Restaurants employing smokers for food preparation often face challenges maintaining optimal equipment function during winter months. One critical aspect of winterization is addressing the chimney or flue, the conduit for smoke and exhaust. Measures are frequently taken to mitigate the adverse effects of cold temperatures and precipitation on this crucial ventilation component.

Neglecting the chimney in winter can lead to several problems. Extreme cold can impede proper draft, resulting in inefficient smoking and potential backflow of smoke into the cooking area. Precipitation, such as snow and ice, can accumulate within the chimney, causing blockages and corrosion. Addressing these issues ensures consistent smoker performance, safety, and longevity of the equipment.

This article explores common strategies restaurants use to protect the smoker chimney from winter’s impact. These strategies range from temporary coverings to more permanent structural modifications, each designed to minimize operational disruptions and safeguard equipment integrity. The methods discussed will offer practical solutions applicable to various smoker types and restaurant settings.

Winter Chimney Protection Strategies for Restaurants

Maintaining optimal smoker operation during winter requires proactive chimney protection measures. The following strategies can help mitigate the detrimental effects of cold temperatures and precipitation.

Tip 1: Install a Rain Cap: A rain cap, typically constructed of metal, deflects rain and snow from entering the chimney. This prevents water damage and potential blockages caused by freezing. Select a cap that is appropriately sized for the chimney’s diameter and securely mounted to withstand wind and ice loads.

Tip 2: Apply a Water-Repellent Sealant: A masonry sealant, designed for high-temperature applications, can be applied to the exterior of the chimney. This sealant helps prevent water absorption into the brick or masonry, minimizing freeze-thaw damage and potential cracking.

Tip 3: Regularly Inspect for Blockages: Conduct routine visual inspections of the chimney, particularly after heavy snowfall or ice storms. Remove any accumulated snow, ice, or debris that may obstruct the flue, ensuring proper ventilation.

Tip 4: Consider a Temporary Chimney Cover: For extended periods of smoker inactivity during winter, a temporary, insulated cover can be placed over the chimney opening. This cover provides an additional layer of protection against the elements and prevents animal entry.

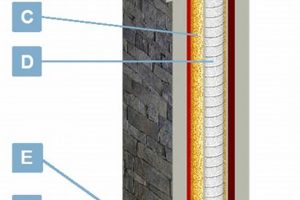

Tip 5: Insulate the Chimney: Applying insulation to the exterior of the chimney helps maintain a consistent flue temperature, improving draft and reducing condensation. High-temperature insulation wraps or blankets are suitable for this purpose.

Tip 6: Maintain Proper Draft: Ensure adequate airflow to the smoker to facilitate proper draft through the chimney. This can be achieved by adjusting air vents or dampers and ensuring that the surrounding area is free from obstructions that could impede airflow.

Implementing these strategies will contribute to consistent smoker performance, reduced maintenance costs, and extended equipment lifespan. Careful consideration of environmental conditions and smoker usage patterns is crucial when selecting the most appropriate protection method.

The preceding strategies offer a foundation for effective chimney winterization. The next section will delve into preventative maintenance practices to further optimize smoker operation during the colder months.

1. Rain Cap Installation

Rain cap installation represents a primary method for protecting smoker chimneys during winter. The device serves as a physical barrier against precipitation and debris, mitigating potential operational disruptions and equipment damage. The appropriateness and effectiveness of the installation are critical to successful winterization.

- Material Composition and Durability

Rain caps are commonly constructed from metals like stainless steel or galvanized steel. Material selection dictates the cap’s resistance to corrosion and structural integrity under winter conditions. A durable cap withstands snow accumulation, ice formation, and wind loads, preventing premature failure and ensuring continued protection. The choice of material is a critical factor in the rain cap’s long-term effectiveness.

- Sizing and Compatibility

Proper sizing is crucial for effective rain cap function. The cap must fit securely over the chimney opening, providing complete coverage without obstructing airflow. Incompatible sizing can lead to inadequate protection against precipitation or restricted ventilation, compromising smoker performance. Ensuring compatibility with the chimney’s dimensions and flue design is paramount.

