The necessity of a flue system for gas-fueled fire features is a critical factor in ensuring safe and efficient operation. These systems are designed to vent combustion byproducts, such as carbon dioxide and water vapor, away from the living space. The presence of an appropriately sized and functioning exhaust pathway is paramount for maintaining indoor air quality and preventing potential health hazards.

Proper venting provides numerous benefits, including mitigating the risk of carbon monoxide poisoning, reducing the buildup of moisture that can lead to mold growth, and preventing damage to interior surfaces from corrosive fumes. Historically, the absence of adequate ventilation has been a significant contributor to respiratory issues and structural deterioration in buildings utilizing combustion-based heating appliances. Modern building codes and appliance standards emphasize the importance of correct flue installation and maintenance.

Understanding the different types of venting options available and how they impact installation requirements is crucial for homeowners and contractors alike. The following sections will delve into the specific venting requirements for various types of gas fire features, addressing common misconceptions and outlining best practices for safe and effective operation.

Essential Guidance for Gas Fireplace Venting

Ensuring the safe and efficient operation of gas fireplaces hinges on adherence to proper venting procedures. The following points offer critical guidance for homeowners and installers.

Tip 1: Understand Appliance Classification: Gas fireplaces are categorized by their venting requirements: direct vent, B-vent, or vent-free. Selecting the appropriate type for the structural conditions is crucial.

Tip 2: Adhere to Manufacturer Specifications: The installation instructions provided by the fireplace manufacturer dictate the precise venting requirements, including pipe diameter, rise, and maximum horizontal run. Deviation from these instructions compromises safety and invalidates warranties.

Tip 3: Regularly Inspect Venting Systems: Annual professional inspections of the flue system are necessary to identify and address potential issues such as blockages, corrosion, or leaks. Early detection prevents costly repairs and hazardous conditions.

Tip 4: Ensure Proper Termination Location: Vent terminations must be located a safe distance from windows, doors, and other air intakes to prevent the re-entry of exhaust gases into the building.

Tip 5: Consider Direct Vent Advantages: Direct vent fireplaces offer enhanced safety and energy efficiency by drawing combustion air from outside the building and exhausting directly to the exterior. This eliminates the need for a traditional chimney and minimizes indoor air quality concerns.

Tip 6: Replace Damaged Components Promptly: Damaged or deteriorated venting components, such as flue pipes or connectors, should be replaced immediately to maintain a secure and leak-free exhaust pathway.

Tip 7: Be Aware of Vent-Free Limitations: While offering installation flexibility, vent-free gas fireplaces release combustion byproducts directly into the living space. Strict adherence to operating guidelines and the use of carbon monoxide detectors are essential.

Proper venting is not merely a suggestion; it is a non-negotiable requirement for the safe and responsible operation of gas fireplaces. Following these guidelines mitigates risks and ensures optimal performance.

The subsequent section provides a comprehensive overview of the code requirements and regulatory standards governing gas fireplace installation and venting.

1. Venting essential for safety.

The assertion “Venting essential for safety” directly correlates to the premise that a gas fireplace necessitates a flue. Complete combustion in a gas fireplace generates byproducts, including carbon dioxide, water vapor, and potentially lethal carbon monoxide. Without proper venting, these substances accumulate within the occupied space, presenting significant health risks. Flue systems provide a designated pathway for these byproducts to exit the dwelling, thereby safeguarding occupants. For example, a poorly maintained or absent flue can lead to carbon monoxide poisoning, a silent and potentially fatal hazard, underscoring the practical importance of understanding and implementing adequate ventilation.

