A structure designed for venting combustion byproducts from heating appliances and fireplaces in dwellings situated within the Portland metropolitan area. These structures, typically vertical, facilitate the safe expulsion of smoke, gases, and particulate matter produced during the burning of fuels such as wood, natural gas, or oil. Their presence is essential for maintaining indoor air quality and preventing the accumulation of hazardous substances.

Proper construction and maintenance of these structures are crucial for ensuring the safety and efficiency of heating systems. A well-maintained structure prevents dangerous backdrafts of carbon monoxide into the living space and minimizes the risk of chimney fires caused by creosote buildup. Historically, these structures have played a significant role in residential heating, evolving in design and materials in response to changing architectural styles and fuel types.

The following article delves into the specific regulations, maintenance practices, common issues, and professional services related to these vital components of Portland residences.

Maintenance and Safety Guidance

Adhering to consistent maintenance protocols and safety measures is paramount for optimal performance and risk mitigation. These guidelines contribute to the longevity of the structure and the well-being of occupants.

Tip 1: Schedule Annual Inspections. A certified professional should conduct a comprehensive assessment annually. This inspection identifies potential structural deficiencies, blockages, and creosote buildup, facilitating timely repairs and preventative measures.

Tip 2: Prioritize Regular Cleaning. Periodic removal of creosote is essential to prevent chimney fires. The frequency of cleaning depends on the type of fuel used and the intensity of usage, but at least once per year is generally recommended.

Tip 3: Ensure Proper Ventilation. Adequate airflow is crucial for efficient combustion and the proper venting of gases. Verify that the flue is appropriately sized for the connected appliance to avoid backdrafting.

Tip 4: Monitor for Signs of Damage. Regularly inspect the structure for cracks, spalling brick, or damaged mortar. Address these issues promptly to prevent further deterioration and potential hazards.

Tip 5: Use Approved Fuel Types. Utilizing the correct fuel for the appliance is vital. Burning unseasoned wood or inappropriate materials can lead to excessive creosote buildup and increase the risk of chimney fires.

Tip 6: Install Carbon Monoxide Detectors. Carbon monoxide (CO) detectors should be installed on every level of the residence, particularly near sleeping areas. Regularly test and maintain these detectors to ensure proper functionality.

Tip 7: Maintain Clearances. Ensure that flammable materials are kept a safe distance from the chimney structure and any connected appliances. Adhering to recommended clearance guidelines minimizes the risk of fire.

Consistent implementation of these strategies enhances the safety, efficiency, and lifespan of the structure. Proactive maintenance mitigates potential risks and ensures proper functionality.

The following sections will address common problems and professional services available in the Portland area.

1. Inspection frequency

The frequency with which a chimney is inspected directly impacts its safety and operational effectiveness. Inadequate inspection intervals can lead to undetected structural degradation, creosote accumulation, or blockages. These conditions, in turn, elevate the risk of chimney fires, carbon monoxide intrusion into the dwelling, and diminished heating system efficiency. Conversely, regular, scheduled inspections allow for the early identification and remediation of potential problems, preventing costly repairs and safeguarding occupants.

For instance, annual inspections conducted by certified professionals in the Portland area often reveal cracks in the flue liner, which can compromise the chimney’s ability to properly vent combustion gases. Addressing these cracks promptly prevents further deterioration and potential carbon monoxide leaks. Similarly, consistent inspection and cleaning schedules mitigate the buildup of creosote, a highly flammable byproduct of wood burning. Ignoring recommended inspection intervals significantly increases the likelihood of a chimney fire, particularly during periods of heavy use.

Therefore, establishing and adhering to a recommended inspection schedule is not merely a preventative measure; it is a critical component of responsible chimney ownership. The consequences of neglecting inspection frequency range from minor efficiency losses to significant safety hazards, underscoring the practical importance of integrating this practice into routine home maintenance. A proactive approach ensures the continued safe and efficient operation of the heating system and protects the well-being of the household.