- Secure Mounting and Stability

A rain cap’s effectiveness hinges on its secure attachment to the chimney. Improper mounting can result in the cap becoming dislodged during high winds or heavy snowfall, rendering it ineffective. Secure mounting methods, such as bolting or clamping, are essential to maintain stability and prevent displacement. Regular inspections should verify the integrity of the mounting system.

- Maintenance and Debris Removal

While rain caps offer protection, they can also accumulate debris, such as leaves or twigs, which can obstruct airflow. Regular maintenance, including debris removal, is necessary to maintain optimal ventilation. Neglecting maintenance can negate the benefits of the rain cap, leading to inefficient smoker operation and potential safety hazards.

These aspects of rain cap installation contribute directly to the overall effectiveness of restaurants’ efforts to protect smoker chimneys during winter. Selecting appropriate materials, ensuring correct sizing and secure mounting, and implementing a maintenance schedule are all essential steps in safeguarding equipment and maintaining consistent smoker performance throughout the winter months. Properly installed rain caps exemplify proactive measures taken to ensure operational continuity.

2. Material Selection

The choice of materials when implementing strategies significantly affects the performance and longevity of efforts. The selection directly impacts the structure’s ability to withstand the elements, maintain functionality, and minimize operational disruptions. In the context of shielding restaurant smoker chimneys during winter, the appropriateness of materials is paramount.

Consider a rain cap constructed from low-grade steel. In environments experiencing heavy snowfall and prolonged freezing temperatures, this material is susceptible to rapid corrosion. As the steel degrades, the rain cap loses structural integrity, potentially collapsing and failing to provide the intended protection. Conversely, employing stainless steel or a high-temperature-resistant polymer offers superior resistance to corrosion and weathering, ensuring the rain cap remains functional throughout the winter. Similarly, insulating materials used to wrap a chimney impact heat retention. Inferior insulation with low R-values allows excessive heat loss, leading to condensation buildup and potential ice formation within the flue. High-quality, weather-resistant insulation maintains flue temperature, promoting efficient draft and preventing blockages. The materials used for sealant also affect winterization: Using a low-quality sealant is more exposed to cracking during the winter.

Ultimately, material selection represents a critical decision point when restaurants address chimney protection. The chosen materials directly influence the effectiveness, durability, and safety of the selected strategy. Improper material choices can lead to equipment failure, increased maintenance costs, and potential safety hazards, emphasizing the need for careful consideration of environmental factors and material properties.

3. Inspection Frequency

Inspection frequency represents a critical component in ensuring the effectiveness of winter chimney protection measures implemented by restaurants. Regular inspections identify potential problems, allowing for timely intervention and preventing significant operational disruptions. The determination of an appropriate inspection schedule is influenced by various factors, including climate severity, chimney construction, and the frequency of smoker usage.

- Assessing Structural Integrity

Frequent inspections enable early detection of structural damage to the chimney, such as cracks, spalling brickwork, or compromised mortar joints. These defects can exacerbate the impact of freezing temperatures and moisture, leading to further deterioration. Timely identification allows for preventative repairs, prolonging the chimney’s lifespan and ensuring safe operation. For instance, monthly inspections during winter months can identify minor cracks before they expand due to freeze-thaw cycles, preventing costly repairs later.

- Evaluating Rain Cap Condition

Routine inspections should assess the condition of the rain cap, checking for damage, corrosion, or displacement. A compromised rain cap fails to adequately protect the chimney from precipitation, leading to water intrusion and potential blockages. Early identification of rain cap issues allows for prompt repair or replacement, maintaining effective chimney protection. Checking rain caps after major snow or ice events can prevent accumulated weight from dislodging or damaging the cap.

- Identifying and Removing Obstructions

Inspections facilitate the identification and removal of obstructions within the chimney flue, such as accumulated debris, animal nests, or ice formations. Blockages impede proper draft, leading to inefficient smoker operation and potential carbon monoxide buildup. Regular inspections minimize the risk of blockages, ensuring adequate ventilation. Quarterly inspections can reveal animal nesting activity that might otherwise go unnoticed until a significant blockage occurs.