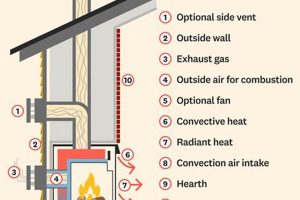

Effective venting is not merely a theoretical concept but a tangible requirement dictated by building codes and appliance standards. Direct vent fireplaces, a specific type, exemplify this principle. They are engineered with a sealed combustion chamber that draws air from outside the structure and expels exhaust gases directly outdoors through a dedicated venting system, bypassing the need for a traditional chimney. This design minimizes the risk of indoor air contamination and enhances energy efficiency. Conversely, the absence of proper venting, even in “vent-free” models, necessitates rigorous adherence to operating guidelines and the strategic placement of carbon monoxide detectors, highlighting the inherent risks associated with incomplete combustion.

In conclusion, the fundamental connection lies in the cause-and-effect relationship between combustion byproducts and human health. Gas fireplaces, by their nature, produce these byproducts, necessitating a mechanism for their safe removal. Venting, often achieved through a dedicated flue or chimney system, provides this essential safety function. Understanding this relationship is crucial for responsible appliance selection, installation, and maintenance, ultimately mitigating the risks associated with gas fireplace operation.

2. Chimney type dictates options.

The statement “Chimney type dictates options” directly relates to the installation and selection process of gas fireplaces. The existing venting infrastructure, or lack thereof, significantly restricts the types of gas fireplaces that can be safely and effectively installed in a given location. The need for a flue, implicit in the phrase “gas fireplace need chimney,” is therefore directly contingent upon the type of venting system available.

- Existing Chimney Compatibility

If a property already possesses a traditional masonry chimney, the options are limited to gas fireplaces designed for natural venting. These units rely on the chimney’s draft to exhaust combustion byproducts. Adapting a chimney for a gas fireplace requires inspection to ensure its integrity and adequate draft capacity. Improper adaptation can lead to dangerous backdrafting of exhaust gases into the living space.

- Direct Vent Alternatives

In the absence of a suitable existing chimney, direct vent gas fireplaces offer an alternative. These systems utilize a sealed combustion chamber and a dedicated venting system that can be routed horizontally through an exterior wall or vertically through the roof. Direct vent systems provide greater flexibility in placement and eliminate reliance on a traditional chimney. However, they require precise installation according to the manufacturer’s specifications to maintain safety and efficiency.

- B-Vent Restrictions

B-vent gas fireplaces represent another option for properties without masonry chimneys. These units use a double-walled metal vent pipe to exhaust combustion gases. However, B-vent systems require a vertical vent run and are not suitable for horizontal venting. Their use is restricted to installations where a vertical vent path is available and meets code requirements. Furthermore, B-vent systems typically require a larger vent diameter than direct vent systems, influencing installation feasibility.

- Vent-Free Considerations

While often marketed as an alternative to traditional venting, “vent-free” gas fireplaces do not eliminate the need for careful consideration of chimney type. In fact, their absence of dedicated venting necessitates heightened awareness of indoor air quality and the risks associated with combustion byproducts. Although they don’t connect to a chimney, their use impacts the air composition within a home, effectively creating a “virtual chimney” effect in the form of general air dilution. Code restrictions and safety precautions are paramount when considering vent-free options.

In conclusion, the availability and type of existing or planned venting infrastructure are decisive factors in determining the appropriate gas fireplace model. While some units can utilize existing chimneys, others require dedicated venting systems or, in the case of vent-free models, a heightened awareness of indoor air quality management. The phrase “Chimney type dictates options” underscores the importance of a thorough assessment of venting capabilities before selecting a gas fireplace, ensuring both safety and efficient operation.

3. Direct vent advantages exist.

The assertion “Direct vent advantages exist” directly addresses the implied requirement in “gas fireplace need chimney.” Direct vent systems represent an alternative solution to the traditional need for a chimney by providing a self-contained venting mechanism. These systems operate by drawing combustion air from outside the dwelling and exhausting combustion byproducts directly to the exterior through a sealed coaxial or co-linear vent pipe. This design eliminates the dependence on existing chimney infrastructure, circumventing the complexities and potential hazards associated with chimney adaptations or deficiencies. For example, in retrofit scenarios where a chimney is absent or structurally unsound, a direct vent fireplace offers a viable and often more cost-effective option compared to rebuilding or repairing a chimney.

