thermal resistance. The thickness of the individual components also plays a significant role; thicker liners provide a longer path for heat to travel, increasing resistance. Practically, this means a homeowner selecting a liner must consider the type of appliance being vented and the anticipated flue gas temperatures. Liners intended for high-temperature applications, such as wood-burning stoves, require higher thermal resistance ratings than those used for gas-fired appliances, which produce lower flue gas temperatures. Installation standards often dictate minimum thermal resistance values based on appliance type and building codes.

In summary, appropriate thermal resistance in chimney flues is paramount for fire safety and chimney performance. Selection of the liner should be carefully considered, based on the specific heating appliance and relevant building codes. Regular inspection is essential to ensure the liner maintains its integrity and continues to provide adequate thermal protection. Addressing concerns related to thermal resistance during the early stages of chimney construction or renovation can significantly reduce the risk of fire and ensure the long-term safety of the structure.

4. Dimensional Accuracy

The precise conformance to specified measurements in each liner section is critical to the overall performance and safety of a chimney. Deviations from intended dimensions, even seemingly minor ones, can lead to significant problems within the venting system. The interior flue dimensions directly impact the chimney’s draft characteristics, influencing the efficient removal of combustion gases. Inaccuracies can create turbulence, impede airflow, and result in backdrafting of dangerous gases into the living space. For example, a liner with a reduced internal diameter due to manufacturing defects will restrict flue gas flow, potentially leading to carbon monoxide buildup.

Dimensional deviations also affect the integrity of the mortar joints between sections. When sections are not uniform in size and shape, it becomes difficult to achieve a tight, consistent seal with mortar. This can create gaps or voids in the joints, allowing flue gases to leak into the chimney structure. Leaking flue gases can corrode the surrounding masonry, weaken the chimney, and create a fire hazard by allowing hot gases to come into contact with combustible materials. Furthermore, dimensional inaccuracies can complicate installation, increasing labor costs and potentially compromising the structural integrity of the completed chimney. Consider a scenario where installers struggle to fit sections together due to size discrepancies. The resulting forced fit can induce stress on the liner material, increasing the risk of cracking or damage.

In conclusion, dimensional accuracy is not merely a cosmetic concern but a fundamental aspect of a proper flue safeguard’s performance. Maintaining precise dimensional control during manufacturing is essential for ensuring efficient venting, preventing gas leaks, preserving structural integrity, and facilitating proper installation. Regular chimney inspections should include verifying the integrity of mortar joints and assessing any signs of dimensional irregularities. Prioritizing dimensional accuracy contributes to a safer and more efficient chimney system, safeguarding both the building and its occupants.

5. Gas Tightness

Gas tightness, referring to the ability to prevent the leakage of gases, constitutes a critical performance characteristic. Within the context of the system, the prevention of flue gas escape from the chimney’s interior to the external building structures is paramount for occupant safety and structural integrity. The potential consequences of compromised gas tightness range from carbon monoxide poisoning to the accelerated degradation of chimney components due to corrosive flue gas exposure. Deficiencies in this characteristic create avenues for harmful gases to permeate living spaces, posing a direct threat to human health and well-being. For example, a hairline crack in a compromised safeguarding element can permit the gradual infiltration of carbon monoxide, leading to chronic exposure and severe health complications.

The attainment of this property depends upon a confluence of factors, including the material’s inherent permeability, the integrity of the mortar joints between individual sections, and the liner’s resistance to cracking under thermal stress. Specifically, improper installation, substandard materials, or inadequate maintenance can all contribute to a loss of the gas-tight seal. For instance, the freeze-thaw cycle can induce cracks within mortar joints, creating pathways for gas egress. Furthermore, the acids present in flue gases can corrode the safeguarding element itself, leading to increased permeability over time. Regular inspections and timely repairs are thus essential for preserving its capacity to contain combustion byproducts effectively. Additionally, newer chimney liner technologies, such as cast-in-place liners, offer improved gas tightness compared to traditional segmented systems.