- Monitoring Insulation Performance

For insulated chimneys, inspections should monitor the condition of the insulation, checking for moisture damage, deterioration, or displacement. Compromised insulation reduces its effectiveness, leading to heat loss and increased condensation within the flue. Early identification of insulation issues allows for corrective action, maintaining optimal thermal performance. Comparing fuel consumption over time alongside inspection results can indicate when insulation is degrading and needs replacement.

Establishing an appropriate inspection frequency, tailored to specific operational and environmental conditions, is essential for maximizing the effectiveness of winter chimney protection measures. Regular inspections proactively address potential problems, preventing costly repairs, ensuring safe operation, and maintaining consistent smoker performance throughout the winter months. Increased inspection frequency should be prioritized during periods of extreme weather or after significant events like heavy storms.

4. Insulation Effectiveness

Insulation effectiveness directly correlates with the efficacy of winter chimney protection strategies employed by restaurants. Adequate insulation minimizes heat loss from the chimney flue, maintaining optimal draft and preventing condensation. This outcome is crucial for ensuring efficient smoker operation and preventing operational disruptions during periods of cold weather. Without sufficient insulation, the flue temperature decreases, hindering smoke evacuation and increasing the risk of creosote buildup, a fire hazard.

A restaurant in a northern climate, experiencing prolonged sub-freezing temperatures, exemplifies the importance of insulation. This establishment initially faced recurring issues with smoker performance during winter, including difficulty maintaining consistent cooking temperatures and excessive smoke backflow into the kitchen. After implementing a comprehensive insulation strategy, involving wrapping the chimney with high-temperature insulation blankets, the restaurant observed a significant improvement in smoker performance. The insulated chimney maintained a higher flue temperature, facilitating proper draft and preventing condensation, which mitigated the previous operational challenges. This highlights the insulation’s direct impact on chimney function.

Insulation effectiveness, therefore, is not merely an ancillary consideration; it is a fundamental component of successful winter chimney protection. Restaurants must carefully evaluate the insulation’s R-value, material composition, and installation method to ensure optimal performance. Neglecting this aspect compromises the entire winterization effort, potentially leading to reduced efficiency, increased safety risks, and costly operational disruptions. Proper insulation is a key preventative measure.

5. Draft Optimization

Draft optimization is inextricably linked to chimney protection strategies employed by restaurants during winter. Maintaining proper draft, the flow of air through the chimney, is crucial for efficient smoker operation. Winter conditions, such as cold temperatures and snow accumulation, can significantly impede draft, necessitating specific interventions, including how the chimney is covered.

- Chimney Height and Exposure

Chimney height directly influences draft. Taller chimneys generally generate stronger draft due to increased buoyancy of the hot exhaust gases. However, taller chimneys are also more exposed to wind and snow, potentially disrupting the airflow. Covering strategies must consider the chimney’s height and exposure to minimize wind-induced downdrafts or snow accumulation that can obstruct the flue and reduce draft. A properly designed chimney cover can act as a windbreak while still allowing adequate ventilation.

- Insulation and Flue Temperature

Insulation of the chimney helps maintain a consistent flue temperature, promoting a stronger and more reliable draft. Cold chimneys experience reduced draft due to the cooling and condensation of exhaust gases. Covering the chimney with insulating materials or implementing a heated chimney system can mitigate heat loss and maintain optimal draft. This is especially crucial in colder climates where extreme temperature differentials can significantly impact draft performance.

- Barometric Dampers and Draft Regulators

Barometric dampers and draft regulators are devices used to control the amount of draft in a chimney system. These devices automatically adjust to maintain a consistent draft, regardless of external weather conditions. While not a form of “covering,” these mechanisms complement covering strategies by fine-tuning draft performance, compensating for fluctuations caused by wind or temperature changes. Effective draft regulation ensures efficient smoker operation and prevents over-firing or backdrafting.