2. Creosote Removal

The accumulation of creosote within a Portland chimney is a direct consequence of incomplete combustion during the burning of solid fuels, primarily wood. This tar-like substance condenses on the interior surfaces of the chimney as flue gases cool, forming layers that progressively reduce the chimney’s draft capacity and significantly increase the risk of chimney fires. The severity of creosote buildup is influenced by factors such as the type of wood burned (softwoods tend to produce more creosote), the moisture content of the wood (wet wood burns less efficiently), and the operating temperature of the heating appliance. Failure to address creosote accumulation poses a substantial threat to the structural integrity of the chimney and the safety of the residence.

Regular and thorough removal of creosote is an indispensable component of chimney maintenance in Portland. Professional chimney sweeps employ specialized tools and techniques, such as rotary brushes and vacuum systems, to effectively dislodge and extract creosote deposits from the flue. The frequency of creosote removal is contingent on the frequency and intensity of wood burning, but annual cleaning is generally recommended, and more frequent cleaning may be necessary for households that rely heavily on wood-burning stoves or fireplaces. Neglecting this crucial maintenance step can result in a chimney fire, which can rapidly escalate, causing extensive damage to the dwelling and posing a serious risk to life.

In conclusion, the proper and timely removal of creosote is not merely a best practice for Portland chimneys; it is an essential safety measure. The proactive management of creosote buildup mitigates the risk of chimney fires, ensures optimal heating system efficiency, and contributes to the overall longevity of the chimney structure. Homeowners should prioritize regular creosote removal as part of a comprehensive chimney maintenance program to safeguard their property and the well-being of their families.

3. Flue Sizing and Portland Chimneys

Flue sizing represents a critical engineering consideration in the context of Portland chimneys. The correct flue size ensures optimal venting of combustion byproducts, influencing both the efficiency of the heating appliance and the safety of the occupants.

- Draft Optimization

An appropriately sized flue generates sufficient draft, the negative pressure that draws combustion gases up and out of the chimney. Undersized flues can impede draft, leading to backdrafting, where dangerous gases like carbon monoxide enter the living space. Oversized flues, conversely, may cool too rapidly, causing condensation and creosote buildup, which can lead to chimney fires. Therefore, accurate flue sizing is paramount for maintaining a safe and efficient venting system. In Portland, where a variety of heating appliances are used, correct flue dimensions are crucial.

- Appliance Compatibility

Different heating appliances, such as wood stoves, fireplaces, and furnaces, require specific flue sizes to function optimally. The appliance manufacturer typically specifies the required flue diameter or area. Installing an appliance with an incompatible flue size can compromise its performance and increase the risk of hazardous conditions. For example, connecting a high-efficiency furnace to an oversized flue designed for a traditional fireplace can result in excessive condensation and corrosion within the chimney. In Portland’s diverse housing stock, matching flue size to appliance type is essential during installation or replacement projects.

- Code Compliance

Local building codes and regulations in Portland mandate adherence to established standards for flue sizing. These codes are designed to ensure the safe and proper venting of combustion gases and to minimize the risk of fire and carbon monoxide poisoning. Code compliance typically involves consulting tables or formulas that consider factors such as appliance input rating, chimney height, and climate conditions. Failure to comply with these regulations can result in penalties and require costly remediation to bring the chimney into conformity. Homeowners should always consult with qualified professionals to ensure adherence to applicable codes during chimney construction or modification.

- Material Considerations

The flue liner material affects sizing calculations due to its thermal properties and internal dimensions. Clay tile liners, common in older Portland chimneys, have different insulating properties compared to stainless steel liners, which can affect draft and condensation rates. Similarly, the internal dimensions of different liner types may vary slightly, requiring adjustments to the overall flue size to maintain optimal performance. When relining an existing chimney, the choice of liner material and its corresponding dimensions must be carefully considered to ensure compatibility with the connected appliance and compliance with local codes.

