The term references a specific configuration of a vertical exhaust duct, typically found in buildings or industrial structures. It denotes a single flue or passage designed to expel combustion gases and other airborne byproducts from a connected heating appliance or industrial process. An example would be a standalone flue servicing a residential fireplace, identified within a building’s plans or inventory using a specific alpha-numeric designation.

These structures play a crucial role in ensuring safe and efficient removal of harmful emissions. Their design and construction are governed by stringent building codes and safety regulations to prevent carbon monoxide poisoning, fire hazards, and environmental pollution. Historically, such structures have been integral to human civilization, evolving from simple openings in roofs to sophisticated engineering feats that manage complex ventilation systems in modern buildings and factories.

This understanding forms a foundational element for the following detailed discussion regarding the structural integrity, maintenance requirements, and regulatory compliance related to exhaust systems in various architectural and industrial contexts. Subsequent sections will delve into specific inspection procedures, repair techniques, and the application of advanced materials in construction.

Guidance Regarding Structures of This Type

The following information offers important considerations regarding the safety, efficiency, and longevity of single-flue exhaust systems. Proper attention to these points can mitigate risks and ensure optimal performance.

Tip 1: Regular Inspection: A thorough examination should be conducted annually by a certified professional. This inspection must include assessing the structural integrity, checking for cracks or deterioration, and verifying proper ventilation.

Tip 2: Obstruction Removal: Clear any obstructions, such as nests or debris, that could impede airflow. Blockages can cause dangerous backdrafts and reduce system efficiency, leading to increased carbon monoxide risks.

Tip 3: Liner Integrity: For systems utilizing liners, ensure the liner is intact and properly sealed. A compromised liner can expose the surrounding structure to corrosive gases and increase the risk of fire.

Tip 4: Proper Appliance Matching: The exhaust structure must be appropriately sized for the connected appliance. Mismatched components can lead to incomplete combustion and increased pollutant emissions.

Tip 5: Weatherproofing: Maintain adequate weatherproofing measures at the top of the structure. This includes a secure cap and proper sealing to prevent water damage and deterioration from exposure to the elements.

Tip 6: Code Compliance: Ensure adherence to all local building codes and regulations pertaining to exhaust systems. Failure to comply can result in penalties and compromise safety.

These guidelines emphasize the need for proactive maintenance and adherence to safety standards. Regular attention to these factors will contribute to a safer and more efficient heating and ventilation system.

The subsequent conclusion will summarize the crucial aspects discussed and reiterate the importance of professional consultation for optimal performance and safety.

1. Structural Integrity

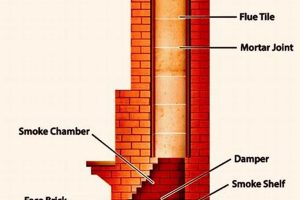

The structural integrity of a designated single-flue exhaust system is paramount to its safe and effective operation. Deterioration or damage to the physical structure can compromise its ability to contain and expel combustion byproducts, leading to potential hazards. The connection between structural soundness and this particular system is direct: the physical structure provides the necessary conduit for the safe evacuation of dangerous gases. Weaknesses, cracks, or collapses in the structure can lead to leaks, backdrafts, and the introduction of harmful substances into the occupied space. A notable example is the failure of mortar joints in older brick chimneys, which can allow carbon monoxide to seep into a building. Therefore, maintaining the structural integrity is not merely a cosmetic concern but a critical safety measure.

The practical significance of understanding this connection extends to inspection and maintenance protocols. Regular assessment of the structure for signs of wear, damage, or instability is essential. This includes visual inspections for cracks, spalling, or displacement, as well as more in-depth evaluations using specialized tools such as cameras or moisture meters. Corrective actions, ranging from minor repairs to complete reconstruction, must be undertaken promptly to address any identified issues. Failure to do so can escalate the problem, leading to more extensive and costly repairs, or, more seriously, creating a life-threatening situation. Consider the case of a crumbling chimney collapsing onto a roof: not only is there structural damage to the building, but also a significant risk of injury to occupants.

In conclusion, the structural integrity is an inseparable component of the safe functionality of a designated single-flue exhaust system. Diligent monitoring and proactive maintenance are crucial to preserving this integrity and mitigating potential risks. The challenges associated with maintaining older structures, in particular, underscore the importance of professional inspection and expert repair. By recognizing and addressing structural concerns promptly, potential hazards can be averted, ensuring the continued safe and efficient operation of the exhaust system and protecting the well-being of building occupants.

