A residential or industrial vertical exhaust system comprises numerous components working in concert to expel combustion byproducts safely. These elements facilitate the efficient removal of smoke, gases, and particulate matter from fireplaces, furnaces, and other heating appliances.

The integrity of this structure is vital for preventing fire hazards and maintaining indoor air quality. Historically, their design has evolved from simple smoke holes to complex engineered systems incorporating advanced materials and techniques. Proper functionality ensures efficient heating and protects inhabitants from dangerous emissions.

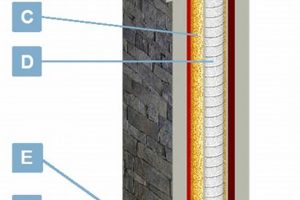

This discussion will outline the key elements constituting a standard system, including the flue liner, chimney cap, crown, flashing, and various other integral components. Each plays a crucial role in the overall performance and safety of the exhaust system.

Guidance on Maintaining a Residential Exhaust System

Proper maintenance of the system is crucial for its longevity and safe operation. Regular inspection and timely repairs can prevent costly damage and potential hazards. The following points offer essential guidance.

Tip 1: Schedule Annual Inspections: A qualified professional should conduct a thorough assessment each year to identify potential issues such as cracks, deterioration, or blockages. Early detection can prevent minor problems from escalating into major repairs.

Tip 2: Clean the Flue Regularly: Creosote buildup within the flue is a significant fire hazard. The frequency of cleaning depends on usage, but at least an annual cleaning is recommended for wood-burning fireplaces.

Tip 3: Ensure Proper Termination Height: The system should extend at least three feet above the roofline and two feet above any structure within ten feet to ensure adequate draft and prevent downdrafts.

Tip 4: Check the Condition of the Cap: A functional cap prevents water, debris, and animals from entering the flue. Examine the cap regularly for damage and replace it as needed.

Tip 5: Monitor Flashing Integrity: The flashing creates a watertight seal where the structure meets the roof. Inspect the flashing for signs of corrosion, damage, or gaps, and repair promptly to prevent leaks.

Tip 6: Address Cracks in the Crown: The crown protects the structure from water damage. Any cracks should be sealed immediately to prevent water penetration and further deterioration.

Tip 7: Utilize Appropriate Fuel: Burning only seasoned wood or the fuel specified for the appliance prevents excessive creosote buildup and extends the life of the flue liner.

Adherence to these guidelines will contribute to the efficient and safe operation of the system. Ignoring these preventative measures can result in serious safety risks and costly repairs.

The subsequent sections will provide a more in-depth analysis of specific components and their functions.

1. Flue Liner

The flue liner is a critical component within the broader framework of a chimney system. Its primary function is to contain and safely vent the products of combustion from a fireplace, furnace, or other heating appliance. Without a properly functioning liner, the structural integrity of the chimney itself is at risk, along with the safety of the building’s occupants.

- Protection Against Combustible Gases

The liner shields the chimney’s masonry from corrosive gases and high temperatures produced during combustion. For instance, acidic compounds present in flue gases can deteriorate brick and mortar, leading to structural damage. A stainless steel or ceramic liner provides a barrier against these damaging effects.

- Prevention of Carbon Monoxide Leakage

A damaged or absent liner can allow carbon monoxide, a deadly odorless gas, to leak into the building’s living spaces. A properly sealed liner ensures that combustion byproducts are directed safely upwards and out of the chimney. Regular inspections and maintenance can identify and address any cracks or breaches in the liner.

- Optimization of Draft Efficiency

A correctly sized and smooth liner contributes to optimal draft, which is essential for efficient combustion and preventing smoke from backing up into the living space. A rough or undersized liner can impede airflow, resulting in poor combustion and potential hazards. Selecting the appropriate liner material and diameter is critical for proper system performance.

- Compliance with Building Codes and Safety Standards

Most building codes mandate the installation of a flue liner to meet safety regulations and ensure the safe operation of heating appliances. Adherence to these codes helps prevent fires and carbon monoxide poisoning. Inspections and certifications verify that the installation meets the required safety standards.

The flue liner is an indispensable element for a functional chimney. Its presence ensures safe operation, protects the structure, and complies with safety standards. Neglecting its importance can lead to hazardous conditions and costly repairs, emphasizing the significance of understanding this component within the complete chimney system.

2. Chimney Cap

The chimney cap constitutes a critical element within a functional exhaust system. As an integral component of residential or industrial vertical exhaust system, its presence directly influences the overall performance, safety, and longevity of the entire structure. The absence or malfunction of this element can initiate a cascade of adverse effects, impacting other integral elements and compromising the entire system’s integrity.

