A vertical structure fabricated from steel, typically cylindrical or rectangular, designed to vent hot flue gases or smoke from a furnace, boiler, stove, or fireplace. These structures provide a safe and efficient conduit for combustion byproducts to be released into the atmosphere, mitigating potential health hazards and structural damage within enclosed spaces. As an example, a manufacturing plant might utilize a large-diameter, insulated structure to expel fumes generated during its production processes.

The implementation of these exhaust systems offers numerous advantages. They enhance air quality by dispersing pollutants high above ground level, reducing localized concentrations. Historically, such systems have played a critical role in industrial development, allowing for the concentrated burning of fuels and powering of machinery. Their robust construction ensures durability and resistance to corrosive elements, providing long-term operational reliability. Furthermore, they facilitate efficient combustion by maintaining adequate draft, optimizing fuel consumption and energy output.

The subsequent sections will delve into specific design considerations, installation procedures, maintenance requirements, and material selection influencing the performance and longevity of these crucial venting components.

Steel Chimney Best Practices

This section offers practical guidance for ensuring optimal performance and longevity of steel venting systems. Adherence to these practices promotes safety, efficiency, and regulatory compliance.

Tip 1: Proper Sizing. Accurate calculation of flue gas volume and temperature is crucial. An undersized exhaust system will restrict airflow, leading to incomplete combustion and potential carbon monoxide buildup. Conversely, an oversized system can result in excessive condensation, accelerating corrosion.

Tip 2: Material Selection. Employ corrosion-resistant steel alloys appropriate for the specific fuel type and combustion conditions. For example, stainless steel is generally preferred for venting appliances that burn corrosive fuels like propane or natural gas.

Tip 3: Insulation Implementation. Adequate insulation minimizes heat loss, maintaining flue gas temperature above the dew point to prevent condensation. This is particularly important in colder climates. Consider using high-temperature, weather-resistant insulation materials.

Tip 4: Regular Inspections. Conduct routine visual inspections for signs of corrosion, damage, or blockages. Pay close attention to joints, connections, and the chimney cap. Early detection of issues prevents costly repairs and potential hazards.

Tip 5: Professional Cleaning. Schedule periodic cleaning by a qualified chimney sweep to remove creosote and other deposits. Creosote buildup poses a significant fire risk and reduces venting efficiency.

Tip 6: Secure Connections. Ensure all connections are properly sealed and secured using appropriate fasteners and sealants. Leaks can compromise system performance and introduce hazardous gases into the occupied space.

Tip 7: Lightning Protection. Consider installing a lightning protection system, especially for tall structures. Lightning strikes can cause severe damage and ignite combustible materials.

Implementing these best practices significantly enhances the safety, efficiency, and lifespan of the venting system. Diligence in these areas contributes to a safer and more sustainable environment.

The subsequent section will explore the regulatory landscape governing the design, installation, and maintenance of these systems.

1. Structural Integrity

Structural integrity is paramount in the design and operation of a steel chimney. It dictates the system’s ability to withstand various stresses, including wind loads, seismic activity, thermal expansion, and the weight of the structure itself. A compromised structural integrity can lead to catastrophic failure, posing significant safety risks and potential environmental hazards. For instance, a weakened foundation, corroded support beams, or inadequate weld joints can compromise the chimney’s stability, increasing the risk of collapse, especially during adverse weather conditions. Adherence to engineering standards and rigorous inspection protocols are crucial to maintaining structural integrity.

The composition and construction methods directly affect the system’s long-term durability and resistance to degradation. Improper welding techniques, the use of substandard steel alloys, or inadequate corrosion protection measures can accelerate structural decline. Regular inspections, including non-destructive testing methods like ultrasonic testing, are necessary to identify hidden flaws and assess the structural health. Consider the example of a tall industrial exhaust system experiencing high winds; its ability to remain standing depends entirely on the initial structural design, material strength, and ongoing maintenance to detect and rectify any weakening over time.

In conclusion, the relationship between structural integrity and these systems is intrinsically linked to safety and longevity. Prioritizing sound engineering practices, using appropriate materials, and implementing comprehensive inspection programs are essential to preserving structural integrity and ensuring the reliable and safe operation of the venting system. Neglecting this aspect can result in costly repairs, operational disruptions, and, more importantly, endanger human life and the environment.

2. Material Durability

Material durability is a fundamental determinant of a steel chimney’s lifespan and operational reliability. The corrosive nature of flue gases, often containing sulfur oxides, nitrogen oxides, and chlorides, necessitates the utilization of steel alloys exhibiting high resistance to chemical attack. Inadequate material selection can lead to accelerated corrosion, structural weakening, and eventual failure of the chimney. For instance, the use of carbon steel in environments with high sulfur dioxide concentrations invariably results in rapid degradation, requiring frequent repairs or premature replacement.