In summary, proper flue sizing is an indispensable aspect of chimney design and maintenance in Portland. Correct dimensions, aligned with appliance specifications, local codes, and material considerations, ensure efficient venting, minimize safety risks, and contribute to the overall performance of the heating system.

4. Material Integrity

Material integrity is a fundamental aspect of a Portland chimney’s structural soundness and operational safety. The long-term durability and performance of these structures are directly contingent upon the quality, condition, and maintenance of the materials used in their construction. Compromised material integrity can lead to a range of issues, from reduced efficiency to catastrophic failure.

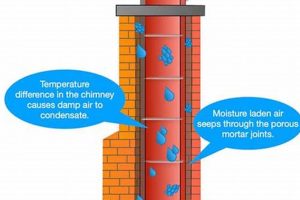

- Brick and Mortar Degradation

Brick and mortar constitute the primary building materials for many Portland chimneys. Over time, exposure to the elements, including freeze-thaw cycles and acidic precipitation, can cause the brick to spall (flake or chip) and the mortar to deteriorate. Deteriorated mortar joints allow water infiltration, exacerbating the damage and potentially weakening the entire structure. Regular inspections and timely repairs, such as tuckpointing (replacing damaged mortar), are essential to maintain the integrity of the brickwork.

- Flue Liner Cracks and Spalling

The flue liner, typically made of clay tile or metal, provides a protective barrier between the combustion gases and the chimney’s structural components. Cracks, spalling, or complete failure of the flue liner can allow hot gases and corrosive byproducts to penetrate the chimney walls, leading to structural damage and increasing the risk of chimney fires and carbon monoxide leaks. Regular inspections using a chimney camera can detect hidden flue liner damage, allowing for prompt repairs or relining.

- Crown Deterioration

The chimney crown, the concrete or mortar slab that covers the top of the chimney, is designed to prevent water from entering the chimney structure. Cracks, erosion, or complete failure of the crown allow water to penetrate the chimney, accelerating the deterioration of the brick and mortar. A properly constructed and maintained crown is essential for protecting the chimney from water damage and extending its lifespan. The material integrity of the crown itself is therefore essential to chimney longevity.

- Metal Component Corrosion

Metal components, such as chimney caps, chase covers, and flashing, are susceptible to corrosion, particularly in Portland’s wet climate. Corrosion can weaken these components, compromising their ability to protect the chimney from the elements and allowing water to enter the structure. Regular inspections and maintenance, including rust removal and protective coatings, can help prevent corrosion and extend the lifespan of metal chimney components. Furthermore, appropriate material selection during installation (e.g., stainless steel) can mitigate corrosion risks.

These aspects of material integrity are critical determinants of a Portland chimney’s longevity and safety. Ignoring these factors leads to accelerated deterioration, increased repair costs, and heightened risks of fire and carbon monoxide exposure. Proactive maintenance and timely repairs, based on thorough inspections, are essential for preserving material integrity and ensuring the continued safe and efficient operation of the chimney.

5. Code Compliance and Portland Chimneys

Strict adherence to building codes is essential for ensuring the safety and functionality of chimneys within the Portland metropolitan area. These codes establish minimum standards for construction, materials, and installation practices, mitigating risks associated with fire, carbon monoxide exposure, and structural failure. Neglecting code compliance can lead to hazardous conditions, legal liabilities, and increased insurance costs.

- Permitting Requirements

In Portland, obtaining the necessary permits prior to constructing, altering, or repairing a chimney is a mandatory step in ensuring code compliance. Permit applications typically require detailed plans and specifications, demonstrating that the proposed work meets the requirements of the applicable building codes. Failure to obtain the required permits can result in fines, stop-work orders, and the potential for forced removal of non-compliant structures. Furthermore, obtaining permits triggers inspections by local authorities, providing an additional layer of oversight and quality control.

