This structure constitutes a vertical passage designed for the expulsion of combustion byproducts from a specific type of heating appliance. It serves as a critical component of a system that utilizes gaseous fuel as its energy source, requiring a dedicated pathway to safely remove emissions from the dwelling. An example would be a metal flue extending from the top of a firebox, channeling exhaust gases out of the building.

Its correct installation and maintenance are paramount for ensuring the safety and efficiency of the heating appliance. Proper venting prevents the accumulation of hazardous gases within the living space, mitigating potential health risks. Historically, these systems have evolved from simple brick structures to more sophisticated metallic designs, reflecting advancements in materials science and engineering principles aimed at improved performance and safety standards.

The following discussion will delve into the various aspects related to this crucial element of residential and commercial heating systems, encompassing material types, installation requirements, inspection protocols, and potential troubleshooting scenarios.

Essential Considerations for Vented Gas Fireplace Chimneys

This section provides crucial guidelines regarding the proper installation, maintenance, and operational considerations for systems designed to vent gaseous byproducts from gas-fueled fireplaces.

Tip 1: Ensure Proper Sizing. The flue must be appropriately sized to match the appliance’s BTU input. Undersized flues can lead to incomplete combustion and the accumulation of carbon monoxide, while oversized flues can result in inadequate draft and condensation issues.

Tip 2: Adhere to Installation Codes. All installations must conform to local building codes and manufacturer specifications. This includes maintaining proper clearances to combustible materials and utilizing approved connection methods.

Tip 3: Conduct Regular Inspections. Routine visual inspections are essential to identify signs of deterioration, blockage, or corrosion. Pay close attention to joints, seams, and the chimney cap.

Tip 4: Maintain Clearances. Keep the area surrounding the exterior termination clear of obstructions, such as snowdrifts, foliage, or debris. Blockages can impede airflow and compromise venting efficiency.

Tip 5: Schedule Professional Servicing. At least annually, engage a qualified professional to inspect and clean the system. This includes checking for leaks, obstructions, and proper draft.

Tip 6: Recognize Potential Hazards. Be aware of the symptoms of carbon monoxide poisoning, such as headaches, dizziness, and nausea. Install carbon monoxide detectors in accordance with safety guidelines.

Tip 7: Use Approved Materials. Only use components that are specifically designed and approved for use with gas-fueled appliances. Mixing and matching materials can compromise safety and performance.

Proper attention to these guidelines will contribute significantly to the safe and efficient operation of these systems, minimizing potential risks and maximizing the lifespan of the appliance.

The following section will explore common troubleshooting scenarios and potential solutions related to these venting systems.

1. Material Composition

The constituent materials used in the fabrication of a system designed for the removal of combustion gases from a gas fireplace directly influence its performance, safety, and longevity. Material selection dictates resistance to corrosion from acidic byproducts of combustion, the ability to withstand high temperatures, and the overall structural integrity of the system. For instance, Type B vents, commonly constructed from aluminum, are suitable for venting appliances with lower exhaust temperatures. However, they are not appropriate for solid fuel appliances, where significantly higher temperatures are generated.

Conversely, stainless steel, particularly 304 or 316 grades, offers superior corrosion resistance and higher temperature tolerance, making it a more durable and versatile option for venting a wider range of appliances, including some high-efficiency gas fireplaces and those that may occasionally burn wood. Inadequate material selection can lead to premature degradation, potentially resulting in gas leaks, carbon monoxide infiltration into the living space, or structural failure of the chimney. A real-world example involves the use of galvanized steel, which, while initially cost-effective, is prone to rapid corrosion when exposed to the acidic flue gases produced by gas appliances, resulting in premature chimney failure.

In summary, careful consideration of material composition is paramount in the design and installation of these venting systems. The appropriate selection, based on the specific appliance characteristics and operating conditions, ensures safe and efficient operation while minimizing the risk of costly repairs or hazardous conditions. Understanding the properties of various materials and their interaction with combustion byproducts is crucial for informed decision-making and long-term system reliability.