2. Draft Optimization

Draft optimization in a designated single-flue exhaust system refers to the process of ensuring efficient and consistent airflow to effectively remove combustion byproducts. The system’s capacity to generate an adequate draft is directly related to its ability to function safely and effectively. Insufficient draft leads to incomplete combustion, resulting in the production of carbon monoxide and other hazardous gases. Furthermore, poor draft can cause backdrafting, where combustion gases enter the living space instead of being expelled, posing a significant health risk. The design, height, and internal dimensions of the flue, as well as external factors like wind and temperature, influence the draft. A properly optimized system ensures the reliable removal of exhaust gases, contributing to both safety and energy efficiency. A real-world example would be a chimney that, due to its inadequate height, struggles to exhaust smoke effectively during periods of calm weather, leading to smoke spillage into the room.

Several factors can impact draft optimization. Obstructions within the flue, such as bird nests or accumulated debris, impede airflow. Improper sizing of the flue relative to the connected appliance can also negatively affect draft. A flue that is too large may cool too quickly, reducing buoyancy and hindering the upward flow of gases. Conversely, a flue that is too small can restrict airflow, leading to backpressure and incomplete combustion. External factors such as prevailing winds and the presence of nearby obstructions can also create downdrafts, disrupting the intended flow of gases. The practical implication of understanding these factors is the necessity for regular inspection and maintenance. Professionals can assess the draft using specialized instruments, identify potential problems, and implement corrective measures, such as cleaning the flue, installing a chimney cap, or adjusting the flue’s dimensions.

In conclusion, draft optimization is a critical component of a designated single-flue exhaust system. The relationship between effective draft and safe, efficient operation is undeniable. Addressing challenges such as obstructions, improper sizing, and external influences is essential for ensuring optimal performance. The overarching goal is to maintain a consistent and reliable draft that effectively removes combustion byproducts, safeguarding the health and well-being of building occupants. Furthermore, proactive maintenance and professional evaluation are key to identifying and resolving draft-related issues before they escalate into more serious problems.

3. Material Degradation

Material degradation is a critical concern in the context of a designated single-flue exhaust system. The structural components are continuously exposed to harsh conditions, including high temperatures, corrosive gases, and environmental factors. This exposure inevitably leads to the deterioration of materials over time, potentially compromising the system’s integrity and safety.

- Corrosion from Combustion Byproducts

Combustion processes generate acidic gases, such as sulfur dioxide and nitrogen oxides, which react with the chimney’s internal surfaces. This chemical reaction corrodes metal liners and erodes mortar joints in masonry structures. The gradual weakening of these materials can lead to leaks, reduced draft efficiency, and the release of harmful gases into the building. For instance, prolonged exposure to flue gases can cause pitting and perforation of stainless steel liners, necessitating costly repairs or replacements.

- Thermal Stress and Fatigue

The cyclical heating and cooling of the chimney during operation creates thermal stress within the materials. This stress can lead to cracking, spalling, and weakening, particularly in rigid materials like brick and concrete. Over time, repeated thermal cycles can cause fatigue failure, where small cracks gradually propagate and compromise the structural integrity of the flue. A practical example is the development of hairline cracks in brick chimneys exposed to extreme temperature fluctuations, which can eventually lead to larger structural failures.

- Weathering and Environmental Exposure

External components of the exhaust system are exposed to weathering elements such as rain, snow, wind, and sunlight. Water penetration can accelerate corrosion and freeze-thaw cycles can cause expansion and contraction, leading to cracking and crumbling. Ultraviolet radiation from sunlight can degrade certain materials, particularly polymeric components used in chimney caps and flashing. An example is the deterioration of a chimney crown due to repeated exposure to freeze-thaw cycles, leading to water damage within the chimney structure.

- Creosote Accumulation and Degradation

In wood-burning systems, creosote, a flammable byproduct of incomplete combustion, accumulates on the inner walls of the flue. Creosote is corrosive and can accelerate the degradation of chimney materials. Furthermore, the buildup of creosote creates a fire hazard, as it can ignite at high temperatures. Regular cleaning and inspection are necessary to remove creosote and prevent material degradation. For example, excessive creosote buildup can penetrate porous masonry materials, making them more susceptible to water damage and eventual structural failure.

The multifaceted nature of material degradation in a designated single-flue exhaust system highlights the need for proactive maintenance and the use of durable, corrosion-resistant materials. Regular inspections, cleaning, and timely repairs are essential to mitigate the effects of degradation and ensure the continued safe and efficient operation of the system. Neglecting these factors can result in costly repairs, potential safety hazards, and reduced service life of the structure.