- Materials and Construction Standards

Building codes specify the acceptable materials and construction methods for chimneys, ensuring that they are structurally sound and resistant to fire and environmental degradation. For instance, codes may dictate the type and thickness of flue liners, the minimum height of the chimney above the roofline, and the required clearances between the chimney and combustible materials. Adherence to these standards is crucial for preventing chimney fires, ensuring proper venting of combustion gases, and maintaining the long-term integrity of the structure.

- Clearance and Fire Safety Regulations

Portland’s building codes include stringent regulations regarding the clearance between chimneys and combustible materials, such as wood framing, roofing materials, and siding. These regulations are designed to prevent the ignition of surrounding materials in the event of a chimney fire or excessive heat transfer. Codes also dictate the requirements for firestopping, which involves sealing gaps and penetrations around the chimney to prevent the spread of fire. Compliance with these clearance and fire safety regulations is paramount for protecting the occupants of the building and preventing property damage.

- Seismic Considerations

Given Portland’s location in a seismically active region, building codes address the specific requirements for chimney construction to withstand earthquake forces. These requirements may include reinforcing the chimney structure with steel rebar, anchoring the chimney to the building foundation, and ensuring that the chimney is properly braced. Adherence to seismic codes is crucial for preventing chimney collapse during an earthquake, which could result in significant property damage and potential injury or loss of life. Regular inspections following seismic events are recommended to assess potential damage and ensure continued structural integrity.

These interconnected facets demonstrate the critical importance of code compliance for chimneys in the Portland area. While stringent, these regulations serve to protect homeowners and the broader community from the inherent risks associated with improperly constructed or maintained chimney systems. Professional chimney service providers are well-versed in local codes and can ensure that all work is performed in accordance with applicable regulations, providing peace of mind and safeguarding against potential hazards.

6. Draft Performance and Portland Chimneys

Draft performance, the capacity of a chimney to effectively exhaust combustion byproducts, is inextricably linked to the safety and efficiency of heating systems in Portland residences. Inadequate draft can lead to the accumulation of hazardous gases, such as carbon monoxide, within the dwelling, posing a significant health risk to occupants. Furthermore, poor draft performance diminishes the efficiency of heating appliances, resulting in increased fuel consumption and higher energy costs. Conversely, optimal draft performance ensures the safe and complete removal of combustion gases, maximizing heating system efficiency and minimizing the risk of indoor air pollution. Inefficient draft happens because of blocked chimney.

Several factors influence draft performance in Portland chimneys, including chimney height, flue size, prevailing wind conditions, and the presence of obstructions, such as bird nests or creosote buildup. Taller chimneys generally generate stronger draft due to the increased pressure differential between the base and the top of the structure. However, chimney height must be appropriately matched to the heating appliance; excessively tall chimneys can lead to over-drafting, which can cool the flue gases too rapidly and result in condensation and creosote formation. Local topography and building height can also significantly impact draft performance, as wind patterns can create downdrafts that impede the upward flow of combustion gases. Blocked chimney will lead to inefficient draft performance.

Therefore, assessing and optimizing draft performance is a critical component of chimney maintenance and safety inspections in the Portland area. Qualified professionals employ specialized tools, such as draft gauges and smoke pencils, to measure draft levels and identify potential problems. Corrective measures may include chimney cleaning, flue relining, chimney height adjustments, or the installation of draft-enhancing devices, such as chimney caps or barometric dampers. Ultimately, ensuring proper draft performance is essential for maintaining a safe, efficient, and environmentally responsible heating system in Portland homes.

7. Professional Repair

Specialized interventions are frequently required to address issues impacting the structural integrity and operational efficiency of chimneys in the Portland area. These structures, subject to environmental stressors and the effects of combustion, necessitate qualified expertise for effective remediation.

- Structural Stabilization

Chimneys can exhibit structural weaknesses stemming from age, seismic activity, or water damage. Professional repair services often involve reinforcing the chimney stack with techniques such as tuckpointing, brick replacement, or the installation of steel supports. These interventions are designed to prevent collapse and ensure the long-term stability of the structure, mitigating potential hazards to the building and its occupants. Ignoring structural issues will lead to future chimney removal.