The selection of appropriate steel alloys, such as stainless steel grades 304, 316, or specialized high-nickel alloys, is crucial in mitigating corrosion risks. These materials possess inherent resistance to oxidation and chemical attack, extending the chimney’s service life. Furthermore, protective coatings, such as epoxy resins or ceramic linings, can provide an additional barrier against corrosive elements. A practical example is the application of a ceramic lining within an industrial exhaust system venting flue gases from a coal-fired power plant, substantially reducing the rate of corrosion compared to an unlined steel chimney. Periodic inspections and maintenance, including the assessment of coating integrity and the detection of corrosion hotspots, are essential for proactively addressing potential material degradation issues.

In summary, the connection between material durability and the functionality of a steel chimney is direct and critical. Employing materials that withstand the corrosive environment, implementing protective measures, and conducting regular inspections are paramount for ensuring the long-term performance and safety of these essential venting systems. Failure to prioritize material durability can result in significant financial burdens associated with repairs, downtime, and potential environmental liabilities.

3. Effective Ventilation

Effective ventilation is integral to the functionality of a steel chimney, serving as the primary mechanism for evacuating combustion byproducts and maintaining safe operating conditions. Without proper ventilation, incomplete combustion can occur, leading to the accumulation of hazardous gases such as carbon monoxide within the enclosed space. This incomplete combustion also reduces the efficiency of the appliance or process generating the flue gases. A properly designed venting system generates sufficient draft, the pressure differential that drives the flow of gases upwards and out of the chimney, thus removing these harmful emissions. For example, in a commercial heating system, a correctly sized and installed steel chimney ensures efficient removal of combustion gases, preventing backdrafting and potential health hazards.

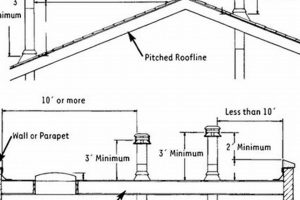

The design of the chimney significantly impacts ventilation efficacy. Factors such as height, diameter, internal smoothness, and insulation contribute to the overall draft. Insufficient height can result in inadequate draft, particularly in areas with prevailing winds or surrounding obstructions. The diameter must be appropriately sized to accommodate the volume of flue gases produced. Internal smoothness minimizes friction, promoting laminar flow and reducing resistance. Insulation maintains flue gas temperatures, enhancing buoyancy and improving draft. The interplay of these variables determines the venting capacity and overall performance. For instance, a steel chimney in a mountainous region must be designed to compensate for changes in atmospheric pressure and wind patterns to maintain effective ventilation.

In conclusion, effective ventilation is not merely a desirable attribute of a steel chimney but a necessity for safe and efficient operation. Design considerations, installation practices, and ongoing maintenance are all crucial in ensuring that the system performs its intended function of safely removing combustion byproducts. Failure to prioritize effective ventilation can result in reduced efficiency, increased risk of carbon monoxide poisoning, and potential structural damage to the chimney itself. Therefore, a thorough understanding of ventilation principles and their application to design and maintenance is essential for all stakeholders involved in the installation and operation of these systems.

4. Thermal Efficiency

Thermal efficiency, in the context of steel chimneys, refers to the system’s ability to retain heat within the flue gases as they are expelled, preventing excessive cooling that can lead to condensation and reduced draft. Maintaining appropriate flue gas temperatures is crucial for optimal combustion and the safe removal of combustion byproducts. Poor thermal efficiency can lead to operational issues and accelerated corrosion.

- Insulation Properties

Insulation plays a crucial role in minimizing heat loss from the chimney walls. Adequate insulation reduces the temperature differential between the flue gases and the external environment, preventing condensation of water vapor and corrosive acids. For example, well-insulated steel chimneys in cold climates experience significantly less corrosion and maintain a stronger draft compared to uninsulated chimneys. The type and thickness of insulation are critical parameters in achieving optimal thermal performance.

- Flue Gas Temperature Maintenance

Maintaining flue gas temperature above the dew point is essential for preventing condensation. Condensation can lead to the formation of corrosive acids that attack the steel structure, reducing its lifespan. The dew point varies depending on the fuel type and combustion process. Effective chimney design and insulation contribute to maintaining flue gas temperatures above this threshold, ensuring longevity and structural integrity. In industrial applications, monitoring flue gas temperatures is often a standard practice to ensure efficient and safe operation.

- Draft Optimization

Thermal efficiency directly influences the chimney’s draft, which is the pressure differential that drives the flow of gases upwards. Warmer flue gases are less dense and therefore rise more readily, creating a stronger draft. Conversely, cooled flue gases are denser and impede the upward flow. Optimizing thermal efficiency, through insulation and proper chimney design, enhances draft, promoting efficient combustion and the complete removal of combustion byproducts. A poorly insulated chimney can suffer from weak draft, leading to incomplete combustion and potential carbon monoxide buildup.