2. Draft Optimization

Effective draft is crucial for the safe and efficient operation of a system designed for the removal of combustion gases from a gas fireplace. Insufficient or excessive draft can lead to a range of problems, including incomplete combustion, back drafting of hazardous gases, and reduced heating efficiency. Proper optimization of draft ensures complete and safe venting of combustion byproducts.

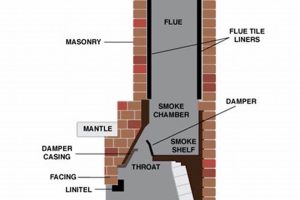

- Chimney Height and Diameter

The height and diameter of the chimney directly influence draft. Taller chimneys generally create a stronger draft due to the increased temperature difference between the flue gases and the ambient air. However, excessively tall chimneys can lead to over-drafting, resulting in increased fuel consumption. Similarly, the chimney’s diameter must be appropriately sized to match the appliance’s BTU input. An undersized diameter restricts airflow, while an oversized diameter can result in insufficient draft. A real-world example involves replacing an old fireplace insert with a newer, more efficient model. If the existing chimney is not appropriately sized for the new appliance, draft issues are likely to arise.

- Flue Blockage and Obstructions

Obstructions within the flue, such as bird nests, debris accumulation, or creosote buildup, can severely restrict airflow and impede draft. Regular inspection and cleaning of the system are essential to maintain adequate draft. In cases where draft issues persist despite cleaning, a chimney inspection using a camera can help identify hidden obstructions or structural damage that may be contributing to the problem. For example, a collapsed chimney liner can significantly reduce the effective diameter of the flue, leading to poor draft and potentially dangerous back drafting.

- Barometric Dampers and Draft Regulators

In some cases, particularly with older or high-BTU appliances, a barometric damper or draft regulator may be installed to help maintain a consistent draft. These devices automatically adjust to variations in atmospheric pressure and chimney temperature, preventing over-drafting or under-drafting. However, improper installation or malfunctioning of these devices can actually worsen draft problems. A common scenario involves a barometric damper that is stuck in the open position, resulting in excessive draft and increased heat loss up the chimney.

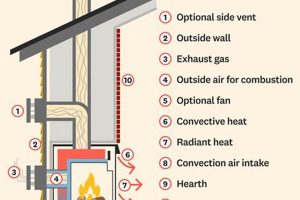

- Appliance Air Supply

Adequate combustion air supply is essential for proper draft and complete combustion. If the appliance does not have access to sufficient air, it will struggle to burn fuel efficiently, leading to incomplete combustion and the production of carbon monoxide. This is especially important in tightly sealed homes where infiltration of outside air is limited. In such cases, installing an external air supply kit can help ensure that the appliance has enough air to operate safely and efficiently. For instance, if a fireplace is installed in a basement without adequate ventilation, providing a dedicated air supply can significantly improve draft and reduce the risk of carbon monoxide poisoning.

These factors collectively contribute to the overall draft performance of a system for venting gas fireplaces. Addressing these elements is vital for safety, efficiency, and regulatory compliance. Consistent, and correct application of these tenets creates a safe environment.

3. Termination Location

The geographical positioning of the external outlet for a chimney system designed to vent combustion byproducts from gas fireplaces directly impacts safety, efficiency, and regulatory compliance. Proper placement mitigates the risk of re-entrainment of exhaust gases, protects building materials from damage, and ensures conformance with local building codes.

- Clearance from Building Openings

The termination point must maintain specified clearances from windows, doors, and other building openings to prevent the entry of exhaust gases into the structure. Insufficient clearance can lead to the infiltration of carbon monoxide and other harmful substances, posing a significant health hazard. Building codes typically mandate minimum distances to ensure adequate dilution and dispersion of exhaust gases. A scenario demonstrating this criticality involves a termination point located directly beneath a bedroom window, which could allow dangerous fumes to enter the sleeping area, particularly during periods of low wind velocity. Failure to adhere to these clearance requirements constitutes a serious safety violation.

- Proximity to Vegetation and Overhangs

The termination point should be located away from overhanging structures, trees, and other vegetation to prevent obstruction of the flue and potential fire hazards. Overhanging branches can impede the flow of exhaust gases, leading to back drafting and reduced venting efficiency. Accumulated debris from vegetation can also block the flue, creating a dangerous situation. A real-world example involves a termination point positioned too close to a tree, where leaves and branches collect on the chimney cap, restricting airflow and increasing the risk of chimney fires.