- Cap Design and Airflow

The design of the chimney cap significantly impacts draft. A well-designed cap protects the chimney from precipitation and debris while minimizing airflow restriction. Caps with small openings or complex designs can impede draft, especially during periods of heavy snowfall or ice accumulation. Selecting a cap design that balances protection with adequate ventilation is crucial for maintaining optimal draft. Regularly clearing snow and ice from the cap is also essential.

These interconnected facets of draft optimization highlight the importance of a holistic approach to winter chimney protection. The “covering” strategy implemented must consider factors such as chimney height, insulation, and the design of the cap to ensure optimal draft and consistent smoker performance throughout the winter months. Neglecting any of these aspects can compromise the effectiveness of the entire winterization effort.

Frequently Asked Questions

This section addresses common inquiries regarding methods restaurants employ to protect smoker chimneys during winter, focusing on practical considerations and effective strategies.

Question 1: What are the primary risks of not protecting a smoker chimney during winter?

Failure to protect a smoker chimney exposes the structure to potential damage from freezing temperatures, snow accumulation, and ice formation. These conditions can lead to reduced draft, chimney blockages, structural deterioration, and potential safety hazards, including carbon monoxide buildup within the restaurant.

Question 2: Is a simple tarp sufficient to cover a smoker chimney during winter?

While a tarp may offer some temporary protection against precipitation, it is generally not sufficient for comprehensive winter protection. Tarps often lack the necessary durability, securement, and insulation properties to withstand prolonged exposure to harsh winter conditions. Furthermore, a tarp can restrict airflow and potentially create a fire hazard if placed too close to the chimney opening.

Question 3: How often should a smoker chimney be inspected during winter?

Inspection frequency depends on the severity of winter conditions and the frequency of smoker use. As a general guideline, monthly inspections are recommended, with more frequent inspections following significant snowfall or ice storms. Inspections should assess structural integrity, rain cap condition, and the presence of any obstructions within the flue.

Question 4: What type of sealant is appropriate for winterizing a masonry smoker chimney?

A high-quality, water-repellent masonry sealant designed for high-temperature applications is recommended. The sealant should be specifically formulated to withstand extreme temperature fluctuations and prevent water absorption into the brick or masonry. Consult with a professional for specific product recommendations based on the chimney’s construction and local climate conditions.

Question 5: Does insulating a smoker chimney require professional installation?

The necessity of professional installation depends on the type of insulation used and the complexity of the chimney structure. Wrapping a chimney with insulation blankets may be a relatively straightforward DIY project, while applying spray foam insulation or modifying the chimney’s structure typically requires professional expertise. Improper installation can reduce insulation effectiveness and potentially create safety hazards.

Question 6: Are there specific regulations regarding chimney height and covering requirements for restaurants?

Local building codes and fire safety regulations may dictate specific requirements regarding chimney height, clearance from surrounding structures, and acceptable covering materials. Consult with local authorities and fire safety professionals to ensure compliance with all applicable regulations. Failure to comply with these regulations can result in fines or operational restrictions.

Implementing appropriate winter protection measures, along with regular inspection and maintenance, ensures continued smoker functionality, reduces maintenance costs, and promotes a safe working environment.

The following section delves into the preventative maintenance practices to optimize smoker operation during winter months.

Conclusion

This exploration of how restaurants cover their smoker chimney in winter has illuminated several crucial aspects of maintaining operational efficiency and safety during the colder months. Effective chimney protection strategies, including the installation of rain caps, the application of water-repellent sealants, and the implementation of regular inspection schedules, contribute significantly to minimizing the adverse effects of winter weather. Material selection, insulation effectiveness, and draft optimization are all critical factors that influence the success of these protective measures.

The information presented underscores the importance of proactive winterization efforts. Restaurants employing smokers should prioritize chimney protection as a key component of their overall maintenance program, ensuring consistent performance, reduced maintenance costs, and a safe working environment throughout the winter season. By diligently addressing the challenges posed by winter weather, restaurants can maintain the integrity of their equipment and continue to deliver high-quality smoked products to their customers.

![Why Chimney Birds Matter: [Chimney Bird] Care Tips Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Why Chimney Birds Matter: [Chimney Bird] Care Tips | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/03/th-25-300x200.jpg)