- Material Selection Impact

The selection of steel alloys and the application of protective coatings influence the overall thermal behavior of the chimney. Certain steel alloys possess higher thermal conductivity than others, impacting heat transfer rates. Protective coatings, such as ceramic linings, can reduce heat loss and improve the chimney’s resistance to corrosion. Therefore, material selection decisions must consider both the mechanical strength and the thermal characteristics of the materials to ensure optimal performance and longevity.

These interconnected facets highlight the importance of considering thermal efficiency in the design, construction, and maintenance of steel chimneys. Neglecting thermal considerations can lead to reduced performance, increased operational costs, and potential safety hazards. By optimizing insulation, maintaining flue gas temperatures, enhancing draft, and selecting appropriate materials, operators can ensure the reliable and efficient operation of these essential venting systems.

5. Code Compliance

Adherence to established codes and standards is an indispensable component of steel chimney design, fabrication, installation, and maintenance. These codes, often promulgated by national or international standards organizations (e.g., UL, ASME, ASTM), establish minimum safety and performance requirements intended to protect life, property, and the environment. The failure to comply with relevant codes can have severe consequences, ranging from operational inefficiencies and increased safety risks to legal liabilities and regulatory penalties. For instance, neglecting to adhere to required stack height regulations can result in inadequate pollutant dispersion, leading to violations of air quality standards and potential fines. Code compliance is not merely a formality but a fundamental aspect of responsible engineering practice.

The practical significance of code compliance is evident in numerous real-world scenarios. In the power generation industry, compliance with boiler and pressure vessel codes ensures that steel chimneys are structurally sound and capable of withstanding the high temperatures and pressures associated with flue gas exhaust. In residential applications, compliance with building codes regarding chimney clearances and material specifications prevents the risk of fire hazards due to overheating or the ignition of combustible materials in close proximity. Furthermore, regular inspections and maintenance programs, as mandated by specific codes, help to identify and address potential deficiencies before they escalate into major problems. The absence of code compliance in these scenarios could result in catastrophic failures, environmental damage, and significant economic losses.

In summary, code compliance forms an integral link in the safe and effective operation of steel chimneys. It provides a framework for ensuring structural integrity, minimizing environmental impact, and protecting public safety. Challenges to maintaining code compliance include keeping abreast of evolving standards, interpreting complex regulations, and implementing effective quality control procedures. However, the commitment to code compliance is essential for ensuring the long-term reliability and sustainability of these critical infrastructure components.

Frequently Asked Questions

This section addresses common inquiries concerning the selection, installation, maintenance, and performance characteristics of steel venting systems.

Question 1: What is the expected lifespan of a steel chimney?

The service life is contingent upon factors such as material grade, operating conditions, and maintenance practices. High-quality stainless steel chimneys, properly maintained and operated within design parameters, can last several decades. Conversely, inadequate material selection or neglect of maintenance can significantly shorten the lifespan.

Question 2: What are the primary advantages of steel chimneys compared to masonry chimneys?

Steel chimneys offer advantages in terms of weight, installation speed, and resistance to seismic activity. They are typically lighter than masonry structures, facilitating easier installation and reducing foundation requirements. Furthermore, their inherent flexibility provides greater resistance to earthquake damage.

Question 3: How often should a steel chimney be inspected?

Annual inspections are recommended to identify potential issues such as corrosion, damage, or blockages. More frequent inspections may be necessary in demanding operating environments or where visual signs of deterioration are evident.

Question 4: What are the common causes of steel chimney failure?

The most frequent causes of failure include corrosion due to acidic flue gases, mechanical damage from wind or seismic events, and inadequate maintenance leading to creosote buildup or blockages. Improper installation can also contribute to premature failure.

Question 5: Can a steel chimney be used for multiple appliances?

Multi-appliance venting is possible, but careful consideration must be given to factors such as appliance compatibility, flue gas volume, and drafting requirements. Consult relevant codes and qualified professionals to ensure safe and efficient operation.

Question 6: What are the key considerations for sizing a steel chimney?

Proper sizing requires accurate calculation of flue gas volume, temperature, and pressure drop. Undersized chimneys can restrict airflow and lead to incomplete combustion, while oversized chimneys can promote condensation and corrosion. Consulting with a qualified engineer is essential for accurate sizing.

Understanding these aspects is critical for ensuring the longevity and safe functionality of such installations. Prioritizing design and maintenance is key.

The subsequent section will provide a summary of the information discussed in previous sections.

Conclusion

This article has presented a comprehensive overview of the steel chimney, highlighting its crucial role in various industrial and residential applications. Discussions encompassed its definition, benefits, best practices, structural integrity, material durability, effective ventilation, thermal efficiency, and code compliance. The enduring function of the steel chimney in safely and efficiently venting combustion byproducts remains paramount.

The integrity and performance of a steel chimney are intrinsically linked to responsible design, meticulous construction, and diligent maintenance. Recognizing the vital role of this component in ensuring safety and environmental responsibility necessitates a continued commitment to best practices and regulatory adherence. Further research and technological advancements should continue to optimize the design and materials used in these critical venting systems, contributing to improved safety, efficiency, and sustainability in the future.