An opening or passage within a vertical structure designed to carry smoke and combustion gases away from a fireplace, furnace, or appliance serves to ensure proper exhaust. Its presence facilitates the expulsion of potentially harmful substances, preventing their accumulation within the inhabited space. For instance, a flue liner installed within a masonry structure provides a designated pathway for these gases, enhancing both safety and efficiency.

Effective ventilation of combustion byproducts is crucial for maintaining indoor air quality and preventing carbon monoxide poisoning. Historically, these systems were rudimentary, but modern designs incorporate features like precise sizing and backdraft prevention to optimize performance and minimize risks. A properly functioning system contributes to energy efficiency by ensuring complete combustion and reducing heat loss.

The subsequent sections will delve into the various types, materials, installation considerations, and maintenance procedures associated with these critical components of residential and commercial heating systems. Furthermore, regulations and safety standards pertinent to their construction and operation will be addressed.

Essential Guidance for Optimal Chimney Ventilation

The following recommendations aim to enhance the function and safety of exhaust systems. Adhering to these guidelines can contribute to improved efficiency and a reduction in potential hazards.

Tip 1: Regular Inspection: Conduct routine examinations of the entire structure for signs of damage, deterioration, or obstructions. Early detection of issues allows for timely repairs, preventing costly and potentially dangerous situations.

Tip 2: Professional Cleaning: Schedule professional cleaning services annually, or more frequently if heavy use occurs. Creosote buildup is a significant fire hazard and impedes proper airflow.

Tip 3: Proper Sizing: Ensure the opening’s dimensions are appropriately matched to the appliance being vented. Undersized systems can lead to backdrafting, while oversized systems may result in inadequate draft.

Tip 4: Liner Integrity: Verify the integrity of the liner material. Cracks, gaps, or corrosion can compromise its effectiveness and allow harmful gases to escape into the building.

Tip 5: Cap Installation: Install a cap to prevent rainwater, debris, and animals from entering the structure. This measure protects against deterioration and blockages.

Tip 6: Damper Functionality: Check the damper for proper operation. A malfunctioning damper can lead to significant heat loss when the fireplace or appliance is not in use.

Tip 7: Fuel Selection: Utilize the recommended fuel type for the appliance. Burning improper fuels can generate excessive creosote or other harmful byproducts.

Implementing these recommendations will contribute significantly to maintaining a safe and efficient heating system, minimizing risks associated with incomplete combustion and structural degradation.

The subsequent discussion will cover advanced troubleshooting techniques and methods for evaluating the overall performance of the ventilation system.

1. Draft

The operational effectiveness of a vertical conduit for exhaust gases hinges critically on the establishment and maintenance of adequate draft. Draft, in this context, refers to the pressure differential that compels the movement of combustion byproducts from the appliance, through the flue, and ultimately into the external environment. Insufficient draft can lead to a variety of adverse consequences, including incomplete combustion, backdrafting of hazardous gases (such as carbon monoxide) into the living space, and reduced heating efficiency.

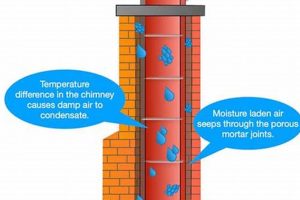

Draft generation is fundamentally a function of temperature differential. Hot gases, being less dense than the ambient air, naturally rise within the vertical structure. The greater the temperature difference between the flue gases and the external air, the stronger the draft. However, various factors can impede or disrupt this natural process. Excessive flue height, inadequate insulation, or external wind conditions can all negatively impact draft. For example, a flue that is too short may not generate sufficient pressure differential to overcome frictional resistance within the system, leading to a weak or even reversed flow. Similarly, downdrafts caused by wind impinging on the chimney termination can introduce cold air into the system, counteracting the buoyant force of the hot gases.

Maintaining proper draft necessitates careful consideration of design parameters, construction techniques, and operational practices. Correct sizing of the flue relative to the connected appliance is paramount. Appropriate insulation minimizes heat loss, sustaining the temperature differential. Regular inspection and cleaning remove creosote and other obstructions that impede airflow. In instances where natural draft is insufficient, mechanical draft inducers may be employed to augment the pressure gradient. Ultimately, ensuring adequate draft is essential for safe and efficient operation, mitigating the risks associated with incomplete combustion and the accumulation of hazardous gases within the building.

