A vertical structure containing a flue or flues, designed to carry smoke and combustion gases away from a fireplace, furnace, or other heating appliance, is a fundamental component of many buildings. These structures facilitate the safe and efficient removal of noxious byproducts from heating processes, preventing their accumulation within the dwelling. For instance, a brick or metal edifice extending from a home’s roof serves as the conduit for expelling smoke generated by a wood-burning stove.

The presence of such structures is vital for maintaining indoor air quality and preventing carbon monoxide poisoning. Their historical prevalence underscores their long-standing role in human comfort and safety, allowing for the controlled use of fire for heating and cooking. Without efficient exhaust systems, dwellings would be uninhabitable due to the accumulation of harmful gases and particulate matter. Thus, these structures represent a significant advancement in building technology and public health.

Subsequent discussions will delve into the design considerations, material selection, and maintenance procedures essential for ensuring the proper function and longevity of these crucial building elements. Further topics will include the regulations governing their construction and inspection, along with troubleshooting common issues that may arise with their use.

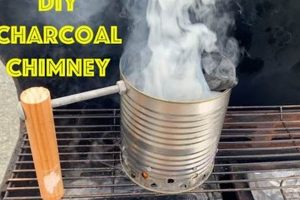

Chimney Management

The following guidance aims to provide actionable steps for ensuring the safety, efficiency, and longevity of these vital building components. Proper maintenance and informed operation are crucial.

Tip 1: Regular Inspection: Schedule professional inspections at least annually. Early detection of cracks, blockages, or deterioration prevents costly repairs and hazards.

Tip 2: Proper Fuel Selection: Utilize fuels recommended for the heating appliance. Burning inappropriate materials can lead to creosote buildup, increasing fire risk.

Tip 3: Routine Cleaning: Engage qualified professionals to clean the flue regularly. Removal of creosote and debris ensures optimal draft and minimizes fire hazards.

Tip 4: Cap Installation: Fit a chimney cap to prevent water, debris, and animals from entering the system. This extends its lifespan and prevents blockages.

Tip 5: Monitor Draft: Ensure adequate draft for proper combustion and exhaust. Insufficient draft indicates potential blockages or issues requiring immediate attention.

Tip 6: Address Moisture Intrusion: Investigate and repair any signs of water damage promptly. Moisture accelerates deterioration and compromises structural integrity.

Tip 7: Maintain Clearances: Ensure proper clearances between the structure and combustible materials. This reduces the risk of fire spread.

Adherence to these guidelines fosters a safe and efficient heating system, minimizing the risk of fire, carbon monoxide poisoning, and structural damage. Proactive management is paramount.

The subsequent section will discuss advanced troubleshooting and repair techniques.

1. Ventilation

Adequate ventilation is intrinsically linked to the function of a chimney. The structure serves as a conduit for the controlled removal of combustion byproducts, making ventilation its primary operational purpose. Without effective ventilation, heating appliances become hazardous due to the accumulation of toxic gases within the inhabited space.

- Draft Generation

The chimney creates a pressure differential, known as draft, drawing combustion gases upwards and out of the building. This draft is influenced by factors such as height, flue diameter, and temperature difference between the flue gases and the ambient air. Insufficient draft impairs ventilation, leading to incomplete combustion and potential backdrafting of fumes.

- Air Supply Interaction

Proper ventilation requires a balanced system that considers the air supply to the heating appliance. If insufficient air is available for combustion, the appliance will not operate efficiently, and harmful gases may be produced. The chimney, therefore, functions as part of a system that necessitates adequate air intake to ensure complete combustion and proper ventilation.

- Flue Gas Composition

The efficiency of ventilation directly impacts the composition of flue gases released into the atmosphere. Incomplete combustion due to poor ventilation increases the levels of pollutants such as carbon monoxide, particulate matter, and nitrogen oxides. The structure, when functioning correctly, facilitates complete combustion and minimizes the emission of harmful pollutants.

