The service concerns professionals who specialize in cleaning and maintaining structures designed to vent combustion byproducts from fireplaces, furnaces, and other heating appliances, specifically in the Commonwealth of Virginia. These specialists operate on the exterior top of buildings, attending to the system’s uppermost component. The work includes removing soot, creosote, and debris, ensuring efficient venting and reducing the risk of chimney fires.

Regular maintenance of these systems is vital for home safety and efficiency. Removing obstructions and accumulated deposits improves airflow, optimizing heating appliance performance and minimizing the potential for dangerous carbon monoxide buildup within a dwelling. Historically, this occupation has played a critical role in preventing structural fires and maintaining healthy indoor air quality in residences.

The following sections will elaborate on the methods employed by these professionals, the tools they utilize, and the key considerations for homeowners when selecting a qualified service provider. Furthermore, regulatory compliance and recommended maintenance schedules will be discussed to provide a thorough understanding of this specialized trade.

Essential Advice for Chimney Maintenance

Maintaining a chimney’s integrity is crucial for the safe and efficient operation of any heating appliance. The following recommendations outline important considerations for homeowners.

Tip 1: Schedule Annual Inspections: A professional inspection can identify potential hazards, such as cracks, blockages, or structural damage, before they escalate into significant problems.

Tip 2: Prioritize Regular Cleaning: Accumulated soot and creosote are highly flammable. Regular cleaning minimizes the risk of chimney fires and ensures proper ventilation.

Tip 3: Address Water Leaks Promptly: Water intrusion can damage the chimney’s structure and lead to costly repairs. Identifying and repairing leaks is essential for longevity.

Tip 4: Maintain a Functional Chimney Cap: A chimney cap prevents rain, snow, leaves, and animals from entering the flue, protecting the system from damage and blockages.

Tip 5: Use Seasoned Firewood: Burning dry, seasoned wood reduces creosote buildup compared to burning wet or green wood.

Tip 6: Ensure Proper Appliance Installation: Correct installation of heating appliances is crucial for safety and efficiency. Use a qualified professional for all installations.

Tip 7: Be Aware of Warning Signs: Recognize warning signs such as smoke entering the room, unusual odors, or excessive creosote buildup. Consult a professional if any of these signs are present.

Adhering to these guidelines enhances the safety and efficiency of a home’s chimney system, safeguarding against potential hazards and ensuring optimal performance.

The next section will discuss common issues encountered during chimney maintenance and effective solutions for addressing them.

1. Inspection Frequency

Inspection frequency constitutes a critical component of comprehensive chimney maintenance performed by professionals operating at elevated heights in Virginia. The regularity with which these inspections occur directly influences the identification and mitigation of potential hazards. Insufficient inspection intervals can result in the undetected accumulation of creosote, structural deterioration due to weather exposure, or the presence of obstructions, all of which can compromise the system’s safety and efficiency.

A practical example highlights this relationship: a homeowner who neglects annual inspections may be unaware of a developing crack in the chimney liner. Over time, this crack can expand, allowing combustion gases to leak into the home, posing a significant carbon monoxide poisoning risk. Furthermore, water infiltration through the crack can exacerbate freeze-thaw damage, leading to costly structural repairs. Conversely, regular inspections can identify the crack early, allowing for timely and cost-effective repairs. The absence or presence of diligent oversight directly impacts homeowner safety and the longevity of the chimney system.

In summation, appropriate inspection frequency, as determined by factors such as usage patterns and fuel type, is an indispensable aspect of preventative chimney care. Neglecting this crucial step increases the risk of fire hazards, structural damage, and potential health risks. Adherence to recommended inspection schedules, facilitated by qualified service providers, is essential for maintaining a safe and efficient residential heating system. The challenge remains in educating homeowners regarding the direct correlation between proactive inspection frequency and long-term chimney integrity.

2. Creosote Removal

Creosote removal constitutes a primary function within the scope of services offered by professionals specializing in chimney maintenance atop structures across the Commonwealth of Virginia. The accumulation of this byproduct of combustion poses a significant fire hazard, necessitating its periodic and thorough elimination.