2. Liner Integrity

Liner integrity constitutes a critical element within the design and functionality of any vertical exhaust structure. The liner serves as a protective barrier, isolating the surrounding building materials from the corrosive byproducts of combustion. Its condition directly impacts the safety, efficiency, and longevity of the entire system.

- Corrosion Resistance

The liner material must exhibit inherent resistance to the corrosive effects of flue gases, which contain acidic compounds such as sulfur dioxide and nitrous oxides. Degradation of the liner can lead to the penetration of these gases into adjacent masonry or wood framing, causing structural damage and potentially releasing harmful substances into the occupied space. Stainless steel and ceramic liners are commonly employed for their superior corrosion resistance properties.

- Thermal Stability

The liner must withstand extreme temperature fluctuations associated with heating appliance operation. Rapid heating and cooling cycles can induce thermal stress, leading to cracking or spalling of the liner material. Such damage compromises the liner’s ability to contain combustion byproducts and exposes the chimney structure to potentially damaging heat. Refractory mortar joints must also maintain their integrity under high temperatures.

- Gas Tightness

An intact liner must provide a gas-tight seal, preventing the leakage of combustion gases into the building. Cracks, gaps, or deteriorated mortar joints can create pathways for carbon monoxide and other hazardous substances to enter the living space. Regular inspections are essential to identify and address any breaches in the liner’s integrity. Pressure testing can also be performed to verify gas tightness.

- Structural Soundness

The liner must possess sufficient structural strength to withstand the mechanical stresses imposed by its own weight, the weight of any overlying components, and external forces such as wind loads. Cracks or collapses within the liner can obstruct airflow, leading to incomplete combustion and the potential for backdrafting. Furthermore, a compromised liner can destabilize the entire chimney structure.

Preserving liner integrity is paramount for maintaining a safe and efficient vertical exhaust system. Regular inspection, appropriate material selection, and timely repairs are crucial for preventing structural damage, ensuring proper ventilation, and mitigating the risks associated with combustion byproducts.

3. Material

The selection of appropriate materials for the construction of a vertical exhaust conduit is of paramount importance, directly influencing its safety, durability, and operational efficiency. Material properties must withstand the harsh conditions inherent in combustion byproduct removal, including high temperatures, corrosive gases, and moisture exposure.

- Clay Tile

Historically, clay tile has been a common material choice. While relatively inexpensive, clay tile exhibits limited resistance to thermal shock and acidic corrosion. Cracking and spalling can occur over time, compromising the liner’s integrity. Its suitability is generally restricted to older, low-efficiency appliances generating lower flue gas temperatures.

- Stainless Steel

Stainless steel liners offer superior corrosion resistance and thermal stability compared to clay tile. They are capable of withstanding high temperatures and the corrosive effects of acidic condensates. Stainless steel is a versatile option suitable for a wide range of appliances, including those burning natural gas, propane, and oil. Various grades of stainless steel are available, with higher grades offering enhanced resistance to specific corrosive agents.

- Cast-in-Place Concrete

Cast-in-place concrete liners provide a durable and monolithic structure. However, concrete is susceptible to cracking due to thermal expansion and contraction. Proper design and installation are crucial to minimize the risk of cracking and ensure the liner’s long-term integrity. Concrete liners are often used in conjunction with other materials, such as clay flue tiles, to provide additional protection against corrosion.

- Aluminum

Aluminum is occasionally utilized for venting certain types of appliances, specifically those that produce relatively low flue gas temperatures and minimal acidic condensation, such as some high-efficiency gas furnaces. However, aluminum is not suitable for venting appliances that burn solid fuels (wood, coal) or oil due to the higher temperatures and corrosive byproducts generated. Its use is typically dictated by specific appliance manufacturer recommendations and local building codes.

The optimal material choice depends on the specific appliance being vented, the fuel type, and the anticipated operating conditions. Consideration must be given to factors such as corrosion resistance, thermal stability, structural integrity, and cost. Adherence to manufacturer’s specifications and local building codes is essential to ensure the safe and effective operation of the vertical exhaust system.