In summary, gas tightness represents a fundamental safety requirement. Its role in maintaining a safe and functional chimney system cannot be overstated. Addressing potential compromises to this characteristic through rigorous inspection protocols, appropriate material selection, and adherence to best practices in installation and maintenance is essential for mitigating the risks associated with flue gas leakage and ensuring the long-term performance of the chimney. Compromised gas tightness can lead to serious consequences, and must be addressed immediately.

6. Corrosion Resistance

The ability to withstand corrosive attack is a paramount attribute impacting the longevity and safety of ceramic components used in chimney construction. The operating environment within a chimney subjects materials to a barrage of corrosive agents, necessitating inherent resistance to degradation for sustained functionality.

- Acidic Condensate Formation

Combustion processes generate a spectrum of acidic gases, including sulfuric and nitric acids, which can condense within the flue, forming corrosive liquids. The level of acidity is dependent upon the fuel being burned, with certain fuels creating a more acidic environment. This acidic condensate attacks the liner material, leading to gradual erosion and weakening. A liner with inadequate resistance will experience accelerated degradation, compromising its ability to contain flue gases and protect the chimney structure. For example, the burning of high-sulfur fuels exacerbates acid formation, necessitating a liner material with exceptional acid resistance.

- Creosote Interaction

In wood-burning systems, creosote, a byproduct of incomplete combustion, accumulates within the flue. Creosote is not only flammable but also exhibits corrosive properties, particularly when combined with moisture. This interaction accelerates the breakdown, reducing its structural integrity and creating pathways for flue gas leakage. Regular chimney cleaning is crucial to mitigate creosote buildup and minimize its corrosive effects. For instance, neglecting chimney cleaning in a wood-burning system can lead to a thick layer of creosote that actively corrodes the interior surface.

- Moisture Absorption

The porosity influences its susceptibility to moisture absorption. Water absorbed into the liner can react with combustion byproducts, creating corrosive solutions that attack the material from within. Furthermore, water absorption increases the risk of freeze-thaw damage, where water expands upon freezing, causing cracks and spalling. Liners with low porosity exhibit superior resistance to moisture-related corrosion. As an example, a liner exposed to prolonged rainwater infiltration will experience accelerated degradation if it is highly porous.

- Sulfate Attack

Sulfate attack is a chemical reaction that can occur when sulfates present in combustion byproducts react with certain components. This reaction leads to the formation of expansive compounds that exert internal pressure, causing cracking and disintegration of the material. Liners specifically formulated to resist sulfate attack are essential for maintaining long-term structural integrity, particularly in systems where high-sulfur fuels are utilized. Consider a chimney where coal is the primary fuel; the high sulfur content necessitates a liner specifically designed to withstand sulfate attack.

The interplay of these facets underscores the critical importance of corrosion resistance. Selection of a component with appropriate resistance to the specific corrosive agents present in the chimney environment is essential for ensuring long-term durability, safety, and performance. Regular inspections and maintenance are vital for identifying and addressing any signs of corrosion before they lead to significant structural damage or safety hazards.

7. Code Compliance

Adherence to established building codes is paramount in ensuring the safe and effective operation of chimney systems. Within this framework, regulations specifically address the selection, installation, and maintenance of ceramic flue safeguarding elements. Strict enforcement of these codes aims to mitigate fire hazards, prevent carbon monoxide intrusion, and guarantee the structural integrity of chimneys throughout their service life.

- Material Standards

Building codes mandate the use of flue safeguarding elements manufactured to specific industry standards, such as those established by ASTM International or Underwriters Laboratories (UL). These standards prescribe minimum requirements for material composition, structural strength, thermal resistance, and corrosion resistance. Compliance with these standards ensures that the liner is capable of withstanding the harsh conditions within a chimney flue and effectively containing combustion byproducts. For instance, codes may require liners to pass specific fire resistance tests to prevent heat transfer to combustible building materials.

- Sizing and Installation Requirements

Codes dictate the appropriate size and configuration of the flue liner based on the type and size of the connected heating appliance. Improper sizing can lead to poor draft, incomplete combustion, and increased creosote buildup in wood-burning systems. Furthermore, codes specify detailed installation procedures to ensure proper alignment, secure mortar joints, and adequate clearances from combustible materials. Improper installation can compromise the liner’s structural integrity and create pathways for flue gas leakage. For example, codes may specify minimum mortar joint thicknesses and require the use of specialized mortar formulations.