Consider, for instance, a system exposed to frequent rainfall without a properly installed cap. Water ingress can accelerate the deterioration of the flue liner, leading to cracks and structural weaknesses. This, in turn, diminishes the liner’s ability to effectively contain corrosive combustion byproducts, potentially damaging the masonry and increasing the risk of carbon monoxide intrusion into the building. Furthermore, the ingress of debris, such as leaves and twigs, can obstruct the flue, impeding the proper expulsion of smoke and gases, thus creating a potential fire hazard. Wildlife intrusion, such as nesting birds or squirrels, can also lead to blockages requiring costly removal and repairs. These examples underscore the chimney cap’s pivotal role in preventing damage to other associated elements.

In summary, the chimney cap is more than a mere aesthetic addition; it serves as a primary defense against external elements that can degrade the performance and safety of the entire exhaust structure. Its proper installation and maintenance are essential for safeguarding the system from water damage, debris accumulation, and animal intrusion. Recognizing the interplay between this element and other aspects of the system provides crucial insight into maintaining a safe and functional exhaust system.

3. Smoke Chamber

The smoke chamber forms a crucial transition zone within the structure, connecting the firebox to the flue. This tapered area plays a significant role in directing combustion gases upward and into the flue, contributing to overall efficiency and safety.

- Transition and Compression of Smoke

The smoke chamber’s primary function is to efficiently channel smoke and hot gases from the relatively wide firebox into the narrower flue. The angled walls compress the smoke, increasing its velocity and facilitating a smoother transition into the flue, thereby enhancing draft. Without this compression, smoke can cool and stagnate, potentially leading to backdrafts and reduced system efficiency.

- Reduction of Turbulence

The tapered design minimizes turbulence as combustion gases rise. Turbulence disrupts airflow, reducing draft and increasing the likelihood of smoke spillage into the living space. A properly constructed chamber with smooth, parged walls helps maintain a laminar flow, ensuring efficient and predictable exhaust.

- Parging and Insulation

The interior of the smoke chamber should be parged with a heat-resistant mortar to create a smooth, airtight surface. This parging prevents gases from seeping through cracks in the masonry, which could lead to carbon monoxide leaks. Additionally, some modern designs incorporate insulation within the smoke chamber to further reduce heat loss and improve efficiency.

- Connection to the Flue Liner

The smoke chamber provides a direct connection point to the flue liner. The liner, extending from the chamber to the top of the chimney, protects the chimney’s masonry from corrosive gases and high temperatures. A secure and properly aligned connection between the chamber and liner is vital for preventing leaks and ensuring the long-term integrity of the entire system.

These aspects of the smoke chamber illustrate its significance within the broader system. It is integral to facilitate proper drafting. Furthermore, this is to say that all components of the system must function correctly to ensure the safe and efficient removal of combustion byproducts.

4. Chimney Crown

The chimney crown, an often-overlooked component, represents a critical protective element within the complete assembly of a chimney system. Positioned atop the chimney stack, it acts as a shield, preventing water intrusion and safeguarding the underlying structure. Understanding its function is essential to appreciate its role amongst the various parts that contribute to a chimneys integrity.

- Water Diversion and Masonry Protection

The primary function of the crown is to deflect rainwater, snow, and ice away from the chimney’s flue and masonry. Without a properly constructed crown, water can penetrate the porous brickwork, leading to freeze-thaw damage during colder months. This deterioration can compromise the chimney’s structural integrity, necessitating costly repairs. The crown’s overhang design is crucial for effectively diverting water and minimizing its contact with the chimney’s surfaces.

- Prevention of Flue Liner Deterioration

The chimney crown indirectly protects the flue liner by preventing water from entering the chimney system. Water within the flue can accelerate the corrosion of metal liners and the degradation of clay tile liners. A well-maintained crown helps prolong the lifespan of the flue liner, ensuring its continued effectiveness in safely venting combustion gases.

- Material Composition and Construction

Chimney crowns are typically constructed from concrete, cement mortar, or metal. Concrete crowns should be properly reinforced to prevent cracking and should have a smooth, sloping surface to facilitate water runoff. Mortar crowns, while less durable than concrete, can be used for smaller chimneys. Metal crowns offer excellent water protection and durability but must be properly installed to prevent corrosion. The choice of material and construction method should be based on the chimney’s size, climate, and aesthetic considerations.

- Maintenance and Repair Considerations

Regular inspection of the chimney crown is essential for identifying cracks, spalling, or other damage. Small cracks can be sealed with a waterproof sealant, while more extensive damage may require patching or complete crown replacement. Addressing crown issues promptly prevents water damage from escalating and compromising the entire chimney system. Proper maintenance ensures the long-term effectiveness of this crucial protective element.