4. Termination

The term “termination,” when referring to a vertical exhaust system, denotes the uppermost point of the chimney structure, where combustion byproducts are released into the atmosphere. Its design and condition are intrinsically linked to the overall performance and safety of the venting system. Improper termination can negate the effectiveness of the system, leading to issues such as backdrafting, accelerated deterioration of the chimney, and potential hazards within the dwelling.

Several factors influence the efficacy of the termination. Adequate height above the roofline is crucial to ensure sufficient draft and prevent downdrafts caused by wind currents. Spark arrestors are frequently incorporated to mitigate the risk of fire from embers escaping the chimney. The presence of a properly designed cap serves to prevent rainwater, snow, and debris from entering the structure, which can lead to moisture damage, blockages, and reduced draft. An incorrectly sized or poorly positioned termination can cause restricted airflow, resulting in incomplete combustion and the accumulation of hazardous gases within the building. A real-world example would be a chimney termination located in close proximity to a taller structure. This configuration can create a zone of negative pressure, drawing exhaust gases back down into the system and potentially into the living space. Conversely, a termination with an inadequate rain cap can lead to water damage within the chimney, which can accelerate the deterioration of masonry and compromise the structural integrity of the entire system.

In summary, the design and maintenance of the system’s terminal element are critical for ensuring safe and efficient venting of combustion byproducts. Proper height, the inclusion of spark arrestors and rain caps, and adherence to local building codes are essential considerations. Neglecting the termination can lead to a cascade of problems, ultimately jeopardizing the health and safety of the building’s occupants and the longevity of the chimney structure itself.

5. Sizing

The dimensional calculation of the vertical exhaust system, often referred to as sizing, represents a critical determinant of its operational efficacy and safety profile. An improperly sized conduit directly impacts the draft characteristics, combustion efficiency, and potential for hazardous byproduct accumulation. The correlation between the dimensions and the performance of the entire ventilation setup necessitates a meticulous approach to sizing calculations, adhering to established engineering principles and manufacturer specifications.

Insufficient cross-sectional area within the ventilation structure restricts the flow of combustion gases, causing back pressure within the heating appliance. This back pressure impedes complete combustion, resulting in reduced heating efficiency and increased production of carbon monoxide. Conversely, an excessively large cross-sectional area can lead to reduced flue gas velocity, resulting in lower flue gas temperatures and increased condensation within the liner. The resulting condensate, often acidic, accelerates corrosion and further reduces draft. For example, installing a six-inch diameter liner on a furnace designed for a four-inch liner will likely cause condensation problems, especially in colder climates. This underlines the imperative of matching the dimensions precisely to the appliance’s specifications.

Proper sizing must account for several parameters, including the appliance’s heat output, fuel type, flue gas temperature, and the height of the ventilation setup. Engineering handbooks and manufacturer guidelines provide detailed sizing tables and calculation methods. Adherence to these standards ensures the vertical exhaust configuration operates within optimal parameters, maximizing efficiency and minimizing the risk of hazardous conditions. Moreover, correct dimensioning promotes longevity of the overall system and enhances the integrity of the building envelope by preventing the escape of harmful combustion byproducts.

6. Obstructions

The presence of impediments within a vertical exhaust structure constitutes a significant threat to its safe and efficient operation. Obstructions disrupt the intended flow of combustion byproducts, leading to a cascade of detrimental effects that can compromise both the performance of the heating appliance and the health of building occupants. Understanding the various forms of impediments and their impact is crucial for maintaining a functional and safe system.

- Creosote Buildup

Creosote, a byproduct of incomplete combustion in wood-burning appliances, accumulates within the flue as a highly flammable residue. This buildup restricts airflow, reduces draft, and significantly increases the risk of chimney fires. Regular inspections and professional cleaning are essential to mitigate this hazard. The severity of creosote buildup is influenced by factors such as wood type, moisture content, and appliance operating practices.

- Animal Nests

Birds, squirrels, and other animals frequently construct nests within vertical exhaust systems, particularly during the spring and summer months. These nests obstruct airflow, potentially causing backdrafting of dangerous gases such as carbon monoxide into the dwelling. Furthermore, the nesting materials themselves can pose a fire hazard. Installation of a properly sized chimney cap prevents animal entry.