- Inspection and Maintenance Protocols

Building codes often include provisions for regular chimney inspections to identify potential hazards and ensure continued compliance with safety standards. These inspections may be required at specific intervals or upon the sale of a property. Inspectors are trained to identify cracks, spalling, and other forms of deterioration that can compromise the liner’s functionality. Codes may also mandate periodic chimney cleaning to remove creosote and other debris that can obstruct the flue and increase the risk of chimney fires. Failure to comply with inspection and maintenance requirements can result in fines or legal action.

- Repair and Replacement Guidelines

Codes provide guidelines for the repair or replacement when it exhibits signs of damage or deterioration. Depending on the extent of the damage, repairs may involve patching cracks with specialized mortar or installing a new liner. Codes may also require the installation of a new liner when a chimney is connected to a different type of heating appliance with different venting requirements. All repairs and replacements must adhere to code requirements to ensure continued safety and compliance. For example, codes may specify the use of approved liner materials and installation techniques for retrofitting existing chimneys.

In summary, diligent adherence to building codes pertaining to ceramic flue safeguarding elements is essential for protecting both property and occupants. Strict enforcement of these regulations ensures that chimney systems are designed, installed, and maintained to the highest safety standards. Failure to comply with these codes can have severe consequences, underscoring the importance of understanding and adhering to all applicable requirements.

Frequently Asked Questions

The following addresses common inquiries regarding the selection, function, and maintenance of ceramic internal flue components within chimney systems.

Question 1: What constitutes the primary function of a clay chimney flue liner?

The core function is to contain and safely expel combustion byproducts, such as smoke, gases, and particulate matter, away from the building’s interior. It also protects the chimney’s masonry from corrosive acids and extreme temperatures.

Question 2: How frequently should a chimney be inspected?

Annual inspections by a qualified chimney sweep are highly recommended. More frequent inspections may be necessary for systems subjected to heavy use or those exhibiting signs of deterioration.

Question 3: What are the potential consequences of a damaged flue liner?

A compromised safeguarding component can lead to the leakage of dangerous gases, including carbon monoxide, into the living space. It can also accelerate the deterioration of the chimney structure and increase the risk of chimney fires.

Question 4: Can any type of mortar be used for repairing flue liner joints?

No. Only specialized refractory mortar formulated to withstand high temperatures and acidic conditions should be used for repairing safeguarding element joints. Ordinary mortar is not suitable and will quickly degrade.

Question 5: What factors influence the lifespan of a ceramic internal chimney component?

The lifespan is affected by fuel type, usage frequency, maintenance practices, and the quality of the original installation. Proper maintenance and prompt repairs can significantly extend its service life.

Question 6: Are there alternative materials available for flue liners?

Yes, alternatives include stainless steel, cast-in-place concrete, and aluminum (for certain gas appliances only). The choice of material depends on the type of appliance being vented and local building codes.

These FAQs provide a foundational understanding. Consultation with a qualified chimney professional is advisable for specific concerns.

The succeeding section will explore common issues and troubleshooting techniques for these chimney components.

Clay Chimney Flue Liner

This exploration has underscored the essential role that a ceramic internal flue component plays in ensuring the safe and efficient operation of chimney systems. From material composition and structural integrity to thermal resistance, gas tightness, corrosion resistance, and code compliance, each characteristic contributes to the overall performance and longevity of the system. Neglecting any of these factors can compromise the liner’s ability to contain combustion byproducts, protect the chimney structure, and safeguard occupants from hazardous gases and fire risks.

Therefore, informed decisions regarding selection, installation, and maintenance are paramount. Prioritizing code compliance, engaging qualified professionals for inspections and repairs, and understanding the specific demands of the heating appliance connected to the chimney are all critical steps in preserving the integrity and extending the lifespan. The proper functioning of a clay chimney flue liner directly affects safety; diligence in its care is not optional, but essential.