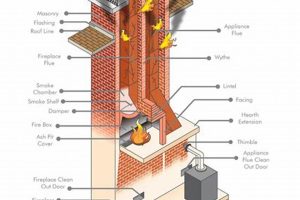

A vertical structure extending from the roof of a building serves as a conduit for expelling combustion byproducts, such as smoke and gases, generated by heating appliances or fireplaces. These structures are commonly constructed of brick, stone, or metal and are integral components of many residential and commercial buildings equipped with solid-fuel or gas-burning systems.

These building features play a critical role in maintaining indoor air quality and ensuring safe and efficient operation of heating systems. Their design facilitates proper draft, which draws air into the combustion chamber and effectively removes harmful emissions from the interior. Historically, they have been central to heating and cooking practices, evolving in design and materials alongside advancements in construction technology and fuel types.

The following discussion delves into the construction, maintenance, and relevant safety considerations associated with these essential architectural elements. Topics addressed include materials selection, inspection procedures, common problems, and methods for ensuring long-term functionality and regulatory compliance.

Essential Considerations for Optimal Performance

Maintaining the integrity of the structure is crucial for safe and efficient operation. Addressing potential issues proactively prevents costly repairs and ensures the longevity of the system.

Tip 1: Regular Inspections: Conduct thorough visual examinations at least annually. Check for cracks, spalling, or deteriorated mortar joints. Early detection of damage prevents moisture intrusion and structural instability.

Tip 2: Professional Cleaning: Schedule professional cleaning services on a regular basis. Creosote buildup is a fire hazard and reduces draft efficiency. Frequency depends on usage and fuel type.

Tip 3: Cap Maintenance: Ensure the cap is in good repair. A properly functioning cap prevents rain, snow, and debris from entering the flue, protecting the interior from damage and blockage.

Tip 4: Addressing Moisture Problems: Investigate and resolve any signs of water damage promptly. Moisture can accelerate deterioration of masonry and promote mold growth. Identify the source of the leak and implement appropriate repairs.

Tip 5: Maintaining Proper Draft: Ensure adequate airflow for efficient combustion. Blockages, undersized flues, or negative pressure within the building can impede draft. Consult a qualified professional to diagnose and correct draft-related issues.

Tip 6: Prompt Repairs: Address any detected damage or deterioration without delay. Small cracks can quickly escalate into larger structural problems. Timely repairs minimize repair costs and prevent safety hazards.

Tip 7: Consider Relining: If the existing flue liner is damaged or deteriorating, consider relining. A new liner improves safety, efficiency, and compliance with current building codes.

Adhering to these recommendations contributes significantly to the safe and efficient operation of the system, minimizing risks and extending its lifespan.

The following sections will provide more in-depth information about specific repair techniques and safety protocols associated with these structural components.

1. Draft Efficiency

Draft efficiency, in the context of a structure designed for expelling combustion byproducts, refers to the system’s ability to effectively remove exhaust gases from a heating appliance or fireplace and vent them safely outside the building. The design and condition of this vertical structure directly impact its draft performance, influencing both safety and heating efficiency.

- Stack Effect and Flue Height

The “stack effect” describes the natural upward movement of heated air within the flue. Increased flue height enhances the stack effect, generating a stronger draft. However, excessive height may lead to heat loss within the flue, potentially reducing overall efficiency. Proper flue height is crucial for optimal draft performance.

- Flue Size and Appliance Compatibility

The flue size must be appropriately matched to the appliance it serves. An undersized flue restricts airflow, leading to incomplete combustion and the potential for dangerous carbon monoxide buildup. An oversized flue can result in excessive cooling of exhaust gases, causing creosote condensation and reduced draft. Correct sizing is essential for safe and efficient operation.

- External Environmental Factors

External conditions, such as wind and temperature, significantly influence draft. Wind blowing across the top of the structure can create a downdraft, forcing exhaust gases back into the building. Cold outdoor temperatures reduce the natural buoyancy of flue gases, weakening the draft. Mitigation strategies include wind-resistant caps and insulated flues.