- Height Above Roofline

The height of the termination point above the roofline is critical for ensuring adequate draft and preventing downwash of exhaust gases. Building codes typically specify minimum height requirements based on roof pitch and proximity to other structures. Insufficient height can result in negative pressure zones that pull exhaust gases back down into the building. A common example is a termination point on a low-sloping roof that is surrounded by taller structures, which can create turbulent airflow and impede proper venting.

- Material Compatibility and Weather Resistance

The materials used for the termination cap and surrounding components must be compatible with the exhaust gases and resistant to weather conditions. Corrosive gases can degrade incompatible materials, leading to premature failure and potential hazards. Weather exposure can also accelerate deterioration, particularly in areas with harsh climates. A common example is the use of galvanized steel caps in coastal environments, which are prone to rapid corrosion from saltwater exposure.

The location of the termination point for a system for venting gas fireplace combustion byproducts involves adherence to code and best practices. These factors must be considered during installation to ensure that the venting system functions safely and efficiently, protecting building occupants from harmful exhaust gases and preventing damage to the structure. Neglecting these considerations compromises system integrity and poses potential risks.

4. Inspection Frequency

Routine assessment of a system designed to exhaust combustion byproducts from gas fireplaces is paramount for maintaining safety and operational efficiency. Established inspection schedules mitigate potential hazards associated with deterioration, blockage, or improper function, thus ensuring the safe and reliable operation of the appliance.

- Annual Professional Evaluation

A qualified professional should conduct a comprehensive inspection at least annually. This assessment encompasses evaluation of the flue’s structural integrity, verification of proper draft, and identification of any obstructions or damage. For example, a certified chimney sweep can detect subtle cracks in the flue liner or assess the condition of the chimney cap, preventing costly repairs and potentially life-threatening situations.

- Seasonal Visual Assessment

Homeowners should perform routine visual checks on a seasonal basis, particularly before and after periods of heavy use. These self-inspections involve examining the exterior for signs of damage, ensuring the chimney cap is in place, and confirming that the area surrounding the termination point is clear of obstructions. Noticing a build-up of debris or unusual staining on the chimney’s exterior, for instance, indicates a potential issue requiring further professional evaluation.

- Post-Event Examination

Following events such as severe weather, including high winds or heavy snowfall, an inspection is recommended. These events can dislodge components, introduce debris into the flue, or compromise the structural integrity of the system. The discovery of missing bricks or a dislodged chimney cap following a storm, for example, necessitates immediate attention to prevent water damage or flue blockage.

- Operational Performance Monitoring

Continuous monitoring of the fireplace’s operational performance provides valuable insights into the venting system’s health. Unusual odors, smoke spillage into the room, or difficulty starting the fire are all indicators of potential venting problems. A persistent gas odor or a malfunctioning carbon monoxide detector, for instance, demands immediate professional intervention.

Consistent adherence to a structured inspection schedule, encompassing both professional assessments and homeowner vigilance, is vital for preserving the functionality and safety of a system designed for venting gas fireplaces. Routine inspection detects problems before escalation into significant safety hazards or costly repairs, upholding the integrity of the appliance and well-being of the building occupants.

5. Code Compliance

Adherence to established codes is a non-negotiable component of any system designed for exhausting combustion byproducts from gas fireplaces. Code requirements are not arbitrary; they represent accumulated knowledge and best practices derived from decades of experience and incident analysis. These regulations aim to ensure the safe and efficient operation of the venting system, minimizing the risk of fire, carbon monoxide poisoning, and property damage. Failure to comply with relevant codes can have severe consequences, including legal liabilities, insurance claim denials, and, most importantly, endangerment of human life. For example, the International Fuel Gas Code (IFGC) and the National Fuel Gas Code (NFGC) outline specific requirements for chimney height, clearances to combustible materials, and proper flue sizing. These provisions are designed to prevent dangerous conditions such as backdrafting and incomplete combustion. A real-world example illustrating the importance of code compliance involves a homeowner who installed a gas fireplace without obtaining the necessary permits or adhering to code requirements. The improperly sized flue led to carbon monoxide buildup in the home, resulting in severe illness and the need for extensive remediation.