In conclusion, the chimney crown plays an important role in protecting the entire chimney structure. Its function in diverting water away from the masonry and flue liner extends the lifespan of these components. Its importance to the structure’s performance makes regular maintenance vital for its longevity.

5. Flashing

Flashing serves as a critical component in the context of a chimney system, forming a watertight barrier where the structure intersects with the roofline. Its function is paramount to prevent water intrusion, which can lead to significant damage to both the chimney itself and the surrounding building structure.

- Material Compatibility and Corrosion Prevention

The choice of flashing material must be compatible with both the roofing material and the chimney’s construction to prevent galvanic corrosion. For instance, using aluminum flashing with copper roofing can accelerate corrosion of the aluminum. Selecting appropriate materials, such as stainless steel or copper, ensures longevity and prevents leaks that can damage the chimney’s masonry and internal components.

- Proper Installation Techniques and Sealing

Effective flashing installation requires precise techniques, including step flashing interwoven with roofing shingles and a counter-flashing embedded in the chimney’s mortar joints. Improper installation, such as insufficient overlap or poorly sealed seams, can create pathways for water ingress. Applying a high-quality sealant at all joints and edges is crucial for maintaining a watertight barrier and preventing moisture-related damage.

- Prevention of Water Damage to Chimney Components

Flashing protects various chimney elements, including the flue liner, smoke chamber, and chimney crown, from water damage. Water penetration can cause the flue liner to crack, the smoke chamber to deteriorate, and the crown to spall and crumble. Properly installed flashing prevents these issues, preserving the chimney’s structural integrity and ensuring its safe and efficient operation. For instance, a damaged flue liner can lead to carbon monoxide leaks, posing a serious health risk to building occupants.

- Integration with Roofing System and Building Envelope

Flashing must be seamlessly integrated with the existing roofing system to provide comprehensive protection against water intrusion. This involves properly overlapping the flashing with the roofing materials and ensuring that the flashing extends far enough up the chimney to prevent water from bypassing the barrier. A well-integrated flashing system contributes to the overall integrity of the building envelope, preventing water damage to interior walls, ceilings, and insulation.

In summary, flashing functions as an essential safeguard, protecting both the chimney’s structural components and the building’s interior from the detrimental effects of water damage. Selection of the appropriate materials and the application of proper installation techniques are vital for its effectiveness in maintaining a safe and durable system.

6. Firebox

The firebox is the foundational element within a chimney system, directly interacting with the combustion process. Its design and integrity profoundly impact the function of subsequent elements, influencing overall performance and safety. Serving as the chamber where fuel is burned, the firebox endures extreme temperatures and must be constructed to withstand prolonged exposure to heat and flames. A compromised firebox can lead to structural damage, increased creosote buildup, and potential fire hazards affecting other integral components. For instance, cracks in the firebox masonry can allow heat to transfer to combustible materials in the adjacent structure, posing a significant risk.

The dimensions and shape of the firebox are also crucial. An improperly sized firebox may lead to incomplete combustion, resulting in increased smoke production and inefficient heating. This, in turn, places a greater burden on the flue liner, potentially accelerating its deterioration due to the increased exposure to corrosive gases. Furthermore, an inefficient firebox can contribute to higher creosote accumulation within the flue, heightening the risk of chimney fires. Consider the example of a shallow firebox design, which often results in more smoke escaping into the room when the fireplace door is opened, necessitating a more robust chimney draft to compensate.

In essence, the firebox is more than just a container for burning fuel; it is a critical determinant of the entire chimney system’s efficiency and safety. Maintaining the firebox in good repair, ensuring its proper dimensions, and utilizing appropriate fuel are essential for optimal performance and longevity of the chimney. Neglecting the condition of the firebox can trigger a chain of events that compromises the functionality and safety of the entire vertical exhaust system, highlighting the inseparable connection between this core element and its associated components.

7. Cleanout Door

The cleanout door, while often inconspicuous, represents an integral access point within a system, directly impacting maintenance efficiency and overall safety. Its placement and functionality are critical considerations in the design and upkeep of the entire structure.

- Facilitating Ash and Debris Removal

The primary purpose of the cleanout door is to provide access for removing accumulated ash, soot, and debris from the base. Without a functional door, cleaning the chimney becomes significantly more difficult, potentially leading to hazardous buildup and reduced efficiency. For example, creosote accumulation in wood-burning systems can create a serious fire risk if not regularly removed. A properly located and accessible cleanout door streamlines this process.