The advantages of direct vent systems extend beyond simply negating the need for a chimney. They enhance safety by minimizing the risk of backdrafting, as the sealed combustion chamber prevents the escape of exhaust gases into the living space. Direct vent systems also improve energy efficiency by utilizing outside air for combustion, reducing the consumption of heated indoor air. Furthermore, direct vent fireplaces offer greater flexibility in placement, as they are not constrained by the location of a chimney. They can be installed against exterior walls, opening up design possibilities in rooms where a traditional fireplace would be impractical. Real-world examples include installations in modern homes with contemporary designs that prioritize clean lines and minimalist aesthetics, where a bulky chimney would detract from the overall architectural vision.

In conclusion, while the phrase “gas fireplace need chimney” underscores the general requirement for venting, the recognition that “Direct vent advantages exist” offers a crucial alternative. Direct vent systems provide a safe, efficient, and versatile solution that bypasses the limitations and potential drawbacks associated with traditional chimney systems. This understanding is practically significant for homeowners, contractors, and designers, enabling informed decisions about gas fireplace installations that prioritize safety, efficiency, and design flexibility. Direct vent systems represent a technological advancement that broadens the applicability of gas fireplaces in a variety of architectural contexts.

4. Inspection identifies potential hazards.

The assertion “Inspection identifies potential hazards” underscores the crucial role of regular assessments in ensuring the safe operation of gas fireplaces, particularly concerning the implicit demand that a “gas fireplace need chimney” or an equivalent venting system.

- Chimney Obstructions and Blockages

Inspections reveal obstructions, such as bird nests or debris accumulation, within the flue. A blocked flue impedes the proper venting of combustion byproducts, leading to carbon monoxide buildup within the dwelling. This directly relates to the need for a chimney or venting system to effectively remove these hazardous gases. Example: A visual inspection can identify a bird’s nest blocking a chimney, preventing the safe operation of the gas fireplace.

- Chimney Degradation and Structural Integrity

Inspections identify structural weaknesses, cracks, or deterioration in the chimney lining. A compromised chimney can leak dangerous exhaust gases into the living space, diminishing the effectiveness of the venting system. This reinforces the principle that a gas fireplace requires a structurally sound chimney or flue to ensure safe operation. Example: A Level 2 inspection with a camera reveals cracks in the flue liner, necessitating repair or relining to prevent gas leakage.

- Vent Connector Issues

Inspections detect improper connections or corrosion in the vent connector between the fireplace and the chimney. Inadequate connections can leak exhaust gases, while corrosion compromises the vent connector’s integrity. This highlights the need for a properly installed and maintained vent connector as part of the overall venting system. Example: An inspection reveals a loose vent connector at the gas fireplace, allowing exhaust gases to escape into the room.

- Carbon Monoxide Detection

While not a direct inspection of the chimney itself, ensuring proper carbon monoxide detector function is a critical element of a safety inspection related to any fuel-burning appliance. Inspection validates the presence and operational status of carbon monoxide detectors within the dwelling. Non-functional detectors negate the safety benefits of a correctly installed chimney or venting system. This emphasizes that reliance on a chimney alone is insufficient without complementary safety measures. Example: An inspector verifies the functionality and placement of carbon monoxide detectors in the home to provide an extra layer of protection against potential gas leaks.

The insights gained through routine inspections are vital in maintaining the integrity and effectiveness of the chimney or venting system associated with a gas fireplace. These inspections address potential hazards that directly undermine the safe operation of the appliance. The discovery and remediation of these issues underscore the understanding that a gas fireplace requires a properly functioning and regularly assessed venting system to ensure the safety and well-being of occupants.