- Obstructions and Blockages

Obstructions within the flue, such as bird nests, debris, or creosote buildup, impede airflow and reduce draft efficiency. Regular inspections and cleaning are necessary to prevent blockages and maintain proper draft. Neglecting these maintenance tasks poses a significant safety hazard and reduces heating system performance.

Effective draft is a critical component of a safe and efficient heating system. Optimizing flue height and size, mitigating external environmental influences, and preventing obstructions are crucial for maintaining proper draft performance and ensuring the safe removal of combustion byproducts from the building. Regular inspections and maintenance are essential for preventing draft-related problems and safeguarding occupants.

2. Material Integrity

Material integrity, with respect to structures designed for expelling combustion byproducts that extend above a building’s roofline, is paramount for ensuring structural stability, operational efficiency, and occupant safety. The materials used in construction must withstand extreme temperature fluctuations, corrosive byproducts of combustion, and prolonged exposure to environmental elements. Degradation of materials compromises the systems ability to safely vent exhaust gases.

- Mortar Joint Deterioration

Mortar joints, the binding agent between bricks or stones, are particularly susceptible to degradation from freeze-thaw cycles and acidic condensation. Deteriorated mortar joints compromise the structural integrity, allowing moisture intrusion and creating pathways for exhaust gas leakage. Regular inspection and repointing are essential to maintain material integrity.

- Brick Spalling

Brick spalling, the surface flaking or crumbling of brickwork, is caused by water absorption followed by freezing and expansion. This process weakens the brick, leading to cracks and eventual disintegration. Protective sealants and proper construction techniques can mitigate spalling and extend the lifespan of brick structures.

- Liner Degradation

Flue liners, often made of clay, metal, or concrete, protect the surrounding masonry from the corrosive effects of combustion gases. Cracks, corrosion, or deterioration of the liner compromise its protective function, exposing the masonry to damaging acids and heat. Regular inspection and timely liner replacement are crucial for preserving overall structural integrity.

- Metal Component Corrosion

Metal components, such as caps, chase covers, and spark arrestors, are vulnerable to corrosion from atmospheric moisture and acidic flue gases. Rust and oxidation weaken these components, potentially leading to structural failure and impaired functionality. Protective coatings and regular maintenance can mitigate corrosion and ensure the long-term performance of metal components.

Maintaining the material integrity of structures designed for expelling combustion byproducts is not merely a matter of aesthetics but a critical safety concern. Failure to address material degradation can lead to structural collapse, hazardous gas leaks, and increased fire risk. Proactive maintenance, including regular inspections, timely repairs, and the use of appropriate materials, is essential for ensuring the continued safe and efficient operation of these vital building components.

3. Water Intrusion

Water intrusion poses a significant threat to the structural integrity and operational efficiency of any structure designed for expelling combustion byproducts. The combination of constant exposure to the elements and the porous nature of common construction materials creates vulnerabilities that can lead to substantial damage if left unaddressed.

- Freeze-Thaw Damage in Masonry

Water absorbed by brick, stone, or mortar expands upon freezing, creating internal pressure that can cause cracking, spalling, and disintegration. This process, repeated over time, weakens the structure and reduces its ability to effectively vent exhaust gases. Severe freeze-thaw damage may necessitate costly repairs or complete reconstruction.

- Corrosion of Metal Components

Water penetration accelerates corrosion of metal components, such as caps, dampers, and chase covers. Rust weakens these components, compromising their structural integrity and functionality. Damaged caps allow further water intrusion, while corroded dampers impede proper airflow. Regular inspection and rust prevention measures are essential for maintaining the lifespan of metal components.