- Formation and Characteristics

Creosote forms as volatile gases released during the burning of wood condense within the relatively cooler flue. This substance adheres to the chimney walls and can manifest in various forms, ranging from a flaky, soot-like deposit to a hard, tar-like glaze. Each form presents different challenges for removal. For example, a homeowner using unseasoned firewood may experience accelerated creosote buildup. The resulting thick, glazed creosote significantly increases the risk of a chimney fire compared to a thinner, soot-like deposit.

- Risk Mitigation

The presence of creosote elevates the risk of chimney fires due to its combustible nature. When exposed to sufficient heat, this accumulated material can ignite, potentially leading to a rapid and intense fire within the chimney flue. These fires can spread to adjacent combustible materials within the building structure. Routine removal by specialized professionals, like those accessed in Virginia, significantly reduces this risk and safeguards the property from potential damage or destruction. The direct effect of decreased creosote buildup means a reduced chance of ignition, and therefore, greater safety for the occupants.

- Removal Techniques

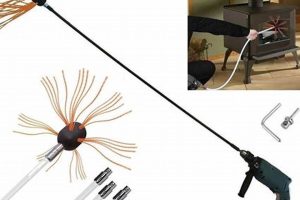

Professionals employ a variety of tools and techniques to effectively remove creosote. These include the use of specialized brushes, scrapers, and rotary cleaning tools designed to dislodge deposits without damaging the chimney liner. In severe cases, chemical treatments may be necessary to soften hardened creosote, facilitating its removal. Consider a situation where a technician assesses a flue with heavy glaze creosote. They may choose to apply a chemical treatment overnight before returning the following day to mechanically remove the softened substance, maximizing effectiveness while preserving the integrity of the chimney.

- Preventative Measures

While professional removal is essential, preventative measures implemented by homeowners can significantly reduce creosote accumulation. These measures include burning seasoned firewood, ensuring adequate airflow to the fire, and maintaining a hot fire. For example, the regular burning of dry, seasoned hardwood reduces the volume of unburned gases released into the chimney, resulting in less creosote formation compared to burning wet or softwood. Adopting these habits complements professional services and contributes to long-term chimney health.

These interwoven facetscreosote formation, risk mitigation, removal techniques, and preventative measuresunderscore the critical role of specialist services in maintaining chimney safety. The effective management of creosote by individuals operating in the residential and commercial areas of Virginia constitutes a core element in fire prevention and overall property protection.

3. Weatherproofing Integrity

Weatherproofing integrity represents a crucial aspect of chimney maintenance provided by professionals who access rooftop structures in Virginia. The connection arises from the chimney’s continuous exposure to environmental elements, leading to potential degradation and functional compromise. Deterioration of weatherproofing components directly affects the overall performance and lifespan of the chimney system. For instance, a damaged chimney crown, intended to deflect water, allows moisture intrusion into the chimney structure. This infiltration accelerates brick and mortar erosion, causing structural instability. This effect is pronounced in regions with significant freeze-thaw cycles, such as those found in Virginia. Repairing the chimney crown and other weatherproofing issues becomes part of the service.

The practical significance of maintaining weatherproofing integrity extends beyond preventing structural damage. Water penetration can saturate the flue liner, hindering its ability to efficiently vent combustion gases. This compromised venting efficiency elevates the risk of carbon monoxide buildup within the dwelling. Additionally, moisture accumulation within the chimney promotes the growth of mold and mildew, impacting indoor air quality. By identifying and addressing weatherproofing issues, specialists mitigate these risks. This includes applying waterproof sealants, repairing or replacing damaged chimney caps, and ensuring the integrity of flashing around the chimney base. Consider a scenario where a skilled technician identifies deteriorated flashing during a routine inspection. Replacing the flashing prevents water from seeping into the attic space and causing significant structural damage, thereby avoiding costly future repairs.