- Flue Relining

Deterioration of the flue liner, the internal conduit for combustion gases, compromises the chimney’s ability to safely vent these byproducts. Professional repair includes flue relining, which involves installing a new liner to restore the chimney’s integrity and prevent the escape of hazardous gases into the living space. Relining materials can vary, with options such as stainless steel, clay tile, and cast-in-place liners, each offering different levels of durability and thermal performance.

- Water Intrusion Mitigation

Water penetration is a significant threat to chimney longevity, accelerating the deterioration of brick, mortar, and other components. Professional repair addresses water intrusion through measures such as crown repair, flashing replacement, and the application of waterproofing sealants. These interventions aim to prevent further damage and protect the chimney from the damaging effects of Portland’s wet climate. This is especially necessary after strong storm.

- Draft Correction

Insufficient draft, the upward flow of combustion gases, can lead to backdrafting and the accumulation of carbon monoxide within the dwelling. Professional repair addresses draft issues through techniques such as chimney height adjustments, flue extensions, or the installation of draft-enhancing devices. These interventions aim to optimize draft performance, ensuring the safe and efficient venting of combustion byproducts. Ignoring draft issues will lead to serious health concern.

Professional repair of these structures in Portland is not merely a cosmetic undertaking; it is a crucial component of maintaining residential safety and preserving property value. Addressing structural weaknesses, flue liner damage, water intrusion, and draft deficiencies requires specialized expertise and adherence to established building codes, underscoring the importance of engaging qualified professionals for chimney maintenance and repair.

Frequently Asked Questions About Portland Chimneys

The following addresses common inquiries regarding the construction, maintenance, and safety of these structures in the Portland metropolitan area.

Question 1: What is the recommended frequency for chimney inspections?

Annual inspections conducted by a certified chimney sweep are strongly advised. More frequent inspections may be necessary for chimneys serving wood-burning appliances that are used extensively.

Question 2: How often should a chimney be cleaned?

Chimney cleaning frequency depends on the type of fuel burned and the amount of usage. However, at least once per year is generally recommended to remove creosote buildup and prevent chimney fires.

Question 3: What are the signs of a damaged chimney?

Visible signs of damage may include cracked or spalling brick, deteriorated mortar joints, a leaning chimney stack, and water leaks inside the dwelling near the chimney.

Question 4: Is it safe to burn wet or unseasoned wood in a fireplace?

No. Burning wet or unseasoned wood produces more smoke and creosote, increasing the risk of chimney fires and reducing heating efficiency. Only dry, seasoned wood should be used.

Question 5: What is the purpose of a chimney cap?

A chimney cap prevents rain, snow, leaves, and animals from entering the chimney. It also helps to prevent downdrafts and improve draft performance.

Question 6: What should be done if a chimney fire occurs?

If a chimney fire occurs, immediately evacuate the building and call the fire department. Do not attempt to extinguish the fire yourself. After the fire is extinguished, have the chimney inspected by a qualified professional before using it again.

Consistent maintenance and prompt attention to potential problems are essential for ensuring the safe and efficient operation of this vital residential component.

The next section provides resources for locating qualified chimney service professionals in the Portland area.

Portland Chimney

This exploration has underscored the critical role these structures play in the safety and functionality of Portland residences. Key considerations include regular inspections, meticulous creosote removal, appropriate flue sizing, maintaining material integrity, and ensuring strict code compliance. Neglecting these aspects poses significant risks, potentially leading to chimney fires, carbon monoxide leaks, and structural failures.

Therefore, prioritizing proactive maintenance and engaging qualified professionals are not merely advisable, but essential for preserving the integrity of these vital components. Continued vigilance and informed decision-making will contribute to the safety and well-being of Portland communities for years to come.