- Damage to Flue Liners

Water intrusion can damage flue liners, particularly those made of clay or concrete. Water penetration weakens the liner, making it more susceptible to cracking or collapse. Damaged flue liners compromise the structural integrity and can lead to dangerous gas leaks into the building. Maintaining a watertight structure is crucial for protecting the flue liner.

- Moisture Damage to Interior Structures

Water that penetrates the structure can seep into the building’s interior, causing damage to ceilings, walls, and surrounding structures. This moisture can also promote mold growth, creating health hazards and further compromising the building’s structural integrity. Addressing water intrusion promptly prevents further damage to the building envelope.

The detrimental effects of water intrusion underscore the importance of preventative maintenance and prompt repairs. Regular inspections, proper sealing, and the installation of appropriate flashing are crucial for minimizing water damage and ensuring the long-term performance and safety of these rooftop structures.

4. Creosote Accumulation

Creosote accumulation within a structure designed for venting combustion byproducts represents a significant fire hazard and a critical factor affecting the system’s operational efficiency. This buildup results from the incomplete combustion of wood and other solid fuels, leading to the condensation of unburned gases and particulate matter on the inner surfaces of the flue.

- Formation and Composition

Creosote forms as a byproduct of incomplete combustion, consisting primarily of condensed volatile organic compounds, tars, and soot particles. These substances adhere to the interior of the flue, forming layers that can range from a flaky soot to a hardened, tar-like glaze. The composition and rate of accumulation depend on factors such as fuel type, combustion efficiency, and flue temperature.

- Stages of Accumulation and Fire Risk

Creosote accumulation progresses through three stages: a flaky, easily removed soot; a granular, harder deposit; and a glazed, tar-like coating. The glazed form poses the greatest fire risk, as it is highly combustible and difficult to remove. Even small amounts of glazed creosote can ignite and cause a dangerous flue fire.

- Impact on Draft and Efficiency

Creosote buildup restricts airflow within the flue, reducing draft efficiency. This diminished draft can lead to incomplete combustion, increased smoke production, and the potential for carbon monoxide to enter the living space. Restricted airflow also reduces the efficiency of the heating appliance, requiring more fuel to achieve the desired temperature.

- Prevention and Removal Methods

Preventing excessive creosote accumulation involves ensuring complete combustion through proper appliance operation, using seasoned firewood, and maintaining adequate airflow. Regular professional cleaning removes accumulated creosote, reducing the risk of fire and improving draft efficiency. Cleaning methods include mechanical brushing, chemical treatments, and power sweeping.

The relationship between these structures and creosote accumulation is one of direct consequence. Neglecting creosote management can compromise the structure’s functionality and safety, underscoring the necessity for diligent maintenance and professional oversight. Regular inspections and proactive cleaning are essential for mitigating the risks associated with creosote accumulation and ensuring the safe and efficient operation of the heating system.

5. Structural Stability

The structural stability of a structure designed for expelling combustion byproducts is paramount for ensuring long-term functionality, safety, and the protection of the building it serves. These vertical extensions are constantly subjected to environmental stresses, including wind loads, thermal expansion and contraction, and the weight of accumulated snow and ice. Compromised structural integrity can lead to collapse, posing a direct threat to life and property.

- Foundation and Support System Integrity

The foundation, whether integrated into the building’s structure or a separate footing, bears the entire weight of the system. Soil settling, erosion, or inadequate construction can compromise the foundation, leading to tilting, cracking, and instability of the structure above. A stable foundation is the essential first line of defense against structural failure.

- Masonry and Material Strength

Brick, stone, and mortar joints must possess adequate compressive strength and resistance to weathering. Deteriorated mortar joints, cracked bricks, or spalling can significantly weaken the structure, increasing its susceptibility to collapse, especially under wind or seismic loads. Regular inspections and timely repairs are crucial for maintaining material strength.

- Lateral Bracing and Support

Lateral bracing, often incorporating metal straps or anchors, provides resistance to lateral forces, such as wind loads. Insufficient or corroded bracing can allow the structure to sway or lean, increasing stress on the foundation and masonry. Proper bracing is essential for maintaining stability in high-wind areas.