- Pressure Dynamics

Ventilation performance is sensitive to pressure variations within the building. Negative pressure created by exhaust fans or other appliances can counteract the chimney’s draft, causing backdrafting and compromising ventilation. Proper design and installation consider these pressure dynamics to ensure consistent and reliable ventilation.

The performance of any structure designed to exhaust combustion gases is fundamentally dependent on the principles of ventilation. Optimizing draft, managing air supply, controlling flue gas composition, and accounting for building pressure dynamics are essential for ensuring the structure fulfills its critical function of safely and efficiently removing hazardous byproducts from heating appliances.

2. Construction Materials

The selection of construction materials is paramount to the functionality and longevity of a structure designed to exhaust combustion byproducts. Material choice directly impacts the ability to withstand extreme temperatures, corrosive flue gases, and environmental exposure. For instance, traditional brick, while offering aesthetic appeal and insulation, can be susceptible to degradation from acidic condensation if not properly lined. This degradation compromises structural integrity and impairs venting efficiency. Conversely, stainless steel liners provide superior resistance to corrosion and heat, extending the lifespan of the system but potentially altering its aesthetic.

The choice of material also dictates the safety performance of the structure. Improper materials can lead to cracking, spalling, or complete failure, creating pathways for flue gases to escape into the living space. This poses a significant risk of carbon monoxide poisoning and fire. A real-world example is the use of unlined clay flues in older homes, which, over time, can develop cracks due to thermal stress. These cracks allow for the leakage of dangerous gases and increase the risk of chimney fires. Therefore, understanding the properties and limitations of different construction materials is critical for ensuring safe and reliable operation.

In summary, the selection of appropriate construction materials is not merely an aesthetic consideration but a fundamental engineering decision with direct implications for safety, efficiency, and durability. The relationship between the structure and its constituent materials is one of cause and effect; the material dictates the structure’s ability to perform its intended function, highlighting the practical significance of informed material selection. Compliance with building codes and professional inspection are essential for ensuring materials are suitable for the specific application.

3. Draft Control

Draft control, an intrinsic function within a chimney system, governs the movement of combustion gases from a heating appliance, through the flue, and ultimately, into the atmosphere. The system’s effectiveness in removing these gases hinges directly on the precision with which the draft is managed. Inadequate draft results in incomplete combustion and the potential for dangerous gas accumulation inside the building. Excessive draft, conversely, can lead to rapid heat loss, reduced heating efficiency, and increased fuel consumption. Therefore, draft control is not merely a peripheral consideration but a critical determinant of safe and efficient operation.

Several factors influence the draft within a chimney. The chimney’s height, diameter, and internal surface characteristics create a pressure differential related to temperature differences between the flue gases and the surrounding air. Environmental factors, such as wind, can also significantly impact the chimney’s draft. Control devices, such as dampers and barometric draft regulators, are frequently employed to modulate the airflow within the flue, compensating for external conditions and maintaining optimal combustion. For example, a properly calibrated barometric draft regulator in an oil-fired furnace system ensures a consistent draft, regardless of wind conditions, leading to more efficient fuel burning and reduced emissions. This demonstrates the direct relationship between effective draft management and operational efficiency.

In conclusion, draft control is an integral component of the safe and efficient operation of a chimney system. Its purpose extends beyond simply expelling combustion gases; it directly impacts the heating appliance’s performance, fuel consumption, and the safety of the building’s occupants. Challenges in achieving consistent draft control arise from variations in environmental conditions and building pressure dynamics. Understanding these challenges and employing appropriate control devices are crucial for maximizing the benefits and minimizing the risks associated with chimney-dependent heating systems.

4. Safety Standards

Stringent safety standards govern the design, construction, and maintenance of structures designed to exhaust combustion byproducts. These standards aim to minimize the risks of fire, carbon monoxide poisoning, and structural failure associated with malfunctioning or improperly installed systems. Strict adherence to these guidelines is not merely a matter of compliance but a fundamental requirement for ensuring public safety.

- Material Approval and Certification

Many jurisdictions require that materials used in the construction or repair of these systems be tested and certified to meet specific performance criteria. This certification assures that the materials can withstand the corrosive effects of flue gases, extreme temperatures, and the stresses of normal operation. For instance, stainless steel liners must meet specific alloy composition standards to ensure resistance to corrosion, preventing premature failure and gas leakage.