4. Code Compliance

The design, construction, and maintenance of a designated single-flue exhaust system are governed by stringent building codes and regulations, established to ensure safety, efficiency, and environmental protection. The direct connection lies in the fact that adherence to these codes is not optional but a legal mandate, essential for the proper functioning and safe operation of the structure. Failure to comply can result in penalties, invalidate insurance coverage, and, most importantly, create hazardous conditions for building occupants. Building codes dictate specifications for materials, dimensions, clearances, and installation practices, all aimed at minimizing the risk of fire, carbon monoxide poisoning, and other dangers. As an example, codes often specify the minimum height a flue must extend above the roofline to ensure adequate draft and prevent downdrafts that could force combustion gases back into the building.

The importance of code compliance extends beyond simply avoiding legal repercussions. It ensures that the structure is built to withstand the stresses of operation and environmental factors, promoting longevity and preventing premature failure. Codes also address issues such as proper ventilation, fire resistance, and emissions control, safeguarding both the building occupants and the surrounding environment. The practical significance of understanding code requirements lies in the ability to identify potential violations during inspections and to ensure that any repairs or modifications are performed in accordance with applicable standards. For instance, replacing a damaged flue liner with a non-approved material could compromise its ability to withstand high temperatures and corrosive gases, leading to a fire hazard and a code violation.

In conclusion, code compliance is an integral component of the design, construction, and maintenance of a designated single-flue exhaust system. Ignoring or neglecting code requirements can have serious consequences, ranging from financial penalties to life-threatening hazards. Therefore, thorough knowledge of applicable codes, diligent inspections, and adherence to best practices are essential for ensuring the safe and efficient operation of these systems. Furthermore, professionals involved in the installation, inspection, and repair should stay informed about updates and revisions to building codes to maintain compliance and ensure the highest level of safety.

5. Regular Maintenance

The longevity, safety, and efficiency of a designated single-flue exhaust system are inextricably linked to the implementation of a consistent and thorough maintenance schedule. Neglecting regular upkeep accelerates deterioration, increases the risk of hazardous conditions, and diminishes the system’s intended performance.

- Inspection and Cleaning

Periodic visual inspections are crucial for identifying potential issues such as cracks, blockages, or signs of corrosion. Removing accumulated debris, soot, and creosote through professional cleaning is essential for maintaining proper draft and preventing chimney fires. Failure to clean regularly can lead to creosote buildup, a highly flammable substance, posing a significant fire hazard. For example, annual cleaning is typically recommended for wood-burning systems to prevent excessive creosote accumulation, whereas gas systems may require less frequent cleaning depending on usage and efficiency.

- Structural Assessment and Repair

Evaluating the structural integrity of the flue, including the masonry, liner, and cap, is critical for preventing collapses and leaks. Addressing cracks, spalling, or mortar deterioration promptly can prevent further damage and potential hazards. Example: Replacing damaged bricks or repairing mortar joints in a timely manner can prevent water infiltration, which can accelerate deterioration and compromise the structural stability of the structure.

- Draft Evaluation and Optimization

Assessing the draft performance ensures the efficient removal of combustion byproducts and prevents backdrafting. Identifying and resolving issues such as obstructions, improper sizing, or negative pressure imbalances within the building is essential. A chimney with inadequate draft may result in incomplete combustion, leading to the release of carbon monoxide into the living space. Professional evaluation and adjustments can optimize the draft and mitigate this risk.

- Component Replacement and Upgrades

Replacing worn or damaged components, such as flue liners, chimney caps, and dampers, ensures the continued safe and efficient operation of the structure. Upgrading to more durable or energy-efficient materials can further enhance performance and longevity. Example: Replacing a clay tile liner with a stainless steel liner provides improved resistance to corrosion and thermal stress, extending the service life of the system. Properly installed chimney cap can prevent water and animal intrusion into the flue.

These facets of regular maintenance collectively contribute to the overall health and performance of a designated single-flue exhaust system. Neglecting any one aspect can compromise the entire system, leading to reduced efficiency, increased safety risks, and ultimately, costly repairs. Consistent adherence to a comprehensive maintenance schedule, performed by qualified professionals, is the best approach for ensuring the long-term safety and reliability of these critical building components.

6. Emission Control

Emission control in relation to a designated single-flue exhaust system encompasses strategies and technologies employed to minimize the release of pollutants into the atmosphere. This aspect is crucial due to the environmental and health impacts associated with combustion byproducts. Effective emission control not only adheres to regulatory standards but also promotes a cleaner and more sustainable environment.