- Flue Liner Integrity and Support

The flue liner, in addition to containing combustion gases, contributes to the overall structural integrity of the system. A damaged or collapsing flue liner can compromise the stability of the surrounding masonry. Proper support and timely replacement of damaged liners are vital for preventing structural problems.

Maintaining structural stability necessitates a comprehensive approach that addresses foundation integrity, material strength, lateral bracing, and flue liner condition. Regular professional inspections, prompt repairs, and adherence to building codes are essential for ensuring the long-term safety and functionality of these vital architectural components.

6. Cap Functionality

The terminal element atop a structure designed for venting combustion byproducts, commonly known as the cap, performs several critical functions essential to the overall performance and longevity of the system. Its design and maintenance directly influence draft efficiency, prevent water intrusion, and mitigate hazards associated with sparks and debris.

- Prevention of Precipitation Ingress

The primary function of the cap is to shield the flue from rain and snow. Water entry can damage the flue liner, corrode metal components, and reduce draft efficiency. A properly functioning cap prevents water intrusion, extending the lifespan of the structure and preventing costly repairs. The absence of a cap, or a damaged one, exposes the internal components to the elements, accelerating deterioration.

- Enhancement of Draft Stability

Certain cap designs, particularly those with specialized wind deflectors, enhance draft stability by minimizing the effects of wind gusts and preventing downdrafts. These caps redirect wind flow, ensuring a consistent upward draft and preventing smoke or exhaust gases from entering the building. In windy locations, a well-designed cap is essential for maintaining proper ventilation.

- Spark Arrest and Debris Exclusion

Caps equipped with mesh screens serve as spark arrestors, preventing embers from escaping and potentially igniting nearby combustible materials. They also prevent birds, animals, and debris from entering the flue, which can obstruct airflow and create fire hazards. Regular inspection and cleaning of the screen are necessary to maintain its effectiveness.

- Corrosion Protection of Crown

The cap can extend over the edges of the chimney crown, the top surface of the masonry structure, preventing water from directly contacting the crown. This protects the crown from freeze-thaw damage and helps maintain the structural integrity of the overall system. A properly sized and installed cap safeguards the investment in the structure.

The multifaceted functions of the cap underscore its importance in ensuring the safe and efficient operation of structures designed for expelling combustion byproducts. Regular inspections and maintenance of the cap are essential for preventing costly repairs, mitigating hazards, and extending the lifespan of the entire system.

7. Code Compliance

Adherence to established building codes is paramount for the safe and efficient operation of any rooftop structure designed for expelling combustion byproducts. These regulations are in place to safeguard occupants from fire hazards, carbon monoxide poisoning, and structural failures. Compliance encompasses various aspects of design, construction, and maintenance, ensuring the system meets minimum safety standards.

- Height and Clearance Regulations

Building codes specify minimum height requirements above the roofline and adjacent structures to ensure adequate draft and prevent downdrafts that could force combustion byproducts back into the building. Proper clearance from combustible materials is also mandated to reduce the risk of fire. Failure to comply with these regulations can lead to inadequate ventilation and increased fire hazards.

- Material and Construction Standards

Codes dictate the types of materials permitted for construction, requiring they meet specific standards for fire resistance, durability, and resistance to corrosion. Proper construction techniques, including mortar joint integrity and flue liner installation, are also stipulated to ensure structural stability and prevent gas leaks. Non-compliant materials or construction methods can compromise safety and shorten the lifespan of the structure.

- Flue Sizing and Appliance Compatibility

Regulations govern the sizing of the flue relative to the connected heating appliance to ensure proper draft and efficient removal of combustion byproducts. An improperly sized flue can lead to incomplete combustion, carbon monoxide production, and creosote buildup. Code compliance requires matching the flue size to the appliance’s output to ensure safe and efficient operation.