5. Codes mandate compliance.

The phrase “Codes mandate compliance” directly and unequivocally links to the implicit requirement that a “gas fireplace need chimney” or an equivalent, code-approved venting system. This principle asserts that the installation and operation of gas fireplaces are subject to stringent regulations established to protect public health and safety. These regulations invariably address the proper venting of combustion byproducts, making the need for a chimney, or alternative venting solution, a legal obligation rather than an optional consideration.

- Building Codes and Venting Requirements

National and local building codes outline specific requirements for the installation of gas fireplaces, including detailed specifications for venting systems. These codes dictate factors such as flue size, material, height, termination location, and clearance from combustible materials. Non-compliance with these provisions constitutes a code violation, potentially resulting in fines, mandatory remediation, or the disabling of the appliance. For instance, the International Fuel Gas Code (IFGC) provides comprehensive guidelines for gas appliance venting, including those pertaining to gas fireplaces. Ignoring these regulations can lead to dangerous situations, such as carbon monoxide poisoning, which the codes are designed to prevent.

- Appliance Listing and Certification

Gas fireplaces must be listed and certified by recognized testing laboratories, such as UL or CSA, to demonstrate compliance with established safety standards. Certification involves rigorous testing to ensure that the appliance functions safely and vents combustion byproducts effectively. A certified gas fireplace is designed to operate with a specific type of venting system, and deviating from the manufacturer’s specifications violates the terms of the certification and potentially invalidates warranties. The appliance’s listing specifies the approved venting methods, reinforcing the obligation to utilize a code-compliant chimney or venting alternative.

- Permitting and Inspection Processes

Most jurisdictions require homeowners or contractors to obtain permits before installing a gas fireplace. The permitting process ensures that the proposed installation meets all applicable code requirements, including venting specifications. Following installation, a code official typically conducts an inspection to verify compliance with the permit and applicable codes. Failure to obtain a permit or pass the inspection can result in legal penalties and the requirement to correct any code violations. The inspection process serves as a critical safeguard, ensuring that the gas fireplace is vented properly and that the installation adheres to all relevant safety standards.

- Consequences of Non-Compliance

The ramifications of failing to comply with codes mandating proper venting for gas fireplaces extend beyond legal penalties. Improper venting can lead to serious health risks, including carbon monoxide poisoning, respiratory problems, and even death. Furthermore, non-compliant installations can void insurance coverage and expose homeowners to liability in the event of property damage or injury resulting from a gas fireplace malfunction. Adherence to code requirements is not merely a matter of legal compliance but a fundamental responsibility to protect the safety and well-being of occupants and the integrity of the building.

In essence, the requirement that “gas fireplace need chimney” is not simply a suggestion but a legally enforced obligation, derived from building codes, appliance certifications, and permitting processes. “Codes mandate compliance” provides the framework that makes the need for a chimney or approved alternative a non-negotiable condition for the safe and legal operation of a gas fireplace.

6. Professional installation crucial

The phrase “Professional installation crucial” directly underscores the inherent necessity implied by “gas fireplace need chimney.” While a gas fireplace might technically function without adherence to proper installation protocols, the safe and efficient venting of combustion byproducts is non-negotiable. Professional installers possess the requisite knowledge and experience to ensure that the venting system, whether a traditional chimney or a direct vent alternative, is correctly configured and compliant with all applicable codes and manufacturer specifications. Incorrect installation can compromise the integrity of the venting system, leading to the escape of dangerous gases into the living space or reduced combustion efficiency. An amateur installation, for instance, might fail to properly seal vent connections, creating a pathway for carbon monoxide leakage. The crucial role of a professional is therefore to mitigate these risks through meticulous execution and adherence to established best practices.