- Combustion Efficiency Optimization

Optimizing the combustion process within the connected appliance is a fundamental aspect of emission control. Ensuring complete combustion minimizes the production of pollutants such as carbon monoxide (CO), particulate matter (PM), and unburned hydrocarbons. This can be achieved through proper air-fuel mixture control, appropriate appliance sizing for the flue, and regular maintenance. Example: A properly tuned gas furnace produces significantly lower CO emissions compared to a poorly maintained one. Correct combustion ensures fewer pollutants are released, thus playing a critical role in improving air quality.

- Flue Gas Treatment Technologies

Certain technologies can be integrated into the exhaust system to further reduce emissions. Catalytic converters, for instance, are used to convert CO and hydrocarbons into less harmful substances like carbon dioxide and water vapor. Particulate filters capture PM before it can be released into the atmosphere. Example: Wood stoves equipped with catalytic converters exhibit significantly lower PM emissions compared to non-catalytic models. This additional treatment enhances air purification by eliminating emissions, contributing positively to environmental quality and potentially reducing health hazards.

- Fuel Selection and Management

The type of fuel used significantly impacts the composition and quantity of emissions. Natural gas and propane typically produce lower emissions compared to solid fuels like wood or coal. Proper fuel storage and handling practices also minimize the release of volatile organic compounds (VOCs). Example: Switching from coal to natural gas for heating can significantly reduce sulfur dioxide emissions. Consequently, selecting suitable fuels, and implementing proper storage solutions help diminish the total release of hazardous emissions, contributing to a healthier environment.

- Regulatory Compliance and Monitoring

Adherence to local, state, and federal regulations pertaining to emissions is essential. Regular monitoring and testing of emissions ensure that the exhaust system meets established standards. This often involves periodic inspections and stack testing to verify compliance. Example: Many jurisdictions require annual inspections of wood-burning appliances to ensure they meet emission standards. Continuous emission tracking ensures that the pollutants expelled are within acceptable regulatory restrictions, sustaining air quality and preventing ecological harm.

These facets highlight the multifaceted nature of emission control in relation to a designated single-flue exhaust system. Effective emission control requires a holistic approach that encompasses optimizing combustion, implementing flue gas treatment technologies, selecting appropriate fuels, and ensuring regulatory compliance. By addressing these areas, the environmental impact of exhaust systems can be significantly reduced, contributing to a cleaner and healthier environment.

Frequently Asked Questions About Designated Single-Flue Exhaust Structures

The following questions and answers address common inquiries and misconceptions regarding these systems.

Question 1: What constitutes a designated single-flue exhaust system?

This term refers to a system designed with a single, dedicated passageway or duct for the expulsion of combustion gases from a specific appliance or source. This is in contrast to systems with multiple flues sharing a common structure.

Question 2: How frequently should such structures be inspected?

It is recommended that a qualified professional inspect these systems at least annually. More frequent inspections may be necessary depending on the type of fuel burned and the system’s usage.

Question 3: What are the primary hazards associated with a poorly maintained structure of this type?

Key hazards include carbon monoxide poisoning due to leaks or blockages, chimney fires resulting from creosote buildup (in wood-burning systems), and structural collapse due to deterioration.

Question 4: Can a single flue serve multiple appliances?

Generally, no. Building codes typically prohibit connecting multiple appliances to a single flue unless specifically designed and approved for such an arrangement.

Question 5: What role does the flue liner play in these systems?

The flue liner provides a protective barrier against corrosive combustion gases, preventing damage to the chimney’s structure and reducing the risk of gas leaks into the building.

Question 6: What are the common indicators of a failing exhaust system of this type?

Warning signs include visible cracks or deterioration in the masonry, a persistent odor of smoke inside the building, and evidence of water damage around the chimney.

Understanding these fundamental aspects of single-flue exhaust structures is essential for ensuring their safe and efficient operation.

The subsequent segment will provide a summary of the key considerations for maintaining these structures and emphasize the importance of professional consultation.

“ja 1 chimney”

This exposition has detailed critical aspects of a designated single-flue exhaust system. Emphasized were the significance of structural integrity, draft optimization, material degradation mitigation, strict code compliance, diligent regular maintenance, and effective emission control. Each element contributes directly to the safe and efficient operation of these systems. Neglecting any of these areas can compromise performance, increase risks, and potentially endanger occupants.

Given the inherent complexities and potential hazards associated with these systems, consulting with qualified professionals for inspections, repairs, and maintenance is not merely advisable, but imperative. Their expertise ensures proper assessment, accurate diagnosis, and adherence to industry best practices, safeguarding both property and well-being. The long-term security and functionality of these systems depend on informed decisions and meticulous execution.

![Play Premier The Chimneys Golf Course | [Location] Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Play Premier The Chimneys Golf Course | [Location] | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/01/th-492-300x200.jpg)