- Clearance Requirements

Building codes dictate minimum clearance distances between a chimney and combustible materials such as wood framing. These clearances prevent heat transfer from the chimney to adjacent building components, reducing the risk of fire. These requirements are based on empirical data and fire modeling, ensuring that the surrounding structure remains within safe temperature limits during operation. Failure to adhere to these clearances is a leading cause of residential fires.

- Inspection and Maintenance Protocols

Regular inspection and maintenance are critical elements of safety standards. Certified professionals conduct inspections to identify potential hazards such as cracks, blockages, or deterioration. Maintenance, including cleaning and repairs, is performed to correct these issues and ensure continued safe operation. Jurisdictions often mandate periodic inspections, particularly upon installation or after significant events such as chimney fires, reinforcing the importance of ongoing monitoring.

- Flue Sizing and Design

Safety standards dictate the appropriate sizing and design of the flue, the internal passageway for combustion gases. Correct sizing ensures adequate draft for efficient exhaust removal while preventing excessive cooling of the gases, which can lead to creosote condensation and chimney fires. Improperly sized flues can result in incomplete combustion, increased emissions, and potential backdrafting of harmful gases into the building. Design considerations include flue height, diameter, and the number of appliances connected to a single flue.

Compliance with safety standards is a continuous process that encompasses material selection, construction practices, maintenance routines, and adherence to code regulations. These standards represent the accumulated knowledge and experience of engineers, fire safety experts, and building officials, reflecting a collective commitment to minimizing the inherent risks associated with combustion-based heating systems. These structures that are built and well maintained with these safety standards give safety to humans.

5. Fuel Compatibility

Fuel compatibility constitutes a critical parameter in the effective and safe operation of any system designed for the exhaust of combustion products. The selection of an appropriate fuel type directly impacts the functionality and longevity of the associated infrastructure. Specific fuel characteristics, such as BTU content, moisture level, and chemical composition, influence the combustion process, the resulting flue gas composition, and ultimately, the potential for corrosion or degradation within the chimney. The introduction of incompatible fuels creates conditions that undermine the structure’s design parameters, leading to accelerated wear and potential hazards. An illustrative example is the burning of unseasoned wood in a fireplace designed for seasoned wood; the higher moisture content in unseasoned wood results in lower combustion temperatures and increased creosote production, a highly flammable substance that accumulates within the flue, significantly elevating the risk of chimney fires.

The construction materials utilized in the chimney must be chemically and thermally resistant to the specific byproducts generated by the intended fuel. Systems designed for natural gas or propane, which produce relatively clean combustion, may utilize different materials than those intended for solid fuels like wood or coal, which generate more corrosive and particulate-laden exhaust. For instance, a system designed for natural gas may employ a single-wall metal flue, whereas a system intended for wood or coal necessitates a more robust, insulated flue liner to withstand the higher temperatures and corrosive effects of the flue gases. Furthermore, the diameter and height of the flue must be appropriately sized for the intended fuel to ensure adequate draft and prevent the buildup of harmful gases. Mismatched fuel and infrastructure can compromise the chimney’s function, potentially leading to backdrafting of carbon monoxide into the dwelling.

In conclusion, fuel compatibility is not a secondary consideration but an integral design requirement for these essential building components. Utilizing inappropriate fuels introduces operational risks and compromises the structural integrity of the system. The consequences range from reduced heating efficiency and increased maintenance requirements to catastrophic events such as chimney fires and carbon monoxide poisoning. Adherence to recommended fuel specifications, coupled with regular inspections and maintenance, is essential for ensuring the safe and efficient operation of these systems and safeguarding the health and safety of building occupants. Proper care and awareness are crucial to prevent issues and help longevity for chimneys.