- Debris Accumulation

Leaves, branches, and other debris can enter the structure, particularly in the absence of a chimney cap. This accumulated material restricts airflow and can contribute to moisture retention within the flue. The presence of debris can also accelerate corrosion and deterioration of the liner. Periodic inspections and removal of debris are necessary to maintain optimal performance.

- Structural Collapse

Deterioration of the internal liner, or external masonry, can result in partial or complete collapse within the structure. This type of obstruction severely restricts airflow, creating a dangerous situation. Structural collapse often necessitates extensive repairs or complete reconstruction of the vertical exhaust system. Early detection of structural issues through regular inspections is crucial to prevent catastrophic failures.

In summary, obstructions of any form impede the designed functionality. These impediments can lead to increased risks of fire, carbon monoxide poisoning, and structural damage. Regular inspections, preventative measures such as chimney caps, and prompt remediation of any identified problems are essential for ensuring the safe and efficient operation of any system venting combustion byproducts.

Frequently Asked Questions Regarding Vertical Exhaust Systems

The following addresses common inquiries concerning these critical components of heating systems. It aims to clarify essential aspects related to their function, maintenance, and safety.

Question 1: What constitutes an adequate frequency for professional cleaning of a vertical flue?

The recommended cleaning frequency depends upon usage patterns and fuel type. Annual professional cleaning is generally advised; however, more frequent cleaning may be necessary for systems used extensively or burning fuels that produce significant creosote buildup. Visual inspection of the flue liner can help determine the need for cleaning.

Question 2: What are the primary indicators of potential compromise?

Indicators include visible cracks or deterioration of the flue liner, spalling or crumbling of masonry, water leaks within the chimney structure, and the presence of excessive creosote buildup. Any of these signs warrant further investigation by a qualified professional.

Question 3: Is a flue cap an essential component?

A flue cap is highly recommended. It prevents the entry of rainwater, snow, debris, and animals, all of which can obstruct airflow and contribute to deterioration. A properly sized and installed cap represents a cost-effective measure for protecting the structure.

Question 4: Can any fuel type be safely burned in any existing system?

No. Each system is designed for specific fuel types. Burning fuels not intended for the system can lead to incomplete combustion, excessive creosote buildup, and potential hazards. Consult appliance manufacturer specifications to determine appropriate fuel types.

Question 5: What are the potential consequences of neglecting regular inspections?

Neglecting inspections can result in undetected deterioration, leading to costly repairs and potential safety hazards, including carbon monoxide poisoning and chimney fires. Regular inspections allow for early detection and remediation of problems, minimizing risks.

Question 6: Are do-it-yourself repairs advisable for vertical exhaust systems?

Do-it-yourself repairs are generally discouraged, particularly for complex issues. These systems require specialized knowledge and expertise to ensure safe and effective operation. Improper repairs can exacerbate problems and create hazardous conditions. It is best to engage a qualified professional for repairs and maintenance.

Key takeaways include the importance of regular cleaning, prompt attention to signs of damage, and adherence to manufacturer specifications. Prioritizing these aspects ensures the safe and efficient operation of a critical heating system component.

The next section will address regulatory compliance and safety standards pertinent to the construction, installation, and maintenance of these ventilation structures.

Vent in Chimney

This exploration has underscored the vital role the “vent in chimney” plays in ensuring safe and efficient combustion byproduct removal. From material selection and proper sizing to maintaining liner integrity and preventing obstructions, each element demands careful consideration. The consequences of neglecting these aspects range from reduced heating efficiency and structural damage to life-threatening hazards such as carbon monoxide poisoning and chimney fires.

Therefore, diligent maintenance, regular inspections by qualified professionals, and adherence to established safety standards are not merely recommended, but imperative. Continued awareness and proactive measures are essential to safeguarding property and preserving the well-being of building occupants. Future advancements in venting technology will undoubtedly emerge, yet the fundamental principles of safe and effective combustion byproduct evacuation must remain paramount.

![Best 6 Inch Chimney Brush & Rods Kit: [Year] Guide Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Best 6 Inch Chimney Brush & Rods Kit: [Year] Guide | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/01/th-573-300x200.jpg)