The importance of professional installation extends beyond mere adherence to code requirements. Experienced installers understand the nuanced aspects of venting systems, including proper flue sizing, draft dynamics, and termination placement. They can assess the specific characteristics of a dwelling and select the appropriate venting solution to ensure optimal performance and safety. For example, an installer will consider factors such as building height, wind patterns, and proximity to nearby structures when determining the ideal location for a vent termination to prevent backdrafting or the re-entry of exhaust gases. Furthermore, professionals possess specialized tools and equipment necessary for proper installation, such as gas leak detectors and combustion analyzers, which are not typically available to homeowners. These tools allow them to verify the integrity and efficiency of the venting system, providing an additional layer of assurance.

In conclusion, the connection between “Professional installation crucial” and “gas fireplace need chimney” is one of cause and effect. Proper venting is essential for the safe operation of a gas fireplace, and professional installation is the primary means of achieving this objective. While DIY installations may appear to offer cost savings, the potential consequences of improper venting far outweigh any perceived financial benefits. The practical significance of this understanding lies in the recognition that professional installation is not merely a desirable option but a fundamental requirement for ensuring the safety, efficiency, and longevity of a gas fireplace system.

Frequently Asked Questions

The following questions address common inquiries regarding the venting requirements for gas fireplaces.

Question 1: Is a chimney always required for a gas fireplace?

No, a traditional masonry chimney is not always required. Direct vent gas fireplaces utilize a sealed combustion system that vents directly to the exterior, bypassing the need for an existing chimney. However, some form of venting is always necessary to exhaust combustion byproducts safely.

Question 2: What are the potential dangers of improper gas fireplace venting?

Improper venting can lead to carbon monoxide poisoning, a potentially fatal condition. Additionally, it can cause the buildup of moisture, leading to mold growth and damage to interior surfaces. The accumulation of unvented gases also poses a fire hazard.

Question 3: How often should a gas fireplace venting system be inspected?

A professional inspection of the venting system is recommended annually. Regular inspections can identify potential issues, such as blockages, corrosion, or leaks, before they escalate into more serious problems.

Question 4: Can a wood-burning fireplace chimney be used for a gas fireplace?

Potentially, but it requires careful assessment and adaptation. The chimney must be thoroughly cleaned and inspected to ensure it is free of creosote and in good working condition. A professional should determine if the chimney is appropriately sized and lined for gas appliance venting.

Question 5: What are the code requirements for gas fireplace venting?

Code requirements vary by jurisdiction, but generally mandate that gas fireplaces be vented in accordance with manufacturer’s specifications and local building codes. These codes specify requirements for flue size, material, height, and termination location.

Question 6: Are “vent-free” gas fireplaces truly vent-free?

While marketed as such, “vent-free” gas fireplaces release combustion byproducts directly into the living space. They require careful adherence to operating guidelines and the use of carbon monoxide detectors to mitigate potential risks. They are not, in fact, truly vent-free, as they impact the air composition within the home.

Proper venting is paramount for the safe and efficient operation of gas fireplaces. Ignoring venting requirements can have severe consequences.

The following section provides a summary of key considerations and best practices for gas fireplace venting.

Gas Fireplace Venting

The preceding discourse has thoroughly examined the inherent relationship between gas fireplaces and the requirement for a suitable venting system. Whether through a traditional chimney or a more modern direct vent configuration, the proper evacuation of combustion byproducts remains a non-negotiable aspect of safe and responsible operation. Disregarding this fundamental principle introduces significant risks, ranging from carbon monoxide poisoning to structural damage. The variety of venting options available necessitates careful consideration of existing infrastructure, building codes, and manufacturer specifications.

The informed homeowner or contractor must recognize that selecting, installing, and maintaining a gas fireplace demands a commitment to safety above all else. Compliance with established codes and the engagement of qualified professionals are paramount. Future advancements in gas fireplace technology may offer more efficient combustion processes, but the fundamental need for a reliable and effective venting system will undoubtedly endure. Prioritizing proper venting ensures the continued enjoyment of gas fireplaces without compromising the health and well-being of building occupants.