In summary, weatherproofing integrity is not merely a supplementary consideration but an essential component of responsible chimney maintenance. The services provided by professionals emphasize protecting chimneys from the detrimental effects of environmental exposure. Ensuring properly sealed systems contributes directly to the longevity, safety, and efficiency of the residential heating system. The ongoing challenge lies in educating homeowners about the long-term benefits and cost-effectiveness of proactive weatherproofing maintenance and the direct correlation between a watertight chimney system and a safe, healthy living environment.

4. Equipment Certification

The validation of tools and apparatus used by chimney maintenance professionals operating at elevated locations in Virginia through formal certification processes directly impacts safety, efficacy, and adherence to industry standards.

- Safety Compliance

Equipment certification ensures that tools such as harnesses, ropes, ladders, and cleaning implements meet established safety criteria. Certified equipment undergoes rigorous testing to verify its ability to withstand intended loads and environmental conditions. For example, a certified harness used by a technician must demonstrate its capacity to prevent falls from rooftops. The employment of certified equipment minimizes the risk of accidents and injuries during the performance of chimney maintenance services.

- Performance Efficacy

Certification verifies that cleaning tools, such as brushes and vacuum systems, meet defined performance standards. Certified brushes, for instance, are designed to effectively remove creosote and debris without damaging the chimney liner. Similarly, certified vacuum systems must demonstrate their ability to capture particulate matter, preventing its release into the atmosphere. Using certified equipment enhances the effectiveness of chimney cleaning operations and contributes to optimal chimney system performance.

- Regulatory Adherence

Many jurisdictions within Virginia mandate the use of certified equipment for specific chimney maintenance tasks. Compliance with these regulations ensures that service providers adhere to established safety protocols and industry best practices. For example, local building codes may require the use of certified ladder systems for accessing rooftops. Employing certified equipment demonstrates a commitment to regulatory compliance and minimizes the risk of penalties or legal liabilities.

- Professional Credibility

The utilization of certified equipment enhances the credibility of chimney maintenance professionals. It indicates a dedication to safety, quality, and adherence to industry standards. Homeowners are more likely to trust and engage service providers who demonstrate a commitment to using certified tools and apparatus. Providing proof of equipment certification can serve as a differentiating factor in a competitive market and contribute to building customer confidence.

In summation, the implementation of certified equipment within the operational framework of chimney maintenance in Virginia contributes significantly to safety enhancement, operational effectiveness, regulatory compliance, and professional credibility. The integration of validated apparatus serves as a crucial element in safeguarding personnel, protecting property, and upholding industry best practices.

5. Local Regulations

Adherence to stipulations promulgated by municipal, county, and state authorities represents a non-negotiable aspect of operations undertaken by chimney maintenance services in Virginia. These legal frameworks exert considerable influence on the methodologies employed, safety protocols observed, and qualifications required of personnel engaged in accessing rooftop structures to service chimneys.

- Licensing and Certification Requirements

Many localities mandate that individuals or companies providing chimney-related services possess specific licenses or certifications. These credentials often necessitate completion of approved training programs and passing competency examinations. Failure to comply with these requirements can result in fines, legal injunctions, or the inability to legally operate within the jurisdiction. For instance, a county ordinance may stipulate that technicians hold a certification from the Chimney Safety Institute of America (CSIA) before undertaking chimney inspections or cleanings.

- Permitting Procedures

Certain chimney-related activities, such as the installation of new chimney liners or the construction of masonry structures, may necessitate obtaining permits from local building departments. These permits ensure that the work conforms to applicable building codes and safety standards. Ignoring permitting requirements can lead to costly rework and potential legal action. For example, if a homeowner hires a service provider to install a new wood stove insert without securing the necessary permits, the municipality may require the removal of the insert and restoration of the chimney to its original condition.

- Safety Standards and Inspection Protocols

Local regulations frequently incorporate specific safety standards governing chimney maintenance practices. These standards may address issues such as fall protection measures, fire safety precautions, and proper disposal of hazardous materials. Additionally, municipalities may conduct inspections to ensure compliance with these safety regulations. Violation of these standards can expose technicians to unnecessary risks and lead to regulatory penalties. As an illustration, regulations might require technicians working on steeply pitched roofs to utilize specific anchor points and safety harnesses to prevent falls.