- Preventing Chimney Blockages

The cleanout door allows for the inspection and removal of obstructions that may impede airflow. Birds’ nests, fallen leaves, and other debris can block the flue, leading to backdrafts and carbon monoxide buildup. Regular access through the cleanout door enables homeowners or professionals to identify and clear these blockages before they cause significant problems. Imagine a scenario where a bird’s nest completely blocks the flue; the cleanout door provides the only practical access point for its removal.

- Enhancing Inspection Capabilities

A cleanout door offers a convenient point for inspecting the condition of the chimney’s interior. Using a flashlight or camera, one can assess the state of the flue liner, check for cracks or damage, and identify potential issues before they escalate. This proactive approach can prevent costly repairs and ensure the safe operation of the entire system. For instance, a cracked flue liner discovered during a routine inspection through the cleanout door can be repaired before it leads to carbon monoxide leaks or structural damage.

- Reducing Maintenance Costs

By simplifying cleaning and inspection, the cleanout door contributes to reduced long-term maintenance costs. Regular cleaning prevents the buildup of creosote and other deposits that can damage the chimney’s structure. Early detection of problems through inspection allows for timely repairs, avoiding more extensive and expensive interventions later. A properly maintained cleanout door, therefore, represents a cost-effective investment in the overall health and longevity of the entire exhaust system.

In summary, the cleanout door plays a vital role in facilitating maintenance, preventing blockages, enhancing inspection capabilities, and reducing maintenance costs. Its presence and functionality are essential considerations for ensuring the safe and efficient operation of a residential or industrial vertical exhaust system.

Frequently Asked Questions

The following questions address common inquiries regarding components and their respective functions within residential and industrial vertical exhaust systems.

Question 1: What is the purpose of a flue liner, and what materials are commonly used for its construction?

The flue liner serves to protect the chimney’s masonry from corrosive combustion byproducts and high temperatures. Common materials include clay tile, stainless steel, and cast-in-place concrete. The choice of material depends on the type of heating appliance and local building codes.

Question 2: How does a chimney cap contribute to the overall performance and longevity of the structure?

The chimney cap prevents water, debris, and animals from entering the flue, thereby minimizing moisture damage, blockages, and potential fire hazards. A properly installed cap extends the life of the chimney and ensures efficient drafting.

Question 3: What role does the smoke chamber play in directing combustion gases, and why is its shape important?

The smoke chamber connects the firebox to the flue, compressing and channeling combustion gases upward. Its tapered shape minimizes turbulence, promotes efficient drafting, and reduces the risk of smoke spillage.

Question 4: Why is a chimney crown necessary, and what are the key considerations for its construction and maintenance?

The chimney crown prevents water from penetrating the chimney’s masonry, protecting it from freeze-thaw damage. Key considerations include using durable materials like concrete or cement mortar, ensuring proper reinforcement, and sealing any cracks promptly.

Question 5: How does flashing prevent water damage, and what materials are commonly used for its fabrication?

Flashing creates a watertight seal where the chimney intersects the roof, preventing water from entering the structure and causing damage. Common materials include aluminum, copper, and stainless steel, selected based on compatibility with the roofing and chimney materials.

Question 6: What is the function of a cleanout door, and where is it typically located?

The cleanout door provides access for removing ash, soot, and debris from the base of the chimney. It is typically located at the bottom of the structure, often in the basement or crawl space, facilitating maintenance and preventing blockages.

Understanding the function and maintenance requirements of each element is critical for ensuring the safe and efficient operation of the entire system. Regular inspections and timely repairs are essential for preserving the chimney’s structural integrity and preventing potential hazards.

The next section will cover common issues and troubleshooting tips for maintaining your system.

Conclusion

This examination of the key elements constituting a standard residential or industrial vertical exhaust system underscores the interdependence of these components. From the protective function of the cap to the foundational role of the firebox, each part contributes to the safe and efficient removal of combustion byproducts. The integrity of these components ensures efficient heating and protects inhabitants from dangerous emissions.

The proper maintenance of each structural system is not merely a matter of routine upkeep but a necessity for ensuring safety and preventing potentially catastrophic events. Neglecting the integrity of these elements can lead to significant structural damage, fire hazards, and health risks. Adherence to recommended inspection and maintenance protocols is, therefore, paramount to preserving the functionality and safety of the entire residential or industrial vertical exhaust system.

![Why Chimney Birds Matter: [Chimney Bird] Care Tips Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Why Chimney Birds Matter: [Chimney Bird] Care Tips | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/03/th-25-300x200.jpg)