- Inspection and Maintenance Requirements

Many jurisdictions mandate regular inspections to identify potential hazards and ensure continued compliance with building codes. These inspections typically focus on structural integrity, flue condition, and creosote accumulation. Code compliance requires adherence to these inspection schedules and prompt correction of any identified deficiencies to maintain safety and prevent potential problems.

The facets of code compliance are all interconnected, working together to minimize risk and ensure the reliable performance of these rooftop structures. Neglecting any aspect of code compliance can have serious consequences, highlighting the need for diligent adherence to established regulations and professional oversight throughout the lifecycle of the system.

Frequently Asked Questions

The following questions address common concerns regarding the function, maintenance, and safety of structures designed for expelling combustion byproducts that are situated on rooftops.

Question 1: What are the primary dangers associated with a deteriorating structure designed for expelling combustion byproducts?

Deterioration can lead to structural collapse, creating a falling debris hazard. Cracks and breaches allow dangerous combustion gases, including carbon monoxide, to leak into the building. Impaired draft efficiency results in inefficient heating and increased fire risk due to creosote buildup.

Question 2: How frequently should structures designed for expelling combustion byproducts be inspected?

It is advisable to conduct a visual inspection at least annually, preferably before the start of the heating season. Systems serving solid-fuel appliances warrant more frequent inspections, potentially every few months during periods of heavy use. Professional inspections by qualified technicians are recommended periodically.

Question 3: What are the key indicators of water intrusion affecting a structure designed for expelling combustion byproducts?

Signs of water intrusion include spalling or crumbling brickwork, deteriorated mortar joints, staining on interior walls or ceilings near the structure, and the presence of efflorescence (a white, powdery deposit) on the exterior. Dampness or water leaks within the firebox also suggest water infiltration.

Question 4: Why is creosote buildup a significant concern in structures designed for expelling combustion byproducts?

Creosote is a highly flammable byproduct of incomplete combustion that accumulates on the inner walls of the flue. This buildup restricts airflow, reduces draft efficiency, and, most importantly, poses a significant fire hazard. A creosote fire can reach extremely high temperatures and spread rapidly, potentially leading to structural damage and building fires.

Question 5: What is the purpose of a cap on a structure designed for expelling combustion byproducts, and why is its condition important?

The cap prevents rain, snow, and debris from entering the flue, protecting the interior from water damage and blockages. It also functions as a spark arrestor, preventing embers from escaping and potentially igniting nearby combustible materials. A damaged or missing cap compromises these protective functions and can lead to various problems.

Question 6: Are there specific building code requirements that govern the construction and maintenance of structures designed for expelling combustion byproducts?

Yes, building codes address various aspects, including minimum height requirements, material specifications, flue sizing, and clearance from combustible materials. These codes are designed to ensure safety and prevent fire hazards. Adherence to local building codes is mandatory and may require periodic inspections.

Proper maintenance and adherence to safety standards are essential for mitigating the risks associated with structures designed for expelling combustion byproducts.

The next section will provide detailed guidance on troubleshooting common problems associated with these structures.

Conclusion

The preceding discussion has illuminated the multifaceted nature of rooftop chimneys, encompassing aspects of design, maintenance, safety, and regulatory compliance. From ensuring structural integrity and material durability to managing draft efficiency and preventing hazardous creosote accumulation, the effective operation of these systems is crucial for maintaining indoor air quality and preventing potential fire hazards.

Given the inherent complexities and potential dangers associated with rooftop chimneys, it is imperative to prioritize regular professional inspections and proactive maintenance. Neglecting these essential tasks can lead to costly repairs, compromised safety, and potential structural failure. Continued vigilance and adherence to established safety protocols will ensure the long-term functionality and security of these essential architectural elements.

![Achieve Five Star Chimney Performance: [Your City] Experts Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Achieve Five Star Chimney Performance: [Your City] Experts | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/02/th-125-300x200.jpg)