- Waste Disposal Requirements

The disposal of chimney debris, including soot, creosote, and damaged chimney components, is often subject to local environmental regulations. These regulations may restrict the disposal of such materials in landfills and require proper containment and transportation to designated waste disposal facilities. Non-compliance with waste disposal requirements can result in environmental contamination and legal repercussions. For example, some jurisdictions may mandate that creosote-contaminated materials be treated as hazardous waste and disposed of accordingly.

Therefore, comprehensive understanding and unwavering adherence to local ordinances are indispensable for chimney service providers operating in Virginia. Compliance not only mitigates legal risks but also fosters a culture of safety and professionalism, ultimately benefiting both the service providers and the homeowners they serve.

Frequently Asked Questions

The following elucidates prevalent inquiries regarding chimney maintenance conducted by professionals accessing rooftops across the Commonwealth of Virginia. The intent is to provide precise, factual answers to commonly raised concerns.

Question 1: What is the optimal frequency for chimney inspections?

The generally accepted standard mandates annual inspections. More frequent evaluations may be necessary based on the type of fuel burned, the frequency of appliance usage, and the age and condition of the chimney system. Properties utilizing wood as a primary heat source should adhere to a more stringent inspection schedule.

Question 2: What are the telltale signs of a hazardous chimney condition?

Indications include visible cracks or crumbling mortar, the presence of excessive creosote buildup, water leaks, smoke emanating into the living space, and unusual odors. Any of these signs warrants immediate evaluation by a qualified professional.

Question 3: Does the presence of a chimney cap obviate the need for inspections?

No. A chimney cap serves to prevent the entry of rain, debris, and animals, but it does not address internal deterioration, creosote accumulation, or structural damage. Regular inspections remain essential regardless of the presence of a cap.

Question 4: What credentials should I seek when selecting a chimney maintenance service?

Certifications from recognized organizations such as the Chimney Safety Institute of America (CSIA) are paramount. Additionally, verifying insurance coverage and reviewing customer testimonials provides further assurance of competence and professionalism.

Question 5: Is DIY chimney cleaning a viable alternative to professional service?

While homeowners may attempt basic cleaning, professional services possess the specialized tools, knowledge, and experience to conduct thorough inspections and address complex issues. DIY efforts may overlook critical problems and potentially exacerbate existing hazards.

Question 6: What is the typical lifespan of a chimney liner, and what factors influence it?

The lifespan of a chimney liner varies depending on the material (clay, metal, or cast-in-place), the type of fuel burned, and the level of maintenance. Generally, clay liners can last 50 years or more with proper care, while metal liners may require replacement after 15-20 years. Regular inspections can identify liner damage and facilitate timely repairs.

The foregoing represents a compilation of critical inquiries pertaining to chimney maintenance practices. Addressing these considerations proactively contributes to the safe and efficient operation of residential heating systems.

The subsequent segment will explore the ethical obligations of chimney maintenance professionals and the implications for homeowner protection.

Concluding Remarks on Chimney Maintenance Services in Virginia

This discourse has presented a comprehensive overview of the role fulfilled by professionals specializing in chimney maintenance throughout Virginia, including those who provide rooftop chimney sweeps va services. Emphasis has been placed on the importance of regular inspections, creosote removal, weatherproofing, and adherence to local regulations. The discussions have underscored the criticality of certified equipment and appropriately credentialed technicians in ensuring both the safety and efficiency of residential heating systems. These elements, when diligently observed, contribute significantly to mitigating the risk of chimney fires and carbon monoxide intrusion.

Given the potential hazards associated with improperly maintained chimney systems, homeowners are strongly encouraged to prioritize regular professional inspections and maintenance. Proactive engagement with qualified service providers, including rooftop chimney sweeps va specialists, offers a tangible investment in home safety and property preservation. The long-term benefits of prioritizing chimney health far outweigh the costs associated with neglect.