The relationship between code compliance and the operational integrity of a venting system is direct and consequential. Codes dictate the appropriate materials, installation methods, and inspection procedures necessary for a safe and functional system. These regulations consider factors such as the appliance’s BTU input, the climate conditions in the region, and the building’s structural characteristics. Code requirements are not static; they are periodically updated to reflect advancements in technology and increased understanding of potential hazards. For instance, recent updates to building codes emphasize the importance of sealed combustion systems and direct vent fireplaces, which draw combustion air from outside the building, minimizing the risk of indoor air quality problems. Similarly, codes now address the proper installation of carbon monoxide detectors, providing an essential safety net in the event of a venting malfunction. A common misconception is that code compliance is merely a bureaucratic hurdle. In reality, adherence to codes is a critical investment in safety and long-term reliability.

In summary, the intersection of code compliance and system functionality is undeniable. Code requirements are not optional guidelines; they are mandatory standards designed to protect lives and property. Proper installation, regular inspection, and adherence to evolving code standards are crucial for maintaining a safe and efficient gas fireplace venting system. A thorough understanding of relevant codes and a commitment to compliance are essential for homeowners, contractors, and building inspectors alike. Neglecting code requirements is not only a violation of the law but also a reckless disregard for the potential consequences.

Frequently Asked Questions About Vented Gas Fireplace Chimneys

This section addresses common inquiries and clarifies crucial aspects regarding the use, maintenance, and safety of systems designed for the removal of combustion byproducts from gas fireplaces.

Question 1: What is the anticipated lifespan of a vented gas fireplace chimney?

The lifespan is influenced by material composition, installation quality, and maintenance practices. A stainless-steel system, properly installed and maintained, may last upwards of 20 years. Aluminum systems typically have a shorter lifespan. Regular inspections and prompt repairs contribute to longevity.

Question 2: How frequently should a vented gas fireplace chimney undergo professional inspection?

Annual professional inspection is recommended. This allows for the detection of issues such as flue blockage, corrosion, or structural damage, which may not be readily apparent during routine homeowner assessments.

Question 3: What are the indicators of a potential problem with a vented gas fireplace chimney?

Indicators include unusual odors, smoke spillage into the room, difficulty starting the fire, visible signs of corrosion or damage, and activation of carbon monoxide detectors. Any of these symptoms warrants immediate professional evaluation.

Question 4: Is it permissible to utilize a chimney intended for wood-burning appliances for a vented gas fireplace?

Generally, it is not recommended to utilize a chimney intended for wood-burning appliances without proper relining. The flue requirements for gas appliances differ significantly from those of wood-burning appliances, and improper venting can result in safety hazards.

Question 5: What are the clearance requirements for a vented gas fireplace chimney in relation to combustible materials?

Clearance requirements vary depending on local building codes and the type of venting system employed. Adherence to manufacturer specifications and local regulations is essential to prevent fire hazards.

Question 6: Can alterations be made to the height or configuration of a vented gas fireplace chimney?

Alterations should only be performed by qualified professionals and in accordance with applicable building codes. Modifications without proper knowledge and expertise can compromise the system’s performance and safety.

These FAQs provide a foundational understanding of these systems. However, professional consultation is always advised for specific installations or troubleshooting.

The following section will delve into the regulatory landscape surrounding these venting systems, providing insight into relevant codes and standards.

Conclusion

This exploration of vented gas fireplace chimney systems has underscored critical aspects of their functionality, safety, and regulatory compliance. Key points highlighted include the importance of proper material selection, draft optimization, adherence to clearance requirements, regular inspection protocols, and unwavering compliance with established codes. Addressing each of these elements is essential for ensuring the safe and efficient removal of combustion byproducts and mitigating potential hazards.

The integrity of the vented gas fireplace chimney is a non-negotiable aspect of residential and commercial heating systems. Continued vigilance in maintaining these systems, coupled with adherence to evolving codes and best practices, remains paramount. Prioritizing safety and proper function ensures the continued benefit of gas fireplace technology without compromising the well-being of building occupants or the structural integrity of the building itself.