6. Maintenance Procedures

Maintenance procedures are intrinsically linked to the long-term functionality and safety of these building features. A neglect of scheduled maintenance can lead to a cascade of detrimental effects, ultimately compromising the structure’s ability to effectively vent combustion byproducts. For instance, the accumulation of creosote within a wood-burning fireplace flue, if left unaddressed, creates a significant fire hazard, potentially leading to structural damage or even the spread of fire to the dwelling itself. Regular cleaning, a critical maintenance procedure, mitigates this risk by removing the flammable buildup. Therefore, the absence of appropriate maintenance transforms the chimney from a safety feature into a potential liability.

Furthermore, maintenance extends beyond merely cleaning the flue. Inspection of mortar joints, flashing, and the chimney crown is essential for identifying and addressing structural deterioration. Cracks or spalling in the masonry can allow water intrusion, which, over time, can weaken the structure and lead to costly repairs. Similarly, damaged flashing can result in leaks, causing water damage to the roof and surrounding areas. Timely repairs, guided by regular inspections, prevent minor issues from escalating into major structural problems. An example of this is the replacement of deteriorated mortar joints, known as repointing, which prevents further water damage and maintains the chimney’s structural integrity. The maintenance protocol is to ensure the integrity and proper working of the chimney.

In essence, maintenance procedures are not merely optional add-ons but integral components of chimney ownership. They represent a proactive approach to preserving the functionality, safety, and longevity of these vital building elements. Neglecting maintenance procedures exposes the building and its occupants to unnecessary risks, while diligent adherence to a maintenance schedule ensures continued safe and efficient operation. The challenge lies in promoting awareness of the importance of maintenance and ensuring that homeowners have access to qualified professionals capable of performing inspections and repairs.

Frequently Asked Questions Regarding Chimneys

This section addresses common inquiries concerning the function, maintenance, and safety of these structures. Understanding these aspects is crucial for homeowners relying on heating systems that utilize flues.

Question 1: What constitutes the primary function of a flue?

The fundamental purpose of a flue is to provide a safe and efficient conduit for the removal of combustion byproducts, such as smoke, gases, and particulate matter, from heating appliances. This prevents the accumulation of hazardous substances within the inhabited space.

Question 2: How frequently should a system be inspected?

It is generally recommended that it be inspected at least annually by a qualified professional. More frequent inspections may be warranted depending on usage and fuel type.

Question 3: What are the potential consequences of neglecting maintenance?

Neglecting maintenance can lead to a variety of issues, including creosote buildup, structural deterioration, flue blockages, and increased risk of fire or carbon monoxide poisoning.

Question 4: What factors influence the draft within a flue?

Several factors influence the draft, including the height and diameter of the flue, temperature differences between the flue gases and ambient air, and external wind conditions.

Question 5: Are there specific fuels that should not be used in certain systems?

Yes, fuel compatibility is crucial. Burning unseasoned wood in a fireplace designed for seasoned wood, for example, can lead to excessive creosote buildup. Similarly, using fuels that are not approved for a specific appliance can damage the chimney and create safety hazards.

Question 6: What are the key indicators of a potential problem with a structure?

Key indicators include visible cracks or spalling in the masonry, water leaks, smoke odors inside the building, and the presence of excessive creosote buildup.

Understanding these questions and their answers is paramount for responsible chimney ownership. Regular maintenance and professional inspections are crucial for ensuring the safety and efficiency of these systems.

The subsequent section will delve into advanced troubleshooting and repair techniques.

What Are Chimneys

This exploration has elucidated that these structures represent essential components of heating systems, serving as conduits for the safe and efficient removal of combustion byproducts. Their functionality is intricately linked to factors such as ventilation, construction materials, draft control, safety standards, fuel compatibility, and consistent maintenance procedures. Deviations from recommended practices within any of these areas can compromise the system’s integrity, posing significant risks to property and human life.

Given the critical role these structures play in maintaining safe and habitable environments, a commitment to responsible ownership is paramount. This entails diligent adherence to established safety protocols, proactive maintenance routines, and the engagement of qualified professionals for inspections and repairs. The continued safe and effective operation of these structures necessitates a collective understanding of their inherent complexities and a steadfast dedication to upholding rigorous safety standards.